Summary of Contents for Pelton & Crane SPIRIT 3000 ELECTROTORQUE-TLC

- Page 1 INTEGRATED ELECTROtorque TLC-4893 Use & Care Manual For SoftWare version V4.00 and higher...

-

Page 2: Table Of Contents

Table oF ConTenTS Spirit 3000 ElEctrotorquE-tlc uSE & carE gEnEral information ..........................3 SafEty ................................4 DEntal unit tEchnical DEScription ......................7 warranty ...............................7 intEnDED purpoSE of ElEctrotorquE-tlc ..................8 proDuct DEScription ..........................9 control panEl ovErviEw ........................9 tEchnical Data for ElEctrotorquE ....................10 tranSformEr 4881 ..........................13 tEchnical Data for tranSformEr ....................14... -

Page 3: General Information

General InForMaTIon deFInITIon oF SyMbolS ProduCT dISPoSal the following symbols and terms may be used contact your local authorized dealer for proper throughout this manual: disposal of the device to ensure compliance with your local environmental regulations. WarnInG: failure to carefully follow the described procedure may result in damage to the InTerFerenCe WITh eleCTroMedICal equipment and/or injury to the patient/operator. -

Page 4: Safety

SaFeTy please read the safety warnings and instructions before using the device. the manufacturer’s liability is applicable only if the device is used in compliance with the directions and safety warnings provided in this manual. Safety warnings are spread throughout the manual. WarnInG: failure to use protective gloves WarnInG: failure to disinfect can expose operator and patient to cross-... - Page 5 SaFeTy (ConTInued) WarnInG: risk of fatal injury. Explosion WarnInG: malfunctions from hazard. the product is not electromagnetic fields. permitted to be used in areas the product meets the applicable subject an explosion hazard. requirements regarding electromagnetic fields. given the complex interactions WarnInG: improper servicing and care may between equipment and cell phones, the...

- Page 6 SaFeTy (ConTInued) Product-Specific noTe: use only original Kavo replacement parts. after servicing, interventions and repairs of the e-motor, the device must be tested according to iEc 62353-vDE 0751-1 before re-use! WarnInG: Eye hazard from the blue light. the WarnInG: improper use of handpieces light on the Kl motor with mini lED/ can result in injury.

-

Page 7: Dental Unit Technical Description

denTal unIT TeChnICal deSCrIPTIon the dental delivery system is a combination of dental equipment components used to carry, position and control the devices used in the practice of dentistry. it delivers air, water, vacuum and low voltage electricity to the dental patient. a dental unit generally has several components including a control head, cuspidor bowl, vacuum utilities, assistant’s utilities, a multifunction syringe and a junction box. -

Page 8: Intended Purpose Of Electrotorque-Tlc

InTended PurPoSe oF eleCTroTorQue-TlC ELECTROtorque is intended for use in the field of dentistry (medical device). It is a dental treatment device for operating extra-low voltage electric dental motors. it is intended for use in practice rooms (interior use) only; it is not permitted for use in areas where there is a risk of explosion. apply and meet the overarching guidelines and/or national laws, national regulations and the rules of technology for medical devices applicable for startup and use of the Kavo product for the intended purpose. -

Page 9: Product Description

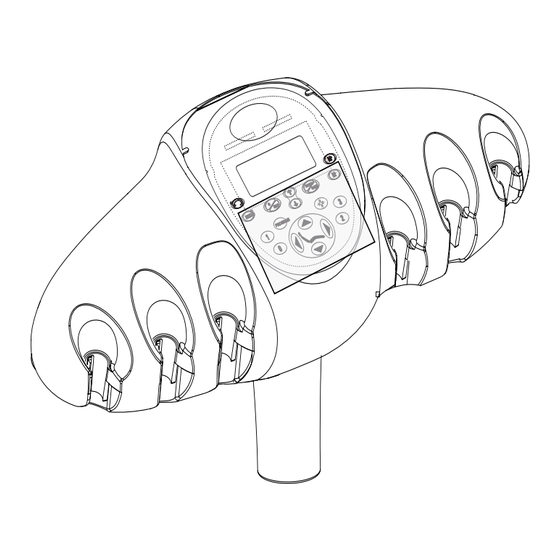

ProduCT deSCrIPTIon the ElEctrotorque-tlc 4893 is a dental treatment unit for operating the dental-electric motor, intra luX motor Kl 702 or 703. Control Panel Overview ENTER ENDO SAVE PROGRAM Reverse mode LED light "Endo mode" key "Reverse mode" key "ENTER / SAVE" key "Memory (M-) down"... -

