Table of Contents

Advertisement

Installation, Operation, Repair and Parts Manual

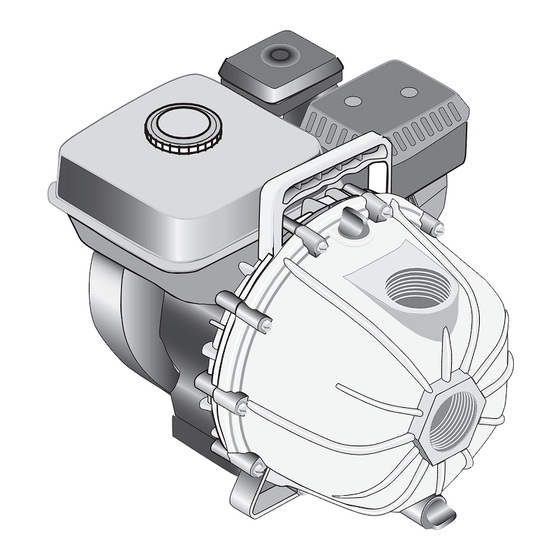

Hypro Self-Priming Polypropylene Centrifugal Pumps

handle big, high-capacity, liquid transfer jobs with ease.

Use them for transferring water, liquid fertilizers, and other

chemicals compatible with pump materials. Make short work

1542P-55SP

1542P-550BSP

1542P-160HSP

Close-Coupled, Gas Engine-Driven,

Self-Priming Poly Centrifugal Pump

Max Flow Rate: ............................ 150 GPM

Max. Pressure: .................................58 PSI

Max. Total Head ............................. 134 FT.

Max. Suction Lift: .............................. 25 FT.

Ports: ........................................ 2" NPT Inlet

Engine ............................PowerPro 5.5 H.P.

or Briggs & Stratton 550

WARNING: Do Not Pump Flammable or Explosive

Fluids Such as Gasoline, Fuel Oil, Kerosene, Etc. Do

Not Use in Explosive Atmospheres. The Pump Should

be Used Only with Liquids that are Compatible with

the Pump Component Materials. Failure to Follow this

Warning Can Result in Personal Injury and/or Property

Damage and Will Void the Product Warranty.

1. DO NOT EXCEED recommended speed, pressure and

temperature (120 degrees F) for pump and equipment

being used.

2. BEFORE SERVICING, drain all liquids from the system

and flush. Remove the spark plug wire from the spark

plug before servicing the pump or engine.

3. Secure the discharge lines before starting the pump.

An unsecured line may whip, causing personal injury

and/or property damage.

4. Check hose for weak or worn condition before each

use. Make certain that all connections are tight and

secure.

Series 1542P-55SP, 1542P-65SP, 1542P-550BSP,

1542P-950BSP, 1542P-160HSP, 1542P-200HSP

Gas Engine-Driven, Self-Priming

Polypropylene Centrifugal Pumps

2" NPT Outlet

or Honda GX160

General Safety Information

Description

of other farm jobs: filling nurse tanks, watering seedbeds,

and transferring liquids. This self-priming model makes it

ideal for de-watering applications.

5. Periodically inspect the pump and the system

components. Perform routine maintenance as required

(see Maintenance section).

6. Protect pump from freezing conditions by draining

liquid and pumping a permanent-type automobile

antifreeze containing a rust inhibitor through the

system, coating the pump interior. A 50% mixture with

water is recommended.

7. Do not operate a gasoline engine in an enclosed area.

Be sure the area is well ventilated.

WARNING: Gasoline is a Highly Combustible Fuel. The

Improper Use, Handling, or Storage of Gasoline Can be

Dangerous. Never Touch or Fill a Hot Engine.

8. Use only pipe, hose and fittings rated for the maximum

psi rating of the pump.

9. Do not use these pumps for pumping water or other

liquids for human or animal consumption.

1542P-65SP

1542P-65SPM

1542P-950BSP

1542P-200HSP

Close-Coupled, Gas Engine-Driven,

Self-Priming Poly Centrifugal Pump

Max Flow Rate: .............................. 200 GPM

Max. Pressure: .................................. 58 PSI

Max. Total Head ...............................134 FT.

