Table of Contents

Advertisement

Quick Links

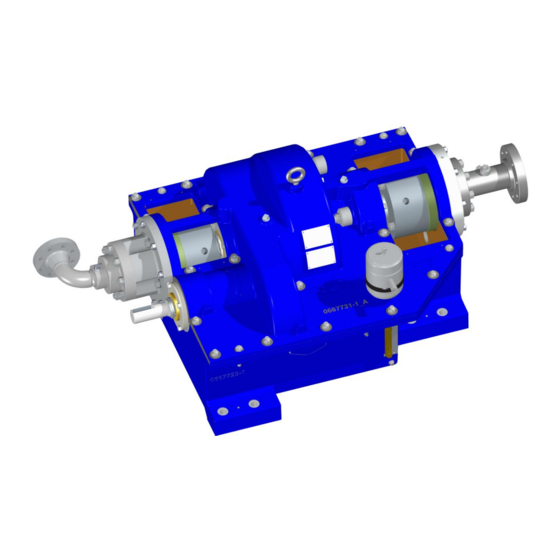

Roto-Jet© RO-FT Pumps

Installation, Operation & Maintenance Manual

Roto-Jet© is a registered trademark.

The document may contain information that is private, confidential and/or privileged. The document must not

be copied in whole or in part, in any form or by any means, and the information in it must not be disclosed to

any person, or used for any purpose other than the specific purpose for which it has been provided, without the

prior written consent of the company.

Document Name: IOM-ROFT-EN

Page | 1

Revision 2

Copyright © 2017, Trillium Pumps USA, All rights reserved

Advertisement

Table of Contents

Summary of Contents for Trillium Roto-Jet RO-FT Series

- Page 1 Document Name: IOM-ROFT-EN Page | 1 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 2 Rev 0 Initial Release Bryce Neilson Kelly Wardell 4-28-15 Rev 1 RO-FT-F Update Kelly Wardell 2-2-17 Rev 2 Branding Update Lane Larsen 1-26-22 Document Name: IOM-ROFT-EN Page | 2 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 3: Table Of Contents

Introduction to RO FT Pump ......................32 Component Descriptions ........................32 5. Transportation and Storage ...................... 33 Transportation Requirements ......................33 5.1.1 Pre transport Requirements......................33 Storage.............................. 33 Document Name: IOM-ROFT-EN Page | 3 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 4 8. Operation ............................ 51 Normal Start Up ..........................51 Operating Checks ..........................51 Pump Shutdown ..........................51 9. Maintenance ..........................52 Maintenance Check Points ........................ 52 Document Name: IOM-ROFT-EN Page | 4 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 5 12.7.1.1 Seal Removal ..........................70 12.7.1.2 Seal Installation .......................... 70 12.7.2 Disengage Seal ..........................71 12.7.3 Engage Seal ..........................73 12.8 Pump assembly ..........................75 Document Name: IOM-ROFT-EN Page | 5 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 6 13.1 Spare Parts ............................. 107 13.2 Ordering Parts ..........................109 Appendix ..........................110 Appendix A Lifting Instructions ......................110 Appendix B Transportation Tie Down Locations .................. 112 Document Name: IOM-ROFT-EN Page | 6 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 7: Introduction

Operation conditions specified may vary from operating conditions from on site. • Illustrations shown in the manual are for reference only and may not match the specified product Document Name: IOM-ROFT-EN Page | 7 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 8: Overview Of The Manual

List of tools required to rebuild pump. Other tools may Tools be required. Parts List of replacement parts and contact information. Appendix Additional information Document Name: IOM-ROFT-EN Page | 8 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 9: Glossary Of Abbreviations

Net Positive Suction Head Installation, Operation & Maintenance MSDS Material Safety Data Sheets General Arrangement International Organization and Standardization Chain of Responsibility Multi Jack Tensioner Document Name: IOM-ROFT-EN Page | 9 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 10: Safety

