Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Bil-Jax X-BOOM 36XT

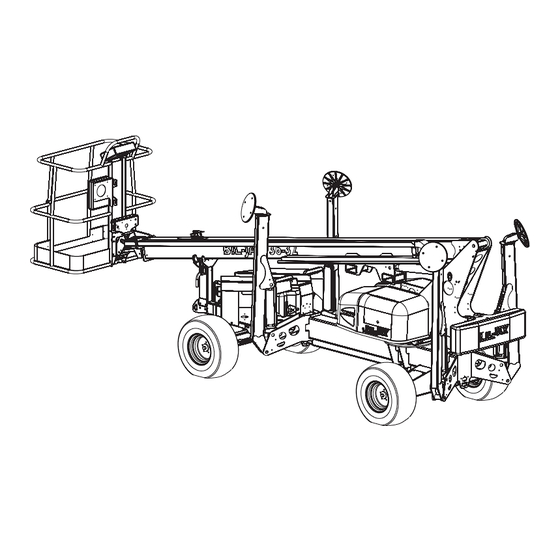

- Page 1 PARTS AND SERVICE MANUAL 36XT BOOM AERIAL WORK PLATFORMS...

- Page 2 Bil-Jax Service Department. Copyright © Bil-Jax, Inc. 2008. All Rights Reserved. “Bil-Jax” is a registered trademark and “A Step Above” and “X-Boom” are trademarks of Bil-Jax, Inc. Contact Bil-Jax for replacement manuals. 125 Taylor Parkway...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Table of Contents Illustrations Tables 1 Safety Legend: Safety Advisories Before Operation During Operation Maintenance Safety Damaged Equipment Policy 2 Specifications Range of Motion Specifications Warranty 3 Equipment Maintenance Daily Service Checks Weekly Service Checks Monthly Service Checks Annual Service Checks Structural Inspection Additional Service Information... -

Page 4: Illustrations

LIST OF ILLUSTRATIONS Figure 2-1 Range of Motion Figure 3-1 Outrigger Position Switch Figure 3-2 Hydraulic Reservoir Figure 3-3 Wheel Nut Tightening Sequence Figure 3-4 Slew Ring Position Measurement Figure 4-1 Lift Cylinder Replacement Figure 4-2 Outrigger Cylinder Replacement Figure 5-1 Decal Locations Figure 5-2 Decal Locations –... -

Page 5: Safety

SAFETY Proper training is required for the safe operation of any mechanical device. Failure to follow all instructions and safety precautions in this manual and attached to the lift will result in death or personal injury. Prior to Operation: Read, understand and obey all instructions and safety precautions in this manual and attached to the lift. -

Page 6: Legend: Safety Advisories

BIL-JAX 36XT LEGEND: SAFETY ADVISORIES The following safety advisories are used throughout this manual to indicate specific hazards when operating or maintaining the machine. Read, understand and obey all safety advisories to prevent improper service, damage to equipment, personal injury or death. -

Page 7: Before Operation

ALWAYS wear a safety harness and energy- absorbing lanyard, such as a safety harness and Minimum Safe Approach Distance Voltage Range lanyard provided by Bil-Jax. (Feet) (Meters) (Phase to Phase) ALWAYS inspect platform floor and outrigger... - Page 8 NEVER exceed the load limits set by the including wires and cables. manufacturer. Use only the Material Lifting Hook, supplied as an option and manufactured by Bil-Jax, ALWAYS engage boom travel latches before towing when lifting materials. Safely stow all tools and trailer.

