Advertisement

Quick Links

Models

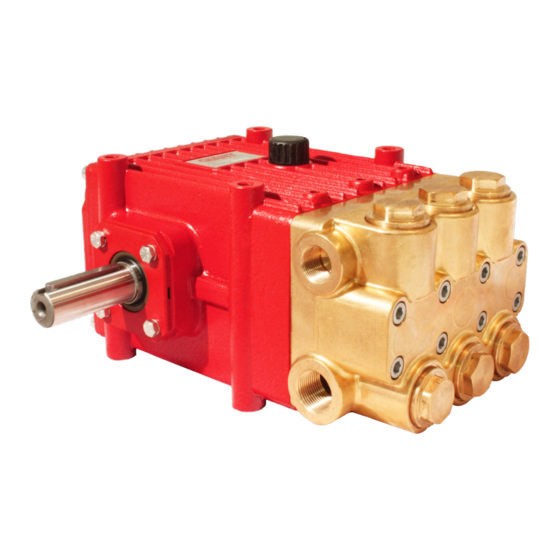

P532, P533 and P536

Updated 04/23

Contents:

Performance Information:

Installation Instructions:

Exploded View:

Parts List/Kits/Torque Specifications:

Repair Instructions:

Trouble Shooting Chart:

Recommended Spare Parts List:

Dimensions:

Warranty Information:

Triplex Ceramic

Plunger Pump

Operating Instructions/

Repair and Service Manual

page 2

page 3

page 4

page 5

page 6

page 7

page 7

back page

back page

Advertisement

Summary of Contents for Giant P532

- Page 1 Triplex Ceramic Plunger Pump Models Operating Instructions/ Repair and Service Manual P532, P533 and P536 Contents: Performance Information: page 2 Installation Instructions: page 3 Exploded View: page 4 Parts List/Kits/Torque Specifications: page 5 Repair Instructions: page 6 Trouble Shooting Chart:...

- Page 2 P532/P533/P536 1. Performance U.S. Measurements Plunger Max. Flow Pressure Max. Speed Power Req’d. Diameter Stroke Model 1450 P533 22.7 2175 34.1 1.26 1.02 1450 * P532 24.4 2175 36.6 1.26 1.10 P536 26.4 1740 1450 31.6 1.42 0.945 Metric Measurements Plunger Max.

- Page 3 Filling quantity: 0.42 gallons (1.6 l) • Quality: Industrial gear oil ISO VG 220 or automotive gear oil SAE 90 GL4 (Giant’s p/n 01154) Intervals: first oil change after 50 operating hours then every 500 operating hours, but at the latest after 12 months 5.

- Page 4 EXPLODED VIEW - P532, P533 and P536...

- Page 5 P532, P533 and P536 SPARE PARTS LIST ITEM PART DESCRIPTION QTY. ITEM PART DESCRIPTION QTY. 04405 Crankcase, Aluminum 13027 Sleeve (P532/P533) 04234 Oil Dipstick Assembly 07144 Sleeve (P536) 04406 Crankcase Cover, Aluminum 04281 Grooved Ring (P532/P533) 04407 O-Ring 04248 Grooved Ring (P536)

- Page 6 REPAIR INSTRUCTIONS - P532, P533 and P536 8. Maintenance and Servicing Plunger surface must not be damaged in For the type of threadlocker used and the required the process. tightening torques, observe the table in the ex- ploded view. If plunger pipe (16A) is worn, remove tensioning 8.1 Special tools required...

- Page 7 Replace plungers Inlet pressure too high Reduce inlet pressure High Crankcase Wrong Grade of oil Giant oil is recommended Temperature Improper amount of oil in crankcase Adjust oil level to proper amount Preventative Maintenance Check-List & Recommended Spare Parts List...

- Page 8 Liability under this warranty is on all non-wear parts and limited to the replacement or repair of those products returned freight prepaid to Giant Industries which are deemed to be defective due to workmanship or failure of material. A Returned Goods Authorization (R.G.A.) number and completed warranty evaluation form is required prior to the return to Giant Industries of all products under warranty consideration.

Need help?

Do you have a question about the P532 and is the answer not in the manual?

Questions and answers