Subscribe to Our Youtube Channel

Summary of Contents for Bil-Jax ODYSSEY 34

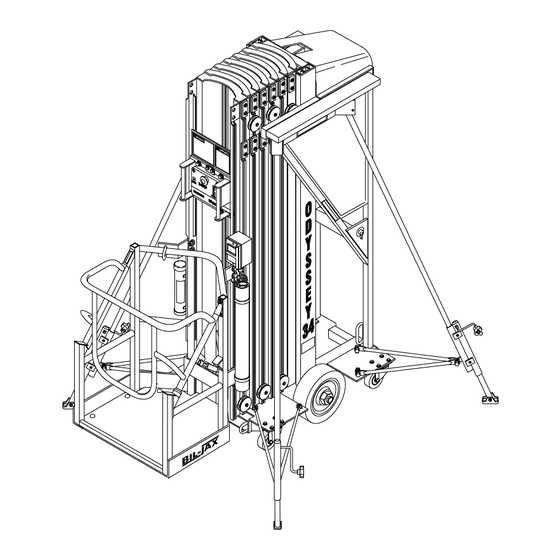

- Page 1 Operation and Maintenance Manual AERIAL WORK PLATFORMS AERIAL WORK PLATFORMS AERIAL WORK PLATFORMS AERIAL WORK PLATFORMS ODYSSEY 34 Electric Hydraulic Lift Platform B33-01-0071...

- Page 2 TELESCOPIC PERSONNEL LIFT This equipment is designed and manufactured in compliance with the duties, re- sponsibilities, and standards set forth for manufacturers in the ANSI 92.3 standard in effect at the time of manufacture. This equipment will meet or exceed applicable OSHA codes and ANSI A92.3 stan- dards when used in accordance with sections 5, 6, 7, 8, 9 &...

-

Page 3: Table Of Contents

Table of Contents Safety ....................... 1-1 Introduction ..................1-1 Before Operation ................1-3 During Operation................1-4 Maintenance Safety ................1-6 Damaged Equipment Policy ............. 1-7 Introduction ....................2-1 General Description................2-1 Specifications ..................2-2 Warranty..................... 2-2 Operation ......................3-1 Operator Controls................3-1 Normal Operating Procedure............ - Page 4 List of Illustrations Figure 3-1. Receiver ....................3-1 Figure 3-2. Transmitter....................3-2 Figure 3-3. ON/OFF Switch ..................3-3 Figure 3-4. Laser Pointer ................... 3-3 Figure 3-5. Outrigger LEDs on Main Frame ............. 3-4 Figure 3-6. Emergency Lowering Valve..............3-5 Figure 4-1. Lift Chain Lubrication................

- Page 5 List of Tables Table 1-1. Minimum Safe Approach Distances ............1-4 Table 2-1. Specifications..................2-2 Table 4-1. Daily/Weekly Service Checks ..............4-1 Table 4-2. Monthly Service Checks ................. 4-2 Table 4-3. Troubleshooting Chart ................4-15 Table 5-1. Replacement Decals................5-1 Table 6-1.

-

Page 7: Safety

The information contained herein is not to be considered as legal advice and is intended for informational purposes only. This information is offered to alert Bil-Jax customers to procedures that may be of concern to them. - Page 8 ODYSSEY 34 Safety Notes This manual contains DANGERS, WARNINGS, CAUTIONS, and NOTES that must be followed to prevent the possibility of improper service, damage to the equipment, or per- sonal injury. DANGER Dangers warn of equipment operation near electrical power lines that could lead to personal injury or death.

-

Page 9: Before Operation

1 — SAFETY BEFORE OPERATION Ensure the following general safety precautions are followed before operating the Odyssey 34 lift. • ALWAYS survey the usage area for potential hazards such as untampered earth fills, unlevel surfaces, overhead obstructions, and electrically charged conductors or wires. -

Page 10: During Operation

ODYSSEY 34 DURING OPERATION Ensure the following general safety precautions are followed during the operation of the Odyssey 34 lift. DANGER This machine is not insulated for use near electrical power lines and DOES NOT provide protection from contact with or close proximity to any electrically charged conductor. - Page 11 1 — SAFETY • NEVER allow electrode contact with any part of the cage platform if welding is being performed by a worker from the cage platform. • NEVER use without the outriggers fully based on the floor. • NEVER override or by-pass manufacturer's safety devices. •...

