Subscribe to Our Youtube Channel

Summary of Contents for Endress+Hauser OFTE20

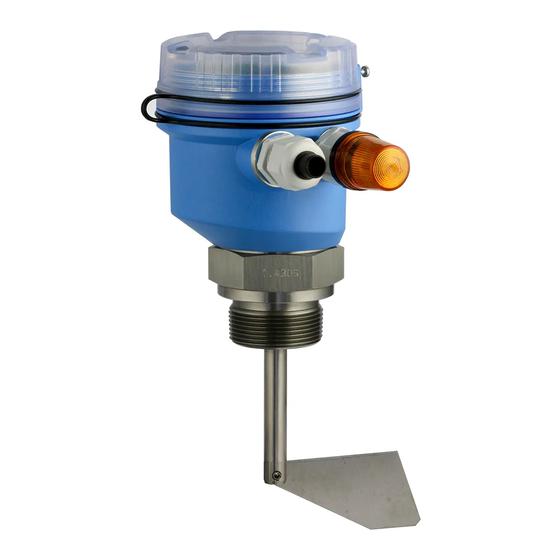

- Page 1 BA01325O/09/EN/04.22-00 71573627 2022-05-31 Operating Instructions Point level switch OFTE20...

-

Page 3: Table Of Contents

Point level switch Table of contents Table of contents Important document Repair ......21 information ..... 4 10.1 General information . -

Page 4: Important Document

Important document information Point level switch Important document information Document function These Operating Instructions contain all the information required in the various life cycle phases of the device: from product identification, incoming acceptance and storage, to installation, connection, operation and commissioning, through to troubleshooting, maintenance and disposal. - Page 5 Point level switch Important document information 1.2.3 Symbols for certain types of information Symbol Meaning Symbol Meaning Permitted Preferred Procedures, processes or actions that Procedures, processes or actions that are permitted. are preferred. Forbidden Procedures, processes or actions that Indicates additional information. are forbidden.

-

Page 6: Safety Instructions

Safety instructions Point level switch Safety instructions Requirements for the personnel The personnel for installation, commissioning, diagnostics and maintenance must fulfill the following requirements: ‣ Trained, qualified specialists must have a relevant qualification for this specific function and task. ‣ Are authorized by the plant owner/operator. -

Page 7: Identification

Ta= -20°C...+60°C DMT 01 ATEX E 040 II 1/2D T110°C S/N: XXXXXXXXXXXX A0023503 1 Nameplate of the OFTE20 point level switch (example) Device name Housing degree of protection Manufacturer' s address Approvals (optional) Serial number Year of manufacture and order code... -

Page 8: Installation Conditions

Mounting Point level switch 4.1.2 Transport and storage Please note the following: • Pack the device so that is protected against impact for storage and transport. The original packaging offers the best protection for this. • The permitted storage temperature is –20 to 60 °C (–4 to 140 °F). Installation conditions Correct and incorrect installation positions are indicated in →... -

Page 9: Installation Instructions

Point level switch Mounting Mechanical load of optional indicator light The optional indicator light must be protected against mechanical load (impact energy > 1 J). More information is provided in the "Technical data" section → 25. Installation instructions NOTICE The device can be damaged if handled incorrectly during installation ‣... - Page 10 Mounting Point level switch A0017363 4 Installation of the version with hinged rotary paddle Attach sealing ring (1) 60x48x3 mm (2.36x1.89x0.12 in). Slide the rotary paddle into the connecting flange (3). Tighten nut with open-ended wrench AF 60 (2). 4.3.1 Turning the housing to the right position A0017364...

- Page 11 Point level switch Mounting A0018473 6 Installation of the flange version Attach sealing ring (1) 60x48x3 mm (2.36x1.89x0.12 in) and insert rotary paddle into connecting flange. Tighten nut (2) with open-ended wrench AF 60. Secure the device using 4 screws (not included in the scope of delivery). 4.3.3 Mounting the weather protection cover The weather protection cover is available as an accessory and can be installed without...

- Page 12 Mounting Point level switch A0017698 7 Mounting the weather protection cover To protect the device from sunlight, arrange the weather protection cover in such a way that provides optimum shade for the device. 4.3.4 Installation in hazardous areas When installing the point level switch in a hazardous area, the securing screw must be tightened to prevent the cover from opening.

-

Page 13: Post-Installation Check

Point level switch Wiring Post-installation check • Are the seals undamaged? • Is the process connection securely tightened? • Do the cable entries point downwards and are they tightened? • Is the cover securely closed and the securing screw securely tightened? Wiring Connection instructions WARNING... -

Page 14: Quick Wiring Guide

Wiring Point level switch Quick wiring guide *Option Test A0017295 9 Terminal assignment of the point level switch Symbol Description Symbol Description Protective ground Connection for signaling empty/full status detection (optional) N (AC), N/L- Power supply L- (DC) Changeover contact L1 (AC), Normally closed contact... - Page 15 Point level switch Wiring 5.2.1 Switching states A0017628 1 = Indicator 2 = Full 3 = Refill Shaft rotation Internal light light (optional, signaling signalling non-Ex only) C (only with Flashes optional rotation monitoring)

