Kohler KDI 1903M Owner's Manual

Hide thumbs

Also See for KDI 1903M:

- Workshop manual (192 pages) ,

- Use and maintenance (42 pages) ,

- Owner's manual (40 pages)

Summary of Contents for Kohler KDI 1903M

- Page 1 KDI 1903M KDI 2504M OWNER MANUAL Internal Communication: For internal & partner use only.

- Page 2 Documentation Translated from the original manual in Italian language. Data reported in this issue can be modified at any time by KOHLER. Important The latest version of this manual is available on the i-Service website, connect to the following link https://iservice.lombardini.it, before downloading the manual, you can select the desired language from the top bar of the...

-

Page 3: Table Of Contents

INDEX General Information ......................5 Manual's purpose ..........................5 Glossary and Definitions ......................... 5 Emission-Related Installation Instructions ................... 5 Service request ..........................6 Engine component identification ....................7 Manufacturer and motor identification data ................. 8 Technical information ......................9 General description of the engine ....................9 Engine specifications ........................ - Page 4 INDEX Check and setting alternator standard belt tension ..............33 5.10 Check fuel filter cartridge ......................34 5.11 Product preservation ........................34 5.12 Engine storage (up to 6 months) ....................34 5.13 Engine storage (over 6 months)....................34 5.14 Engine starting after storage ......................35 Information about replacements ..................

-

Page 5: General Information

KOHLER reserves the right to make, at any time, changes in the engines for technical or commercial reasons. • These changes do not require KOHLER to intervene on the marketed production up to that time and not to consider this manual as inappropriate. •... -

Page 6: Service Request

GENERAL INFORMATION 1.4 Service request • The complete and updated list of authorized Kohler Co. service centers can be found on websites: www.kohlerengines.com dealers.kohlerpower.it & • If you have any questions regarding your warranty rights and responsibilities or the location of the nearest Kohler Co. -

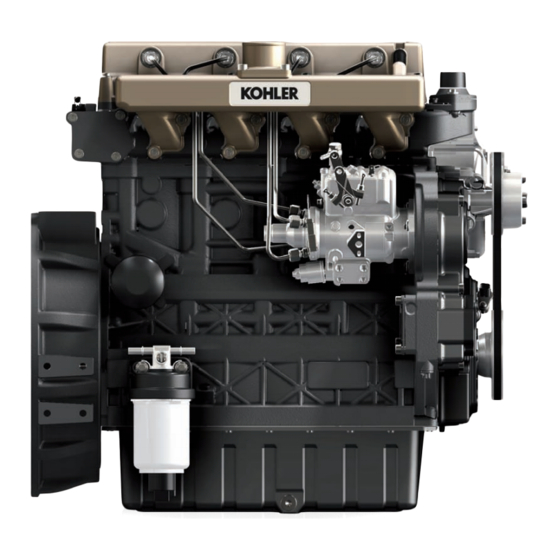

Page 7: Engine Component Identification

GENERAL INFORMATION 1.5 Engine component identification Internal Communication: For internal & partner use only. -

Page 8: Manufacturer And Motor Identification Data

GENERAL INFORMATION 1.6 Manufacturer and motor identification data... -

Page 9: Technical Information

TECHNICAL INFORMATION 2 TECHNICAL INFORMATION 2.1 General description of the engine • 4-stroke, in-line cylinders Diesel engine; • Liquid-cooling system; • valves per cylinder with hydraulic tappets; • Direct Injection. 2.2 Engine specifications Tab. 2.1 UNIT TECHNICAL DATA MEASURE Engine type KDI 1903 M KDI 2504 M Cylinders... -

Page 10: Engine Dimensions (Mm)

TECHNICAL INFORMATION 2.3 Engine dimensions (mm) KDI 1903 M KDI 2504 M... -

Page 11: Oil

TECHNICAL INFORMATION 2.4 Oil Important • The engine may be damaged if operated with improper oil level. • Do not exceed the MAX level because a sudden increase in engine rpm could be caused by its combustion. • Use only the recommended oil to ensure adequate protection, efficiency and service life of the engine. •... -