Page 10: Technical Data For Electrotorque

ProduCT deSCrIPTIon Technical data for eleCTrotorque 4893 Media Supply data TlC System pressure 1.8 - 4.0 bar / 26 - 58 psi Spray air 1.0 - 2.5 bar / 14.5 - 36.2 psi Spray water 0.8 - 2.0 bar / 11.6 - 29 psi cooling air outlet on motor coupling 6 - 10 nl/min. - Page 11 ProduCT deSCrIPTIon- TeChnICal daTa For eleCTroTorQue Technical data for eleCTrotorque 4893 option Motor Speed motor speed range 100 - 40,000 rpm maximum speed for forward mode 40,000 rpm maximum speed for reverse mode 40,000 rpm Motor Torque torque max. 3.0 ncm rated Voltage motor voltage 22 v ac...

- Page 12 ProduCT deSCrIPTIon Requirements, classification protection class overvoltage category contamination level application part type b (in accordance with iEc/En 60601-1) ip class ip40 Intermittent operation operating mode operating time 0.5 minutes interval 9 minutes ambient conditions permissible ambient temperature range +5 °c to +40°c / 41°f to 104°f permissible up to maximum relative humidity 80 % permissible up to a maximum of...

-

Page 13: Transformer 4881

ProduCT deSCrIPTIon Transformer 4881 052505 r04... -

Page 14: Technical Data For Transformer

ProduCT deSCrIPTIon- TeChnICal daTa For TranSForMer note the electrical connection for the transformer must comply with the country-specific regulations and requirements that are in place for medical devices. dimensions and Weight width 87 mm / 3.42 “ height 71 mm / 2.80 “ Depth 147 mm / 5.89 “... -

Page 15: Rating Plate For Transformer

ProduCT deSCrIPTIon- raTInG PlaTe For TranSForMer 4881 Rating plate for transformer 0087.4 Rating plate for transformer 4881 Manufacturer Note: Consult accompanying docu ments and safety instructions Transformer model Operating mode: Intermittent opera tion It has a 1 minute operating time and a 9 minute interval. -

Page 16: Preparation For Use

PreParaTIon For uSe note: ElEctrotorque tlc may only be operated with the intramatic luX Kl 702 or intralux Kl 703 lED and the 4881 transformer. note: a short amount of spray water can leak from a damaged magnetic valve ventilation. the magnetic valve ventilation should be controlled at regular intervals. - Page 17 PreParaTIon For uSe Connecting the Transformer Set the selector switch so that the required voltage, 115v or 230v, can be read. noTe: the electrical connection for the Selector transformer must comply with the Switch country-specific regulations and requirements that are in place for medical devices.

-

Page 18: Operation

oPeraTIon General operation after medical treatment of a patient, let spray air check all input values before use. in the and spray water leak for at least 20 seconds. opErativE mode the motor speed is displayed on screen and in the EnDo mode because of stagnation, water- or air-conveying the trepan speed is displayed on screen. -

Page 19: Operative Mode

oPeraTIon automatic Calibration of the Foot Control the calibration of the foot control to maximal system pressure proceeds automatically in the background (automatic calibration of the foot control). Starting the Motor press the foot control down once as far as it will go (maximal pressure) in order to calibrate the foot control. - Page 20 oPeraTIon Keys Function Select or change speed settings 1 - 6 (M1 - M6). Switch to endodontics mode The LED is turned on when the device is in ENDO mode. Turning SAFEdrive on / off Set OPERATIVE mode The device is in OPERATIVE mode when the LED in the "Endo" does not shine. When the LED in the "Endo"...

- Page 21 oPeraTIon Memory 40,000 30,000 20,000 15,000 10,000 5,000 Briefly press the M- or M+ key to retrieve user speed M1 - M6. Change and save user speed Briefly press the M- or M+ key to select the M1 - M6 memories to be changed. The set speed is displayed.

- Page 22 oPeraTIon Turning SAFEdrive on / off NOTE: The SAFEdrive function is a monitoring function for detection of defective straight and contra-angle handpieces. These can heat up strongly due to additional fric tion and possibly cause burn injuries. KaVo recommends to activate the SAFEdrive function during treatments inside the oral cavity in order to reduce the risk of burn injuries caused by defective straight and contra-angle handpieces.

- Page 23 oPeraTIon ble defects can be detected by continuous monitoring of the idling properties of the handpiece during its use. If the protective function is triggered, the SAFEdrive initially reduces the motor speed and then stops the motor altogether if the excessive load persists. NOTE: SAFEdrive works only with KaVo straight and contra-angle handpieces of the 25LP/25LPA/25LPR/25LCA series.