-

Page 9: Maintenance Safety

ALWAYS consult an authorized Bil-Jax technician if repairs are necessary. ALWAYS turn the key switch OFF and remove key before performing maintenance. -

Page 10: Damaged Equipment Policy

BIL-JAX 36XT DAMAGED EQUIPMENT POLICY Safety Statement At Bil-Jax, we are dedicated to the safety of all users of our products. All Bil-Jax lifts are designed, manufactured and tested to comply with current applicable federal OSHA and ANSI codes and regulations. -

Page 11: Specifications

SPECIFICATIONS Bil-Jax, Inc. is dedicated to the continuous improvement of this and all Bil-Jax products. Therefore, equipment information is subject to change without notice. The following information is based on ideal working conditions. Machine performance may vary based on work environment and on machine options. -

Page 12: Range Of Motion

BIL-JAX 36XT RANGE OF MOTION Figure 2-1. Range of Motion... -

Page 13: Specifications

2 — SPECIFICATIONS SPECIFICATIONS SERIAL NUMBER____________________________ Working Height 43 ft 6 in Outrigger Footprint 13.4 m Length 12 ft 2 in 3.7 m Maximum Platform Height 37 ft 6 in Width 11 ft 4 in 11.4 m 3.4 m Maximum Horizontal Outreach Footpad Diameter 12.5 in From Centerline... -

Page 14: Warranty

A list of those components and their warranties is available upon written request to Bil-Jax. Bil-Jax shall not in any event be liable for the cost of any special, indirect, or consequential damages to any person, product, or thing. Bil-Jax’s maximum liability under this warranty is limited to the amount paid to Bil-Jax for the product. -

Page 15: Equipment Maintenance

It is the practice of Bil-Jax, Inc. to issue Service and/or Safety Bulletins, which may include updates to the information contained in this manual. In such instances, procedures contained in Bil-Jax Service Bulletins or Safety Bulletins supersede the information contained in manuals. -

Page 16: Daily Service Checks

BIL-JAX 36XT DAILY SERVICE CHECKS The following maintenance procedures should be Verify that boom down limit switches operate performed daily or before each operation. correctly. Verify that all decals are correctly applied and in Down limit switches are actuated when the boom is in a fully lowered, stowed position. -

Page 17: Figure 3-2 Hydraulic Reservoir

3 — EQUIPMENT MAINTENANCE Inspect hydraulic system and fluid levels. Check all hydraulic hoses and fittings for leaks and damage. Tighten or replace as necessary to prevent hydraulic oil or pressure loss. The hydraulic oil level should be checked with the booms down, all outriggers raised and the trailer wheels on a level surface. -

Page 18: Weekly Service Checks

BIL-JAX 36XT WEEKLY SERVICE CHECKS Perform the following service checks at least once each week in addition to all recommended Daily Service Checks: Check Battery electrolyte level. If electrolyte level is low, add enough water to bring the electrolyte level to the top of the plates. -

Page 19: Monthly Service Checks

3 — EQUIPMENT MAINTENANCE MONTHLY SERVICE CHECKS Perform the following service checks at least once each month: Clean all battery terminals. Check battery for loose connections or damaged wires. Verify proper operation of manual lowering valves and hand pump Refer to Section 3 for manual boom operating procedures. -

Page 20: Annual Service Checks

BIL-JAX 36XT ANNUAL SERVICE CHECKS Perform the following service checks at least once Check slew bearing for wear or damage. each year: Check bolts for wear or damage. Replace Hydraulic Oil and Oil Filter. With the boom lift fully retracted, measure the distance between the slew ring gear and the Drain hydraulic reservoir, clean and replace oil. -

Page 21: Structural Inspection

3 — EQUIPMENT MAINTENANCE STRUCTURAL INSPECTION ADDITIONAL SERVICE INFORMATION A comprehensive structural inspection of the unit shall be performed under any of the following Seals on hydraulic cylinders should be replaced every five conditions. years or as indicated by machine performance. Ten years from the date of manufacture and every All service checks should be performed on a machine that five years thereafter. -

Page 22: Troubleshooting

BIL-JAX 36XT TROUBLESHOOTING Refer to Table 3-2 for basic troubleshooting operations. Additional information can be found in the Bil-Jax Model 45XA Operator’s Manual. Contact the Bil-Jax Service Department with any questions or before attempting any advanced troubleshooting operations. Table 3-1. Troubleshooting Steps... -

