Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MasterForce 241-0725

-

Page 2: Table Of Contents

TABLE OF CONTENTS Table of contents ……………………………………………………………………....General safety warnings ………………………………………………………………………… 3–4 Eye, ear & lung protection ………………………………………………………………………. 3–4 Electrical safety …………………………………………………………………………………... Power tool safety ……………………………………………………………………....5–6 General safety rules ……………………………………………………………………………... Work area ………………………………………………………………….……………………... Electrical safety …………………………………………………………………………………... Personal safety …………………………………………………………………………………... 5–6 Power tool use and care .……………………………………………………………………….. -

Page 3: General Safety Warnings

GENERAL SAFETY WARNINGS WARNING: Before using this tool or any of its accessories, read this manual and follow all Safety Rules and Operating Instructions. The important precautions, safeguards and instructions appearing in this manual are not meant to cover all possible situations. It must be understood that common sense and caution are factors which cannot be built into the product. -

Page 4: Electrical Safety

GENERAL SAFETY WARNINGS POWER TOOL SAFETY EYE, EAR & LUNG PROTECTION – cont’d WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT. WARNING: Dust that is created by power sanding, sawing, grinding, drilling, and other construction activities may contain chemicals that are known to cause cancer, birth defects, or other genetic abnormalities. -

Page 5: Power Tool Safety

WARNING: Read all safety warnings and When operating a power tool outdoors, use all instructions. Failure to follow the warnings an extension cord suitable for outdoor use. and instructions may result in electric shock, fire Use of a cord suitable for outdoor use reduces and/or serious injury. -

Page 6: Power Tool Use And Care

POWER TOOL SAFETY PERSONAL SAFETY – cont’d Keep cutting tools sharp and clean. Properly Dress properly. Do not wear loose clothing maintained cutting tools with sharp cutting or jewelry. Keep your hair, clothing, and edges are less likely to bind and are easier to gloves away from moving parts. -

Page 7: Specific Safety Rules

SPECIFIC SAFETY RULES WARNING: Know your drill. Do not plug Secure the workpiece. Use clamps or a vise to the drill into the power source until you have hold the workpiece. It is safer than using your read and understand this Instruction Manual. hand and it frees both hands to operate the tool. -

Page 8: Extension Cord Safety

EXTENSION CORD SAFETY WARNING: Keep the extension cord clear of the working area. Position the same as indicated on the nameplate. the cord so it will not get caught on the Running at lower voltage will damage the workpiece, tools, or any other obstructions motor while you are working with the power tool. -

Page 9: Product Specifications

PRODUCT SPECIFICATIONS SAVE THESE INSTRUCTIONS FOR REFERENCE... -

Page 10: Symbols

SYMBOLS WARNING: Some of the following symbols may appear on the drill. Study these symbols and learn their meaning. Proper interpretation of these symbols will allow for more efficient and safer operation of this tool. Three-phase alternating current Volts with neutral Read all safety warnings and Amperes instructions... -

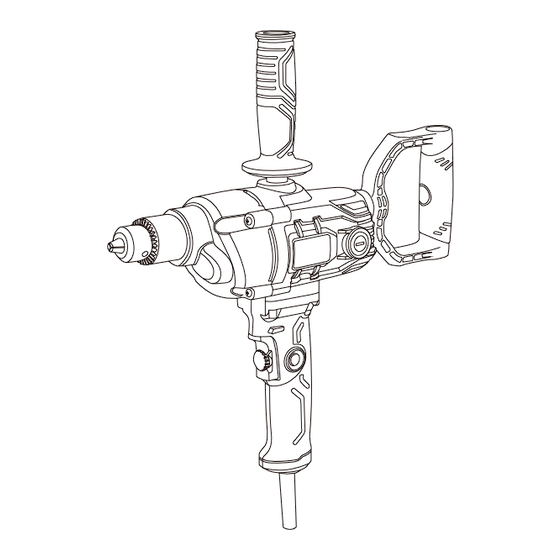

Page 11: Know Your Drill

KNOW YOUR DRILL... -

Page 12: Assembly And Operating

ASSEMBLY AND OPERATING INSTALLING AUXILIARY HANDLE AND reverse switch to the left. To make the drill D HANDLE rotate counter-clockwise, push the WARNING: forward/reverse switch to the right. The auxiliary handle and D handle must be installed as it will provide NOTES: additional control over the drill during heavy a) Never change the position of the forward/... -

Page 13: Lock-On Switch

ASSEMBLY AND OPERATING have set the speed you desire, when the INSTALLING DRILL BITS switch is completely depressed and the “Lock- WARNING: Never hold the chuck body On” button engaged, the tool speed will with one hand and use the drill power to change to the speed you dialed in. -

Page 14: Removing Bits

ASSEMBLY AND OPERATING INSTALLING DRILL BITS – cont’d DRILLING When drilling in smooth hard surfaces such as metal, use a center punch to mark the desired hole location. This will prevent the drill bit from slipping off center as the hole is started. The workpiece to be drilled should be secured in a vice or with clamps to keep it from turning as the drill bit rotates (Fig. -

Page 15: Driving Screws

ASSEMBLY AND OPERATING DRILLING – cont’d DRIVING SCREWS 4. Move the drill bit into the workpiece When driving screws, care must be taken to use applying only enough pressure to keep the the bit that correctly fits the screw being driven. bit cutting. -

Page 16: Retightening A Loose Chuck

MAINTENANCE CHUCK REMOVAL – cont’d 4. Open the chuck jaws and remove the hex RETIGHTENING A LOOSE CHUCK key. 5. Open the chuck jaws as far as possible. After installing the chuck once it has been removed, the chuck may become loose on the 6. -

Page 17: Replacing Carbon Motor Brushes

MAINTENANCE REPLACING CARBON MOTOR BRUSHES GENERAL MAINTENANCE The carbon motor brushes will wear down and require replacing. The time intervals between WARNING: When servicing, use only replacements will vary depending upon the identical replacement parts. The use of any working environment and the hours of use. It is other part may create a hazard or cause recommended that the brushes be checked product damage. -

Page 18: Exploded View

EXPLODED VIEW... -

Page 19: Parts List

PARTS LIST WARNING: When servicing, use only original equipment replacement parts. The use of any other parts may create a safety hazard or cause damage to the drill. Any attempt to repair or replace electrical parts on this saw may create a safety hazard unless repairs are performed by a qualified technician. - Page 20 PARTS LIST...

- Page 22 Rev 1.0 5-19-20...

Need help?

Do you have a question about the 241-0725 and is the answer not in the manual?

Questions and answers