Table of Contents

Advertisement

Available languages

Available languages

Quick Links

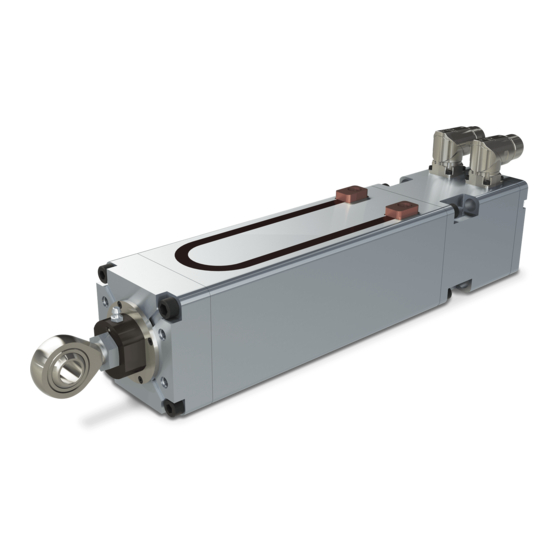

CSW &

CSWX

Please refer to the CSW &

ACTUATOR INSTALLATION:

Thrust Rod Connection:

ROD END ATTACHMENT FOR ROUND ROD ACTUATOR: Hold

flats on round rod stationary using a fixture, vise, or opposing

wrench. Torque weld gun connection linkage or rod eye up to

table value shown:

80 N-m

200 N-m

M12

M16

59 ft-lb

147.5 ft-lb

ROD END ATTACHMENT FOR DOUBLE FLAT ROD ACTUATOR:

Hold flats on the thrust rod stationary using a fixture, vise, or

opposing wrench. Do not rely on the anti-rotate feature inside

the actuator to oppose the installation torque. Torque weld gun

connection linkage or rod eye up to table value shown:

80 N-m

200 N-m

M12

M16

59 ft-lb

147.5 ft-lb

Front Head Connection:

FRONT FACE TAPPED HOLES: Torque M8 fasteners to 25 N-m

(18.4 ft-lb)

FRONT FACE SIDE TAPPED HOLES: Torque M10 Shoulder bolts

to 45 N-m (33.2 ft-lb)

TRUNNIONS: Mate trunnions with integral trunnion receptacles

on the actuator. Ensure the actuator pivots on the trunnion pins

without binding.

Water Cooling Connections:

G1/4 female threads provided. Torque fitting to 12 N-m (8.9 ft-lb)

or value provided by fitting manufacturer. Do not exceed 18 N-m

(13.3 ft-lb).

Tolomatic • URL: https://www.tolomatic.com • Email: help@tolomatic.com • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Integrated Motor/Actuator

CSWX

Manual 2750-4025 for complete information

Cable Routing and Connections:

Cable Installation Guideline

200 N-m

M20

147.5 ft-lb

Fully seat and tighten the mating cable connector to the power

and feedback connectors on the actuator.

OPERATION:

If the actuator is equipped with a brake, provide the specified

DC voltage to release the brake and allow operation.

200 N-m

M20

HOMING THE ACTUATOR: When homing the ServoWeld™ actu-

147.5 ft-lb

ator avoid excessive force. During the homing procedure, do

not exceed 20% of continuous thrust or speeds of 2.5 mm/sec.

Exceeding these recommendations can cause permanent dam-

age to the actuator. Careful attention should always be taken to

prevent exceeding the physical limits of the actuator.

Operate the actuator within the force and speed range, and weld

schedule approved by Tolomatic, Inc.

MAINTENANCE:

NEW UNIT: All ServoWeld™ actuators have been lubricated at

the factory and are ready for installation. If the actuator is placed

in storage for more than 1 year after it is received, the actuator

should be lubricated through the lubrication port on the thrust

rod with 20 grams (0.7 oz) or 23 ml (0.75 fl oz) of Kluber Isoflex

Topas NCA52 grease (Tolomatic, PN: 1150-1017) and cycled at

least two full strokes prior to running in a loaded condition.

PERIODIC MAINTENANCE: In typical applications, it is recom-

mended to re-lubricate the CSW/CSWX C-gun actuators every

10 million welds and X-gun/Pinch gun actuators every 5 million

welds or every 1 year whichever comes first.

It is recommended that the actuator be visually inspected after

initial startup and twice a year thereafter, specifically checking

for uneven wear or discoloration of the thrust rod which may

indicate side loading and lead to premature seal failure. Contact

the nearest Tolomatic service center with any concerns or ques-

tions.

Installation, Operation & Maintenance

2

1

Best

OK

Quick Start:

2750-4026_03_CSW-C

3

4

Only if

Not

Required

Recommended

Advertisement

Table of Contents

Summary of Contents for Tolomatic ServoWeld CSW

- Page 1 Contact the nearest Tolomatic service center with any concerns or ques- tions. Tolomatic • URL: https://www.tolomatic.com • Email: help@tolomatic.com • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174...

- Page 2 Dichtungsversagen führen können. Kabelführung Wenden Sie sich bei Bedenken oder Fragen an das nächstgele- und Anschlüsse: gene Tolomatic-Servicezentrum. Richtlinie zur Kabelinstallation Am Besten Nicht Nur wenn empfohlen erfordelich Tolomatic • URL: https://www.tolomatic.com • Email: help@tolomatic.com • Fax: (763) 478-8080 • Telefon: 1-763-478-8000...

- Page 3 Comuníquese con el centro de servicio de Tolomatic más cerca- no si tiene dudas o preguntas. Tolomatic • https://www.tolomatic.com • Correo electrónico: help@tolomatic.com • Fax: (763) 478-8080 • Telefon: 1-763-478-8000...

- Page 4 没有任何约束或卡住。 动缸后,储藏在库存中超过1年,那么电动缸应该通 过推力杆上的加油嘴注入20克(0.7盎司)或23毫升 (0.75盎司)的 Kluber Isoflex Topas NCA52润滑油来润 滑(Tolomatic,料号:1150-1017),然后在承受载荷 水冷连接: 情况下之前,伸出和缩回2个完全的行程。 G 1/4 母螺纹。将水冷接头上扭力到12牛-米(8.9磅- 英尺)或者扭力值由接头制造商提供。不要超过18 定期的维护:在典型的应用中,建议每1000万次焊 牛-米(13.3磅-英尺) 接对CSW/CSWX C型枪推杆进行重新润滑,每500万次 焊接对X型枪/夹枪推杆进行重新润滑,或者每1年一 次,以先到者为准。 推荐在首次调试后和之后的每一年2次,需要对电动 缸做外观检查,特别地是检查是否有不均匀的磨损 或推力杆的掉色,这表明可能有侧向载荷的现象并 且会导致过早的密封失效。有任何的关切和问题, 请联系最近的Tolomatic服务中心。 Tolomatic • 网站 https://www.tolomatic.com • 电子邮件 help@tolomatic.com • 传真 (763) 478-8080 • 电话机 1-763-478-8000...

Need help?

Do you have a question about the ServoWeld CSW and is the answer not in the manual?

Questions and answers