Page 23: Error Code Definitions

3 — EQUIPMENT MAINTENANCE ERROR CODE DEFINITIONS The DISPLAY PANEL located on the ground control panel indicates the present operating status of the boom lift. If an error condition is detected by the control processor during start-up or operation, the appropriate error code will be displayed on this panel. - Page 24 BIL-JAX 36XT ERROR MESSAGE DEFINITION OF ERROR COMMENTS 031 OPEN CIRCUIT JIB DOWN A load of less than 70mA detected when jib down Check for faulty jib down solenoid circuit was energized coil and wiring. 032 SHORTED CIRCUIT JIB Excessive load detected when jib down circuit...

- Page 25 3 — EQUIPMENT MAINTENANCE ERROR MESSAGE DEFINITION OF ERROR COMMENTS 056 SHORTED CIRCUIT Excessive load detected in right front outrigger Check for faulty solenoid RF OUTRIGGER circuit on power-up. coil/wiring at outrigger. 057 OPEN CIRCUIT A load of less than 70mA detected in left rear Check for faulty solenoid LR OUTRIGGER outrigger circuit on power-up.

- Page 26 BIL-JAX 36XT...

-

Page 27: Cylinder Replacement

Perform all maintenance procedures only in an area that is well-lit and well-ventilated. Bil-Jax, Inc. is not responsible for personal injury or property damage resulting from the improper use of equipment or failure to follow all procedures and related safety precautions. -

Page 28: Lift Cylinder Replacement

BIL-JAX 36XT LIFT CYLINDER REPLACEMENT Use the following procedure to remove and replace hoses to prevent leakage. Plug or cap exposed hose fittings and cylinder ports. faulty or damaged hydraulic cylinders on the boom lift: At the base of the cylinder, unbolt and remove retainer plate from each side of the pivot pin. -

Page 29: Outrigger Cylinder Replacement

4 — CYLINDER REPLACEMENT OUTRIGGER CYLINDER REPLACEMENT Unplug the cylinder valve solenoid. Use the following procedure to remove and replace faulty or damaged hydraulic cylinders on the Place absorbent cloths below the cylinder ports and outriggers: detach hydraulic hoses from the cylinder. Elevate hoses to prevent leakage. - Page 30 BIL-JAX 36XT...

-

Page 31: Replacement Decals

REPLACEMENT DECALS Decals contain information that is required for the safe and proper use of the aerial work platform. Decals should be considered necessary components of the machine and should be checked before each use to verify that they are correctly attached and legible. Use the following guides to find the correct location of all decals. -

Page 32: Table 5-1 Replacement Decal Descriptions

B06-00-0062 NOTICE: AC Power B06-00-0503 NOTICE: Handle Applications B06-00-0068 NOTICE: Hydraulic System Oil B06-00-0504 NOTICE: Emergency Hand Pump B06-00-0161B Bil-Jax Logo, Black Transfer DANGER: Before Use/Main B06-00-0505 B06-00-0404 WARNING: Outrigger Crush Toe Instruction/Hazards (ground) B06-00-0405 WARNING: Pinch Point B06-00-0506 NOTICE: Emergency Lowering... -

Page 33: Figure 5-1 Decal Locations

5 – DECAL PLACEMENT Figure 5-1. Decal Locations... -

Page 34: Table 5-2 Replacement Decal Descriptions - Ce

B06-00-0505 B06-00-0062 NOTICE: AC Power Instruction/Hazards (ground) B06-00-0068 NOTICE: Hydraulic System Oil B06-00-0506 NOTICE: Emergency Lowering B06-00-0161B Bil-Jax Logo, Black Transfer CAUTION: Manual Boom B06-00-0541 Functions B06-00-0173 Fall Protection Attachment Points B06-00-0545 Bil-Jax Website Transfer B06-00-0404 WARNING: Outrigger Crush Toe... -

Page 35: Figure 5-2 Decal Locations - Ce

5 — REPLACEMENT DECALS Figure 5-2. Decal Placement – CE... - Page 36 BIL-JAX 36XT...