-

Page 12: Maintenance Safety

Battery Maintenance Ensure the following general safety precautions are followed when battery maintenance is being performed on the Odyssey 34 lift. • ALWAYS check battery acid level daily. Check battery test indicator for proper state of charge on maintenance free batteries before using lift. -

Page 13: Damaged Equipment Policy

Federal OSHA and ANSI codes and regulations. Damage Policy There may be occasions when a Bil-Jax lift is involved in an incident that results in struc- tural damage to the lift. This can seriously compromise the ability of the lift to perform in a safe manner. - Page 14 ODYSSEY 34...

-

Page 15: Introduction

Emergency lowering of the platform is accomplished by means of a manual control valve located on the pump/motor unit. The Odyssey 34 lift features a displacement type of cylinder that will not rust or corrode during storage since the cylinder rod is immersed in oil. It is important that the cylinder rod be kept clean and undamaged for the protection of the cylinder head packing. -

Page 16: Specifications

A list of those components and their warranties is available upon written re- quest to Bil-Jax. Bil-Jax shall not in any event be liable for the cost of any special, indirect or consequen- tial damages to anyone, product, or thing. This warranty is in lieu of all other warranties expressed or implied. -

Page 17: Operation

Odyssey 34 lift. When the operator pushes a pushbutton on the platform transmitter, the transmitter sends a signal to the receiver, the receiver proc- esses that signal and controls the various lift functions. -

Page 18: Figure 3-2. Transmitter

ODYSSEY 34 Transmitter The transmitter is located on the mast directly above the platform. The transmitter con- tains four controls, pushbuttons, an pushbutton, and an DOWN ENABLE pushbutton. The controls on the upper control box are used to raise and EMERGENCY STOP lower the unit. -

Page 19: Figure 3-3. On/Off Switch

When the red dot from laser pointer is in the area where you want to work, this is the position you want the Odyssey 34 lift to be located before setting the outriggers. Refer to Figure 3-4. -

Page 20: Normal Operating Procedure

ODYSSEY 34 NORMAL OPERATING PROCEDURE Perform the following procedures to operate the Odyssey 34 lift. Read and follow all safety precautions contained in Section 1 and all responsi- bilities outlined in the ANSI A92.3 reprint contained in Section 7 of this manual. -

Page 21: Emergency Lowering Procedure

EMERGENCY LOWERING PROCEDURE The Odyssey 34 lift is equipped with a manual lowering valve in case of emergency situa- tions to lower the platform. The emergency lowering valve is located on the hydraulic pump. The valve may be accessed through the opening on the side of the machine. To lower the platform, turn the red knob on the valve counterclockwise. - Page 22 ODYSSEY 34...

-

Page 23: Maintenance

Maintenance SCHEDULED SERVICE CHECKS Daily/Weekly Service Checks Perform the following daily/weekly service checks as listed in Table 4-1. Table 4-1. Daily/Weekly Service Checks Daily Service Check before use Weekly Check chain assemblies for split leaves, loose pins, excessive wear, or elongation. Check battery electrolyte level. -

Page 24: Table 4-2. Monthly Service Checks

ODYSSEY 34 Monthly Service Checks Perform the following monthly service checks as listed in Table 4-2. Table 4-2. Monthly Service Checks Every Every Every Every Service Check month 6 months 12 months 48 months Clean battery terminals. Check operation of manual emergency lowering valve. -

Page 25: Lubrication

4 — MAINTENANCE LUBRICATION Lubrication makes operation of the Odyssey 34 lift more efficient and extends the life of the unit. Perform the following lubrication procedures. Oil lift chains with clean 40W oil weekly or as needed. Refer to Figure 4-1. -

