Summary of Contents for NEC NEAX 7400 ICS

- Page 1 AD-25182501 ISSUE 1.0.1 Model 120 Installation Procedure Manual OCTOBER, 1995 NEC Australia Pty. Ltd.

- Page 2 NEC Australia Pty. Ltd. reserves the right to change the specifica- tions, functions, or features, at any time, without notice. NEC Australia Pty. Ltd. has prepared this document for use by its employees and customers. The information contained herein is the property of NEC Australia Pty.

- Page 3 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 ISSUE PAGE N0. 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 ISSUE PAGE N0. 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1...

- Page 4 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 ISSUE PAGE N0. 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 ISSUE PAGE N0. 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1...

- Page 5 ISSUE PAGE N0. ISSUE PAGE N0. ISSUE PAGE N0. 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 1.0.1 ISSUE PAGE N0. ISSUE 1.0.1 ISSUE 2 ISSUE 3 ISSUE 4 DATE OCTOBER, 1995 DATE DATE DATE ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8 DATE DATE DATE...

- Page 6 IMPORTANT SAFETY CONSIDERATIONS Never install telephone wiring during a lightning storm. Never install telephone jacks in wet locations unless the jack is specifically designed for wet locations. Never touch uninsulated telephone wires or terminals unless the telephone line has been disconnected at the network interface.

- Page 7 A. When the power supply cord or plug is damaged or frayed. B. If liquid has been spilled into the product. C. If the product has been exposed to rain or water. D. If the product does not operate normally by following the operating instructions. Adjust only those controls, that are covered by the operating instructions because improper adjustment of other controls may result in damage and will often require extensive work by a qualified technician to restore the product to normal operation.

- Page 8 AD-25182501 ISSUE 1.0.1 OCOTBER, 1995 NEAX7400 ICS Model 120 Installation Procedure Manual CHAPTER INTRODUCTION GENERAL INFORMATION INSTALLATION PROCEDURE...

-

Page 9: Table Of Contents

AD-25182501 ISSUE 1 OCTOBER, 1995 NEAX7400 ICS Model 120 Installation Procedure Manual TABLE OF CONTENTS Page LIST OF ILLUSTRATIONS ........................LIST OF TABLES ............................CHAPTER 1 INTRODUCTION ......................PURPOSE ............................REFERENCE MANUAL ........................HOW TO FOLLOW THIS MANUAL .................... SCOPE OF INSTALLATION PROCEDURES .............. - Page 10 TABLE OF CONTENTS (CONTINUED) Page PROCEDURE ............................NAP-200 -001 Unpacking ........................1. Unpacking Procedure ..................... -002 Marking and Drilling ......................1. Confirmation of the Equipment Layout ................. 2. Marking and Drilling ......................2.1 Floor Standing Installation.................... 2.2 Wall-Mounting ........................ -003 Installation of Main Equipment ..................1.

-

Page 11: List Of Illustrations

LIST OF ILLUSTRATIONS Figure Title Page Reference Manuals for Installation ...................... Scope of Installation Works........................PABX Trunking Diagram ........................1-PIM Configuration for Floor Standing Installation................2-PIM Configuration for Floor Standing Installation................8-PIM Configuration for Floor Standing Installation................1-PIM Configuration for Wall-Mounting Installation ................4-PIM Configuration for 19-Inch Rack-Mounting Installation ............ - Page 12 LIST OF ILLUSTRATIONS (CONTINUED) Figure Title Page 003-24 Connection of the BUS Cables......................003-25 Modular Layout for 1 PIM Configuration ..................003-26 Modular Layout for 2 PIM Configuration ..................003-27 Modular Layout for 3 PIM Configuration ..................003-28 Modular Layout for 4 PIM Configuration ..................003-29 Modular Layout for 5 PIM Configuration ..................

- Page 13 LIST OF ILLUSTRATIONS (CONTINUED) Table Title Page 007-15 Outline of the External TAS Indicator Connection ................. 007-16 MDF Cross Connection for a TAS Indicator with a Battery ............007-17 MDF Cross Connection for a TAS Indicator without a Battery) ............ 007-18 Outline of the Paging Equipment Connection ................

- Page 14 LIST OF TABLES Table Title Page Description of Symbols in Trunking Diagram..................Procedure for Unplugging/Plugging Circuit Cards ................003-1 Recommended Fasteners ......................... 006-1 MDF Cables for PIM .......................... 007-1 LTC Connector Accommodation...................... 007-2 LTC0-LTC2 MDF Cross Connection Information ................LIST OF TABLES AD-25182501 Page vi Revision 1.0.1...

-

Page 15: Chapter 1 Introduction

CHAPTER 1 INTRODUCTION 1. PURPOSE This manual explains the installation procedure for the NEAX7400 ICS Model 120 PABX. Before engaging in installation , the installer is required to confirm materials to be prepared and the site conditions. Thereafter, the installer should perform each installation step according to the procedures described in Section 2 of Chapter 3. 2. -

Page 16: Scope Of Installation Procedures

3. HOW TO FOLLOW THE MANUAL The Installation Procedure is shown by means of flowcharts with a NAP (NEC Action Procedure) Number and the detail of the work for each step is described in the corresponding NAP. 4. SCOPE OF INSTALLATION WORKS This manual covers the installation shown in Figure 1-2. -

Page 17: Chapter 2 General Information

CHAPTER 2 GENERAL INFORMATION 1. TRUNKING DIAGRAM A typical trunking diagram for the PABX is shown in Figure 2-1. LONG-LINE EXTENSION C.O. LINE AUCA INCLUDING SINGLE-LINE AUCA DID LINE TELEPHONE TELEPHONE WITH MESSAGE WAITING PBSND LAMP 2W E&M TIE LINE 16CFT MLDT 4W E&M... - Page 18 Table 2-1: Description of Symbols in Trunking Diagram SYMBOL DESCRIPTION SYMBOL DESCRIPTION Amplifier for External Speaker ETHER Enternet Controller, for use with AP01 AP00 SMDR/Hotel Application Card Firmware Processor Card AP01 OAI Interface Card External Key SN694 ATTCON Interface Card Line Circuit Card AUCA Analog Universal Circuit Card...