-

Page 37: Material Safety Data

MATERIAL SAFETY DATA The following Material Safety Data Sheets describe the correct procedures for the safe handling of chemical components within the Model 45XA Articulating Boom Lift, as well as any potential health and safety hazards related to these chemicals. Material Safety Data Sheets are included here in accordance with applicable federal and state regulations. - Page 38 BIL-JAX 36XT MATERIAL SAFETY DATA SHEET FOR LEAD ACID BATTERIES, WET, FILLED WITH ACID (Continued) SECTION V -- HEALTH HAZARD DATA Primary Routes of Entry: Inhalation: YES Skin: Ingestion: Health Hazards: Acute EYES, SKIN, RESPIRATORY SYSTEM & DIGESTIVE SYSTEM Chronic: EYES, SKIN, RESPIRATORY SYSTEM &...

- Page 39 6 – MATERIAL SAFETY DATA MATERIAL SAFETY DATA SHEET DEXRON III/MERCON AUTOMATIC TRANSMISSION FLUID (HYDRAULIC OIL) SECTION I -- GENERAL INFORMATION TRADE NAME: CITGO TRANSGARD™ ATF, DEXRON III/MERCON EMERGENCY TELEPHONE NUMBERS: 918.495.4700 (medical); 800.424.9300 (chemical) CHEMICAL FAMILY: AUTOMATIC TRANSMISSION FLUID, LUBRICATING OIL CAS NUMBER: MIXTURE.

-

Page 41: Appendix: Replacement Parts

REPLACEMENT PARTS APPENDIX: Use only parts manufactured and/or authorized by Bil-Jax, Inc. when replacing damaged components. See page 89 for replacement part ordering information. Only personnel properly trained and authorized to operate all equipment and familiar with all boom functions should attempt to repair or replace any part of the boom lift. - Page 42 Assembly Description Page Outrigger Engine Front Rest Front Axle Rear Axle Slew Ring Counterweight Control Compartment Pump Compartment Battery Compartment Cover Boom Cable Track Boom Nose Platform Hydraulic Pump...

- Page 43 Assembly Description Page Boom and Rotation Hydraulic Lines Outrigger Hydraulic Lines Trailer Hydraulic Lines – 4WD Wire Harnesses Manifold Wire Harness Gas Engine Wire Harness Choke/Throttle Solenoid Wire Harness Engine Relays Wire Harness ATC Fuse Holder Start/Stop/Run Wire Harness Generator Switcher Box Wire Assembly –...

- Page 44 OUTRIGGER ASSEMBLY...

- Page 45 OUTRIGGER ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00120 Outrigger Weldment A-00046 Grommet – 1.5 x 1.25 x 1.75 A-00032 Bearing A-00020 Pin, 1.25 x 5.5 A-00019 Pin Retainer, 1.25 0096-0016 Cap Screw, M10 x 25 0096-0041 Hex Nut, Self-Locking, M10 A-00060 Pin, 1.25 x 4.25 A-00138...

- Page 46 ENGINE ASSEMBLY (I) 16 17...

- Page 47 ENGINE ASSEMBLY (I) PARTS LIST Item No. Part No. Description Qty. A-01063 Cover Front 0096-0014 Cap Screw, M10 x 20 0096-0041 Hex Nut, Self-Locking, M10 A-01064 Cover Top A-01067 Cover Side – Left A-01069 Cover Side – Right 0096-0001 Cap Screw, M6 x 16 0096-0039 Hex Nut, Self-Locking, M6 B42-01-1006...

- Page 48 ENGINE ASSEMBLY (II) 31 32...