• Suitable pressure relief must be included in the suction pipe work. Document Name: IOM-ROFT-EN Page | 10 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 11 Vapors leak past seals. Appropriate risk assessment must be made regarding the nature of the product in the pump and necessary safety precautions put in place to protect from exposure to product vapors. Document Name: IOM-ROFT-EN Page | 11 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 12: Operating Conditions

• Liquid waste disposal from servicing of pumps or stagnant water from pumps stored for long periods, causes water and/or soil contamination. Document Name: IOM-ROFT-EN Page | 12 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 13: Emergency Procedures

Ensure you are familiar with site and local procedures and requirements. NOTICE MSDS Always refer to MSDS of substance before handling. Document Name: IOM-ROFT-EN Page | 13 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 14: Technical Data

Double check proper oil level is in place Oil Nameplate On side of case to indicate oil level Abrasive Pumping Recommended fluid to pump Patent Information Indicates patents on pump Document Name: IOM-ROFT-EN Page | 14 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 15: Nameplates

Suction MAWP Suction maximum allowable working pressure for the suction portion Discharge maximum allowable working pressure for the discharge Discharge MAWP portion of pump. Document Name: IOM-ROFT-EN Page | 15 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 16: Model Number Description

28.575 642.7 1060.2 1060.2 1 1/4 31.750 893.5 1097 1487.3 1097 1487.3 NOTICE ANTI- SEIZE COMPOUND Use anti-seize compound when assembling all fasteners. Document Name: IOM-ROFT-EN Page | 16 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 17: Attach Pitot Tube To Seal Plate

Item # 207 MJT Tensioner Bolts Item # 142 12.8.4 Attach Pitot tube to seal plate Rotor Cover Drain Plug Item # 221 17.6 Document Name: IOM-ROFT-EN Page | 17 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 18: Oil Pans And Gear Ratios

OVER FILLING OIL The pump must be stopped to check the oil level. Over-filling will cause oil to drain out of gear case. Document Name: IOM-ROFT-EN Page | 18 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 19: Materials

(A351 CD4MCu) Input Shaft 4140 Carbon Steel (A193) Pitot Tube 17-4-PH* Stainless Steel (A564) or Inconel* (718) Gearbox Casing Carbon Steel (A216 WCB) Document Name: IOM-ROFT-EN Page | 19 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 20: Dimensional Drawings

Roto-Jet© RO-FT Pump Dimensional Drawings Side View Front View Document Name: IOM-ROFT-EN Page | 20 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 21 Roto-Jet© RO-FT Pump Top View Bottom View Document Name: IOM-ROFT-EN Page | 21 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 22: Section Drawings

Roto-Jet© RO-FT Pump Section Drawings Pump Assembly Document Name: IOM-ROFT-EN Page | 22 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 23 NUT,DISCH ELB & SUCT SPOOL STUD,DISCHARGE ELBOW BREATHER,CASE PITOT TUBE SIGHT GLASS, OIL SUMP NUT,TENSIONER O-RING,PUT,DISCH SEAL PLATE STUD,SUCT SPOOL DOWELL PIN, PUT Document Name: IOM-ROFT-EN Page | 23 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 24 DISCHARGE SHAFT SCREW,ROTOR COVER O-RING SUCT/DISCH SHFT OILER RING NUT,HEX O-RING, WSP SEAL SHAFT STUD,ROTOR FLINGER, SUCTION SHAFT DRAIN PLUG,RTR CVR SET SCREW Document Name: IOM-ROFT-EN Page | 24 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 25 Rotating Assembly Drive Assembly Document Name: IOM-ROFT-EN Page | 25 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 26 Roto-Jet© RO-FT Pump Case Assembly Document Name: IOM-ROFT-EN Page | 26 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 27 Roto-Jet© RO-FT Pump Industrial Seal Assembly Seal Plate Assembly Document Name: IOM-ROFT-EN Page | 27 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 28 Roto-Jet© RO-FT Pump Pump Section Pump Side View Document Name: IOM-ROFT-EN Page | 28 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 29: Seal Selection Information