-

Page 19: System Configurations

2. SYSTEM CONFIGURATIONS The PABX system provides three kinds of installation methods as follows: • Floor Standing Installation • Wall-Mounting Installation • 19-Inch Rack-Mounting Installation Examples of system configurations for each installation method are shown in Figures 2-2 to 2-6. RACK PARTS BASE FRONT... - Page 20 RACK PARTS PIM1 PIM0 BASE BASE FRONT Figure 2-3 2-PIM Configuration for Floor Standing Installation Note: The configuration shown applies only to installations which connect to an existing MDF. If the MDFM and/or BATTM are to be used, only wall-mounting or rack mounting configurations are permitted. Refer to Figures 002-2 and 003-5 to 003-13.

- Page 21 RACK PARTS PIM3 PIM2 PIM7 PIM6 PIM1 PIM0 PIM5 PIM4 FRONT BASE Figure 2-4 8-PIM Configuration for Floor Standing Installation Note: The configuration shown applies only to installations which connect to an existing MDF. If the MDFM and/or BATTM are to be used, only wall-mounting or rack mounting configurations are permitted. Refer to Figures 002-2 and 003-5 to 003-13 AD-25182501 CHAPTER 2...

- Page 22 RACK PARTS BASE Figure 2-5 1-PIM Configuration for Wall-Mounting Installation CHAPTER 2 AD-25182501 Page 8 Revision 1.0.1...

- Page 23 Front Rear View View Figure 2-6: 4-PIM Configuration for 19-Inch Rack-Mounting Installation AD-25182501 CHAPTER 2 Page 9 Revision 1.0.1...

-

Page 24: Chapter 3 Installation Procedure

CHAPTER 3 INSTALLATION PROCEDURE 1. PRECAUTIONS 1.1 Power, Ground Cabling and LIU (for Australia) The power and ground cabling is to be installed only by an AUSTEL Licensed Contractor. The G.P.O. which provides the AC power should be on a dedicated circuit, and must be installed near the PABX in an easily accessible position. -

Page 25: Static Electricity Guard

1.3 Static Electricity Guard The installer must wear a grounded wrist strap to protect circuit cards from static electricity. CAUTION The installer must hold the card name label area, when plugging or unplugging the circuit card,. If you touch another area, you may be exposed to hazardous voltages. •... - Page 26 • WHEN MAKING A SWITCH SETTING ON A CIRCUIT CARD CIRCUIT CARD WEAR A WRIST STRAP AND PERFORM THE WORK ON A GROUNDED CONDUCTIVE WORK SURFACE. • WHEN CARRYING A CIRCUIT CARD CONDUCTIVE CIRCUIT POLYETHYLENE CARD WHEN CARRYING A CIRCUIT CARD AROUND, KEEP THE CARD IN A CONDUCTIVE POLYETHYLENE BAG.

-

Page 27: Procedure For Unplugging/Plugging Circuit Cards

1.4 Procedure for Unplugging/Plugging Circuit Cards When removing a circuit card from the PIM, or when mounting a circuit card in the PIM, follow the procedure given in Table 3-1 below. Table 3-1 Procedure for Unplugging/Plugging Circuit Cards PROCEDURE CIRCUIT CARD CONDITION PLUG IN UNPLUG... - Page 28 This section explains the procedures for installing the PABX system. The installer should follow the procedure shown in the following flowchart. In the flowchart, a NAP (NEC Action Procedure) Number is denoted to the right side of each step. The NAP Number refers to the details for each procedure.

- Page 29 MOUNTING NAP- 200-008 CIRCUIT CARDS SYSYEM INITIALIZATION NAP- 200-009 SYSTEM DATA ENTRY OPERATION NAP- 200-010 TEST Figure 3-3 Procedure Flowchart (Continued) The mark shown below is attached to the NAP sheet for each procedure in which circuit cards are handled. When doing such a procedure, the installer must exercise caution, to prevent damage caused by static electricity (See paragraph 1.3 in this chapter).

- Page 30 NAP- 200-001 Sheet 1/1 Unpacking ATTENTION Contents Static Sensitive Handling Precautions Required 1. Unpacking Procedure (1) Check the received quantity of packages containing the PABX system with the description on the shipping document. (2) Check the packaging for external damage done by transportation, and record it as necessary. (3) Unpack the modules.

- Page 31 NAP- 200-002 Sheet 1/2 Marking and Drilling 1. Confirmation of the Equipment Layout Install the equipment in an area which provides adequate ventilation and is easily accessible to service personnel. 2. Marking and Drilling 2.1 Floor Standing • By referring to Figure 002-1, mark and drill the installation holes for the main equipment. •...

- Page 32 NAP- 200-002 Sheet 2/2 Marking and Drilling 2.2 Wall-Mounting • Locate and mark the wall mounting points as shown in Figure 002-2. ANCHOR (x4/PIM) PABX BOTTOM POSITION BASE BOTTOM POSITION BASE UNIT: mm Figure 002-2 Wall Mounting Points Note: The BATTM and MDFM have the same dimensions as a PIM. CHAPTER 3 AD-25182501 Page 18...

- Page 33 NAP- 200-003 Sheet 1/29 Installation of Main Equipment 1. Installation of Modules Install modules according to the installation procedures for Floor Standing, Wall-Mounting or 19-Inch Rack Mounting installation. 1.1 Installation of the BATTM and MDFM • Due to weight considerations, it is preferable to Floor-mount the BATTM. •...

- Page 34 NAP- 200-003 Sheet 2/29 Installation of Main Equipment 1.2 Floor Standing Installation Connect the RACK PARTS to the rear of the BASE. RACK PARTS BASE REAR Figure 003-2 Connection of RACK PARTS and BASE CHAPTER 3 AD-25182501 Page 20 Revision 1.0.1...

- Page 35 NAP- 200-003 Sheet 3/29 Installation of Main Equipment When the system is a multiple-PIM configuration, connect the RACK PARTS to each other as shown in Figure 003-3. Position the BASE over the holes drilled as per Figure 002-1, and secure the BASE to the floor, using anchor bolts.