- Page 49 ENGINE ASSEMBLY (II) PARTS LIST Item No. Part No. Description Qty. A-01046 Engine 21HP (See Manufacturer’s Literature) 0096-0098 Cap Screw, M8 x 35 0096-0040 Hex Nut, Self-Locking, M8 A-01048 Pump – Dual – 4.5 GPM A-01055 Dual Pump Mount 0096-0110 Cap Screw, M10 x 110 0096-0093 Washer, M10...

- Page 50 FRONT REST ASSEMBLY...

- Page 51 FRONT REST ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-03145 Front Rest Weldment 0096-0024 Cap Screw, M12 x 100 0096-0042 Hex Nut, Self-Locking, M12 A-00157 Front Rest Pad 0096-0017 Cap Screw, M10 x 30 0096-0041 Hex Nut, Self-Locking, M10 A-00159 Boom Latch 0096-0016...

- Page 52 FRONT AXLE ASSEMBLY...

- Page 53 FRONT AXLE ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-01010 Front Axle Weldment – 4WD A-01097 Bushing, 1.5” OD x 1.25” ID A-01020 Front Yoke – Left A-01021 Front Yoke – Right A-01070 Pin – 1.25” x 1.625” A-00019 Pin Retainer –...

- Page 54 REAR AXLE ASSEMBLY...

- Page 55 REAR AXLE ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00175 Hydraulic Cover 0096-0010 Cap Screw, M8 x 20 0096-0067 Clip Nut, M8 A-01032 Hydraulic Motor – Rear 0096-0024 Cap Screw, M12 x 100 0096-0042 Hex Nut, Self-Locking, M12 A-01037 Axle Cover...

- Page 56 SLEW RING ASSEMBLY...

- Page 57 SLEW RING ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-02189 Slew Assembly and Adapter Slew Ring Slew Ring Drive A-00149 Base Ring Adapter 0090-0461 Cap Screw, 1/2-13 x 2 0090-0212 Lock Washer, 1/2 0096-0033 Flat Head Cap Screw, M16 x 35 0096-0054 Flat Head Cap Screw, M16 x 50 0090-0643...

- Page 58 COUNTERWEIGHT ASSEMBLY...

- Page 59 COUNTERWEIGHT ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00270 Counterweight 0096-0065 Cap Screw, M20 x 80 0096-0045 Hex Nut, Self-Locking, M20...

- Page 60 CONTROL COMPARTMENT ASSEMBLY 17 18 19 20...

- Page 61 CONTROL COMPARTMENT ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00712 Lower Control Box A-00233 Lower Control Mount A-00290 Cover Stop Bracket 0096-0016 Cap Screw, M10 x 25 0096-0041 Hex Nut, Self-Locking, M10 A-00295 Level Sensor 0096-0002 Cap Screw, M6 x 20 0096-0039 Hex Nut, Self-Locking, M6 A-00287...

- Page 62 PUMP COMPARTMENT ASSEMBLY...

- Page 63 PUMP COMPARTMENT PARTS LIST Item No. Part No. Description Qty. A-00268 Tire Iron/Jack Handle B04-07-0033 Clamp 0096-0001 Cap Screw, M6 x 16 0096-0039 Hex Nut, Self-Locking, M6 A-00290 Cover Stop Bracket 0096-0002 Cap Screw, M6 x 20 0096-0014 Cap Screw, M10 x 20...

- Page 64 BATTERY COMPARTMENT ASSEMBLY 26 27...

- Page 65 BATTERY COMPARTMENT ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00215 Battery Box Weldment – Left A-00220 Battery Box Weldment – Right A-00278 Battery Hinge Pin 0096-0050 Washer, Flat, M16 0090-0147 Cotter Pin A-00271 Battery Clamp 0096-0010 Cap Screw, M8 x 20 0096-0040 Hex Nut, Self-Locking, M8 A-00219...

- Page 66 COVER ASSEMBLY...