Roto-Jet© RO-FT Pump Pump Front View Seal Selection Information See seal manufacturer O&M for specific seal information General Arrangement Drawings Document Name: IOM-ROFT-EN Page | 29 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 30 Roto-Jet© RO-FT Pump Typical Arrangement Document Name: IOM-ROFT-EN Page | 30 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 31 Roto-Jet© RO-FT Pump Document Name: IOM-ROFT-EN Page | 31 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 32: Description

Shafts are identical except for the length. Below is a visual difference between each. Factory Cartridge Seal Shaft API 682 90mm Cartridge Seal Shaft RO-FT16-1 RO-FT16-2 Document Name: IOM-ROFT-EN Page | 32 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 33: Transportation And Storage

• Do not store spare bearing or rotating assemblies near vibration or in a damp area. Document Name: IOM-ROFT-EN Page | 33 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 34: Rotor Drain Process

These chemicals must be identified before disassembly, and the correct MSDS must be made available and appropriate safety management precautions put in place. Document Name: IOM-ROFT-EN Page | 34 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 35: Long Term Storage (Up To 24 Months)

These provisions are applicable to Roto-Jet© pump proprietary items only. For the appropriate storage procedures for non Roto-Jet© pump items, refer to specific requirements from the manufacturer. Document Name: IOM-ROFT-EN Page | 35 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 36: Installation

Pump Working Envelope The working envelope is a safe working environment for replacing of parts or working on the pump assembly. Recommended X= 6 feet. Document Name: IOM-ROFT-EN Page | 36 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 37: Foundations

6.4A. Then suction flanges, discharge flanges and coupling faces should be checked by means of a level. Corrections may be made for flange or coupling level or plumb by shims under the pump or motor. Document Name: IOM-ROFT-EN Page | 37 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 38: Alignment

When checking alignment or performing any work on the pump or additional components, electrical service must be locked out with an approved lockout and key. Failure to lockout equipment could result death or serious injury Document Name: IOM-ROFT-EN Page | 38 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 39: Alignment Checks

Check the alignment again after any This corrects any misalignments that an mechanical adjustments adjustment may have caused Document Name: IOM-ROFT-EN Page | 39 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 40: Couplings

(Figure 6-8). Never use a straight taper (concentric) (Figure 6-7) reducer in a horizontal suction line, as it tends to form an air pocket in the top of the reducer and the pipe. Document Name: IOM-ROFT-EN Page | 40 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 41: Bolt Tightening Procedure

Always use cross pattern (180 degrees) for tightening bolts, for even pressure. Repeat sequence two-three times. Use calibrated torque wrench for correct tension. See ORQUE ABLES Document Name: IOM-ROFT-EN Page | 41 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 42 Ensure that pipes are aligned with the pump flanges and supported independent of the pump and as close to the pump as practical. Document Name: IOM-ROFT-EN Page | 42 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 43 430(1930) Moment ft-lbf (Nm) Each Nozzle 340 (460) 700 (950) 170 (230) 350 (470) 260 (350) 530 (720) 460 (620) 950 (1280) ft*lbs Document Name: IOM-ROFT-EN Page | 43 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 44: Before Start Up

The Roto-Jet© RO-FT pump has guards (Item# 164, 165) in place to protect the user from bodily harm. Below is a picture of the guards on the package assembly. Document Name: IOM-ROFT-EN Page | 44 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 45: Bypass/Filtration System

A vortex breaker, screen, and/or baffle may be required if tank is small or the bypass return line is too close to the pump suction line. Document Name: IOM-ROFT-EN Page | 45 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 46: Filtration

Consult factory for filtration and special parts recommendations if this level is exceeded. Document Name: IOM-ROFT-EN Page | 46 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 47: Commissioning

Check to be sure pitot tube is secured and held in place. Pitot tube MJT needs to be properly torqued. See ORQUE ABLES Document Name: IOM-ROFT-EN Page | 47 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 48: Motor Setup

Always refer to seal manufacturer and follow manufactures recommendations for seal support systems and control device setup. 7.3.1 Control Devices See seal support documentation for exact manufacturer recommendations. Document Name: IOM-ROFT-EN Page | 48 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 49: Commissioning Procedure