- Page 36 NAP- 200-003 Sheet 4/29 Installation of Main Equipment Connect the PIM to the RACK PARTS as shown in Figure 003-4 using the 4 screws provided with the RACK PARTS. When the system is a multiple-PIM configuration, connect all PIM and RACK PARTS. Ensure that the PIM’s are bolted together as shown in Figure 003-5.

- Page 37 NAP- 200-003 Sheet 5/29 Installation of Main Equipment When the system is a multiple-PIM configuration, connect PIMs to each other as shown in Figure 003-5, using the 3 hex-bolts supplied. Note Note FRONT Note 1 : The BATTM and/or the MDFM can be installed the same as the PIM. Note 2 : For simplicity, the BASE and RACK PARTS are not shown.

- Page 38 NAP- 200-003 Sheet 6/29 Installation of Main Equipment 1.3 Wall-Mounting Installation Locate the four mounting points using the template as shown by Figure 003-6. ANCHOR (x 4) PABX BOTTOM POSITION RACK PARTS BOTTOM POSITION Unit : mm Figure 003-6 Wall Mounting Points CHAPTER 3 AD-25182501 Page 24...

- Page 39 NAP- 200-003 Sheet 7/29 Installation of Main Equipment Using four appropriate fasteners for the type of wall construction (locally provided; see Table 003-1), secure the RACK PARTS as shown by Figure 003-7. Table 003-1 Recommended Fasteners WALL TYPE RECOMMENDED FASTENER PLASTER BOARD “BUTTERFLY”...

- Page 40 NAP- 200-003 Sheet 8/29 Installation of Main Equipment Attach four M4 machine screws (provided) to the RACK PARTS at the location as shown by Figure 003-7. For easy attachment of the PABX, approx. 4 mm spacing should be provided between the inner face of the M4 machine screw and the RACK PARTS front channel.

- Page 41 NAP- 200-003 Sheet 9/29 Installation of Main Equipment M4 MACHINE SCREW-B (x4/PIM) SECURED TO RACK PARTS (PROVIDED WITH RACK PARTS) (WALL) SCREW-A (x4/PIM) ANCHOR (x4/PIM) SECURING RACK PARTS TO WALL (SEE FIGURE 002-2) (LOCALLY PROVIDED) (SEE TABLE 003-1) RACK PARTS M5 MACHINE SCREW-C (x4/PIM) (PROVIDED WITH RACK PARTS) (SEE FIGURE 003-10)

- Page 42 NAP- 200-003 Sheet 10/29 Installation of Main Equipment When mounting the RACK PARTS to a wall, connect all the RACK PARTS to each other, and connect the BASE to the bottom RACK PARTS using the M5 Machine screws (provided), as shown in Figure 003-10. RACK PARTS M5 MACHINE SCREW-C (x2/JOINT AREA)

- Page 43 NAP- 200-003 Sheet 11/29 Installation of Main Equipment For floor and wall-mounted installations, refer to Figures 003-11 to 003-18 for the recommended layout of the modules. Notes: - MDF cable lengths are 1.5 metres 10 Pair MDF0 PIM0 - MDF0 must be minimum 300mm 10 Pair 10 Pair above floor.

- Page 44 NAP- 200-003 Sheet 12/29 Installation of Main Equipment Notes: - MDF cable lengths are 1.5 metres 10 Pair MDF1 PIM2 - PIM 2 - LTC 2 connect to (L) Krone (MDF 1) 10 Pair 10 Pair - LTC 0-1 connect to (R) Krone (MDF 0). TPF1 10 Pair 10 Pair...

- Page 45 NAP- 200-003 Sheet 13/29 Installation of Main Equipment Notes: - MDF cable lengths are 1.5 metres - PIM 3 - LTC 0-2 connect to (L) Krone PIM3 (MDF 1). - 240V connects to 4 way power board. - BATTM0 can be supplied for external MDF1(L) battery backup either as MIN.

- Page 46 NAP- 200-003 Sheet 14/29 Installation of Main Equipment Figure 003-15 Modular Layout for 5 PIM Configuration CHAPTER 3 AD-25182501 Page 32 Revision 1.0.1...

- Page 47 NAP- 200-003 Sheet 15/29 Installation of Main Equipment Figure 003-16 Modular Layout for 6 PIM Configuration AD-25182501 CHAPTER 3 Page 33 Revision 1.0.1...

- Page 48 NAP- 200-003 Sheet 16/29 Installation of Main Equipment Figure 003-17 Modular Layout for 7 PIM Configuration CHAPTER 3 AD-25182501 Page 34 Revision 1.0.1...

- Page 49 NAP- 200-003 Sheet 17/29 Installation of Main Equipment Figure 003-18 Modular Layout for 8 PIM Configuration AD-25182501 CHAPTER 3 Page 35 Revision 1.0.1...

- Page 50 1.4 19-Inch Rack-Mounting Installation 1.3.1 NEC Australia can provide a rack assembly, which can be configured as follows: Up to four PIM’s at the front, and the requisite number of MDF units and/or sealed batteries at the rear. Refer to Figure 2-6 for a typical example.

- Page 51 NAP- 200-003 Sheet 19/29 Installation of Main Equipment L = Left C = Centre R = Right 10 Pair 10 Pair 19"KRONE Pair BACK MOUNT 10 Pair (MDF/TPF) 10 Pair 10 Pair SHELF 3 MAX. BACKUP, 78 A-H 26A-H (SHELF 1+2+3) 26A-H PIM0 MDF (L)

- Page 52 NAP- 200-003 Sheet 20/29 Installation of Main Equipment L = Left C = Centre R = Right 10 Pair 10 Pair 10 Pair 10 Pair 19"KRONE BACK MOUNT 10 Pair 10 Pair (MDF/TPF) 10 Pair 10 Pair 10 Pair 10 Pair PIM1 19"KRONE Pair...