Page 26: Figure 4-2. Wheel And Axle Lubrication

ODYSSEY 34 Grease both wheels and axles at the grease fittings on each wheel semiannually with wheel bearing grease. Refer to Figure 4-2. Figure 4-2. Wheel and Axle Lubrication Lubricate the steel mast slides with dry silicone spray semiannually. Apply a light spray coating to the slide surfaces as shown in Figure 4-3. -

Page 27: Hydraulic System

4 — MAINTENANCE HYDRAULIC SYSTEM Hydraulic system maintenance varies by the amount of use and the environment in which the lift is used. Constant attention to keep the oil clean and the reservoir properly filled will help prevent possible damage to the system. Hydraulic System Inspection Check the hydraulic hose and fittings for leaks and damage daily. -

Page 28: Figure 4-4. Pressure Relief Valve Adjustment

ODYSSEY 34 Pressure Relief Valve Reset Perform the following procedure to reset the pressure relief valve. Refer to Figure 4-4. Disconnect the hydraulic hose from the main pressure port. Install a 4000 psi gage into the main pressure port in the pump unit. - Page 29 Hydraulic Cylinder Repair CAUTION Removing the hydraulic cylinder from the Odyssey Lift requires major disassem- bly of the unit. Contact Bil-Jax for assistance before removing the hydraulic cylin- der from the unit. Hydraulic Cylinder Removal It is recommended that Bil-Jax be contacted for assistance before removing the hydraulic cylinder.

- Page 30 ODYSSEY 34 Disassemble and inspect the hydraulic cylinder as follows: Remove retaining ring (14, Figure 4-5) by rotating cylinder head (5) clockwise until the edge of the retaining ring appears in the milled opening of cylinder tube (12). Pull cylinder head (5) assembly off the end of cylinder rod (1) and from cylinder tube (12).

-

Page 31: Figure 4-5. Hydraulic Cylinder Exploded View

4 — MAINTENANCE Install static back-up ring (6) and static o-ring (7) into the static seal groove in the head. Make sure the back-up ring is installed closest to the retaining ring groove. Allow the assembled head to sit 1 hour to allow the seals to return to shape. -

Page 32: Electrical System

ODYSSEY 34 ELECTRICAL SYSTEM Regular maintenance is necessary to keep the electrical system in proper working order. Check daily all electrical wires for cuts, broken wires, potential short circuits, and any other damage. Battery Care and Charging The electric system is designed to provide power for a normal work shift. However, the charge life of the battery pack depends on machine usage. -

Page 33: Lift Chains And Slide Blocks

4 — MAINTENANCE LIFT CHAINS AND SLIDE BLOCKS WARNING Do not operate a unit on which any chain assembly is damaged or in need of re- placement. Operating a unit with a damaged chain can cause severe injury or death to personnel and damage to equipment. Inspect all lift chains daily. - Page 34 If a chain is loose, it will need to be adjusted. After the platform is completely lowered, raise the complete Odyssey 34 lift with a fork lift. Insert the forks into the fork lift openings in the base from the lower control box end.

-

Page 35: Figure 4-8. Slide Block Adjustment

4 — MAINTENANCE Slide Block Adjustment Annually check for wear on the slide blocks and replace or retighten as necessary. If the lift exhibits excessive mast sway, it is probable that the slide blocks need adjustment. The slide blocks should be adjusted so that there is no air gap between the slide block and the mast the slide block is moving against. -

Page 36: Figure 4-9. Guide Peg Adjustment

ODYSSEY 34 Guide Peg Adjustment Annually check for wear on guide pegs (9, Figure 6-1 and 1, Figure 6-2) and replace or retighten as necessary. If any of the masts exhibit excessive side sway, it is probable that the guide pegs need adjustment. The guide pegs should be adjusted so that there is no air gap between the guide peg and the mast. -