Max. Suction Lift: ................................25 FT.

Ports: .......................................... 2" NPT Inlet

Engine ............................. PowerPro 6.5 H.P.

or Briggs & Stratton 950

Form L-1514

Rev. D

2" NPT Outlet

or Honda GX200

Advertisement

Table of Contents

Summary of Contents for Pentair Hypro 1542P Series

- Page 1 Series 1542P-55SP, 1542P-65SP, 1542P-550BSP, 1542P-950BSP, 1542P-160HSP, 1542P-200HSP Gas Engine-Driven, Self-Priming Form L-1514 Polypropylene Centrifugal Pumps Rev. D Installation, Operation, Repair and Parts Manual Description Hypro Self-Priming Polypropylene Centrifugal Pumps of other farm jobs: filling nurse tanks, watering seedbeds, handle big, high-capacity, liquid transfer jobs with ease. and transferring liquids.

-

Page 2: Plumbing Installation

Hazardous Substance Alert Please Note: It is illegal to ship or transport any 2. Before returning unit for repair, drain out all liquids and hazardous chemicals without United States flush unit with neutralizing liquid. Then, drain the pump. Environmental Protection Agency Licensing. Attach a tag or include a written notice certifying that this has been done. -

Page 3: Plumbing Diagram

Plumbing Diagram Hazardous Suction Can trap persons FIGURE A against suction inlet. Always use strainer on suction hose to prevent entrapment. -

Page 4: Operation And Maintenance

Operation and Maintenance Preparations Before Starting the Engine Operation of the Pump 1. Fuel: Check fuel level in tank, and do not over fill. Use 1. Idle the engine for 3 to 5 minutes to warm it up. fresh, clean automotive fuel. Note: DO NOT FILL 2. -

Page 5: Repair Instructions

Repair Instructions Always flush pump with water or neutralizing agent before servicing. PUMP HOUSING DISASSEMBLY Seal replacement requires that the pump be fully removed from the engine. Observe carefully the disassembly process to ensure an easy assembly process. Replace all worn and eroded parts. Fig. - Page 6 SEAL REPLACEMENT AND PUMP HOUSING ASSEMBLY 1. Install slinger ring on engine shaft. (See Figure 5.) 2. Lubricate and install the o-ring around back side of metal portion of the seal (See Figure 6). Insert the stationary portion of the new mechanical seal by carefully pushing only on the outer metal ring as you press it into the casing cover.

-

Page 7: Troubleshooting Guide

Running the Engine Refer to engine operation section of this manual for start- ing and operating instructions. Pump performance varies depending on engine RPM. Refer to engine operation to adjust engine speed. MAINTENANCE Pump Lubrication Pump liquid end does not require any grease or oil for lubrication. -

Page 8: Engine Safety Precautions

Pump Engine Operation and Maintenance Engine Safety Precautions: Add Gasoline Fill gas tank with clean, fresh gasoline. This should be Gasoline can Fire and explosion hazard. unleaded fuel that has an octane rating of 86 or higher. explode. Store gasoline away from the engine. Add gaso- Do not fill the tank to overflowing. -

Page 9: Engine Maintenance

Engine Maintenance Engine Troubleshooting If the engine won’t start: Air Filter • Check that there is gas in the tank. The air filter should be checked every month for dust • Make sure the fuel valve is “ON” and that the engine and dirt accumulation. - Page 10 1542P-55SP, 1542P-65SP, 1542P-65SPM 1542P-550BSP, 1542P-950BSP, 1542P-160HSP, 1542P-200HSP Gasoline Engine-Driven Plastic Transfer Pump NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE PUMP MODEL NUMBER. Reference numbers are used ONLY to identify parts in the drawing and are NOT to be used as order numbers.

- Page 11 Notes...

- Page 12 Returns are to be shipped with the RMA number clearly marked on the outside of the package. Hypro shall not be liable for freight damage incurred during shipping. Please package all returns carefully. All products returned for warranty work should be sent shipping charges prepaid to: HYPRO / PENTAIR Attention: Service Department 375 Fifth Avenue NW...

Need help?

Do you have a question about the Hypro 1542P Series and is the answer not in the manual?

Questions and answers