Table of Contents

Advertisement

Quick Links

Instruction Manual

Volute Pump

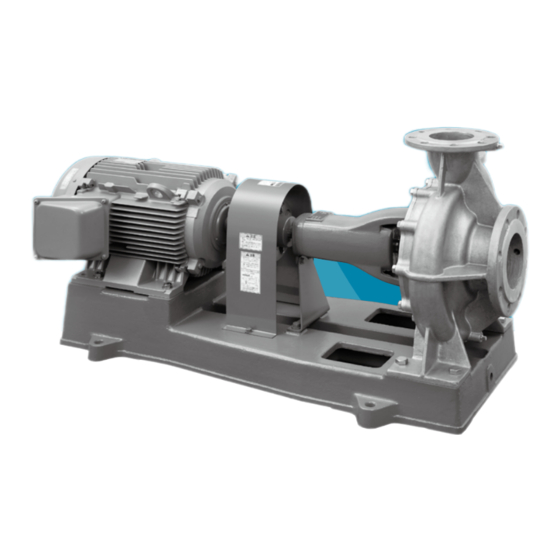

Model: SJS / SJ4S

SJS-e / SJ4S-e

Warning

Do not carry out operation, inspection or maintenance of the pump until you read this manual and

understand the content.

Keep this manual carefully at hand so that it can be consulted at anytime when operating, inspecting or

maintaining the pump.

For contractors who carry out equipment work:

Please be sure to deliver this manual to the customer who will operate, inspect or maintain the pump.

TERAL INC.

Advertisement

Table of Contents

Summary of Contents for Teral SJS-e

- Page 1 Instruction Manual Volute Pump Model: SJS / SJ4S SJS-e / SJ4S-e Warning Do not carry out operation, inspection or maintenance of the pump until you read this manual and understand the content. Keep this manual carefully at hand so that it can be consulted at anytime when operating, inspecting or maintaining the pump.

-

Page 2: Limited Warranties

(6) Failures and breakage caused by use or storage outside the specification range 4. Teral Inc. shall not be liable for the damage caused by incorrect or reckless use of the pump. Cost and expenses incurred for sending engineer(s) in such a case shall be borne by the user. -

Page 3: Table Of Contents

Purpose of this manual The purpose of this manual is to provide the user with detailed information necessary to properly operate, maintain and inspect the pump. Incorrect operation of this product may lead to an unexpected accident. Please use the product correctly according to this instruction manual. This manual contains the following information and is intended for persons experienced in the operation of pumps, or for those who have been trained by such experienced operators. -

Page 4: Safety Precautions

1. Safety precautions Before using the unit, thoroughly read this “Safety precautions” to properly use the product. Information described below is vital to safe and proper use of the unit and prevention of hazard and/or damage. Types and meanings of safety signs and graphic symbols This instruction manual divides precautions into the following four categories according to the level of hazards (or the severity of the accident). - Page 5 For overhaul, replacement of parts, or repairs, Do not put your fingers or foreign objects into any contact Teral or the service center specified by openings or rotating part of the motor during Teral. operation.

- Page 6 Do not run the pump with tools or other objects cannot be resolved, immediately stop the placed on the unit. operation, turn off the power, and then contact Teral Otherwise, it may lead to an injury or damage. or its service provider.

-

Page 7: Location Of Warning Labels And Caution Labels

Location of warning labels and caution labels The figure shows the locations of warning labels and caution labels. If these labels become dirty and illegible or if they are peeled off, replace them with a new one. Warning Caution Observe all the warnings and cautions affixed to the machine as well as those described in this instruction manual. -

Page 8: Configuration And Overview Of The Pump

2. Configuration and overview of the pump This chapter describes the standard specifications of the pump. If you have purchased a customized product, some information in this chapter may not be applicable to your unit. Refer to the delivery specifications for the details separately. Model type description S J S 3 . -

Page 9: Standard Specifications

* 2 The liquid exceeding 80°C might be available, depending on the usage condition. Contact your nearest office of Teral. * 3 The total suction head shows the values when the water temperature is 20 °C. The maximum value of the total suction head decreases when the pump is used with warm water. -

Page 10: Installation

3. Installation Before using the pump Upon receiving the pump, check the following points first. The container may greatly incline depending on its center of gravity. Caution Before unpacking, ensure that the delivered container is placed in the correct orientation (not upside down). Pay special attention to nails especially when opening a wooden crate. - Page 11 Caution Install the product so that the total suction head (suction height + suction pipe resistance) is as small as possible within the standard specifications. Caution Do not install the pump at an upward curve of piping (where air is trapped). Failure to observe this may cause the pump to run dry, and seize up the sliding part in the pump.

-

Page 12: Installation Procedure

(7) If the system could be exposed to the freezing temperature in winter, ensure to take measures to prevent freezing in the pump room or to prevent the pump, sluice valves, piping, and other devices from freezing. (8) Use sound-insulating materials for door and walls of the pump room. Especially if there is a risk that the noise may cause problem, take necessary measures against the noise. -

Page 13: Precautions For Piping Work

(8) Be sure to align the shafts correctly. Although the shaft is aligned at the factory before shipment, it could get misaligned during transportation or installation (at fastening the anchor bolts). Check the alignment and re-align it after the installation is complete. Parallel ruler Max. - Page 14 (2) Be sure to provide pipe supports so that the weight of pipes is not applied directly to the pump main body. Caution Be sure to provide pipe supports for the pipes. Otherwise, the main shaft may be displaced from the center, thus leading to the equipment damage, vibration, or noise.