Page 12: Fuel

Jet fuels, the certification primary filter must be with lubricity dosing capability. (*1) Contact Kohler for information about the approved filter for this purpose. Power and torque might be 1% to 5% lower due to low fuel 100% (EN density compared to standard diesel fuel. - Page 13 Jet fuels, the certificati primary filter must be with lubricity dosing capability. (*1) Contact Kohler for information about the approved filter for this purpose. Sulphur Fuel S < 500 ppm High Sulphur Fuel S <...

-

Page 14: Coolant Recommendation

HOAT are not all maintenance free and it is recommended to have SCA (Supplemental Coolant Additives) added at the first maintenance interval. 2.7 Battery recommendations Battery not supplied by Kohler Tab. 2.7 RECOMMENDED BATTERIES AMBIENT TEMPERATURE BATTERY TYPE >... -

Page 15: Safety Information

Any improvement must be verified at KOHLER testing laboratories before application of the engine. • In case the approval to a modification is not granted, KOHLER shall not be deemed responsible for any consequential failures or damages to the engine. - Page 16 • Do not mix fuel with elements such as oil or kerosene. Failure to comply with this prohibition will cause the non-operation of the catalyst and non-observance of the emissions declared by KOHLER . • Pay attention to the temperature of the oil filter when the filter itself is replaced.

- Page 17 SAFETY INFORMATION Important • Only use the eyebolts A installed by KOHLER to move the engine (Fig. 3.1). • The angle between each lifting chain and the eyebolts shall not exceed 15° inwards. • The correct tightening of the lifting screws is 25Nm.

-

Page 18: Safety Signal Description

SAFETY INFORMATION 3.3 Safety signal description • To ensure safe operation please read the following statements and understand their meaning. • Also refer to your equipment manufacturer's manual for other important safety information. • This manual contains safety precautions which are explained below. •... - Page 19 SAFETY INFORMATION Warnings Hereunder is a list of safety warnings that may be found in the manual, which advise you to pay attention when carrying out particular procedures that may be potentially dangerous to the operator or things. Danger This indicates situations of grave danger which, if ignored, may seriously threaten the health and safety of individuals.

-

Page 20: Information And Safety Signals

SAFETY INFORMATION 3.4 Information and safety signals HIGH PRESSURE FLUID RISK OF PUNCTURE ACCIDENTAL START High Pressure Fluids can puncture skin and cause severe injury or death. Accidental Starts can Do not work on fuel system without proper training or safety cause severe injury or equipment. - Page 21 SAFETY INFORMATION Carbon Monoxide can cause severe nausea, fainting or death. CALIFORNIA WARNING - DECLARATION 65 Avoid inhaling exhaust fumes and Engine exhaust from this product contains chemicals known to never run the engine in a closed the State of California to cause cancer, birth defects, or other building or confined area.

-

Page 22: Safety And Environmental Impact

Regulations and directives regarding environmental impact. In order to minimise the impact on the environment, KOHLER now provides a number of indications to be followed by all persons handling the engine, for any reason, during its expected lifetime. - All components and fluids must be disposed of in accordance with the laws of the country in which disposal is taking place. -

Page 23: Information About Use

INFORMATION ABOUT USE 4 INFORMATION ABOUT USE 4.1 Pre-start check • Read carefully the following pages and carry out the operations described below in accordance with the instructions specified. Important • Non compliance with the operations described in the following pages involves the risk of damages to the engine and vehicle on which it is installed as well as personal and/or property damage. -

Page 24: Refuelling

• In those countries where fuel has a high sulphur content, its is advisable to lubricate the engine with a high alkaline oil or alternatively to replace the lubricating oil recommended by KOHLER more frequently. • To avoid explosions or fire outbreaks, do not smoke or use open flames during the operations. -

Page 25: Oil Filling

INFORMATION ABOUT USE 4.5 Oil filling Important • For safety precautions see Par. 2.4. • Before proceeding with operation, read Par. 3.2.2. • Do not use the engine with the oil level below the minimum. 1. Loosen the oil filler cap A or the oil filler cap C if the cap A is not accessible. - Page 26 INFORMATION ABOUT USE NOTE: Before proceeding with any operation on the engine, stop it and allow it to cool. Warning • Presence of steam pressurized coolant danger of burns. 1. Loosen the cap A and fill the radiator with coolant composed 50% ANTIFREEZE and 50% decalcified water.