Page 37: Troubleshooting

4 — MAINTENANCE TROUBLESHOOTING Table 4-3. Troubleshooting Chart Problem Cause Correction Control panel LEDs will not Low voltage*. Recharge battery or replace if dam- light and audio program aged. ‘Hal’ will not respond. Master power switch turned off. Turn on master power switch. Emergency stop button is activated Pull out on emergency stop button. - Page 38 ODYSSEY 34 Table 4-3. Troubleshooting Chart, Continued Problem Cause Correction Pump/motor will not run button is activated Turn button coun- EMERGENCY STOP EMERGENCY STOP when is selected. (pushed in). terclockwise to deactivate. Motor start relay is not activating. Check voltage at white wire on motor start relay.

-

Page 39: Replacement Decals

B06-00-0289 Hydraulic Fluid Level B06-00-0293 Maximum Capacity….350 Lbs. B06-00-0360 Warning….Tip Over Hazard B06-00-0361 Warning….(Various) B06-00-0362 Warning….(Odyssey™ Instructions) B06-00-0363Y Bil-Jax (Both sides of toe board) B06-00-0364 Odyssey 34 (Vertical transfer decal) B06-00-0365 Danger….Swing down outriggers… B06-00-0366 Caution….Always secure outriggers… B06-00-0367 Warning….Pinch Point... -

Page 40: Figure 5-1. Replacement Decals

ODYSSEY 34 B06-00-0363Y Figure 5-1. Replacement Decals... -

Page 41: Figure 5-2. Decal Locations, Carriage And Base

5 — REPLACEMENT DECALS 0361 0362 0365 0366 0151 0367 0192 0364 SERIAL NO. PLATE 0363Y Figure 5-2. Decal Locations, Carriage and Base... -

Page 42: Figure 5-3. Decal Locations, Continued

ODYSSEY 34 0009 0146 0139 0034 0286 (BELOW ACCESS HOLE IN SIDE COVER) 0360 0189 0293 0135 0289 (ON HYDRAULIC FLUID TANK) Figure 5-3. Decal Locations, Continued... -

Page 43: Parts List

Parts List... -

Page 44: Aluminum Masts Parts List

ODYSSEY 34 ALUMINUM MASTS PARTS LIST Refer to Table 6-1 for the parts list for the aluminum masts. Figure 6-1. Aluminum Masts Exploded View... -

Page 45: Table 6-1. Aluminum Mast Parts List

6 — PARTS LIST Table 6-1. Aluminum Mast Parts List Item No. Part No. Description Mast Assembly, Carriage Mast Assembly Mast Assembly Mast Assembly Mast Assembly Mast Assembly B18-00-0139 Cover, Mast 0090-0344 Screw, 10-24 x 1/2 in. Threadcutting B26-00-0021 Sheave with Bushing, 2 in. B36-01-0025 Axle, 5/8 in., Sheave B07-06-5407... - Page 46 ODYSSEY 34 Figure 6-1. Aluminum Masts Exploded View, Continued...

- Page 47 6 — PARTS LIST Table 6-1. Aluminum Masts Parts List, Continued Item No. Part No. Description Mast Assembly, Carriage Mast Assembly Mast Assembly Mast Assembly Mast Assembly Mast Assembly B07-06-5437 Bracket, Cable 0090-0927 Screw, Socket Head, 1/4-20 x 1 in. B26-00-0020 Sheave, Cable 0090-0472...

-

Page 48: Main (Welded) Mast Parts List

ODYSSEY 34 MAIN (WELDED) MAST PARTS LIST Refer to Table 6-2 for the parts list for the main (welded) mast. Figure 6-2. Main (Welded) Mast Exploded View... -

Page 49: Table 6-2. Main (Welded) Mast Parts List

6 — PARTS LIST Table 6-2. Main (Welded) Mast Parts List Item No. Part No. Description B31-00-0030 Guide Peg B04-07-0108 Axle Bolt, Roller B05-05-0006 Roller B07-06-5386 Plate, Clamping, Roller B07-06-5387 Plate, Mounting, Roller 0090-0363 Screw, Set, 1/4-20 x 3/4 in. B29-00-0138 Plate, Mounting, Bracket 0090-0419... -