- Page 53 NAP- 200-003 Sheet 21/29 Installation of Main Equipment L = Left C = Centre R = Right PIM2 MDF (C) LTC1 10 Pair 10 Pair 10 Pair MDF (C) 10 Pair 10 Pair 10 Pair MDF (R) 19"KRONE LTC0 BACK MOUNT 10 Pair 10 Pair 10 Pair...

- Page 54 NAP- 200-003 Sheet 22/29 Installation of Main Equipment PIM3 MDF (R) L = Left LTC1 C = Centre R = Right MDF (R) MDF (R) LTC0 LTC2 10 Pair 10 Pair 10 Pair 10 Pair 19"KRONE 10 Pair 10 Pair BACK MOUNT 10 Pair 10 Pair...

- Page 55 NAP- 200-003 Sheet 23/29 Installation of Main Equipment 2.1 Cable Connections and Switch Settings on PZ-PW86 Note: This version is now obsolete. WARNINGS, RE MODE SWITCH: SEGMENT 1: Set to ON. SEGMENT 2: Set to ON (left) only, which is 27 volts (FLOAT). The OFF setting is 28 volts (EQUALIZE), to be used only for periodic boost-charging of EXTERNAL VENTED batteries.

- Page 56 NAP- 200-003 Sheet 24/29 Installation of Main Equipment 2.2 Cable Connections and Switch Settings on PZ-PW86(A) Note: This is now the standard version. WARNINGS, RE MODE SWITCH: SEGMENT 1: Set to OFF. SEGMENT 2: Set to “OFF” for 27 volts float, which is optimum for sealed batteries. This setting is also to be used for periodic boost-charging of EXTERNAL VENTED batteries.

- Page 57 NAP- 200-003 Sheet 25/29 Installation of Main Equipment (1) Confirm the connection of the PWR CNT CA-A and power/ringer cables as shown in Figure 003-25 (These cables are pre-installed). PZ-PW86 BWB (Back Wiring Board) CARD SLOT AREA PWR0B PWR0A LTC CONNECTOR AREA PWR1 PWR CNT CA-A POWER OUTPUT CABLE (CR,E)

- Page 58 NAP- 200-003 Sheet 26/29 Installation of Main Equipment The AC CORD-A (AC Power Cable) wiring to the PZ-PW86 power unit(s) is shown below for a 2-PIM system. Notes: 1. The multi-way AC outlet is not provided on a single-PIM system. 2.

- Page 59 NAP- 200-003 Sheet 27/29 Installation of Main Equipment When the system is a multiple-PIM configuration, mount the BS00 Card in the BUS slot of PIM0. Also, mount the BS01 Card in each BUS slot of PIM1 to PIM7. When the system is a single PIM configuration, neither the BS00 nor BS01 is needed. BUS SLOT PIM3 PIM7...

- Page 60 NAP- 200-003 Sheet 28/29 Installation of Main Equipment When the system is a multiple-PIM configuration, connect all the BUS Cards (BS00/BS01) to each other using BUS cables, as shown in Figure 003-29. 700mm 48-TW-0.7 CONN CA Figure 003-28 BUS Cable CHAPTER 3 AD-25182501 Page 46...

- Page 61 NAP- 200-003 Sheet 29/29 Installation of Main Equipment BS01 BS01 PIM3 PIM7 BS01 BS01 PIM2 PIM6 BS01 BS01 PIM1 PIM5 BS00 BS01 PIM0 PIM4 48-TW-0.7 CONN CA Figure 003-29 Connection of the BUS Cables AD-25182501 CHAPTER 3 Page 47 Revision 1.0.1...

- Page 62 NAP- 200-004 Sheet 1/9 Installation of Peripheral Equipment 1. Installation of SN694 ATTCON Screw the handset support onto the bottom of the console as shown in Figure 004-1. Note: The handset support can be mounted at either the right side or left side of the console body. PAN-HEAD TAPPING SCREW (M3, 10mm LENGTH) WASHER (M3)

- Page 63 NAP- 200-004 Sheet 2/9 Installation of Peripheral Equipment ATTENTION Contents Static Sensitive Handling Precautions Required Connect an ATT cable to the SN694 ATTCON according to the steps below. • Remove the screw from the connector cover. • Press the retaining clip in the direction of (a) and slide the cover in the direction of (b).

- Page 64 NAP- 200-004 Sheet 3/9 Installation of Peripheral Equipment ATTENTION Contents Static Sensitive Handling Precautions Required Connect the ATT cable to Main Equipment as shown in Figure 004-3. PABX PN-CS00 INSTALLATION CABLE PIM0 (MAX. 296m) SN694 ATTCON ATI CA-A (4m) ATI CA-A ATI CA-A 1 : ATT CONNECTOR 2 : HOUSING CONNECTOR...

- Page 65 NAP- 200-004 Sheet 4/9 Installation of Peripheral Equipment ATTENTION Contents Static Sensitive Handling Precautions Required INSTALLATION CABLE SN694 ATTCON INSTALLATION CABLE Note ATI CA-A MAX. 296m (WITH 0.5 DIAM. CABLE) 1 : CHAMP CONNECTOR 2 : CHAMP CONNECTOR 3 : CHAMP CONNECTOR 4 : ATT OVRA OVRB...

- Page 66 NAP- 200-004 Sheet 5/9 Installation of Peripheral Equipment 2. Installation of SN611 ATTCON Screw the handset support onto the bottom of the console as shown in Figure 004-4. HANDSET SUPPORT SN611 ATTCON Figure 004-4: Mounting of Handset Support to SN611 ATTCON CHAPTER 3 AD-25182501 Page 52...

- Page 67 NAP- 200-004 Sheet 6/9 Installation of Peripheral Equipment ATTENTION Contents Static Sensitive Handling Precautions Required To provide the console with the headset in place of the handset, unplug the modular cord from the handset and then plug the modular cord to the Jack Set. SN611 ATTCON MODULAR...

- Page 68 NAP- 200-004 Sheet 7/9 Installation of Peripheral Equipment ATTENTION Contents Static Sensitive Handling Precautions Required Set the switch located inside the console according to type of headset/handset connected. • Slide the directory out of the way. Then insert a flat screw driver’s blade into the notched opening and apply light upward pressure until the access panel is clear of the front lip.

