Kohler KDI-1903TCR Owner's Manual

Diesel

Hide thumbs

Also See for KDI-1903TCR:

- Workshop manual (315 pages) ,

- Owner's manual (64 pages) ,

- Workshop manual (200 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Kohler KDI-1903TCR

-

Page 1: Um Kdi 1903Tcr_2504Tcr _ Cod. Ed0053029490 - 2° Ed_Rev

KDI 1903TCR - KDI 2504TCR OWNER MANUAL... -

Page 2: Um Kdi 1903Tcr_2504Tcr _ Cod. Ed0053029490 - 2° Ed_Rev. 01

REGISTRATION OF MODIFICATIONS TO THE DOCUMENT Any modifications to this document must be registered by the drafting body, by completing the following table. Drafting Code Date Model Date Written by Endorsed Edition Revision body document issue N° Review DICOM/ATLO ED0053029490 51269 2°... -

Page 3: Table Of Contents

INDEX INDEX Air filter cartridge replacement ..........33 Emission-Related Installation Instructions ......6 Air filter check..............23 Engine dimensions ..............10 Alternator belt, Check Poly-V ..........26 Engine component identification .........7 Alternator standard belt tension, Check and setting ..26 Engine oil replacement ............29 Engine storage over 6 months ...........28 Engine storage up to 6 months ..........28 Battery recommendations ..........13 Engine starting after storage..........28... - Page 4 INDEX INDEX Identification, Engine component ........7 Recommendations, Battery ..........13 Identification data, Manufacturer and motor ......8 Radiator heat-exchange surface, Check of the ....24 Information and safety signals...........17 Refuelling ................20 Information, safety ..............14 Remarks, General ..............14 Remote oil filter cartridge replacement (optional) ..31 Replacement, Engine oil .............29 Replacement, Fuel filter cartridge........32 Label for EPA rules ...............9...

- Page 5 INDEX INDEX Useful information about failures ........34 Useful information about maintenance ......22 Warranty responsibilities, Owner’s ........35 Water filter cartridge fuel, Control ........27 Your warranty rights and obligations, California emission control warranty statement ....35 UM KDI 1903TCR_2504TCR _ cod. ED0053029490 - 2° ed_rev. 01...

-

Page 6: Definitions, And Glossary

Service request • Authorized service centers can be found in the service handbook (received with the product purchased). • The complete and updated list of authorized Kohler Co. ser vice centers can be found on our web site: http://www.lombardinigroup.it/dealer-locator. • If you have any questions regarding your warranty rights and responsibilities or the location of the nearest Kohler Co. -

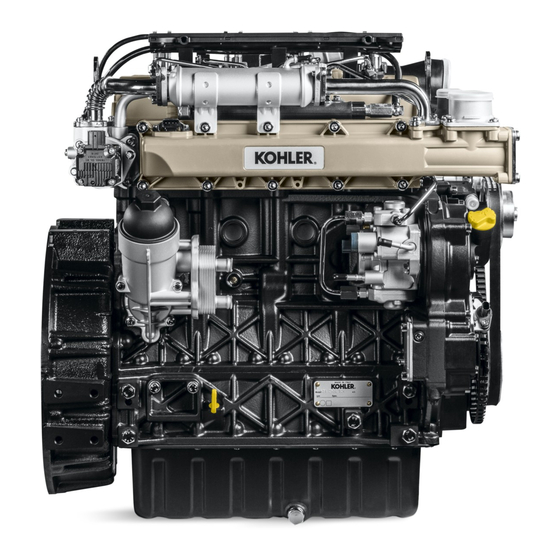

Page 7: Engine Component Identification

GENERAL INFORMATION Engine component identification SIDE VIEW A Oil filler cap Thermostat Turbocharger Oil filler cap Oil pressure sensor Starter motor Water temperature sensor Oil steam separator Water pump Oil drain plug Nameplate Alternator SIDE VIEW B EGR Cooler High injection pump Valve EGR Oil cooler Oil filter... -

Page 8: Identification Data, Manufacturer And Motor

GENERAL INFORMATION Manufacturer and motor identification data The nameplate motor identification is find side A or side B. SIDE VIEW A SIDE VIEW B Engine type Engine serial number Manufacturer identification Peak Engine version Approval data and "EC" directives UM KDI 1903TCR_2504TCR _ cod. ED0053029490 - 2° ed_rev. 01 Index... -

Page 9: Epa Rules, Label For

GENERAL INFORMATION Label for EPA rules POS. DESCRIPTION Model year in compliance with the rules Power category (kW) Engine displacement (L) Particulate emission limit (g/kWh) Engine family ID Emission Control System = ECS Fuel with low sulphur content Injection timing (*BTDC) Injector opening pressure (bar) Production date (example: 2013.JAN) UM KDI 1903TCR_2504TCR _ cod. -

