Summary of Contents for Carlisle ms 610190-10

- Page 1 SERVICE MANUAL MS Module Assembly Model: 610190-10 (Automatic) 610190-11 (Manual) 2813 ll (2) D PA-19-07-R3 (02/2022) 1 / 26 www.carlisleft.com...

- Page 2 MANUAL CHANGES NOTE: This manual has been changed from revision PA-19-07-R2 to revision PA-19-07-R3. Reasons for this change are noted under “Manual Change Summary” inside the back cover of this manual. PA-19-07-R3 (02/2022) 2 / 26 www.carlisleft.com...

-

Page 3: Table Of Contents

CONTENTS CONTENTS SAFETY: Safety Precautions ................................4 Hazards / Safeguards ..............................5 ATEX/FM: 9-11 European ATEX Directive ..............................9 Label ....................................10 MS Module Identification .............................11 INTRODUCTION: Specifications ................................12 INSTALLATION: 13-15 Dip Switch Settings ..............................13 Wiring Schematic Automatic ............................14 Wiring Schematic Manual .............................15 OPERATION: 16-21 Module Communications Capabilities .........................16... -

Page 4: Safety

This information relates to USER SAFETY and PREVENTING and safety literature for your equipment, contact your local EQUIPMENT PROBLEMS. To help you recognize this Carlisle Fluid Technologies representative or Carlisle Fluid information, we use the following symbols. Please pay Technologies technical support. - Page 5 SAFETY Return To Contents AREA SAFEGUARDS HAZARD Tells where hazards Tells how to avoid the hazard. Tells what the hazard is. may occur. Fire Hazard Spray Area Fire extinguishing equipment must be present in the Improper or inadequate spray area and tested periodically. operation and maintenance procedures will cause a fire Spray areas must be kept clean to prevent the...

- Page 6 SAFETY Return To Contents AREA SAFEGUARDS HAZARD Tells where hazards Tells how to avoid the hazard. Tells what the hazard is. may occur. Explosion Hazard Spray Area Improper or inadequate Electrostatic arcing must be prevented. Safe sparking operation and maintenance distance must be maintained between the parts being procedures will cause a coated and the applicator.

- Page 7 SAFETY Return To Contents AREA SAFEGUARDS HAZARD Tells where hazards Tells how to avoid the hazard. Tells what the hazard is. may occur. Spray Area / Electrical Discharge High Voltage There is a high voltage device Parts being sprayed and operators in the spray Equipment that can induce an electrical area must be properly grounded.

- Page 8 SAFETY Return To Contents AREA SAFEGUARDS HAZARD Tells where hazards Tells how to avoid the hazard. Tells what the hazard is. may occur. Electrical Electrical Discharge Unless specifically approved for use in hazardous Equipment locations, the power supply, control cabinet, and all High voltage equipment is other electrical equipment must be located outside utilized in the process.

-

Page 9: Atex/Fm

ATEX/FM Return To Contents ATEX/FM EUROPEAN ATEX DIRECTIVE 2014/34/EU, ANNEX II The following instructions apply to equipment covered by by suitably trained personnel in accordance with the certificate number FM 19ATEX0004X, FM 21UKEX0140X: manufacturer's documentation. The equipment may be used with ignitable powders with The certification of this equipment relies upon the apparatus groups II and with temperature class T6. - Page 10 ATEX/FM Return To Contents MS Powder Module 610190-XX ATEX Product Marking Definitions Ex Certificate Number: FM 19ATEX0004X and FM 21UKEX0140X FM = Notified Body performing EU-type examination 19 = Year of examination ATEX = Reference to ATEX Directive 0004 = Document serial number X = Special conditions for safe use apply Product Marking II (2) D...

-

Page 11: Ms Module Identification

ATEX/FM Return To Contents MS MODULE IDENTIFICATION 610190 - XX 10 (AUTOMATIC) 11 (MANUAL) BASE MODEL NO. (Ordering information only) www.carlisleft.com 11 / 26 PA-19-07-R3 (02/2022) - Page 12 ATEX/FM TUBING DIAGRAM FOR USE WITH 610190-10 Supply 6 bar Inlet (87 psig) Air Pressure (max) PA-19-07-R3 (02/2022) 12 / 26 www.carlisleft.com...