- Page 67 COVER ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-03240 Cover – Left A-03239 Cover – Right A-00228 Cover Brace A-00252 Hinge 0096-0002 Cap Screw, M6 x 20 0096-0039 Hex Nut, Self-Locking, M6 0090-1080 Pop Rivet A-00258 Controls Cover – Left Side B42-01-1002 Hinge, Controls Cover A-00292...

- Page 68 BOOM ASSEMBLY (I)

- Page 69 BOOM ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00552 Hydraulic Master Cylinder A-00024 Pin, .75 x 8.5 A-00017 Pin Retainer – .75 0096-0016 Cap Screw, M10 x 25 0096-0041 Hex Nut, Self-Locking, M10 A-00026 Pin, .75 x 7.0 A-00551 Hydraulic Boom Cylinder A-00021...

- Page 70 BOOM ASSEMBLY (II)

- Page 71 BOOM ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00510 Telescopic Boom Tube A-00550 Hydraulic Extension Cylinder A-00535 Slider 0096-0018 Cap Screw, M10 x 40 0096-0041 Hex Nut, Self-Locking, M10 A-00032 Bearing 0096-0033 Flat Head Cap Screw, M16 x 35 A-00027 Pin, .75 x 7.0 A-00017...

- Page 72 CABLE TRACK ASSEMBLY...

- Page 73 CABLE TRACK ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00531 Slide Tube 0096-0010 Cap Screw, M8 x 20 0096-0040 Hex Nut, Self-Locking, M8 A-00532 Tube Slider A-00529 Tube Slider Back 0096-0018 Cap Screw, M10 x 40 0096-0017 Cap Screw, M10 x 30 0096-0041 Hex Nut, Self-Locking, M10 B00-00-0031...

- Page 74 BOOM NOSE ASSEMBLY 25 26 10 11...

- Page 75 BOOM NOSE ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-00979 Bulkhead Mount 0096-0016 Cap Screw, M10 x 25 A-00601 Platform Pivot Weldment A-00025 Pin, 1.0 x 6.5 A-00018 Pin Retainer – 1.0 0096-0041 Hex Nut, Self-Locking, M10 0096-0015 Socket Head Cap Screw, M10 x 20 A-00033 Bearing...

- Page 76 PLATFORM ASSEMBLY...

- Page 77 PLATFORM ASSEMBLY PARTS LIST Item No. Part No. Description Qty. A-03350 Platform Weldment – 5’ A-03359 Platform Floor 0096-0102 Cap Screw, M8 x 25 0096-0040 Hex Nut, Self-Locking, M8 A-03361 Upper Control Box Mount 0096-0016 Cap Screw, M10 x 25 0096-0041 Hex Nut, Self-Locking, M10 A-00466...

- Page 78 PUMP ASSEMBLY (A-00254)

- Page 79 PUMP ASSEMBLY PARTS LIST Item No. Part No. Description Qty. B02-15-0496 Manifold, Valve Housing B02-14-0108 Valve, Counterbalance B02-15-0472 Manual Pump, Extend/Retract/Rotate B02-14-0089 Valve, Cartridge (Outrigger Check) B02-14-0109 Valve, Cartridge (Outrigger) B02-14-0091 Valve, Check B02-14-0110 Valve, Check B02-14-0094 Valve, Proportional B02-14-0095 Coil Sterling, Proportional Valve B02-14-0111 Valve, Relief...

- Page 80 PUMP ASSEMBLY, CONTINUED...

- Page 81 PUMP ASSEMBLY PARTS LIST, CONTINUED Item No. Part No. Description Qty. B02-15-0513 Reservoir B02-15-0470 Pump Assembly, 2.09 CCM B02-15-0471 Motor, Pump, 24 VDC B02-15-0500 Coupling, .875 x 2.795 B02-15-0501 Filter, Hydraulic B02-15-0476 Sight Glass B02-15-0477 Socket Head Cap Screw, M8 x 85 B02-02-0247 Fitting, Plug, M14 x 1.5 x 5.8 B02-15-0478...