Page 10: Dimensions, Engine

TECHNICAL INFORMATION 1.1. General description of the engine - - 4-stroke,-in-line-cylinders-Diesel-engine; - - Turbocharger-with-Waste-gate-valve; - - Liquid-cooling-system; - - Direct-injection. - - 4-valves-per-cylinder-with-hydraulic-tappets;- 1.2 Engine specifications Tab. 1.1 UNIT TECHNICAL DATA MEASURE ENGINE TYPE KDI 1903 TCR KDI 2504 TCR CYLINDERS BORE STROKE... -

Page 11: Fuel

TECHNICAL INFORMATION 1.4 Oil Important Danger •-The- engine- may- be- damaged- if- operated- with- improper- oil- •-Prolonged- skin- contact- with- the- exhausted- engine- oil- can- level.- cause-cancer-of-the-skin.- •-Do-not-exceed-the-MAX-level-because-a-sudden-increase-in- •-If-contact-with-oil-cannot-be-avoided,-thoroughly-wash-your- engine-rpm-could-be-caused-by-its-combustion.- hands-with-soap-and-water-as-soon-as-possible.- •-Use-only-the-recommended-oil-to-ensure-adequate-protection,- •-For-the-exhausted-oil-disposal,-refer-to-Par. 5.6 DISPOSAL efficiency-and-service-life-of-the-engine.- and SCRAPPING. •-The-use-of-lubricants-other-than-recommended-may-shorten- the-engine-life.- •-Viscosity-must-be-appropriate-to-the-ambient-temperature-to- which-the-engine-is-to-be-exposed-(Par. - Page 12 TECHNICAL INFORMATION 1.5.2 Biodiesel fuel •-Fuels-containing-10%-methyl-ester-or-B10,-are-suitable-for-use-in-this-engine-provided-that-they-meet-the-specifications-listed- in-the-Tab. 1.3. • DO NOT USE-vegetable-oil-as-a-biofuel-for-this-engine.- •-Any-failures-resulting-from-the-use-of-fuels-other-than-recommended-will-not-be-warranted. Tab. 1.3 FUEL COMPATIBILITY Certification Warranty Compatible Engine waste emission coverage EN-590,-DIN-51628---Military-NATO-fuel-F-54-(S=10-ppm) No-1-Diesel-(US)---ASTM-D-975-09-B---Grade-1-D-S-15- (S=15-ppm) No-1-Diesel-(US)---ASTM-D-975-09-B---Grade-1-D-S-500- (S=500-ppm) No-2-Diesel-(US)---ASTM-D-975-09-B---Grade-2-D-S-15 No-2-Diesel-(US)---ASTM-D-975-09-B---Grade-2-D-S-1500 ARCTIC-(EN-590/ASTM-D-975-09-B) High-sulfur-fuel-<-5000-ppm-(<0.5%) High-sulfur-fuel->-5000-ppm-(<0.5%) High-sulfur-fuel->-10000-ppm-(>1%) Civil-Jet-Fuels-Jet-A/A1 Civil-Jet-Fuels-Jet-B Bio-Fuels-(EN14214) (1)- Except-for-catalyst-clogged-and-EGR.- (3)- Except-for-catalyst-clogged-and-EGR.- Shorter-oil-change-intervals.

-

Page 13: Battery Recommendations

TEXACO REVKOGEL 2000 PARAFLU LLC L255A LLC A432 1.7 Battery recommendation Battery not supplied by Kohler RECOMMENDED BATTERIES AMBIENT TEMPERATURE BATTERY TYPE 90 Ah/20 h - 450 A/DIN from-0°C-to -15°C 90 Ah/20 h - 885 A/EN 90 Ah/20 h - 855 CCA/SAE 110 Ah/20 h - 500 A/DIN from -15°C to -25°C... -

Page 14: General Remarks

• In case the approval to a modification is not granted, KOHLER prescribed health and safety requirements. Any use of the shall not be deemed responsible for any consequential machine other than that described cannot be considered as failures or damages to the engine. - Page 15 • Fully tighten the tank cap each time after refuelling. Do not Important fill the tank right to the top but leave an adequate space for • Only use the eyebolts A installed by KOHLER to move the the fuel to expand. engine (Fig. 2.1).