-

Page 27: Information About Maintenance

INFORMATION ABOUT MAINTENANCE 5 INFORMATION ABOUT MAINTENANCE 5.1 Useful information about maintenance • This chapter shows all operations described in the Tab. 5.1 and Tab. 5.2. if you have the skills appropriate may be directly carried out by the user. •... -

Page 28: Periodic Maintenance

INFORMATION ABOUT MAINTENANCE 5.2 Periodic maintenance The intervals of preventive maintenance in Tab. 5.1, Tab. 5.2, Tab. 5.3 and Tab. 5.4 refer to the engine operating under normal operating conditions with fuel and oil meeting the recommended specifications. CLEANING AND CHECKING PERIOD (HOURS) OPERATION DESCRIPTION PAR. -

Page 29: Oil Level Check (Standard Dipstick)

The air filter must be cleaned and replaced more frequently under very dusty conditions. (3) - In case of low use: 36 months. (6) - Contact authorized KOHLER workshops. (7) - The replacement interval is only an indication, it strongly depends from environmental condition and hose status detected during regular visual inspection. -

Page 30: Oil Dipstick On Cylinder Head

• Before proceeding with operation, read Par. 3.2.2. NOTE: Components not necessarily supplied by KOHLER. 1. Release the two clasps D of the cover A. 2. Remove the cartridges B. 3. Clean the inside components A and C with a damp cloth. -

Page 31: Rubber Hoses Check

Important • Before proceeding with operation, read Par. 3.2.2. • If hoses are damaged contact an authorized KOHLER workshop. 1. Loosen the four capscrews E and remove guard F. 2. Check that the: • Fuel system hoses A are intact. -

Page 32: Check Coolant Level

Fig 5.8 Warning • Presence of steam pressurized coolant danger of burns. NOTE: Component not necessarily supplied by KOHLER. 1. Start the engine without the radiator cap A. 2. Top liquid up until the pipes inside the radiator are covered by about 5 mm. -

Page 33: Check And Setting Alternator Standard Belt Tension

Let the engine run for some minutes, then let it cool down at ambient temperature and repeat the operations 2, 3, 4 and 5 in case the belt tension results out of the above mentioned values. Fig 5.13 NOTE: Contact KOHLER authorised workshops for replacement. Internal Communication: For internal & partner use only. -

Page 34: Check Fuel Filter Cartridge

INFORMATION ABOUT MAINTENANCE 5.10 Check fuel filter cartridge Important • Before proceeding with operation, read Par. 3.2.2. Danger • For safety precautions see Chap. 1. Gently loosen the water drain plug A without removing it. 2. Spill out the water if present. 3. -

Page 35: Engine Starting After Storage

INFORMATION ABOUT MAINTENANCE 5.14 Engine starting after storage 1. Remove the protective sheet. 2. Use a cloth soaked in degreasing product to remove the protective treatment from the external parts. 3. Inject lubricating oil (no more than 2 cm ) into the intake ducts. 4. -

Page 36: Information About Replacements

INFORMATION ABOUT REPLACEMENTS 6 INFORMATION ABOUT REPLACEMENTS 6.1 Engine oil replacement Danger • Disconnect the negative wire (-) from the battery to avroid accidental engine stating. Important Fig. 6.1 • Before proceeding with operation, read Par. 3.2.2 • Place engine on level sur face to ensure accurate measurement of oil level. -