7. Turn the pump OFF a. Turn OFF pump and allow to completely stop. b. Close the Discharge valve c. Turn OFF seal supply, if applicable Document Name: IOM-ROFT-EN Page | 49 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 50: Commissioning Checklist

EFORE TART Alignment LIGNMENT Prime OMMISSIONING ROCEDURE & S Seal Support ECHANICAL UPPORT Guards UARDS Bypass/Filtration YPASS ILTRATION YSTEM Startup- Procedure ORMAL TART Document Name: IOM-ROFT-EN Page | 50 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 51: Operation

Failure to lockout equipment may result in injury. Document Name: IOM-ROFT-EN Page | 51 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 52: Maintenance

Maintenance Check Points Check the indicated parts of the pump periodically as part of the maintenance process as shown Document Name: IOM-ROFT-EN Page | 52 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 53: Vibration Monitoring

& S UPPORT Pitot Tube Annually NNUAL NNUAL NSPECTION NSPECTION Rotor Cover Annually NNUAL NNUAL NSPECTION NSPECTION Vibration Monitoring Contact factory for vibration specifications. Document Name: IOM-ROFT-EN Page | 53 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 54: Annual Inspection

It is recommended during an annual inspection and tear down to replace elastomers that may compress or leak if not in good condition. See for complete list of replacement parts. 13.1 PARE ARTS Document Name: IOM-ROFT-EN Page | 54 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 55: Decommissioning

Cut proof gloves must be worn while handling parts with sharp edges. NOTICE TOOLING Only impact type sockets must be used with air or electric impact tools. Document Name: IOM-ROFT-EN Page | 55 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 56: Decommissioning Steps

8. Drain pump and decontaminate if necessary. 9. If removing pump for rebuild leave feet in place. This will minimize or eliminate need for realignment. Document Name: IOM-ROFT-EN Page | 56 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 57: Disposal

7. All metal and alloys can be recycled if they are decontaminated and are not classified as hazardous material under applicable environmental regulations. Document Name: IOM-ROFT-EN Page | 57 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 58: Troubleshooting

Suction or Discharge Line Plugged Unplug line. Remove all gas from suction line. Re-pipe so air Gas or Vapor Pocket in Suction Line cannot be trapped. Document Name: IOM-ROFT-EN Page | 58 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 59: Not Enough Liquid Delivered At End Delivery Point Or Through Flow Meter

Inlet Cavitation B. Reduce inlet pipe friction losses. C. Increase height of fluid in sump. D. Pressurize suction vessel. E. Lower the pump. Document Name: IOM-ROFT-EN Page | 59 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 60: Not Enough Pressure On Discharge Pressure Gauge

Liquid runs from drain hole Possible Causes Corrective Action Dismantle pump, clean and inspect O-ring grooves. Leakage past O-rings Inspect O-rings. Replace parts as necessary Document Name: IOM-ROFT-EN Page | 60 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 61: Pump Overloads Driver

Better to provide gas separation chamber on suction line near pump. Mechanical failure of critical pump parts Check bearings and pitot tube for damage. Document Name: IOM-ROFT-EN Page | 61 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 62: Pump Vibration

Check pump rotor for evidence of erosion. Displacement of metal within rotor could create an Unbalance of rotating assembly unbalanced condition. Rebalance or replace rotor assembly. Document Name: IOM-ROFT-EN Page | 62 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 63: Bearings Overheat Or Wear Rapidly

Intermittent operation at this point Operating at extremes of pump curve is allowed; however prolonged operation will result in damage of pitot tube. Document Name: IOM-ROFT-EN Page | 63 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 64: Assembly/Disassembly

1. Rotating assembly needs to be balanced to G0.67 as per API 610 12 2. Run out needs to be verified with rotating assembly spec. Continue assembly, see 12.8.1 R OTATING ASSEMBLY Document Name: IOM-ROFT-EN Page | 64 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 65: Gears

Place gear onto shaft making sure not to catch keys in gear slot Tip: While not necessary it is recommended discharge shaft is installed on rotor prior to gear installation Document Name: IOM-ROFT-EN Page | 65 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 66: Gear Removal

