Summary of Contents for Endress+Hauser CPY7B

- Page 1 Products Solutions Services BA00128C/07/EN/14.16 71344205 Operating Instructions CPY7B Electrolyte vessel...

-

Page 2: Table Of Contents

Accessories ....13 Technical data ....13 Endress+Hauser... -

Page 3: Document Information

CPY7B Document information Document information Warnings Structure of information Meaning This symbol alerts you to a dangerous situation. DANGER Failure to avoid the dangerous situation will result in a fatal or serious injury. Causes (/consequences) Consequences of non-compliance (if applicable) ‣... -

Page 4: Basic Safety Instructions

Basic safety instructions CPY7B Basic safety instructions Requirements for the personnel • Installation, commissioning, operation and maintenance must only be carried out by technical personnel trained to perform these tasks. • The technical personnel must be authorized by the plant operator to carry out the specified activities. -

Page 5: Incoming Acceptance And Product Identification

CPY7B Incoming acceptance and product identification Incoming acceptance and product identification Incoming acceptance Verify that the packaging is undamaged. Notify your supplier of any damage to the packaging. Keep the damaged packaging until the matter has been settled. Verify that the contents are undamaged. -

Page 6: Scope Of Delivery

Installation conditions Instructions for installing in pressurized systems General ‣ Only the pressure-resistant versions – CPY7B-B or CPY7B-C – should be operated in pressurized systems. ‣ Never exceed the maximum permitted pressure of 11 bar (160 psi) at an ambient temperature of 30 °C (86 °F). -

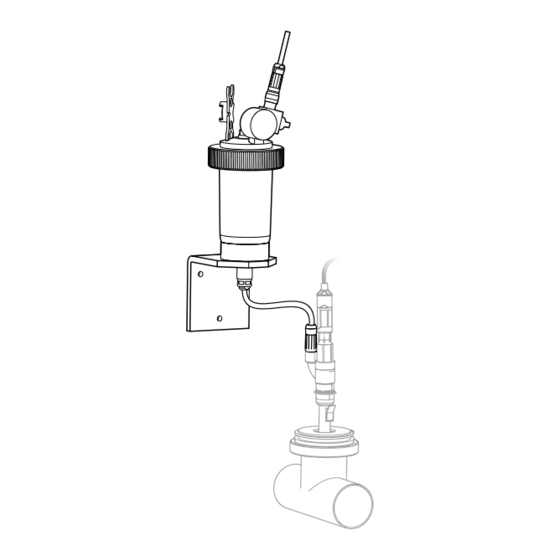

Page 7: Installing The Electrolyte Vessel

CPY7B Installation Installing the electrolyte vessel 4.2.1 Wall mounting CPY7B-B0/C0 CPY7B-A0 A0005479 1 Wall mounting Hose union with check valve Hose connection Manually operated valve Pressure gauge (accessory) Fixing bracket Thread adapter nut Lock nut Spacer tube Endress+Hauser... -

Page 8: Post-Installation Check

Installation CPY7B 4.2.2 Installation on an assembly CPY7B-B1/C1 CPY7B-A1 A0005480 2 Installation on the CPA111 assembly head Pressure gauge (accessory) Hose union with check valve Spacer tube Manually operated valve Lock nut Thread adapter nut Hose connector Hose connection... -

Page 9: Commissioning

Fill the vessel with electrolyte: ‣ ‣ ‣ Open the manually operated valve Hold by the hybrid open-ended Do not overfill the vessel. wrench (a) and loosen the coupling The first four steps are not required for the unpressurized version (CPY7B-A). Endress+Hauser... -

Page 10: Venting

Commissioning CPY7B Venting Having topped up the electrolyte, you have to vent the electrolyte hose. CAUTION Minor skin or eye injuries are possible as a result of contact with the electrolyte ‣ Wear safety gloves and protective goggles. Release the electrolyte hose connection on the sensor. -

Page 11: Maintenance

Cut off the compressed air supply using the manually operated valve (toggle to horizontal position). Observe the pressure gauge on the CPY7B. If the pressure has not dropped after 15 minutes, the couplings are leak-tight. If the pressure has dropped, re-tighten the couplings. Check the seal to ensure it is intact and seated correctly. -

Page 12: Repairs

The product must be returned if repairs or a factory calibration are required, or if the wrong product was ordered or delivered. As an ISO-certified company and also due to legal regulations, Endress+Hauser is obliged to follow certain procedures when handling any returned products that have been in contact with medium. -

Page 13: Disposal

CPY7B Accessories Disposal Observe the local regulations. Accessories KCl solution CPY4 • Top-up electrolyte solution, concentration 1.5 or 3 mol/l • Volume 100 ml or 1000 ml Diaphragm pipe CPY6 • For pH/redox measurement with bridge electrolyte • Order No. 50068478 Pressure gauge •... - Page 14 Technical data CPY7B Process The process temperature limits and process pressure limits for the entire system are determined by the limits of the components used (assembly, electrode, cable, accessories, etc.). Mechanical construction 9.3.1 Dimensions CPY7B-*0 CPY7B-*1 Ø99 (3.90) Ø99 (3.90) 3 x Ø7 (0.28)

- Page 15 CPY7B Technical data 9.3.3 Weight 0.450 kg (1 lbs) 9.3.4 Materials Pressure vessel Polycarbonate O-rings EPDM Unpressurized hose PTFE Pressure hose PTFE Spiral hose Polyamide PA12W Special wick ABC thread 9.3.5 Pressure connection Pressure hose ID 4 (0.16")/AD 6 (0.24") Valve for air pump 5 mm (0.2") diameter...

- Page 16 *71344205* 71344205 www.addresses.endress.com...

Need help?

Do you have a question about the CPY7B and is the answer not in the manual?

Questions and answers