- Page 15 ・ Attach a foot valve with a strainer to the end of the suction pipe to prevent entry of foreign objects. Immerse the foot valve in water and set it at a depth of at least twice the diameter of the pipe from the surface of water to prevent the suction of air.

- Page 16 (15) In case of double mechanical seal specification, observe the following instructions. ・ Set up another pump for flushing liquid circulation, as flushing from an external source is required for the seal faces. ・ Refer to the internal structure drawing for double mechanical seal structure. ・...

-

Page 17: Precautions For Wiring Work

(equivalent to IE3) motor-equipped products tends to become higher than that of standard efficiency (IE1) motor-equipped products. If you have any questions, contact your nearest office of Teral. Note When switching from an IE1 motor-equipped product, it is necessary to verify the applicability of its protection device on the primary side of the pump. - Page 18 Do not use the inverter to drive a motor equipped with a self-protecting device. • When driving a 400V-class motor, contact your nearest office of Teral. In some cases it might be necessary to take measures for inverter surge. •...

-

Page 19: Operation

4. Operation Check items before test operation 4.1.1 Check items related to the electrical system Warning Before changing the wiring, be sure to turn off the main power supply. Otherwise, you may receive an electric shock. Warning Do not use the product at any voltage other than the rated value. A fire or electric shock may occur. -

Page 20: Running The Pump (Test Operation)

(4) If the sluice valve is installed on the suction side, fully open the valve. (5) Prime the pump until water overflows from the priming funnel or the priming port. At that time, loosen the air vent cock to release air from the pump. Warning When priming the pump (air venting), prevent the damage of the motor and parts from the spouting water. - Page 21 (1) Chec k the rotation direction of the pump by turning ON and OFF the po wer switch once or twice. Normal rotation is clockwise when viewed from the motor side. If the pump shaft rotates in reverse, swap two of the three wires of the power cable.

- Page 22 [For reference only] Relation between the total amplitude (a) and the vibration velocity (V) V×4×10 π×n a: Total amplitude (μm) V: Vibration velocity (mm/s) n: Equipment rotation speed (min 600 800 1000 1500 2000 3000 4000 6000 8000 Rotation speed (min Standard vibration value at the bearing section (9) Stop the pump.

-

Page 23: Maintenance And Inspection

Caution For overhaul, replacement of parts, or repairs, ask the vendor, the servicing company specified by Teral, or your nearest Teral sales office. Incorrect work may cause a failure or accident. Precautions for maintenance and inspection (1) Observe the following instructions, in particular, during daily inspection. -

Page 24: Shaft Seal Parts

Warning In the event of a power failure, be sure to turn off the power switch. The pump may suddenly start up on restoration of the power, which leads to a danger. ○ Check the strainer fitted on the pump suction side, for any clogging. Clean it if it is clogged. Caution Periodically clean the strainer located on the pump suction side. -

Page 25: Double Mechanical Seal

5.2.2 Double mechanical seal Caution Carefully handle the flushing liquid. Do not touch the liquid with bare hands and ware a goggle to protect your eyes. Also keep your hands and face away from the flushing part, when the pump is operating. Liquid leaks and it may lead to eye injury. (1) The double mechanical seal must never run dry without lubrication. - Page 26 (5) Insert the gland packing rings carefully one by one, as far as it will go. In addition, the rings should be oriented so that each of their adjacent cut slits will be 90 to 120 degrees apart. (6) Gland packing is a consumable part. Its life depends on the quality of liquid, having foreign objects or no, pressure, etc.

-

Page 27: Maintenance Checklist

Maintenance checklist Inspection interval Consumables Inspection Criterion Inspection point Inspection item Half- Timing of replacement method (Reference page) Daily Monthly Yearly yearly (as a guide)* Between 0 and 40°C Temperature Measure (2-2) Check against the Less than 85% RH (2-2) ... -

Page 28: Troubleshooting

6. Troubleshooting If you find any abnormal conditions of the pump, carefully investigate the problem. For overhaul, replacement of the parts or repairs, ask the vendor or contact Teral or our servicing companies. Problem Cause (Reference page) Action (Reference page) Check the wires and connections to repair or Wiring is disconnected or broken. - Page 29 Problem Cause (Reference page) Action (Reference page) The bearing is worn or damaged. (5-1) Contact Teral or our servicing companies because disassembly and inspection are required. The grease is deteriorated. Overheat of bearing Incorrect installation of the pump and the Check and correctly install or realign them.

- Page 30 Head Office 230, Moriwake, Miyuyki-cho, Fukuyama-city, Hiroshima, 720-0003, Japan Tel.084-955-1111 Fax.084-955-5777 Overseas Div. TERAL Koraku Bldg., 2-3-27, Koraku, Bunkyo-ku, Tokyo, 112-0004, Japan Tel.03-3819-6890 Fax.03-3818-6790 TP-346-01 TP-448-00...

Need help?

Do you have a question about the SJS-e and is the answer not in the manual?

Questions and answers