Advertisement

For further operating, installation, or maintenance assistance:

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.FEMYERS.COM

PH: 888-987-8677

© 2013 Pentair, Ltd. All Rights Reserved.

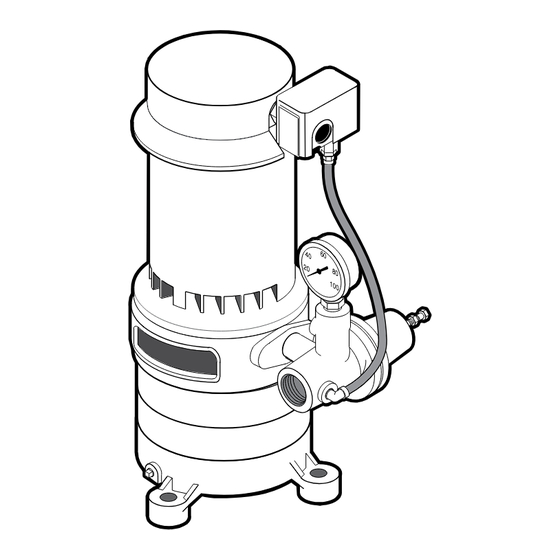

Multi-Stage Deep Well Jet Pumps

MVPH-100

MVPH-150

MVPH-200

Installation/Operation/Parts

Call 1-888-987-8677

4 0

6 0

2 0

8 0

1 0 0

1 HP

1-1/2 HP

2 HP

368 1293ASB NF

OWNER'S MANUAL

MY757 (Rev. 02/05/13)

Advertisement

Summary of Contents for Pentair Myers MVPH-100

- Page 1 1 HP MVPH-150 1-1/2 HP MVPH-200 2 HP 368 1293ASB NF Installation/Operation/Parts For further operating, installation, or maintenance assistance: Call 1-888-987-8677 293 WRIGHT STREET, DELAVAN, WI 53115 WWW.FEMYERS.COM PH: 888-987-8677 MY757 (Rev. 02/05/13) © 2013 Pentair, Ltd. All Rights Reserved.

-

Page 2: General Safety

Safety READ AND FOLLOW ELECTRICAL SAFETY SAFETY INSTRUCTIONS! Capacitor voltage may be hazardous. To discharge motor capacitor, hold insulated handle This is the safety alert symbol. When you see this screwdriver BY THE HANDLE and short capacitor symbol on your pump or in this manual, look for one of terminals together. -

Page 3: Table Of Contents

Table of Contents Page General Safety .....................2 Warranty......................3 Installation ......................4-7 Electrical ......................8-9 Operation .....................10-11 Maintenance ....................12-13 Troubleshooting ....................14 Repair Parts ....................15-16 Limited Warranty F.E. MYERS warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from defects in material and workmanship for the Warranty Period shown below. -

Page 4: Installation

Installation BEFORE YOU INSTALL YOUR PUMP Dirt and Scale Plug Pump and Pipes! NOTE: For proper performance, pump MUST be matched to ejector and to well depth. Use shallow well installation for wells up to 25 ft depth to water and deep well ejector for depths up to 130 ft. Step 1. - Page 5 Installation PIPING IN THE DEEP WELL Pump Pump See Figures 7 and 8. Gasket Gasket Adapter Flange Adapter Flange NOTE: Deep well installations are either single pipe (2” wells) or double pipe (4” and larger wells). In a double pipe installation, the larger pipe is the suction pipe and the smaller pipe is the drive pipe (very deep wells Threadless Coupling may use suction and drive pipes of the same diameter).

- Page 6 Installation SINGLE PIPE EJECTOR INSTALLATION Pump mounted Single pipe installations require (see Figure 8): on Casing a. Galvanized steel pipe Adapter b. Leather packer-type ejector with built-in foot valve c. Turned couplings (supplied with packer-type ejector) d. Well casing adapter. Step 1.

- Page 7 Installation PRESSURE TANK INSTALLATION – DEEP WELL The Pressure Tank provides a reservoir of water under pressure and Standard Tank maintains cushion of air pressure to prevent pipe hammering and possible damage to plumbing components. When water is drawn off through house Air Volume fixtures, the pressure in the tank is lowered and the pressure switch starts Control...

-

Page 8: Electrical

Electrical Disconnect power before working on pump, motor, pressure switch, or wiring. MOTOR SWITCH SETTINGS 1 HP motor terminal boards (located under the motor end cover) should look like those below. If the motor can operate at either 115 or 230 volts, it is set at the factory to 230 volts. Do not change motor wiring if line voltage is 230 volts, or if you have a single voltage motor. - Page 9 Electrical Connection Procedure: Step 1. Connect the ground wire first as shown in Figure 12. The ground wire must be a solid copper wire at least as large as the power supply wires. Step 2. There must be a solid metal connection between the pressure switch and the motor for motor grounding protection.

-

Page 10: Operation

Operation PRIMING THE PUMP NEVER run pump dry. Running pump without water may cause pump to overheat, damaging seal and possibly causing burns to persons handling pump. Fill pump with water before starting. NEVER run pump against closed dis charge, to do so can 1 0 0 boil water inside pump, causing hazardous pressure in unit and possibly scalding persons handling pump. - Page 11 Operation Step 4. Once unit has primed and pressure stabilized, slowly open regulator valve (turn counterclockwise - Figure 15A) until pressure falters (pressure gauge needle flutters; pump may become noisy - 1 0 0 see Figure 15B). At this point, close regulator valve slightly (turn clockwise) until pressure stabilizes.

-

Page 12: Maintenance

Maintenance PUMP DISASSEMBLY/ASSEMBLY Step 1. Pull disconnect switch. Disconnect power lines from pressure switch. Step 2. Remove the two cap screws holding the pump to the flange adapter. Don’t disturb the piping in the well. Step 3. Remove the flange adapter gasket and scrape the surfaces clean. Step 4. - Page 13 Maintenance Step 3. Make sure that the shaft keys are in place on the shaft. If they are not, squeeze them in place now with slip joint pliers. Do not tap them or hit them with a hammer; you could bend the shaft (see Figure 22).

-

Page 14: Troubleshooting

Troubleshooting SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION Motor will not run Disconnect switch is off Be sure switch is on. Fuse is blown or circuit breaker tripped Replace fuse or reset circuit breaker. Starting switch is defective DISCONNECT POWER; Replace starting switch. Wires at motor are loose, Refer to instructions on wiring (Page 8). -

Page 15: Repair Parts

Repair Parts 1 0 0 Repair Parts – Multi-Stage Jet Part With MVPH-100 MVPH-150 MVPH-200 Description Used 1 HP 1-1/2 HP 2 HP Motor-115/230V Single Phase A300CH A300DH A300EH Motor-230V Single Phase A300FH AE300GH Motor Canopy U18-1300 U18-1355 U18-1355 Connector J43-13C J43-13C J43-13C... - Page 16 Repair Parts Item 1-Remove paper backing form gasket before applying. Item 2-Align locating lug on 1 0 0 flange with locating lug on base volute. 489 0194 Adapter Flange – (Not included with pump) Part J216-26 J216-27 376 1293 Description Qty.

Need help?

Do you have a question about the Myers MVPH-100 and is the answer not in the manual?

Questions and answers