- Page 82 BOOM AND ROTATION HYDRAULIC LINES (A-00269)

- Page 83 BOOM AND ROTATION HYDRAULIC LINES PARTS LISTS Item No. Part No. Description Fittings B02-01-0274 #4 x 42” Hydraulic Hose 4-6 FFORX 4-4 FFORX B02-01-0275 #4 x 42” Hydraulic Hose 4-6 FFORX 4-4 FFORX B02-01-0276 #6 x 66” Hydraulic Hose 6-6 FFORX 6-6 FFORX B02-01-0277 #6 x 66”...

- Page 84 OUTRIGGER HYDRAULIC LINES (A-03182) OUTRIGGER HYDRAULIC LINES PARTS LIST Item No. Part No. Description Qty. B02-01-0213 #4 x 28” Hydraulic Hose B02-01-0214 #4 x 28” Hydraulic Hose B02-01-0215 #6 x 56” Hydraulic Hose B02-01-0216 #6 x 56” Hydraulic Hose B02-01-0219 #6 x 28”...

- Page 85 TRAILER HYDRAULIC LINES – 4WD (A-01075)

- Page 86 TRAILER HYDRAULIC LINES PARTS LISTS Item No. Part No. Description B02-01-0402 #10 x 28” Hydraulic Hose B02-01-0401 #8 x 154” Hydraulic Hose B02-01-0398 #8 x 16” Hydraulic Hose B02-01-0400 #8 x 24” Hydraulic Hose B02-01-0399 #8 x 18” Hydraulic Hose B02-01-0386 #6 x 30”...

- Page 87 FITTINGS Part No. Description Qty. B02-02-0259 #6 MORFS - #6 MORB, STR B02-02-0293 #8 MORFS - #8 MORB, STR B02-02-0260 #6 MORFS - #6 MORB, 90º B02-02-0287 #4 MORFS - #4 MORB, STR B02-02-0288 #4 MORFS - #4 MORB, 90º B02-02-0289 #4 MORFS, Tee B02-02-0294...

- Page 88 WIRE HARNESSES Upper Control Platform Plug Motor Motor Cntl Cntl P4 & P5 Platform Connector Connector Turntable Connector Analog Connector Lift/Engine Connector Prop Coil Strobe Valve Level Prim Sensor Boom Boom Motor Motor Pump Controller Controller Main Speed Enable Speed Enable Press Switch...

- Page 89 MANIFOLD WIRE HARNESS (A-00785) Deutsch Term. 0462-201-16141 Deutsch Orange DT06-2S Wires Label Wires 2 Pin Plug White W2S Wedge Connected Both Ends Wire Color & Sealed Green Orange 12020786 Blue 6 Pin Male Conn White 1208089040 Green White/B Male Term 12015323 9"...

- Page 90 CHOKE /THROTTLE SOLENOID WIRE HARNESS (A-01042) 1" A-01042 Label Rev- Put Wires Weather Pack FM Term in 16" 12089188 Split Cable Seal tubing 12015323 FM Housing Heat Seal 12015792 Both ends 20" 18ga TXL Or Equivalent ENGINE RELAYS WIRE HARNESS (A-01044) Solder inline &...

- Page 91 ATC FUSE HOLDER (A-01049) ATC Fuse Holder Waytek # 46278 or Equivalent 5/16" Ring ¼” Female Spade Ins Term 4"- 6" Leads 4"- 6" Leads 12 ga Wire 12 ga Wire START/STOP/RUN WIRE HARNESS (A-01098) 2" A-01098 Label Rev - Split Tube Wrap 10"...