Page 50: Mast Cylinder And Slide Blocks Parts List

ODYSSEY 34 MAST CYLINDER AND SLIDE BLOCKS PARTS LIST Refer to Table 6-3 for the parts list for the mast cylinder and slide blocks. Figure 6-3. Mast Cylinder and Slide Blocks Exploded View... -

Page 51: Table 6-3. Mast Cylinder And Slide Blocks Parts List

6 — PARTS LIST Table 6-3. Mast Cylinder and Slide Blocks Parts List Item No. Part No. Description B31-00-0032 Block, Slide 0090-0042 Bolt, 3/8-16 x 1 in. 0090-0210 Washer, Lock, 3/8 in. B07-06-5414 Bracket, Cylinder 0090-0389 Screw, Set, 1/4-20 x 1/2 in. 0090-0403 Screw, 10 x 1 in. -

Page 52: Power Unit And Controls Parts List

ODYSSEY 34 POWER UNIT AND CONTROLS PARTS LIST Refer to Table 6-4 for the parts list for power unit and controls. Figure 6-4. Power Unit and Controls Exploded View 6-10... -

Page 53: Table 6-4. Power Unit And Controls Parts List

6 — PARTS LIST Table 6-4. Power Unit and Controls Parts List Item No. Part No. Description B02-05-0025 Pump, Hydraulic 0090-0210 Washer, Lock, 3/8 in. 0090-0045 Bolt, 3/8-16 x 1-1/2 in. B18-00-0138 Enclosure, Charger B01-10-0003 Receptacle, Flush Mount 0090-0225 Screw 8-32 x 1/2 in. 0090-0419 Washer, Flat, 1/4 in. -

Page 54: Main Frame And Outriggers Parts List

ODYSSEY 34 MAIN FRAME AND OUTRIGGERS PARTS LIST Refer to Table 6-5 for the parts list for the main frame and outriggers. Figure 6-5. Main Frame and Outriggers Exploded View 6-12... -

Page 55: Table 6-5. Main Frame And Outriggers Parts List

6 — PARTS LIST Table 6-5. Main Frame and Outriggers Parts List Item No. Part No. Description B11-01-0091 Frame Weldment, Main B01-03-0042 Switch and LED Assembly 0090-0191 Nut, Jam, Nylon Lock, 1/2-13 B23-00-0004 Guide, Spring B39-00-0039 Spring 0090-0923 Capscrew, 1/2-13 x 3-1/4 in. 0090-0737 Screw, 10-24 x 1-1/4 in. -

Page 56: Platform Parts List

ODYSSEY 34 PLATFORM PARTS LIST Refer to Table 6-6 for the parts list for the platform. Figure 6-6. Platform Exploded View 6-14... -

Page 57: Table 6-6. Platform Parts List

6 — PARTS LIST Table 6-6. Platform Parts List Item No. Part No. Description 0090-0344 Screw, Thread Cutting, 10-24 x 1/2 in. B01-10-0169 Control Box, Upper (Refer to Table 6-9 for Parts Breakdown) 0090-0046 Bolt, 3/8-16 x 1-3/4 in. 0090-0210 Washer, Lock, 3/8 in. -

Page 58: Covers Parts List

ODYSSEY 34 COVERS PARTS LIST Refer to Table 6-7 for the parts list for the cover. Figure 6-7. Covers Exploded View 6-16... -

Page 59: Table 6-7. Covers Parts List

6 — PARTS LIST Table 6-7. Covers Parts List Item No. Part No. Description B18-00-0142 Cover, Right 0090-0159 Nut, 1/4-20 B34-00-0006 Trimlok, 1/8 in. 0090-0344 Screw, Thread Cutting, 10-24 x 1/2 in. B18-00-0140 Cover, Back B18-00-0141 Cover, Left B05-000-0028 Cord, Outrigger Tie-Down B04-07-0032 Clamp, Cable, DG-6 0090-0183... -