- Page 13 INTRODUCTION TUBING DIAGRAM FOR USE WITH 610190-11 Supply 6 bar Inlet (87 psig) Air Pressure (max) www.carlisleft.com 13 / 26 PA-19-07-R3 (02/2022)

-

Page 14: Introduction

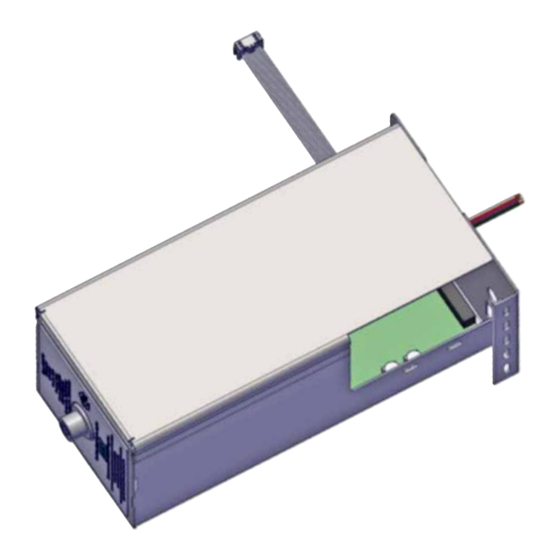

INTRODUCTION Return To Contents INTRODUCTION SPECIFICATIONS Dimension Weight: 1.65 kg (3.6 pounds) Depth: 265 mm (10.4 inches) Width: 93 mm (3.6 inches) Height: 144 mm (5.6 inches) Electrical data Main: 24 VDC Input power: External voltage to applicator: max. 10 Veff External current to applicator: max. -

Page 15: Installation

INSTALLATION Return To Contents INSTALLATION An Ethernet cable may be connected to the MS Module to WA R N I N G allow customers to connect the module to a networked PLC for coordinated control of their Powder System. MS Modules †... -

Page 16: Wiring Schematic Automatic

INSTALLATION Return To Contents WIRING SCHEMATIC AUTOMATIC CORONA GUN CONNECTOR (460138) CONNECT WITH REST OF GROUND LINES IN CUSTOMER’S CABINET. YELLOW CONNECT WITH POWER SUPPLY IN CUSTOMER’S CABINET. WIRES ARE TO HAVE CUT 40MM LONG AND 35MM LONG HEAT SHRINK IS TO BE APPLIED TO END OF OPEN WIRE. -

Page 17: Wiring Schematic Manual

INSTALLATION Return To Contents WIRING SCHEMATIC MANUAL CORONA GUN CONNECTOR (460138) CONNECT WITH REST OF GROUND LINES IN CUSTOMER’S CABINET. CONNECT WITH POWER SUPPLY IN CUSTOMER’S CABINET. 1. UNLESS OTHERWISE NOTED IN THE TABLE BELOW PORTS ARE TO BE LEFT OPEN (461819) (461821) (461829) -

Page 18: Operation

OPERATION Return To Contents OPERATION Module Communications Capabilities MS Modules are most often used in powder systems present on the MS Module main circuit board (Figure 5). installations where multiple powder applicators are being The first three octets of the static IP, and the first digit of the controlled. -

