Table of Contents

Summary of Contents for UNIRAC NXT UMOUNT

- Page 1 INSTALLATION GUIDE UNIRAC Code-Compliant Installation Manual © 2022 by Unirac, Inc. All rights reserved. PUB2023APR23 UNIRAC welcomes input concerning the accuracy and user-friendliness of this publication. Please write to publications@unirac.com.

-

Page 2: Table Of Contents

INSTALLATION GUIDE TABLE OF CONTENTS NXT SYSTEM COMPONENTS ....... . 1-3 SYSTEM LAYOUT . - Page 3 • • 4” STAINLESS-STEEL LAG BOLT 4” STAINLESS-STEEL LAG BOLT with with sealing EPDM washer. sealing EPDM washer. • • UNIRAC PROVIDED SEALANT UNIRAC PROVIDED SEALANT (if applicable) (if applicable) STRONGHOLD RAIL CLAMP STRONGHOLD RAIL CLAMP: Use to secure rails...

- Page 4 NXT SYSTEM COMPONENTS INSTALLATION GUIDE PAGE FLASHKIT PRO FLASHKIT PRO: : Use with Stronghold Rail Use with Stronghold Rail Clamp to secure rail through roofing material Clamp to secure rail through roofing material to building structure. Aluminum L-foot with to building structure. Aluminum L-foot with EPDM grommet, aluminum flashing, ...

-

Page 5: Nxt System Components

NXT SYSTEM COMPONENTS INSTALLATION GUIDE PAGE S.NO. PART DESCRIPTION PART NUMBER NXT UMOUNT RAIL - 168" MILL 168RLM1 RAIL NXT UMOUNT RAIL - 168" DARK 168RLD1 RAIL SPLICE NXT UMOUNT RAIL SPLICE RLSPLCM1 & RLSPLCM2 STRONGHOLD ATT KIT COMP MILL... -

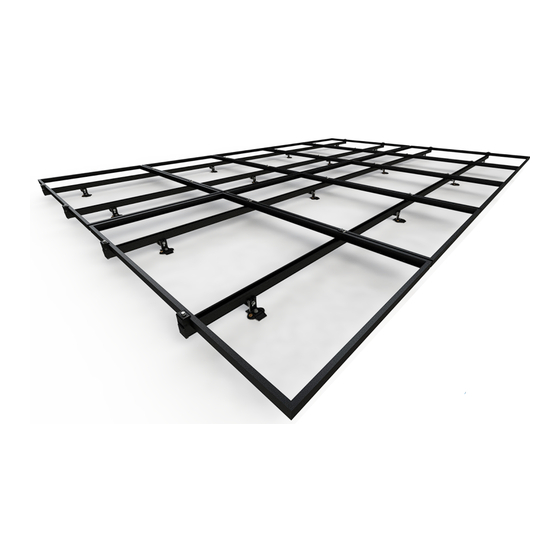

Page 6: System Layout

LAYING OUT ROOF ATTACHMENTS Locate and mark the position of the roof attachment within the installation area. Refer to Unirac NXT UMOUNT D&E Guide & U-Builder for rail spans and cantilevers. Follow module manufacturer installation requirements allowable spacing based on appropriate mounting locations. Modules should be placed such that they overhang the rails symmetrically. -

Page 7: Thermal Break

The values displayed are the maximum allowed rail length, in feet, without a thermal break. If your span is less than 48”, refer to the NXT UMOUNT Design & Engineering Guide for max lengths of continuous rail before a thermal break is required. - Page 8 Pilot holes are not necessary to be drilled for self-drilling screws. But if holes surface. surface. are drilled to identify the rafter, they should be backfilled with sealant before installing the attachment. Note: See Page 8 for instructions on placing extra butyl pads or contact Unirac team for further information.

-

Page 9: Stronghold Attachment With Butyl Installation

4 additional deck screws. • It is recommended to begin installation with the screws on the upslope side 2. Unirac recommended spans are only valid with Unirac supplied screws. of the attachment and continue installing the screws on the downslope side of the attachment for best fit. - Page 10 Note: • Extra butyl pads are NOT included in the KIT. • Pre-stock with extra butyl pads from Unirac Kits in case installation is required over overlap or gap. WARNING Installing attachment on uneven surfaces, shingle gaps or overlaps, creates a risk for water leakage and Installing attachment on uneven surfaces, shingle gaps or overlaps, creates a risk for water leakage and rail clamp misalignment due to gap created between the adhesive and roof surface.