Page 60: Jack Assembly Parts List

ODYSSEY 34 JACK ASSEMBLY PARTS LIST Refer to Table 6-8 for the parts list for the jack assembly. Figure 6-8. Jack Assembly Exploded View 6-18... -

Page 61: Table 6-8. Jack Assembly Parts List

6 — PARTS LIST Table 6-8. Jack Assembly Parts List Item No. Part No. Description B00-00-0123 Cap, Plastic B46-00-0030 Handle Kit Bushing Handle Groove Pin B22-00-0012 Bevel Gear Kit Bushing Groove Pin Bevel Gear, Vertical Bevel Gear, Horizontal Dowel Pin Washer, 0.53 ID x 1.06 OD B22-00-0013 Support Plate Kit... -

Page 62: Upper Control (B01-10-0169) Parts List

ODYSSEY 34 UPPER CONTROL (B01-10-0169) PARTS LIST Refer to Table 6-9 for the parts list for the upper control (Transmitter). 7, 8 Figure 6-9. Upper Control (Transmitter) Table 6-9. Upper Control (Transmitter) Parts List Item No. Part No. Description B06-00-0370... -

Page 63: 6-10 Lower Control (B01-10-0170) Parts List

6 — PARTS LIST 6-10 LOWER CONTROL (B01-10-0170) PARTS LIST Refer to Table 6-10 for the parts list for the lower control (Receiver). 10, 11 Figure 6-10. Lower Control (Receiver) Table 6-10. Lower Control (Receiver) Parts List Item No. Part No. Description B01-01-0125 Cable, Extender, 18 in. -

Page 64: 6-11 Hydraulic Unit Parts List

ODYSSEY 34 6-11 HYDRAULIC UNIT PARTS LIST #20 AWG WIRE, 6.25" LENGTH GROUND SCREW 5/16 TERM. (+ BATT.) BLACK GROUND YELLOW BLACK 12.15 19.79 9/16 SAE PORT 9/16 SAE AUX. RETURN PORT PRESSURE-RETURN 1.734 12 VDC N.C. POPPET VALVE N.O. POPPET... -

Page 65: Table 6-11. Hydraulic Unit Parts List

6 — PARTS LIST Table 6-11. Hydraulic Unit Parts List Item No. Part No. Description B02-15-0089 Bolt, 5/16 x 3 in., Gr 8 Hex B02-15-0119 Coupling, SAE 9T 020/40 B02-02-0087 Plug, #6 ORM B02-15-0128 Ball, Steel, 3/8 in. B02-15-0091 Seal, Shaft B02-15-0093 Washer, 0.338 x 0.625 x 0.060 in. -

Page 66: 6-12 Hydraulic System Schematic Diagram

ODYSSEY 34 6-12 HYDRAULIC SYSTEM SCHEMATIC DIAGRAM Down Valve Flow Control NO Valve Lift Cylinder B02-03-0019 Flow Control B02-14-0040 Pressure Pump Unit Relief B02-05-0025 DB-1411 Figure 6-12. Hydraulic System Schematic Diagram 6-24... -

Page 67: 6-13 Electrical Schematic

6 — PARTS LIST 6-13 ELECTRICAL SCHEMATIC Figure 6-13. Electrical Schematic 6-25... -

Page 68: 6-14 Electrical Layout

ODYSSEY 34 6-14 ELECTRICAL LAYOUT Figure 6-14. Electrical Layout 6-26... -

Page 69: Ansi Reprint

ANSI Reprint The following sections are reprinted from the ANSI A92.3-1990 code in effect at the time of manufacture. Permission to reprint has been granted by the Scaffold Industry Association. 5. Responsibilities of Dealers 5.1 Basic Principles. Sound principles of safety, training, inspection, maintenance, applications, and operation consistent with all data available regarding the parameters intended use and expected environment shall be applied in the training of operators, in maintenance, application, and operation of the aerial platform with due consideration of... - Page 70 ODYSSEY 34 5.9 Record Retention. Dealer(s) shall retain the following records for at least 3 years: (1) Name and address of the purchaser of each aerial platform by serial number and the date of delivery (2) Records of the person(s) trained upon each delivery of an aerial platform (3) Records of the predelivery preparation performed prior to each delivery.