-

Page 16: Safety Signals Description

SAFETY INFORMATION 2.3 Safety signal description • To ensure safe operation please read the following statements • This manual contains safety precautions which are explained and understand their meaning. below. • Also refer to your equipment manufacturer's manual for other •... -

Page 17: Information And Safety Signals

State of California to cause cancer, birth defects, or other reproductive harm. 2.5 Safety and environmental impact In order to minimise the impact on the environment, KOHLER Every organisation has a duty to implement procedures to now provides a number of indications to be followed by... -

Page 18: Location Of Safety Signals On Engine

SAFETY INFORMATION 2.6 Safety precautions • Check the good condition of safety signals. • Position them as shown in Par. 2.7. • The user must replace them with original ones if they are • Clean with a cloth, water and soap. deteriorated and illegible. -

Page 19: Check, Pre-Start

INFORMATION ABOUT USE 3.1 Pre-start check • Read carefully the following pages and carry out the • Increase the frequency of maintenance operations in heavy operations described below in accordance with the working conditions (engine starts but stops, very dusty and instructions specified. -

Page 20: Filling, Oil

• In those countries where diesel has a high sulphur content, its is advisable to lubricate the engine with a high alkaline oil or alternatively to replace the lubricating oil recommended by KOHLER more frequently. • To avoid explosions or fire outbreaks, do not smoke or use open flames during the operations. -

Page 21: Coolant Filling

INFORMATION ABOUT Use 3.6 Coolant filling Warning • As well as lowering the freezing point, the antifreeze also • An anti-freeze protection liquid (ANTIFREEZE) - mixed with raises the boiling point. decalcified water - must be used. • A 50% mixture is recommended to ensure a general level at • The freezing point of the refrigerant mixture depends on the protection prevents the formation of rust, galvanic currents amount concentration in water. and calcium deposits. NOTe: Before proceeding with any operation on the engine, stop it and allow it to cool. Warning • Presence of steam pressurized coolant danger of burns. 1 - Loosen the cap A and fill the radiator with coolant composed of: 50% ANTIFREEZE and 50% decalcified water. 2 - Top liquid up until the pipes inside the radiator are covered by about 5 mm. Do not overfill the radiator, but leave room for the coolant to expand. -

Page 22: Maintenance, Periodic

After 6 checks with cleaning Dry air cleaner external cartridge The replacement must be carried out by (2) (6) authorized KOHLER workshops The replacement must be carried out by authorized Fuel line hose KOHLER workshops (1) - In case of low use: 12 months. -

Page 23: Air Filter Check

Fig. 4.4 Fig. 4.3 4.5 Air filter check NOTE: Components not necessarily supplied by KOHLER. 1 - Release the two clasps F of the cover A. 2 - Remove the cartridges B and G. 3 - Remove the cap C. -

Page 24: Check Of The Radiator Heat-Exchange Surface

Components must be replaced if they have clear signs of cracks, tears, cuts, leaks and do not retain a certain degree of elasticity. Important • If hoses are damaged contact an authorized KOHLER workshop. Fig. 4.7 1 - Check that the: - Fuel system hoses A are intact. -

Page 25: Belt Tension, Check And Setting Alternator Standard

Warning • Presence of steam pressurized coolant danger of burns. NOTE: Component not necessarily supplied by KOHLER. 1 - Start the engine without the radiator cap A. 2 - Top liquid up until the pipes inside the radiator are covered by about 5 mm. -

Page 26: Alternator Belt, Check Poly-V

Let the engine run for some minutes, then let it cool down 40 Nm at ambient temperature and repeat the operations 2, 3, 4 and 5 in case the belt tension results out of the above mentioned values. NOTE: Contact KOHLER authorised workshops replacement. Fig. 4.13 4.10 Check Poly-V alternator belt NOTE: The poly-v belt is not adjustable. -

Page 27: Control Water Filter Cartridge Fuel

INFORMATION ABOUT MAINTENANCE NOTE: If the poly-v belt tension results out of the above mentioned values contact KOHLER authorised workshops for replacement. Fig. 4.15 4.11 Control water filter cartridge fuel NOTE: When turn on lights on control water filter cartridge fuel Par. -

Page 28: Engine Storage Over 6 Months

INFORMATION ABOUT MAINTENANCE 4.12 Product preservation 11 - When cleaning the engine, if using a pressure washer or steam cleaning device, avoid directing the nozzle on electrical components, cable connections and sealed Important rings (oil seals etc). If cleaning engine with a pressure washer or steam •... -

Page 29: Engine Oil Replacement

INFORMATION ABOUT REPLACEMENTS Danger Disconnect the negative wire (-) from the battery to avoid accidental engine starting. 5.1 Engine oil replacement Important • Place engine on level sur face to ensure accurate measurement of oil level. NOTE: Perform this operation with warm engine, to get a better fluidity of the oil and get a full discharge of oil and impurities contained in it. 1 - Loosen the oil filler cap A (Fig. 5.1). 2 - Remove the oil dipstick B. Fig. 5.1 3 - Remove the oil drain plug D and the gasket E (the oil drain plug is on both sides of the oil sump). -