-

Page 24: Operation Endo

If damage or overheating is evident, replace the handpiece or have it repaired. oPeraTIon Operation ENDO Keys Function Changing parameter values and modes Select or save parameters (M1–M6) Select parameter/mode Switch to OPERATIVE mode NOTE: When switching from OPERATIVE mode to ENDO mode, a small amount of spray water drains. - Page 25 oPeraTIon The LED in the "Endo" key is turned on. The device is in ENDO mode. The message is indicated for 3 seconds in the dis play, if the message has not been deactivated in the USER MENU. Setting the parameters In ENDO mode, six different parameter settings (M1 - M6) can be selected.

- Page 26 oPeraTIon Press the "UP" key to increase the torque. Press the "DOWN" key to reduce the torque. Press the "M-" or "M+" key for more than 2 seconds until you hear a signal. The selected parameter memory was changed. Select torque mode There are three different torque modes in Endo mode: Autoreverse Torque Control only...

- Page 27 oPeraTIon Torque Control only Press the foot pedal. The motor starts. The torque is limited to the set threshold. The speed reduces until it stops depending on the load. The direction of rotation is always to the right. When the set torque threshold is reached, a signal sounds, and the light flashes Press the "CCW"...

-

Page 28: User Menu Operation

oPeraTIon uSer Menu operation the following menu items can be called in the uSEr mEnu. 1. rESEt foot control 2. unit air prESSurE 3. EnDo ratio 4. EnDo chip air 5. warning SignalS 6. factory SEttingS 7. lcD contraSt 8. lcD brightnESS 9. - Page 29 oPeraTIon press the “* / ESc” key to exit the uSEr mEnu. re-adjusting the Foot Control the calibration of the foot control to maximal system pressure proceeds automatically in the background (automatic calibration of the foot control). Minor pressure fluctuations are balanced automatically by this measure.

- Page 30 oPeraTIon Checking device Connection Pressure Select menu item 2. unit air prESSurE in the uSEr mEnu. in the submenu, item 2. unit air prESSurE the current drive pressure on the device is shown by the “bar” unit. this value is governed by the foot control being used and the system pressure.

- Page 31 oPeraTIon Setting Chip air for endo Mode Select menu item 4. Endo chip air in the uSEr mEnu. press the “EntEr / SavE” key to select that menu item. press the “up” or “Down” key to select the chip air setting (on / off).

- Page 32 oPeraTIon resetting user Settings to Factory defaults the user can reset the changed values back to the factory setting. Select menu item 6. factory SEttingS in the uSEr mEnu. press the “EntEr / SavE” key to select that menu item. press the “up”...

- Page 33 oPeraTIon Setting Contrast for display (lCd) Select menu item 7. lcD contraSt in the uSEr mEnu. press the “EntEr / SavE” key to select that menu item. press the “up” or “Down” key to set the required value. Press the “ENTER / SAVE” key to confirm the selection.

- Page 34 oPeraTIon Setting Fiber optic Voltage The fiber optic voltage can be changed to between 3.0 v and 3.6 v only when the motor is switched off. During setting the bulb turns on. noTe: KaVo recommends a fiber optic voltage setting of 3.2 v.

- Page 35 oPeraTIon Press the “ENTER / SAVE” key to confirm the selection. Selecting the Torque display the torque can be shown in ncm or % in the Endo mode: ▪ 1:1 transmission: 100 % = 3 Ncm ▪ 3:1 transmission: 100 % = 8 Ncm WarnInG: Damaged files as a result of incorrect input values.

- Page 36 oPeraTIon Select menu item 12. EnDo warning in the uSEr mEnu. press the “EntEr / SavE” key to select that menu item. press the “up” or “Down” key to activate or deactivate the EnDo warning (on /off). Press the “ENTER / SAVE” key to confirm the selection.

- Page 37 oPeraTIon Setting the language the following menu languages are available: English italian Spanish french german menu item 13. Select languagE in the uSEr mEnu. 13. LANGUAGE ENGLISH press the “EntEr/SavE” button to select the menu item. press the “up” or “Down” key to select the desired language.

- Page 38 oPeraTIon SafEdrive reduces the probability of overheating of defective or poorly maintained handpieces and thus minimizing the risk of burns to the patient. possible defects by continuous monitoring of the idling properties of the handpiece during its use. if the protective function is triggered , the SafEdrive initially reduces the motor speed and then stops the motor altogether if the excessive load persists.