Page 19: Ethernet/Modbus Registers

OPERATION Return To Contents ETHERNET/MODBUS REGISTERS Name Description REG_CTRL_WORD CONTROL WORD REGISTER REG_CTRL_WORD_BIT_ON Board enable REG_CTRL_WORD_BIT_START Start board (if enabled) REG_CTRL_WORD_BIT_TRIBO_ON Tribo enable REG_CTRL_WORD_BIT_VALVE_PID_START_CMD Valve PID direct start command REG_CTRL_WORD_BIT_TOPCOAT_GUN 0-Manual 1-Automatic topcoat … REG_CTRL_WORD_BIT_CLOCK_IN Communication clock in from master REG_CTRL_WORD_BIT_WASH_ON Enable mode wash REG_CTRL_WORD_BIT_START_AUTOTUNING... - Page 20 OPERATION Return To Contents ETHERNET/MODBUS REGISTERS (Cont.) Name Description REG_FREQUENCY_SETPOINT Setpoint for frequency in Hz divided by 100 (CP2 only) REG_AUTOTUNING_UA_LIMIT Limit for uA for autotuning fails (CP2 only) REG_SETPOINT_WASH_VALVE_1 Setpoint wash valve 1 in bar*100 REG_SETPOINT_WASH_VALVE_2 Setpoint wash valve 2 in bar*100 REG_SETPOINT_WASH_VALVE_3 Setpoint wash valve 3 in bar*100 REG_CABLE_SELECTION...

- Page 21 OPERATION Return To Contents ETHERNET/MODBUS REGISTERS (Cont.) Name Description REG_ALM_WORD ALARM WORD REGISTER REG_ALM_WORD_BIT_MISSING_UA_CORONA Missing uA for Corona gun REG_ALM_WORD_BIT_EXCEEDING _UA Exceeding uA REG_ALM_WORD_BIT_MISSING_UA_TRIBO Missing uA for Tribo gun Reserved ex. Missing kV alarm Reserved ex. Filter alarm REG_ALM_WORD_BIT_EXCEEDING_KV_CORONA Exceeding kV for Corona gun …...

- Page 22 OPERATION Return To Contents ETHERNET/MODBUS REGISTERS (Cont.) Name Description REG_PID_UA_FB_ERROR_SUM PID uA error sum feedback Reserved ex. PID uA input Reserved ex. PID KV input Reserved ex. barcode / type REG_SW_VERSION software version REG_PRINT_TYPE print type [0=”CP1”,1=”CP2”] REG_FB_VALVE_1_BAR Valve 1 feedback in bar*100 REG_FB_VALVE_2_BAR Valve 2 feedback in bar*100 REG_FB_VALVE_3_BAR...

- Page 23 OPERATION Return To Contents ETHERNET/MODBUS REGISTERS (Cont.) Name Description REG_FB_DI_BIT_DIP_1 Digital input dip switch 1 feedback REG_FB_DI_BIT_DIP_2 Digital input dip switch 2 feedback REG_FB_DI_BIT_DIP_3 Digital input dip switch 3 feedback REG_FB_DO 111 DIGITAL OUTPUT FEEDBACK REGISTER REG_FB_DO_BIT_RELAY Digital Output relay feedback REG_FB_DO_BIT_LED44 Digital Output led 44 feedback REG_FB_DO_BIT_BOARD_START...

-

Page 24: Parts Identification

PARTS IDENTIFICATION Return To Contents PARTS IDENTIFICATION Figure 7: MS Module Exploded View MS MODULE - PARTS LIST Description Item Part # 461608 MAIN CIRCUIT BOARD CP2 VER 1.2 460138 WIRE HARNESS, CORONA GUN CONNECTOR, MS TOPCASE 610170 3 PROPORTIONAL VALVE BLOCK ASS’Y 461849 18-8 STAINLESS STEEL SOCKET HEAD SCREW M3X0.5 461851... -

Page 25: Manual Change Summary

MANUAL CHANGES Return To Contents MANUAL CHANGE SUMMARY PA-19-07-R3 - Replaces PA-19-07-R2 with the folowing changes: Change Description Page(s) Update SAFETY section Make text changes to ATEX/FM section 9-10 www.carlisleft.com 25 / 26 PA-19-07-R3 (02/2022) - Page 26 WARRANTY POLICY This product is covered by Carlisle Fluid Technologies’ materials and workmanship limited warranty. The use of any parts or accessories, from a source other than Carlisle Fluid Technologies, will void all warranties. Failure to reasonably follow any maintenance guidance provided, may invalidate any warranty.

Need help?

Do you have a question about the ms 610190-10 and is the answer not in the manual?

Questions and answers