Page 37: Oil Filter Cartridge Replacement

INFORMATION ABOUT REPLACEMENTS 6.2 Oil filter cartridge replacement Important • Before proceeding with operation, read Par. 3.2.2 Warning • In case of low use replace it 12 months. • For disposal of oil filter cartridge refer to Par. 6.6 DISPOSAL SCRAPPING. -

Page 38: Fuel Filter Cartridge Replacement

INFORMATION ABOUT REPLACEMENTS 6.4 Fuel filter cartridge replacement Important • Before proceeding with operation, read Par. 3.2.2. Warning • In case of low use replace il 12 months. • To replace the cartridge with Option B filter, it is necessary to use the ST_55 tool cod. -

Page 39: Air Filter Cartridge Replacement

6.5 Air filter cartridge replacement Important • Before proceeding with operation, read Par. 3.2.2. NOTE: Component not necessarily supplied by KOHLER. 1. Release the two fastenings F of the cover A. 2. Remove the cartridge B. 3. Reinstall: •... -

Page 40: Information About Failures

Battery voltage too low Recharge the battery or replace it Low fuel level Refuel Frozen fuel Contact KOHLER authorised workshops Clogged fuel filter Replace with a new filter The engine does not Air suction in fuel system Contact KOHLER authorised workshops... - Page 41 Clean the radiator; if the problem persists, contact Clogged radiator KOHLER authorised workshops In the event that the solutions proposed in Tab. 7.2 do not eliminate the trouble, contact a KOHLER authorized workshop. Internal Communication: For internal & partner use only.

-

Page 42: Information About Warranty

If no hour meter is installed on the application, the Operating Hours will be calculated as 4 hours of use per day for 5 days per week beginning on the date of purchase. Kohler Co.’s obligation under this warranty is expressly limited, at its option, to an appropriate adjustment, repair or replacement of such part or parts as found to be defective following an inspection by Kohler Co. - Page 43 2. As the off-road & marine engine owner, you should however be aware that Kohler Co. may deny you warranty coverage if your off-road & marine engine or a part shows signs of malfunction or failed due to abuse, neglect, improper maintenance or unapproved modifications.

- Page 44 4. You are responsible for initiating the warranty process. The ARB & US EPA suggests that you present your off-road & Marine engine to a Kohler Co. dealer as soon as a problem exists. The warranty repairs should be completed by the dealer as expeditiously as possible.

- Page 45 The [current model year – {2+ current model year}] heavy-duty off-road & marine engines are warranted for the periods listed below. If any emission-related part on your engine is defective, the part will be repaired or replaced by Kohler Co. VARIABLE SPEED OR 1,500 HOURS OR TWO YEARS, KW <19...

-

Page 46: Glossary

9 GLOSSARY 9.1 Glossary and Definitions A component that transforms mechanical energy into AC electrical energy. Alternator Authorised workshop Kohler authorised service centre. Internal diameter of the cylinder in combustion engines. Bore A device in charge of filtering exhausted gas. Catalyst Combustion Chemical reaction of a mixture composed of fuel and fuel (air) inside a combustion chamber. - Page 47 GLOSSARY It is a mixture of products by means of a chemical conversion of oils and animal and/or Methyl ester vegetable fat, which is used to produce Biofuel. Min. Minutes. Minimum. Model Model, engine identification plate, which indicates the engine's model. Paragraph.

- Page 48 GLOSSARY SYMBOLS AND UNITS OF MEASUREMENT SYMBOL UNIT OF MEASUREMENT DESCRIPTION EXAMPLE α degree Rotation/inclination angle 1° square centimetre Area 1 cm Ø millimetre Circumference Ø 1 mm newton-metre Torque 1 Nm millimetre 1 mm µm 1/1000 of a millimetre (micron) 1 µm Length hour...

- Page 49 GLOSSARY Internal Communication: For internal & partner use only.

Need help?

Do you have a question about the KDI 1903M and is the answer not in the manual?

Questions and answers