- Page 69 NAP- 200-004 Sheet 8/9 Installation of Peripheral Equipment ATTENTION Contents Static Sensitive Handling Precautions Required • Set the switch according to the type of headset/handset connected. C: Carbon Type Handset/Headset S: Electret type Headset (e.g. “Supra”) term D: D Type Handset (Dynamic) •...

- Page 70 NAP- 200-004 Sheet 9/9 Installation of Peripheral Equipment ATTENTION Contents Static Sensitive Handling Precautions Required Plug the line cord into the modular jack located at the bottom of the console. For the MDF cross connection for SN611 ATTCON, refer to NAP- 200-007 (Figure 007-13). LINE CORD PABX MODULAR...

- Page 71 NAP- 200-005 Sheet 1/4 Connection of Battery 1. Internal Battery Connection Mount a battery unit (24V, 3.4 AH) into each PIM as shown in Figure 005-1. Set the “MODE” Switch on the PZ-PW86/PZ-PW86(A) power unit(s) to the correct Float Voltage, as shown in NAP-200-003.

- Page 72 NAP- 200-005 Sheet 2/4 Connection of Battery Plug the battery-cable connector into the BATT1 connector on the PZ-PW86 as shown in Figure 005-2. Secure the batteries and battery-cable using tie-wraps as shown in Figure 005-2. PLUG IN TO BATT 1 CONNECTOR ON PZ-PW86 FRONT TIE WRAP...

- Page 73 NAP- 200-005 Sheet 3/4 Connection of Battery When the system is a multiple PIM configuration, provide the following connections to the internal batteries. PZ-PW86 PZ-PW86 BATT2 BATT2 PIM3 PIM7 BATT1 BATT1 – – – – CA-A CA-A CABLE CABLE PZ-PW86 PZ-PW86 BATT2 BATT2...

- Page 74 NAP- 200-005 Sheet 4/4 Connection of Battery 2. External Battery Connection When using an external battery, provide the following connections. Notes: 1. One battery pack is required for each 4-PIM stack, to ensure that sufficient recharge current is available. 2. The capacity of each external battery is determined by the customers’ back-up requirements. 3.

- Page 75 NAP- 200-006 Sheet 1/3 Cable Running to MDF 1. Cable Running to MDF Usually a pre-wired MDF is provided ex-factory for new installations. In this case, 50-wire ribbon cables are used between the PABX and the MDF, as shown in NAP-200-003. In order to facilitate the termination of standard 25-pair cables which are shown in Figure 006-2 from the system to an existing MDF, the length of each cable to be used should be determined according to the distance between the MDF and the system, and each cable should be labelled at both ends using cable number or cable...

- Page 76 NAP- 200-006 Sheet 2/3 Cable Running to MDF Table 006-1: MDF Cables for PIM FROM CABLE CABLE NUMBER DESIGNATION MODULE CONNECTION LTC0 0 LTC0 PIM0 LTC1 0 LTC1 LTC2 0 LTC2 LTC0 1 LTC0 PIM1 LTC1 1 LTC1 LTC2 1 LTC2 LTC0 2 LTC0 PIM2...

- Page 77 NAP- 200-006 Sheet 3/3 Cable Running to MDF For connection to an existing MDF, bring the MDF cables into the Main Equipment through the cable hole(s) of the BASE as shown in Figure 006-2. Plug the CHAMP connector of each cable to its LTC connector located on the PIM, and screw them together. LTC CONNECTOR PABX PIM1...

- Page 78 NAP- 200-007 Sheet 1/42 Termination of Cables on MDF 1. Cable Connection to MDF Connect the cables to the MDF referring to Figure 007-1 and Table 007-1. 0 ~ 7 LTC1 LTC0 LTC2 FRONT Figure 007-1: Location of Card Slot and LTC Connector Table 007-1: LTC Connector Accommodation LTC CONNECTOR CARD SLOT NUMBER...

- Page 79 NAP- 200-007 Sheet 2/42 Termination of Cables on MDF Figure 007-2 shows the relationship between Line Equipment Number (LEN) and Card Slot Number (LT Number). LEN 0000 ~ 0255 0195 0199 0203 0207 0211 0215 0219 0223 0227 0231 0235 0239 0243 0247...

- Page 80 NAP- 200-007 Sheet 3/42 Termination of Cables on MDF LEN 0256 ~ 0511 0451 0455 0459 0463 0467 0471 0475 0479 0483 0487 0491 0495 0499 0503 0507 0511 0450 0454 0458 0462 0466 0470 0474 0478 0482 0486 0490 0494 0498 0502...

- Page 81 NAP- 200-007 Sheet 4/42 Termination of Cables on MDF Figure 007-3 shows the LTC Connector Pin Arrangement. PIM0 (LTC0 ~ LTC2) LTC0 LTC1 LEN0000 0001 LEN0024 LT00 0002 0025 LT06 0026 0003 0004 0027 0005 0028 LT01 0029 0006 LT07 0007 0030 0008...

- Page 82 NAP- 200-007 Sheet 5/42 Termination of Cables on MDF PIM1 (LTC0 ~ LTC2) LTC0 LTC1 LEN0088 LEN0164 0089 LT06 0165 0090 LT00 0166 0091 0167 0092 0168 0093 LT07 0169 0094 LT01 0170 0095 0171 0096 0172 0097 LT08 0173 0098 LT02 0174...

- Page 83 NAP- 200-007 Sheet 6/42 Termination of Cables on MDF PIM2 (LTC0 ~ LTC2) LTC0 LTC1 LEN0128 LEN0152 0129 0153 LT00 LT06 0130 0154 0131 0155 0132 0156 0133 0157 LT01 LT07 0134 0158 0135 0159 0136 0160 0137 0161 LT02 LT08 0138 0162...

- Page 84 NAP- 200-007 Sheet 7/42 Termination of Cables on MDF PIM3 (LTC0 ~ LTC2) LTC0 LTC1 LEN0216 LEN0192 0217 LT06 0193 0218 LT00 0194 0219 0195 0220 0196 0221 LT07 0197 0222 LT01 0198 0223 0199 0224 0200 0225 LT08 0201 0226 LT02 0202...