Page 30: Cartridge Replacement, Oil Filter

INFORMATION ABOUT REPLACEMENTS 9 - Fit and remove the oil dipstick B to check the level. Pour in fluid until reaching the MAX level mark. 10 - Upon completion, reinstall the oil dipstick B completely. 11 - Tighten the cap A or C. Fig. 5.4 Warning Oil filter cartridge replacement (Par. 5.2) fuel filter replacement (Par. 5.4) In case of low use replace it 12 months. For disposal of oil filter cartridge and fuel filter refer to Par. 5.6 DISPOSAL and SCRAPPING. 5.2 Oil filter cartridge replacement 1 - Loosen the cap A. -

Page 31: Cartridge Replacement (Optional), Remote Oil Filter

INFORMATION ABOUT REPLACEMENTS 4 - Fit and tighten the cover A on the oil filter support F, tightening it with a torque wrench G (tightening torque of 25 Nm). 25 Nm Fig. 5.7 NOTE: Click on the icon ( ) to play the procedure. 5.3 Remote oil filter cartridge replacement (optional) 1 - Unscrew and remove the cartridge A using the appropriate wrench. 2 - Lubricate the gasket and screw on the new cartridge A using the appropriate wrench. -

Page 32: Filter Cartridge Replacement, Fuel

INFORMATION ABOUT REPLACEMENTS 5.4 Fuel filter cartridge replacement 1 - Disconnect the cable A of the water presence sensor C. 2 - Remove the water presence sensor C from its cartridge B. 3 - Loosen the cartridge B using the appropriate wrench F (Fig. 5.10). 4 - Lubricate the gasket D of the new cartridge B. Important • Do not fill the new cartridge B with fuel. Fig. 5.9 5 - Tighten the new empty cartridge B (Fig. 5.10) on the diesel fuel filter support E using the special wrench F (tightening torque of 17 Nm). -

Page 33: Air Filter Cartridge Replacement

INFORMATION ABOUT REPLACEMENTS 5.5 Air filter cartridge replacement NOTE: Component not necessarily supplied by KOHLER. 1 - Release the two fastenings F of the cover A. 2 - Remove the cartridges B and G. 3 - Reinstall: - the new cartridges B and G. - the cover A checking the right tightness of fastenings F. Fig. 5.11 5.6 Disposal and scrapping • In case of scrapping, the engine shall be disposed of in • The parts only composed of plastic material, aluminium and appropriate locations, in conformity with the law in force. steel can be recycled if collected by the appropriate centers. • Before scrapping, it is necessary to separate the rubber or • Waste oil must properly be recycled and disposed of in the... -

Page 34: Useful Information About Failures

Cheap fuel Clean the tank and refuel with quality fuel performance Replace the engine oil; if the problem persists, High oil sump level contact KOHLER authorised workshops Slow acceleration Clogged fuel filter Replace the fuel filter Engine jerking Clogged fuel pipes Contact KOHLER authorised workshops Insufficient coolant level Fill up to the level Replace the engine oil; if the problem persists, High oil sump level Engine overheats contact KOHLER authorised workshops Clean the radiator; if the problem persists, contact Clogged radiator KOHLER authorised workshops - In the event that the solutions proposed in Tab. 6.2 do not eliminate the trouble, contact a KOHLER authorized workshop. UM KDI 1903TCR_2504TCR _ cod. ED0053029490 - 2° ed_rev. 01 Index... -

Page 35: Your Warranty Rights And Obligations

• The Air Resources Board suggests that you present your heavy-duty off-road engine to a Kohler Co.. dealer as soon • Kohler Co. cannot deny warranty solely for the lack of as a problem exists. receipts or for your failure to ensure the performance of all recommended scheduled maintenance. - Page 36 NOTES ................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................UM KDI 1903TCR_2504TCR _ cod. ED0053029490 - 2° ed_rev. 01 Index...

-

Page 37: Index

NOTES ................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................UM KDI 1903TCR_2504TCR _ cod. ED0053029490 - 2° ed_rev. 01 Index... -

Page 38: Um Kdi 1903Tcr_2504Tcr _ Cod. Ed0053029490 - 2° Ed_Rev. 01 Index

NOTES ................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................UM KDI 1903TCR_2504TCR _ cod. ED0053029490 - 2° ed_rev. 01 Index... -

Page 39: Index

NOTES ................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................UM KDI 1903TCR_2504TCR _ cod. ED0053029490 - 2° ed_rev. 01 Index... - Page 40 Translated from the original manual in Italian language. Data reported in this issue can be modified at any time by KOHLER. FORM NO. FORM NO. ED0053029490 ED0053029490 ISSUED ISSUED 27/07/2013 15/01/2013 REVISED REVISED DATE DATE 27/07/2013 15/01/2013 Lombardini s.r.l. is a part of Kohler Group.

Need help?

Do you have a question about the KDI-1903TCR and is the answer not in the manual?

Questions and answers