- Page 92 GENERATOR SWITCHER BOX ASSEMBLY (A-03040) Box-A-01015 B01-06-0056 B01-01-0180 30 Amp Relay B01-10-0354 DPST – NO 20 Amp Circuit Breaker Allied Electronics W/.250 Male Spade Terminal #850-0345 Allied Electronics Or Equivilant #886-0036 Or Equivilant Ground Stud B W G B W G Cord Grip Heyco #3231 Or Equivilant...

- Page 93 IEC CORD MALE – US MARKETS (A-03042) 18" A-03042 SO cable or Label Equivalent North America Minimum Requirements 120V Male Plug IEC 90 Degree Plug Current 15 AMP Interpower IEC 60320 C19 Voltage 120/240VAC Mold 012 GENERATOR 110V WIRE HARNESS (A-03043) 12-3 SO Or Equivilant .0625"...

- Page 94 CORD ASSEMBLY 110V GENERATOR (B01-01-0178) 24" ¼” Female Spade B01-01-0178 ¼” Female Spade 14-3 #10 Ring Terminal SO or Equivalent Delphi Weather Pack 4" 12015793 3 Pin Female Housing Label 12124580 Female Terminal 12/14ga 12010293 Seal 12/14ga CORD ASSEMBLY GENERATOR SWITCH (B01-01-0179) 28"...

- Page 95 SWITCHER BOX ASSEMBLY – CE MODELS (A-03040CE) Box-A-01015 B01-01-0180 B01-06-0056 30 Amp Relay DPST – NO B01-10-0354 Allied Electronics 20 Amp Circuit Breaker W/.250 Male Spade Terminal #850-0345 Allied Electronics Or Equivilant #886-0036 Or Equivilant B W G G W B Cord Grip Heyco #3231 Or Equivilant...

- Page 96 PUMP AND CYLINDER WIRE HARNESS (A-00716)

- Page 97 OUTRIGGER SWITCH & COIL WIRE HARNESS (A-00746)

- Page 98 ANALOG HARNESS (A-00715) 770680 Label Individual A-00715 Wire Labels AMP 770520-1 1" Pump Speed Signal ¼” FM Spade Insulated 3' (36") 18 ga Green Motor Cntrl Enab ¼” FM Spade Insulated 15" Loom 3' (36") 18 ga Yellow Ground Weather Pack Housing 12010973 2 Pin Housing 12"...

- Page 99 PLATFORM-GROUND COMMUNICATION CABLE (A-00714)

- Page 100 MATERIAL LIFT HOOK ASSEMBLY (OPTION A-00846)

- Page 101 MATERIAL LIFT HOOK PARTS LIST Item No. Part No. Description Qty. A-00977 Platform Mount Weldment – LS A-00982 Load Sense Weldment 0096-0055 Cap Screw, M12 x 190 0096-0042 Hex Nut, Self-Locking, M12 A-00988-1 Load Cell 0096-0089 Cap Screw, M12 x 65 A-00990A Load Sense Spacer A A-00990B...

- Page 102 BATTERY LAYOUT Motor 0-5V Enable Controller Drive 200 AMP Fuse Motor Pump Contactor 24VDC 100AMP B01-06-0058 200 AMP Fuse B+ M- Enable 0-5V Main Pump Motor Contactor 24VDC 100AMP B01-06-0058 Item No. Kit No. A-00272 30” Red, 2 Gauge, 5/16 Ring – Lug 45”...

-

Page 103: Ordering Replacement Parts

ORDERING REPLACEMENT PARTS To order replacement parts, contact the Bil-Jax Service Department by phone at 800-537-0540, by fax at 419-446-8202 or by email at techsupport@biljax.com. For swift service, always have the part number available, as well as the equipment model and serial number. When ordering parts by fax or email, always provide the above information. - Page 105 NOTES...

- Page 106 Distributed by: 125 Taylor Parkway Archbold, OH 43502 Phone (419) 445-8915 (800) 537-0540 (419) 445-0367 biljax http://www. .com...

Need help?

Do you have a question about the X-BOOM 36XT and is the answer not in the manual?

Questions and answers