Recommended: Use of hydraulic shop press is the recommended procedure for removal. Using such method will reduce chance of damage and injury. Use of bearing puller not recommended. Document Name: IOM-ROFT-EN Page | 66 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 67: Bearings

Cylindrical roller bearings need to be captured with inner race lip. Install spacer (Item #413) and loose ring first. Document Name: IOM-ROFT-EN Page | 67 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 68: Bearing Removal

Inspect shafts after pressing off to make sure tolerances are held and there is no deep scoring in the shaft surface. Replace shaft as necessary Document Name: IOM-ROFT-EN Page | 68 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 69: Bearing Isolator Installation

BEARING ISOLATOR INSTALATION • The Isolator is a one-piece assembly. Don’t try to separate the parts • O-Ring will shear due to tight tolerances. Document Name: IOM-ROFT-EN Page | 69 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 70: Seals

EAL PLATE Install seal bolts and nuts k. Attach pitot tube 12.8.4 A TTACH ITOT TUBE TO SEAL PLATE Engage seal 12.7.3 E NGAGE Document Name: IOM-ROFT-EN Page | 70 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 71: Disengage Seal

Isolate machinery 10.1 ECOMMISSIONING TEPS b. Remove seal piping and flush port (if installed) c. Insert seal clip and lock into place Document Name: IOM-ROFT-EN Page | 71 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 72 Roto-Jet© RO-FT Pump d. Loosen grub screws enough to clear shaft e. Remove 4 seal gland bolts and nuts. Document Name: IOM-ROFT-EN Page | 72 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 73: Engage Seal

These are general instructions. Requirements for your seals may vary. Refer to seal manufacturer instructions for your seal. a. Isolate machinery 10.1 ECOMMISSIONING TEPS b. Tighten 4 gland bolts and nuts c. Tighten grub screws Document Name: IOM-ROFT-EN Page | 73 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 74 Remove seal clips and make sure they clear the rotation of the seal e. Attach seal piping and flush port plug Pressurize seal reservoir (if applicable) Document Name: IOM-ROFT-EN Page | 74 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 75: Pump Assembly

Install completed rotating assembly (Item# 200) into gear case. 12.8.1 R OTATING ASSEMBLY d. Install completed drive shaft assembly (Item# 400) into gear case. 12.8.2 D RIVE HAFT SSEMBLY Document Name: IOM-ROFT-EN Page | 75 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 76 Install drain plug (Item# 102) g. Install all studs ( X-19 Item# 131 Short Studs, X-2 Item# 157 Long Studs) in bottom gear case. Document Name: IOM-ROFT-EN Page | 76 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 77 Fill gear case with recommended oil to proper level. see EAR AND EARING UBRICATION Install lifting eye (Item# 107) on top half of case Document Name: IOM-ROFT-EN Page | 77 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 78 Be sure bearing caps do not interfere with top half of case. Pulling bearing caps away from mating surface will allow sufficient clearance to avoid shearing o-rings. Document Name: IOM-ROFT-EN Page | 78 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 79 Install 4 alignment pins (Item# 130). Drive pins with light blows from hammer. m. Fasten all 4 bolts (Item# 125) in suction bearing plate (Item# 106). Be sure bearing isolator drain hole is pointed down. Document Name: IOM-ROFT-EN Page | 79 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 80 Use shims to be sure shaft axial end play is at least .003” and no more the .010” b. After shim adjustment be sure to torque down shaft nut and lock in place with lock ring Document Name: IOM-ROFT-EN Page | 80 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 81 Fasten all 21 nuts starting with bolting around bearings and continuing as shown. q. Install observation plugs (Item# 134) and drain plug holes Document Name: IOM-ROFT-EN Page | 81 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 82 Engage both suction and discharge seals 12.7.3 E NGAGE w. Install discharge elbow 12.8.5 A TTACH ISCHARGE LBOW Install suction spool 12.8.6 I NSTALL SUCTION SPOOL Document Name: IOM-ROFT-EN Page | 82 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 83: Rotating Assembly