- Page 85 NAP- 200-007 Sheet 8/42 Termination of Cables on MDF PIM4 (LTC0 ~ LTC2) LTC0 LTC1 LEN0280 LEN0256 0281 LT06 0257 0282 LT00 0258 0283 0259 0284 0260 0285 LT07 0261 0286 LT01 0262 0287 0263 0288 0264 0289 LT08 0265 0290 LT02 0266...

- Page 86 NAP- 200-007 Sheet 9/42 Termination of Cables on MDF PIM5 (LTC0 ~ LTC2) LTC0 LTC1 LEN0320 LEN0344 0321 0345 LT00 LT06 0322 0346 0323 0347 0324 0348 0325 0349 LT01 LT07 0326 0350 0327 0351 0328 0352 0329 0353 LT02 LT08 0330 0354...

- Page 87 NAP- 200-007 Sheet 10/42 Termination of Cables on MDF PIM6 (LTC0 ~ LTC2) LTC0 LTC1 LEN0384 LEN0408 0385 0409 LT00 LT06 0386 0410 0387 0411 0388 0412 0389 0413 LT01 LT07 0390 0414 0391 0415 0392 0416 0393 0417 LT02 LT08 0394 0418...

- Page 88 NAP- 200-007 Sheet 11/42 Termination of Cables on MDF PIM7 (LTC0 ~ LTC2) LTC0 LTC1 LEN0472 LEN0448 0473 LT06 0474 0449 LT00 0450 0475 0451 0476 0452 0477 LT07 0453 0478 LT01 0454 0479 0455 0480 0456 0481 LT08 0457 0482 LT02 0458...

- Page 89 NAP- 200-007 Sheet 12/42 Termination of Cables on MDF MDF Cross Connections Cross connections on the MDF for each 25-pair cable in LTC0 to LTC2 are shown in Table 007-2. Table 007-2 LTC0-LTC2 MDF Cross Connection Information TYPE OF INTERFACE CARD 2-WIRE 4-WIRE...

- Page 90 NAP- 200-007 Sheet 13/42 Termination of Cables on MDF Table 007-2 LTC0-LTC2 MDF Cross Connection Information (Continued) TYPE OF INTERFACE CARD 4-WIRE 2-WIRE SLOTS E&M TIE E&M TIE (4 COT) (2COT) (2LDT) LINE LINE (AUC) (4LC) (AUC) (2ODT) (2ODT) TxT0 TxR0 RxT0 RxR0...

- Page 91 NAP- 200-007 Sheet 14/42 Termination of Cables on MDF Table 007-2 LTC0-LTC2 MDF Cross Connection Information (Continued) TYPE OF INTERFACE CARD SN611 EXT. PAGE/ SLOTS Dterm 65 Dterm 65 ATTCON/ EXT. KEY EXT. RELAY MOH/BGM (4DLCA) (2DLCB) Dterm 6D/16D (DK00) (DK00) (COT) (2DLCC)

- Page 92 NAP- 200-007 Sheet 15/42 Termination of Cables on MDF Table 007-2 LTC0-LTC2 MDF Cross Connection Information (Continued) TYPE OF INTERFACE CARD SN611 Dterm 65 Dterm 65 EXT. PAGE/ SLOTS ATTCON/ EXT. KEY EXT. RELAY (4DLCA) (2DLCB) MOH/BGM Dterm 6D/16D (DK00) (DK00) Note 2 Note 2...

- Page 93 NAP- 200-007 Sheet 16/42 Termination of Cables on MDF C.O./D.I.D. Trunks 4 Line C.O. Trunks (PN-4COTE and PN-4DITB). PIM0 LTC0 PN-4COTE/PN-4DITB LEN0000 (No. 0) TO C.O. LINE LEN0001 (No. 1) TO C.O. LINE LT00 LEN0002 (No. 2) TO C.O. LINE LEN0003 (No.

- Page 94 NAP- 200-007 Sheet 17/42 Termination of Cables on MDF 2 Line C.O. Trunk (PN-2COTD) PIM0 LTC0 PN-2COTD LEN0001 (No. 0) TO C.O. LINE LEN0000 (No. 1) TO C.O. LINE LT00 LTC0 (J) LEN0000 LEN0001 Figure 007-5: MDF Cross Connection for 2 Line C.O. Trunk (PN-2COTD) CHAPTER 3 AD-25182501 Page 80...

- Page 95 NAP- 200-007 Sheet 18/42 Termination of Cables on MDF Tie Line Trunk 4W E&M Trunk (PN-2ODTA) PIM0 PN-2ODTA 04 M1 LEN0001 (No. 1) 03 E1 02 M0 LEN0000 (No. 0) 01 E0 LTC0 LT00 (Tx Ring) TxR0 TxT0 (Tx Tip) TO TIE LINE LEN0000 (No.

- Page 96 NAP- 200-007 Sheet 19/42 Termination of Cables on MDF 1 LTC CONNECTOR 2 CN1 CONNECTOR (FRONT CONNECTOR) LTC0 (J) TxT0 TxR0 TxR0 TxT0 LEN0000 RxT0 RxR0 RxR0 RxT0 TxT1 TxR1 TxR1 TxT1 LEN0001 RxT1 RxR1 RxR1 RxT1 LEN0001 LEN0000 Figure 007-6 MDF Cross Connection for a 4W E&M Trunk Card (PN-2ODTA) (Continued) CHAPTER 3 AD-25182501 Page 82...

- Page 97 NAP- 200-007 Sheet 20/42 Termination of Cables on MDF LD Trunk (PN-2LDTA) PIM0 LTC0 PN-2LDTA LEN0001 (No. 0) TO TIE LINE LEN0000 (No. 1) TO TIE LINE LT00 LTC0 (J) LEN0000 LEN0001 Figure 007-7: MDF Cross Connection for an LD Trunk (PN-2LDTA) AD-25182501 CHAPTER 3 Page 83...