-

Page 11: Roof Preparation For Lag Installation

ROOF PREP FOR LAG BOLT INSTALL INSTALLATION GUIDE PAGE MARK ARRAY LOCATION: DRILL PILOT HOLES: Drill a 7/32” pilot Mark array location and determine hole at each roof attachment. Clean roof roof attachment locations based surface of dirt, debris, snow, and ice. Fill on array layout. -

Page 12: Stronghold Attachment Installation

SEAL: Drop the rail clamp assembly into the open Place the Stronghold attachment base assembly Insert tip of UNIRAC provided sealant into port. Inject slot of L-Foot. over the pilot hole. Align indicator marks of until sealant exits vent. Follow sealant manufacturer's mount with chalk line. -

Page 13: Flashkit Pro Installation

FLASHKIT PRO INSTALLATION INSTALLATION GUIDE PAGE INSTALL FLASHKIT PRO FLASHING: INSTALL L-FOOT: Fasten L-foot and FIX RAIL CLAMP ONTO L-FOOT: Remove Add a U-shaped bead of roof sealant flashing into place by passing the bolt from rail clamp. Place bolt through to the underside of the flashing included lag bolt and pre-installed slot in L-foot and though hole in Rail... -

Page 14: Attachment Orientations

(E) and (F) above. Note: For high snow loads, use orientations (C) or (D). Refer to NXT UMOUNT Design and Engineering Guide for specific requirements. Note: For high snow loads, use orientation (F). Refer to NXT UMOUNT Design and Engineering Guide for specific requirements. - Page 15 -FLASHKIT-DOWNSLOPE IMAGE-5-FLASHKIT-UPSLOPE Flashkit Pro L-foot and Rail Clamp can be installed in either orientation shown in image (G) and (H) above. Note: For high snow loads, use orientation (H). Refer to NXT UMOUNT Design and Engineering Guide for specific requirements.

-

Page 16: Rail Installation

RAIL INSTALLATION IMAGE-2-INSTALL STEP-2 IMAGE-1-INSTALL STEP-1 INSTALLATION GUIDE PAGE IMAGE-1-INSTALL STEP-1 IMAGE-2-INSTALL STEP-2 IMAGE-3-ISO VIEW IMAGE-3-ISO VIEW IMAGE-4-RAIL FIX IMAGE-2-INSTALL STEP- IMAGE-1-INSTALL STEP-1 IMAGE-5-CAUTION-RAIL CLAMP IMAGE-5-CAUTION-RAIL CLAMP IMAGE-2-INSTALL STEP-2 IMAGE-1-INSTALL STEP-1 IMAGE-2-INSTALL STEP-2 IMAGE-1-INSTALL STEP-1 POSITION RAIL ONTO RAIL CLAMP: TIGHTEN RAIL ONTO RAIL CLAMP : IMAGE-4-RAIL FIX With the bolt in the pre-assembled (loose) position, Insert the rail flange on one side of the clamp... -

Page 17: Structural Splice

INSTALLATION GUIDE PAGE SPLICE INSTALLATION (IF REQUIRED PER SYSTEM DESIGN) If your installation uses NXT UMOUNT Rail Splice, attach the rails together either before installing the rail or after. Use marking on the splice for centering the connection. To install, slide the splice into the rail on each rail and drag it to the center of the marking. -

Page 18: System Grounding

IMAGE-2-RACK SYSTEM GROUND IMAGE-6-LUG INSTALL STEP-4 SYSTEM GROUNDING: SYSTEM GROUNDING: Rails can be bonded using an NXT UMOUNT MLPE & Rails can be bonded using an NXT UMOUNT MLPE & SYSTEM GROUNDING WITH MLPE & LUG CLAMP: SYSTEM GROUNDING WITH MLPE & LUG CLAMP: Insert the rail nut profile in... -

Page 19: Mlpe Mounting

TORQUE VALUE: 20 ft-lbs. IMAGE-6-MLPE INSTALL-RIGHT IMAGE-7-MLPE INSTALL-WRONG IMAGE-6-MLPE INSTALL-RIGHT IMAGE-7-MLPE INSTALL-WRONG Note: Refer to Unirac MLPE Mount Installation Guide for details at IMAGE-11-BOLT TIGHTEN-BLOW UP IMAGE-7-MLPE INSTALL-WRONG CAUTION https://unirac.com Ensure that MLPE is always installed on the top of lock-tooth washer. -

Page 20: Wire Management

WIRE MANAGEMENT INSTALLATION GUIDE PAGE IMAGE-2-WIRE MGMT CLIP INSTALL STEP-2 IMAGE-3-WIRE MGMT CLIP STEP-3 IMAGE-1- WIRE MGMT CLIP INSTALL STEP-1 IMAGE-2-WIRE MGMT CLIP INSTALL STEP-2 IMAGE-1- WIRE MGMT CLIP INSTALL STEP-1 IMAGE-3-WIRE MGMT CLIP STEP-3 IMAGE-1- WIRE MGMT CLIP INSTALL STEP-1 IMAGE-6-WIRE TIE INSERT IMAGE-3-WIRE MGMT CLIP STEP-3 INSTALL NS WIRE MANAGEMENT CLIP:... -