- Page 39 oPeraTIon using SaFedrive when SafEdrive is activated and the instrument head becomes too hot, the message “ovErhEat warning” appears on the ElEctrotorque tlc display. in addition, a periodic warning tone sounds. if the problem continues for more than 5 seconds, the message ovErhEat Error appears, the motor is automatically stopped, and the motor is prevented from restarting.

- Page 40 oPeraTIon Turning the aCTual SPeed display on and off when is the actual SpEED” display is active, the current motor speed is shown while the motor is operating. this display can be turned on or off. menu item 15. Select actual SpEED from the uSEr mEnu.

-

Page 41: Preparation, Cleaning And Disinfecting

PreParaTIon, CleanInG & dISInFeCTInG Preparation methods adapted from DIN EN ISO17664 pelton & crane recommends that only original pelton & crane or Kavo parts be used for the operation or repairs of this product on account of the rigorous safety, functional and dedicated suitability testing which these parts undergo. - Page 42 dISInFeCTInG WarnInG: germ formation. infection. after medical treatment of a patient, let spray air and spray water leak for at least 20 seconds. because of stagnation, water- or air-conveying lines in treatment units must be flushed or blown through before initial operation and after standing times (weekend, public holiday, vacation, etc.) the sterilization of the ElEctrotorque must be effected via the treatment unit in the opErativE mode.

- Page 43 dISInFeCTInG Manual Internal disinfection the disinfection of the ElEctrotorque must be conducted through the treatment centre. connect the ElEctrotorque to the treatment centre. follow the instructions for disinfection of the treatment centre. this product should be used according to the instructions of the manufacturer and the instructions for use of the treatment centre.

-

Page 44: Service

SerVICe pelton & crane recommends the sole use of original pelton & crane and Kavo parts® for operation and repairs as these have been tested extensively for safety, functioning and specific suitability. authorized to repair and service the pelton & crane and Kavo products: •Technicians of Pelton &... - Page 45 SerVICe insert the new Kavo mini lED lamp into the recess such that the contact surface corresponds to that of the mount. Slide the lamp into the mount. place the sleeve on the motor and pull up. noTe: the Kavo mini lED lamp is a semiconductor element and must be operated with direct current only.

-

Page 46: Troubleshooting

TroubleShooTInG notE this product displays error messages and/or instructions optically on its display. Error numbers can be between 1 and 30. the motor is shut off upon any malfunction. System Message: 1 Overload See user manual Examples of error displays if the error message does not disappear or the error is reported again, contact Service. -

Page 47: Electromagnetic Compatibility Information

eleCTroMaGneTIC CoMPaTIbIlITy InForMaTIon MEDICAL ELECTRICAL EQUIPMENT ELECTROMAGNETIC COMPATIBILITY (INSTRUCTIONS FOR USE) ELECTROMAGNETIC COMPATIBILITY Electrical medical devices are subject to special EMC safety measurements and, as a result, the equipment must be installed according to the Pelton and Crane installation instruction manual. PORTABLE ELECTRONIC DEVICES Portable and mobile high frequency electronic communications equipment may interfere with electronic medical devices. - Page 48 eleCTroMaGneTIC CoMPaTIbIlITy InForMaTIon Guidance and manufacturer's declaration-electromagnetic emissions The Model 3000 delivery unit intended for use in the electromagnetic environment specified below The customer or the user of the 3000 delivery unit should ensure that it is used in such an environment.

- Page 49 eleCTroMaGneTIC CoMPaTIbIlITy InForMaTIon Guidance and manufacturer's declaration-electromagnetic immunity The Model 3000 delivery system is intended for use in the electromagnetic environment specified below. The customer or the user of the 3000 delivery system should ensure that it is used in such an environment. Immunity Test Compliance Level IEC60601 Test Level...

- Page 50 eleCTroMaGneTIC CoMPaTIbIlITy InForMaTIon Guidance and manufacturer's declaration-electromagnetic immunity The Model 3000 delivery system is intended for use in the electromagnetic environment specified below. The customer or the user of the 3000 delivery system should ensure that it is used in such an environment. Immunity Test Compliance Level IEC60601 Test Level...

- Page 51 052505 r04...

- Page 52 0473 ©2013 11727 fruehauf Drive p/n 052505 rev. 04, 04/10/13 charlotte, nc, 28273 - uSa printed in uSa we reserve the right to make any alterations which may be due to any technical improvements...

Need help?

Do you have a question about the SPIRIT 3000 ELECTROTORQUE-TLC and is the answer not in the manual?

Questions and answers