2. Install drain pugs (Item# 221) into rotor cover and torque as required see ORQUE ABLES 3. Install o-ring (Item# 208) onto shaft Document Name: IOM-ROFT-EN Page | 83 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 84 5. Install set screws (Item# 222) into shaft until they touch the rotor cover. 6. Heat oil flinger spacer (Item# 220) to 250°F and install with lip side toward rotor cover. Document Name: IOM-ROFT-EN Page | 84 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 85 Pump b. Install discharge shaft onto rotor 1. Install studs (Item# 213) into rotor (Item# 201) 2. Install o-ring (Item# 208) onto shaft Document Name: IOM-ROFT-EN Page | 85 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 86 Shaft has interference fit. Pull shaft into bore with nuts using alternating pattern. 4. Install set screws (Item# 222) till they touch rotor 5. Install gear (Item# 421)onto shaft 12.5.1 G EAR INSTALLATION Document Name: IOM-ROFT-EN Page | 86 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 87 Bolt pattern is non- symmetric. Be sure bolt pattern is aligned before fastening bolts. 1. Refer 6.6.1 IGHTENING ROCEDURE Refer ORQUE ABLES ****Balance is required at this point **** 12.4 B ALANCING ROCEDURE Document Name: IOM-ROFT-EN Page | 87 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 88 Suction shaft build 1. Install oiler ring (Item# 209) 2. Install bearing installation 12.6.1 B EARING 3. Install o-ring (Item# 212) onto shaft Document Name: IOM-ROFT-EN Page | 88 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 89 Roto-Jet© RO-FT Pump 4. Install bearing spacer (Item# 119) 5. Put bearing spacer ring into place (Item# 155) Document Name: IOM-ROFT-EN Page | 89 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 90 7. Put lock ring (Item# 109) and lock nut (Item# 110) onto shaft and torque as required see ORQUE ABLES 8. Install O-ring (Item# 156) under bearing cap Document Name: IOM-ROFT-EN Page | 90 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 91 Discharge shaft build 1. Install spacer (Item# 160) onto shaft 2. Install bearing installation 12.6.1 B EARING 3. Install o-ring (Item# 212) onto shaft Document Name: IOM-ROFT-EN Page | 91 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 92 Roto-Jet© RO-FT Pump 4. Install bearing spacer (Item# 111) 5. Install wave springs (Item# 114) Document Name: IOM-ROFT-EN Page | 92 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

- Page 93 8. Install O-Ring (Item# 156) under bearing cap h. Install Pitot tube (Item# 139) with O-ring (Item# 134) installed. Assemble Rotor see 12.8.1 R OTATING ASSEMBLY Document Name: IOM-ROFT-EN Page | 93 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 94: Drive Shaft Assembly

Install o-ring (Item# 408) h. Install lock ring (Item# 430) and locknut (Item# 431) onto shaft and hand tight. Install o-ring (Item# 115) under bearing cap Document Name: IOM-ROFT-EN Page | 94 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 95: Attach Seal Plate

Mount seal plate (Item# 105 Suction, Item# 104 Discharge) with seal spacer (Item# 158) installed. d. On Discharge Seal, be sure pitot tube has O-ring installed on taper (Item #143) Document Name: IOM-ROFT-EN Page | 95 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 96: Attach Pitot Tube To Seal Plate

Pull pitot tube (Item# 139) into plate (Item# 104) b. Align pin (Item# 145) with notch in seal plate (Item# 104) at 12 o’clock. Document Name: IOM-ROFT-EN Page | 96 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 97: Attach Discharge Elbow

Center Gasket in place (Item# 122) d. Set spool in place (Item# 120) e. Install nuts (Item# 136) and torque as required see ORQUE ABLES Document Name: IOM-ROFT-EN Page | 97 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 98: Pump Disassembly