- Page 98 NAP- 200-007 Sheet 21/42 Termination of Cables on MDF 2 Line DID Trunk (PN-AUCA) PIM0 LTC0 PN-AUCA LEN0000 (No. 0) TO DID LINE LEN0001 (No. 1) TO DID LINE LT00 LTC0 (J) LEN0000 LEN0001 Notes: 1. The PN-AUCA card can also be used as a long-line extension circuit and also for the Power Failure Transfer (PFT) function.

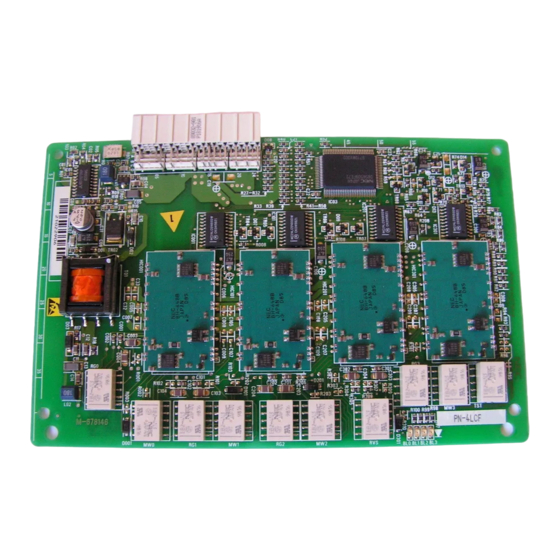

- Page 99 NAP- 200-007 Sheet 22/42 Termination of Cables on MDF Single Line Telephone (SLT) Standard Line (PN-4LCE/4LCF) PIM0 LTC0 TO SINGLE PN-4LCE/4LCF LINE TELEPHONE LEN0000 (No. 0) LEN0001 (No. 1) LT00 LEN0002 (No. 2) LEN0003 (No. 3) LTC0 (J) LEN0000 LEN0001 LEN0002 LEN0003 Figure 007-9 MDF Cross Connection for a Single Line Telephone (Standard Line)

- Page 100 NAP- 200-007 Sheet 23/42 Termination of Cables on MDF Long Line (PN-AUCA) PIM0 LTC0 PN-AUCA TO SINGLE-LINE LEN0000 (No. 0) TELEPHONE (FOR LONG LINE) TO SINGLE-LINE LEN0001 (No. 1) TELEPHONE (FOR LONG LINE) LT00 LTC0 (J) LEN0000 LEN0001 Note 1: The PN-AUCA card can also be used as a DID Trunk card, but the preferred option for that application is PN-4DITB.

- Page 101 NAP- 200-007 Sheet 24/42 Termination of Cables on MDF term /DSS Console Standard Line (PN-4DLCA) Note: Applies only to Dterm 65 series. PIM0 LTC0 term TO D /DSS CON- PN-4DLCA SOLE LEN0000 (No. 0) Green LEN0001 (No. 1) LT00 LEN0002 (No. 2) MODULAR TERMINAL* See Below LEN0003 (No.

- Page 102 NAP- 200-007 Sheet 25/42 Termination of Cables on MDF Long Line (PN-2DLCB) Note: Applies only to Dterm 65 series. PIM0 LTC0 term TO D /DSS CON- PN-2DLCB SOLE LEN0000 (No. 0) Green LEN0001 (No. 1) LT00 MODULAR TERMINAL* See below LTC0 (J) LEN0000 LEN0001...

- Page 103 NAP- 200-007 Sheet 26/42 Termination of Cables on MDF SN611 ATTCON and Dterm 6D/16D series telephones. PIM0 LTC0 PN-2DLCC TO SN611 ATTCON or Dterm 6D/16D YELLOW GREEN LEN0000 (No. 0) BLACK LT00 LEN0001 (No. 1) MODULAR TERMINAL* See below LTC0 (J) LEN0001 LEN0000 * The colours shown are the most common.

- Page 104 NAP- 200-007 Sheet 27/42 Termination of Cables on MDF Day/Night Mode Change by External Key Note: Refer to the Command Manual to set the PN-DK00 in the Key Scan mode. PIM0 LTC0 PN-DK00 TO KEYS LEN0000 LT00 LEN0002 LTC0 (J) LEN0000 LEN0002 Figure 007-14 MDF Cross Connection for Day/Night Mode Change by External Key...

- Page 105 NAP- 200-007 Sheet 28/42 Termination of Cables on MDF External TAS Indicator Outline of the Connections PABX TAS Indicator with Battery PN-DK00 Card PZ-PW86 Card PABX PN-DK00 Card TAS Indicator without Battery (24V. nominal) PZ-PW86 Card -27V Figure 007-15 Outline of the External TAS Indicator Connection AD-25182501 CHAPTER 3 Page 91...

- Page 106 NAP- 200-007 Sheet 29/42 Termination of Cables on MDF MDF Cross Connection • When using a TAS Indicator with a Battery Note: Refer to the Command Manual to set the PN-DK00 in the Relay-Drive mode. PIM0 LTC0 TAS INDICATOR PN-DK00 WITH BATTERY –...

- Page 107 NAP- 200-007 Sheet 30/42 Termination of Cables on MDF MDF Cross Connection • When using a TAS Indicator without a Battery Note: Refer to the Command Manual to set the PN-DK00 in the Relay-Drive mode. PIM0 LTC0 TAS INDICATOR PN-DK00 WITHOUT BATTERY (24V.

- Page 108 NAP- 200-007 Sheet 31/42 Termination of Cables on MDF (9) Paging Equipment The cross connection for customer-owned paging equipment is shown in Figure 007-18 and Figure 007-19, as an example. Requirement for the Paging Equipment • Input Impedance : 600 ohm Refer to the Command Manual to set •...

- Page 109 NAP- 200-007 Sheet 32/42 Termination of Cables on MDF MDF Cross Connection Notes: 1. The current capacity of the opto-coupler (PN-DK00 card) is 125 mA. The isolator’s relay must be compatible with nominal 24 Volt circuits, and the suppression diode shown is mandatory.