Page 21: Combo Clamp Installation

COMBO CLAMP INSTALLATION INSTALLATION GUIDE PAGE 1/2" 1" min INSTALL COMBO (END) CLAMPS: INSERT COMBO CLAMP: INSTALL END MODULE: Position first module onto rails Install Combo Clamps starting at the aligned end of Insert Combo Clamp from one side of and engage module frame with end clamps. -

Page 22: Hidden End Clamp Installation

HIDDEN END CLAMP INSTALLATION GUIDE PAGE INSTALL MODULE END CLAMPS: The End clamp is INSTALL END CLAMPS ON RAIL: POSITION END CLAMPS: NOTE: supplied as kit with pre assembled end cap. The Slide the end clamp assembly on Slide the end clamp assembly To assist insertion of the clamp into the rail, hold the twist ties clamp should be installed on the rails prior to... -

Page 23: Finishing Touches

IMAGE-2X-COMBO CLAMP CAP FINISHING TOUCHES INSTALLATION GUIDE PAGE FOR HIDDEN CLAMP Pro Tip: Pro Tip: Module For best appearance, leave For best appearance, leave Module enough space for the bolt enough space for the bolt head while cutting the rail head while cutting the rail ends to perfectly snap fit ends to perfectly snap fit... -

Page 24: Bonding Connection & Ground Paths

BONDING CONNECTIONS & GROUNDING PATHS INSTALLATION GUIDE PAGE IMAGE-5-BONDING MICROINVERTER MOUNT IMAGE-6-RACK SYSTEM GROUND IMAGE-2-BONDING COMBO MID-END CLAMP ASSEMBLY IMAGE-1-NXT RAIL BONDING RAIL SPLICE BONDING COMBO MID-END CLAMP ASSEMBLY Aluminum combo mid-end clamp cap with stainless steel bonding pins that pierce Bonding Hardware creates bond between Splice bar and each rail section. - Page 25 BONDING CONNECTIONS & GROUNDING PATHS IMAGE-1-ISO VIEW IMAGE-2-RACK SYSTEM GROUND IMAGE-2-RACK SYSTEM GROUND IMAGE-3-LUG INSTALL STEP-1 IMAGE-3-LUG INSTALL STEP-1 IMAGE-4-LUG INSTALL STEP-2 IMAGE-4-LUG INSTALL STEP-2 INSTALLATION GUIDE PAGE IMAGE-1-MLPE INSTALL STEP-1 IMAGE-2-MLPE INSTALL STEP-2 IMAGE-3-MLPE INSTALL STEP-3 IMAGE-4-MLPE INSTALL STEP-4 IMAGE-8-ILSCO LUG WITH GROUND WIRE IMAGE-7-ILSCO LUG INSTALL IMAGE-5-LUG INSTALL STEP-3...

- Page 26 BONDING CONNECTIONS & GROUNDING PATHS INSTALLATION GUIDE PAGE RACKING SYSTEM GROUND Ground Lug w/ Bare BONDING Copper Wire MICROINVERTER Note: Only one lug per module MOUNTS row required BONDING RAIL SPLICE BONDING COMBO CLAMPS ALTERNATE ROW - TO - ROW BONDING METHOD...

- Page 27 See below for interconnection information. MODULE REMOVED INTERCONNECTION INFORMATION There is no size limit on how many NXT UMOUNT & PV modules can be mechanically interconnected for any given configuration, provided that the installation meets the requirements of applicable building and fire codes.

-

Page 28: Mechanical Load Test

UL 2703. NXT UMOUNT has achieved system level performance for steep sloped roofs and low sloped roofs. System level fire performance is inherent in the NXT UMOUNT design, and no additional mitigation measures are required. See table below for definition of steep sloped and low sloped roofs. The system is to be mounted over fire resistant roof covering rated for the application. -

Page 29: Compatible Modules

SYSTEM CERTIFICATION PAGE Electrical Bonding and Grounding Test Modules The list below is not exhaustive of compliant modules but shows those that have been evaluated and found to be electrically compatible with the NXT UMOUNT system. Manufacture Module Model / Series... - Page 30 SYSTEM CERTIFICATION PAGE Electrical Bonding and Grounding Test Modules The list below is not exhaustive of compliant modules but shows those that have been evaluated and found to be electrically compatible with the NXT UMOUNT system. Manufacture Module Model / Series...

- Page 31 SYSTEM CERTIFICATION PAGE Electrical Bonding and Grounding Test Modules The list below is not exhaustive of compliant modules but shows those that have been evaluated and found to be electrically compatible with the NXT UMOUNT system. Manufacture Module Model / Series...

- Page 32 COMPATIBLE MODULES SYSTEM CERTIFICATION PAGE Electrical Bonding and Grounding Test Modules The list below is not exhaustive of compliant modules but shows those that have been evaluated and found to be electrically compatible with the NXT UMOUNT system. Manufacture Manufacture...

Need help?

Do you have a question about the NXT UMOUNT and is the answer not in the manual?

Questions and answers