- Page 71 7 — ANSI REPRINT 6.6 Maintenance Safety Precautions. Before adjustments and repairs are started on an aerial platform, the following precautions shall be taken as applicable: (1) All controls in the "off" position and all operating features secured from inadvertent motion by brakes, blocks, or other means (2) Powerplant stopped and starting means rendered inoperative (3) Platform lowered to the full down position, if possible, or otherwise secured by blocking or cribbing to prevent dropping (4) Hydraulic oil pressure relieved from all...

- Page 72 ODYSSEY 34 7.2 Manuals. Users shall keep and maintain copy(ies) of the operating and maintenance manual(s) required in 4.17 of this standard. The operating manual(s) shall be stored in the location required in 4.18 of this standard. These manuals are considered an integral part of the aerial platform and are vital to communication of necessary safety information to users and operators.

- Page 73 7 — ANSI REPRINT 7.7 Before Operation. Before authorizing an operator to operate an aerial platform, the user shall ensure that the operator has: (1) Been instructed by a qualified person in the intended purpose and function of each control (2) Read and understood the manufacturer's operating instructions and user's safety rules, or been trained by a qualified person on the contents of the manufacturer's operating instructions and user's safety rules (3) Understood by reading or by having a qualified person explain all decals, warnings,...

- Page 74 ODYSSEY 34 7.11.7 Work Area. The operator shall ensure that the area surrounding the aerial platform is clear of personnel and equipment before lowering the platform. 7.11.8 Fueling. The engine shall be shut down while fuel tanks are being filled.

- Page 75 7 — ANSI REPRINT 8.2 Manuals. The operator shall be aware that the operating safety manuals, including the manual that defines the responsibilities of dealers, owners, lessors, lessees, users, and operators are stored on the aerial platform and the location where they are stored. The operator shall be familiar with the manuals stored on the aerial platform and consult them when questions arise with respect to the aerial platform.

- Page 76 ODYSSEY 34 8.10 Warnings and Instructions. The operator and other personnel on the platform shall comply with the requirements in 8.10.1 through 8.10.17. 8.10.1 Personnel Footing. Personnel shall maintain a firm footing on the platform floor while working thereon. Use of planks, ladders, or any other devices on the aerial platform for achieving additional height or reach shall be prohibited.

- Page 77 7 — ANSI REPRINT 9. Responsibilities of Lessors 9.1 Basic Principles. Sound principles of safety, training, inspection, maintenance, application, and operation consistent with all data available regarding the parameters of intended use and expected environment shall be applied in the performance of responsibilities of lessors with due consideration of the knowledge that the unit shall be carrying personnel.

- Page 78 ODYSSEY 34 M.S.A.D. = Minimum Safe Approach Distance (See Table 7-1). DENOTES PROHIBITED ZONE • Do not allow machine, personnel, or conductive materials inside prohibited zone. • Maintain M.S.A.D. from all energized lines and parts as well as those shown.

-

Page 79: Table 7-1. Minimum Safe Approach Distance (M.s.a.d.) To Energized

7 — ANSI REPRINT Table 7-1. Minimum Safe Approach Distance (M.S.A.D.) to energized (exposed or insulated) power lines and parts. Minimum Safe Approach Distance Voltage Range (Phase to Phase) (Feet) (Meters) 0 to 300V Avoid Contact Over 300V to 50KV 3.05 Over 50KV to 200KV 4.60... - Page 80 ODYSSEY 34 7-12...

- Page 81 125 Taylor Parkway Archbold, OH 43502 Phone (419) 445-9675 (800) 527-5333 (419) 445-0367...

Need help?

Do you have a question about the ODYSSEY 34 and is the answer not in the manual?

Questions and answers