- Page 110 NAP- 200-007 Sheet 33/42 Termination of Cables on MDF LTC0 (J) LEN0000 LEN0002 LEN0004 LEN0005 LEN0006 LEN0007 Figure 007-19 MDF Cross Connection for Paging Equipment (Continued) CHAPTER 3 AD-25182501 Page 96 Revision 1.0.1...

- Page 111 NAP- 200-007 Sheet 34/42 Termination of Cables on MDF (10) External Music Equipment The cross connection for customer-owned external music equipment is shown in Figure 007-21 and Figure 007-22, as an example. Requirement for the External Music Equipment • Output level : Less than 0 dbm (Adjustable) On/Off control is optional.

- Page 112 NAP- 200-007 Sheet 35/42 Termination of Cables on MDF MDF Cross Connection Notes: 1. The current capacity of the opto-coupler (PN-DK00 card) is 125 mA. The isolator’s relay must be compatible with nominal 24 Volt circuits, and the suppression diode shown is mandatory.

- Page 113 NAP- 200-007 Sheet 36/42 Termination of Cables on MDF LTC0 (J) LEN0000 LEN0002 LEN0004 LEN0005 LEN0006 LEN0007 Figure 007-21 MDF Cross Connection for External Music Equipment (Continued) AD-25182501 CHAPTER 3 Page 99 Revision 1.0.1...

- Page 114 NAP- 200-007 Sheet 37/42 Termination of Cables on MDF External Music Equipment (continued) • An AUSTEL-approved isolator must always be included between the Music Source and the PABX trunk. • If a D.C. voltage is supplied together with the audio from the external music equipment, a coupling capacitor must be added as shown in Figure 007-22.

- Page 115 NAP- 200-007 Sheet 38/42 Termination of Cables on MDF (11) External Background Music (BGM) Source The cross connection for customer-owned external BGM sources is shown in Figure 007-23. Note: A maximum of 10 BGM sources can be provided in the system. PIM0 LTC0 PN-4COT/PN-2COT...

- Page 116 NAP- 200-007 Sheet 39/42 Termination of Cables on MDF (12) Power Failure Transfer (PFT) The PFT function is included in the PN-AUCA Card. (a) Outline of the Connection. PABX TO C.O. LINE PN-AUCA PN-4COT/PN-2COT Figure 007-24 Outline of the PFT Connection CHAPTER 3 AD-25182501 Page 102...

- Page 117 NAP- 200-007 Sheet 40/42 Termination of Cables on MDF (b) MDF Cross Connection PIM0 LTC0 PN-4COT/PN-2COT Ring C.O.R0 LEN0000 (No. 0) C.O.T0 C.O. C.O.R1 Ring LEN0001 (No. 1) C.O.T1 C.O. LT00 PN-AUCA 4Q-TW-0.3 CONN CA Ring Sta. R0 LEN0004 (No. 0) Sta.

- Page 118 NAP- 200-007 Sheet 41/42 Termination of Cables on MDF LTC0 (J) 26 C.O.T0 C.O.R0 C.O.R0 26 C.O.T0 LEN0000 27 C.O.T1 C.O.R1 C.O.R1 27 C.O.T1 LEN0001 LEN0004 Sta.T0 Sta.R0 Sta.R0 30 Sta.T0 LEN0005 Sta.T1 Sta.R1 Sta.R1 31 Sta.T1 Figure 007-25 MDF Cross Connection for the PFT (Continued) Note: The third and fourth circuits in the PN-4COT card cannot be used for the PFT function.

- Page 119 NAP- 200-007 Sheet 42/42 Termination of Cables on MDF (13) Alarm Display Panel (ALM DSPP). Cross connection for the Alarm Display Panel is shown below. ALARM DISPLAY PANEL PIM0 LTC0 PN-CP00 FRONT PZ-PW86 –27V -27V REAR LTC0 (J) Figure 007-26: MDF Cross Connection for Alarm Display Panel AD-25182501 CHAPTER 3 Page 105...

- Page 120 NAP- 200-008 Sheet 1/2 Mounting of Circuit Cards 1. Mounting Procedure For testing, turn on the “SW” switch on the PZ-PW86/PW86(A) Card(s). Make sure that each “ON” lamp (Green) is lit. Note: This switch also controls the battery feed. BATTERY START PZ-PW86(A) (PZ-PW86(A) only).

- Page 121 NAP- 200-008 Sheet 2/2 Mounting of Circuit Cards ATTENTION Contents Static Sensitive Handling Precautions Required Before mounting circuit cards, confirm the folowing items. • Wrist Strap and Conductive Work Surface are prepared. • Switch setting of circuit cards is already completed (Refer to the Circuit Card Manual). •...

- Page 122 NAP- 200-009 Sheet 1/3 System Initialization and System Data Entry ATTENTION Contents Static Sensitive Handling Precautions Required 1. System Initialization • There are two methods for System Initialization. The first method is to Clear All Data, except LEN0000 as a CAT terminal, and then program the System Data. The second method is to use the Resident System Program, which causes the system to configure itself automatically to the default settings, wherever the line/ trunk cards are installed.

- Page 123 NAP- 200-009 Sheet 2/3 System Initialization and System Data Entry ATTENTION Contents Static Sensitive Handling Precautions Required 2. System Data Entry • There are two methods for data entry, both of which employ a CAT or a MAT. 2.1 CAT (Customer Administration Terminal) term term Any D...

- Page 124 NAP- 200-009 Sheet 3/3 System Initialization and System Data Entry ATTENTION Contents Static Sensitive Handling Precautions Required To reset CAT mode: While “COMMAND = -” is displayed on LCD: Lift the handset (off hook) - SPKR lamp is off. Replace the handset (on hook) - CNF, ANS lamps are off.

- Page 125 NAP- 200-010 Sheet 1/1 Operation Test 1. Operation Test Confirm the system data accuracy and hardware configuration (including cable connections) by the following operation test: • Basic Connection Test at MDF - Station Line Test (Operator Call from all stations) - Central Office Trunk Test (Incoming, Outgoing) Tie Line Trunk Test (Incoming, Outgoing) •...

Need help?

Do you have a question about the NEAX 7400 ICS and is the answer not in the manual?

Questions and answers