-

Page 16: Post-Connection Check

Wiring Point level switch 5.2.2 Inserting the cable A0017367 10 Removing the housing cover and inserting the cables A0017366 11 Connecting the cables to the terminals Post-connection check Device condition and specifications Notes Are cables or the device damaged? Visual inspection Electrical connection Notes... -

Page 17: Operation

Point level switch Operation Operation WARNING The device is not explosion-protected if the housing is open. ‣ The device may only be opened in the hazardous area if no supply voltage is applied. Therefore the device may only be operated in a de-energized state or outside the hazardous area. -

Page 18: Indicator Light (Optional)

Operation Point level switch *Option A0017353 13 Inspection glass to observe rotational movement Indicator light (optional) The point level switch is optionally fitted with an indicator light that lights up when the rotary paddle stops. Testing the internal switch When the housing cover is open, the function of the internal switch to switch off the motor can be checked by inserting a screwdriver into the opening provided in the electronics cover and by moving the handle in the direction of the arrow. -

Page 19: Commissioning

Point level switch Commissioning Commissioning Post-installation and post-connection check Checklists: • Post-installation check → 13 • Post-connection check→ 16 Setting the switching pressure (sensitivity) The switching threshold can be adapted to the weight of the bulk solids in 3 stages via an operating element that is accessible from above (also possible during operation): •... -

Page 20: Point Level Switch With Rotation

Maintenance Point level switch Point level switch with rotation monitoring The table below shows the output signal of the point level switch with rotation monitoring for overfill protection. Rotation monitoring of the point level switch (optional) Power supply Motor Output signal of Internal light "full"... -

Page 21: Repair

Point level switch Repair Repair 10.1 General information Due to its design, the device cannot be repaired. 10.2 Spare parts Contact the supplier where necessary. Always quote the serial number of the device when ordering spare parts! Type Housing cover Flange version Hinged rotary paddle, 304 Double rotary paddle... -

Page 22: Technical Data

Technical data Point level switch Technical data 11.1 Input 11.1.1 Measured variable Level (in line with the orientation and length) 11.1.2 Measuring range The measuring range depends on the installation location of the device and the selected length of the shaft 75 to 300 mm (2.95 to 11.81 in) or the rope extension up to max. 2 000 mm (6.56 ft). -

Page 23: Performance Characteristics

Point level switch Technical data 11.3.2 Supply voltage • 24 V DC ±15% • 24 V AC ±10%, 50/60 Hz • 115 V AC ±10%, 50/60 Hz • 230 V AC ±10%, 50/60 Hz An overload protection element (rated current ≤ 10 A) is required for the power cable. 11.3.3 Power consumption Max. -

Page 24: Mounting

Technical data Point level switch 11.5 Mounting 11.5.1 Mounting location Installation position → 2, 8 Permitted Not permitted Comments Vertical from the top Angled from the top Cable entry must point downwards From the side Cable entry must point downwards;... -

Page 25: Environment

Point level switch Technical data 11.6 Environment The device must be protected against direct sunshine. A weather protection cover is available as an accessory, see the "Accessories" section → 29. All values not indicated as per DIN EN 6054-1. 11.6.1 Ambient temperature range –20 to 60 °C (–4 to 140 °F) -

Page 26: Mechanical Construction

Technical data Point level switch 11.7.3 Solids weight ≥ 80 g/l (4.99 lb/ft³) 11.7.4 Grain size ≤ 50 mm (1.97 in) 11.8 Mechanical construction 11.8.1 Design, dimensions 113 (4.45) 105 (4.13) 103 (4.06) SW(AF) 157 (6.18) 131 (5.16) A0017076 16 Dimensions of the point level switch, dimensions in mm (in) Indicator light (optional) Version with rope extension, can be shortened... - Page 27 Point level switch Technical data (2.87) 145 (5.71) 145 (5.71) (2.87) A0017664 17 Dimensions of the rotary paddle - standard and hinged, for shaft and rope extension, dimensions in mm (in) Dimensions depending on the version Process connection NPT 1¼", NPT 1½", G 1½" Length of shaft 75 to 300 mm (2.95 to 11.81 in) 11.8.2...

-

Page 28: Operability

Technical data Point level switch Designation Material Shaft 1.4305 / 303 Rope extension 1.4401 / 316 Rotary paddle (standard / hinged) 1.4301 / 304 Shaft seal Process connections In stainless steel 1.4305 / 303 or PBT 11.8.4 Cable entries 2 x cable gland, M20 x1.5 (optionally 1 x cable gland M20 x 1.5 and indicator lamp) Permitted cable diameter 5 to 9 mm (0.2 to 0.35 in) - Page 29 Point level switch Technical data 11.11.1 Device-specific accessories Accessories Description Flanged version, incl. seal 150 (5.91) and nut for the process 120 (4.72) 2 (0.08) connection 18 (0.71) 48 (1.89) A0018472 18 Dimensions of the flange connection, dimensions in mm (in) Order as an accessory in the product structure...

- Page 30 Technical data Point level switch Protective cover Used to protect the measuring device from the adverse effect of the weather and sunlight when fitted in the roof of a silo. 103 (4.06) 175 (6.89) 201.5 (7.93) 298.5 (11.75) A0017694 19 Dimensions of the protective cover, dimensions in mm (in) Order as an accessory in the product structure...

- Page 32 *71573627* 71573627...

Need help?

Do you have a question about the OFTE20 and is the answer not in the manual?

Questions and answers