EMOVAL h. Remove 4 bolts in drive shaft bearing cap (Item# 125) Remove 4 bolts (Item# 130) in each rotating assembly bearing caps Document Name: IOM-ROFT-EN Page | 98 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 99 Remove rotating assembly using lifting strap Instructions PPENDIX IFTING n. Remove pitot tube and inspect 12.9.6 D ISASSEMBLE SSEMBLE OTATING SSEMBLY o. Assemble pump UMP ASSEMBLY Document Name: IOM-ROFT-EN Page | 99 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 100: Remove Suction Spool

Remove any accessories from access ports c. Unbolt 8 nuts holding spool to suction seal plate d. Remove gasket and clean surfaces. Document Name: IOM-ROFT-EN Page | 100 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 101: Remove Discharge Elbow

Remove any discharge spools or piping attached to the elbow b. Remove any instruments or bypass lines from Accessory Ports c. Remove 8 nuts from elbow Document Name: IOM-ROFT-EN Page | 101 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 102: Detach Pitot Tube From Seal Plate

Note: Elbow will push on MJT. If the elbow is not pushing on the MJT, loosen MJT a few turns. a. Tighten elbow nuts enough to relieve taper fit e. Remove elbow Document Name: IOM-ROFT-EN Page | 102 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 103: Remove Seal Plate

Engage lifting eye e. Remove 8 nuts from seal plate Use jack bolts in lift off holes to drive off seal plate Document Name: IOM-ROFT-EN Page | 103 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 104: Disassemble/Assemble Rotating Assembly

Set rotating assembly into fixture or pipe Tip: 12” pipe spool works well Reengage lifting eyes and lift half of rotor apart d. Remove rotor bolts and lifting eyes Document Name: IOM-ROFT-EN Page | 104 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 105 Bolt rotating assembly together using alternating pattern to ensure faces remain as parallel as possible 12.8.1 R OTATING ASSEMBLY Torque bolts as required 3.2 T ORQUE ABLES Document Name: IOM-ROFT-EN Page | 105 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 106: Suction/Discharge Shaft Removal

Mark point on rotor and shaft to make sure they align correctly b. Remove nuts c. Push shaft off using jack screws. Once shaft is separated from rotor, inspect o-ring and replace if necessary Document Name: IOM-ROFT-EN Page | 106 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 107: Parts

SHIM, DRIVE SHAFT, .005 SHIM, DRIVE SHAFT, .015 BEARING,BALL 55MM ANG CNT BRASS CAGE LOCKWASHER, 55MM LOCKNUT, 55MM BEARING,CYL ROLLER 55MM BRASS CAGE Document Name: IOM-ROFT-EN Page | 107 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 108 SHIM, DRIVE SHAFT, .005 SHIM, DRIVE SHAFT, .015 BEARING,BALL 55MM ANG CNT BRASS CAGE LOCKWASHER, 55MM LOCKNUT, 55MM BEARING,CYL ROLLER 55MM BRASS CAGE Document Name: IOM-ROFT-EN Page | 108 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 109: Ordering Parts

ORIGINAL PARTS Parts will be furnished in original materials unless specified as a material change. All material substitutions should be discussed with the factory. Document Name: IOM-ROFT-EN Page | 109 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... -

Page 110: Appendix

Notice LIFTING COMPONENTS Store all lifting equipment in a dry corrosive free environment All lifting points must be routinely inspected and maintained Document Name: IOM-ROFT-EN Page | 110 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 111 Never lift pump by any other component by use of straps, chains or hooks. Document Name: IOM-ROFT-EN Page | 111 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

-

Page 112: Appendix B Transportation Tie Down Locations

Tie down should be across the base plate or on the lifting lugs. The package should never be tied down over motor, coupling guard, pump or seal pots. Doing so may damage components. Document Name: IOM-ROFT-EN Page | 112 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved... - Page 113 For optimum service and technical assistance, please contact our factory for the distributor or representative nearest to your project: Trillium Pumps USA Tel 801-359-8731 Document Name: IOM-ROFT-EN Page | 113 Revision 2 Copyright © 2017, Trillium Pumps USA, All rights reserved...

Need help?

Do you have a question about the Roto-Jet RO-FT Series and is the answer not in the manual?

Questions and answers