Summary of Contents for Flowserve CS

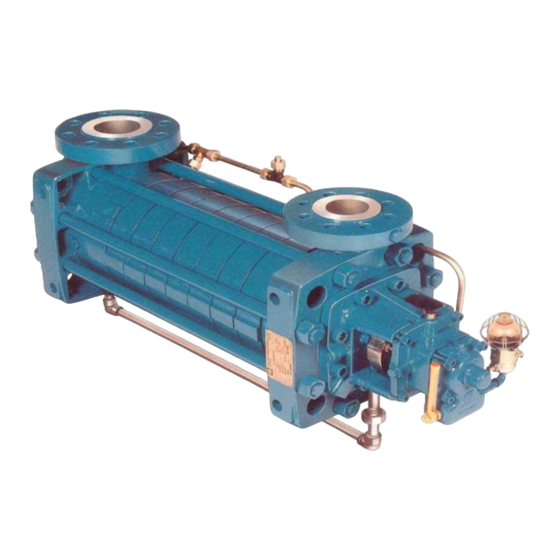

- Page 1 ® Pump Division Type: CS CENTRIFUGAL PUMPS USER INSTRUCTIONS: INSTALLATION, OPERATION, MAINTENANCE User Instructions 923CS036E001 – 08/03...

-

Page 2: Table Of Contents

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 CONTENTS 6.1 Security ............ 37 6.2 Preventive maintenance schedule.... 37 PAGE 6.3 Disassembly and rebuilding...... 39 Cover..............1 6.4 Torque values........... 39 CONTENTS ............. 2 6.5 Coupling ........... 39 INDEX .............. 3 6.6 (Shaft sealing) Packing......40 PREFACE ............ -

Page 3: Index

CS USER INSTRUCTIONS ENGLISH 923CSE001 - 08/03 ® Pre-operational checks ......5.2 ..28 Preventive maintenance schedule ..6.2 ..37 INDEX Prior to installation / operation ....4.2 ..16 SECT. PAGE Protection systems ........4.18 ..27 Additional sources of information ..10.3 ..65 PUMP DESCRIPTION......3 .. -

Page 4: Preface

These instructions are intended to facilitate familiarization with the product and its permitted use. Operating the product in compliance with these Flowserve products are the result of more than a instructions is important to help ensure reliability in century of progressive study and development. Our service and avoid risks. -

Page 5: Copyright

CS USER INSTRUCTIONS ENGLISH 923CSE001 - 08/03 ® select, install or use authorized Flowserve parts and This symbol indicates explosive atmosphere accessories is considered to be misuse. Damage or zone marking according to ATEX. It is used in failure caused by misuse is not covered by safety instructions where non-compliance in the Flowserve's warranty. - Page 6 PIPEWORK BEFORE DISMANTLING THE PUMP mount expansion joints, unless allowed by The appropriate safety precautions should be taken Flowserve in writing, so that their force, due to where the pumped liquids are hazardous. internal pressure, acts on the pump flange.

- Page 7 CS USER INSTRUCTIONS ENGLISH 923CSE001 - 08/03 ® Where Flowserve has supplied only the bare shaft CLEANNESS pump, the Ex rating applies only to the pump. The Oil, grease, and liquids leaks may make slippery party responsible for assembling the pump set shall...

- Page 8 CS USER INSTRUCTIONS ENGLISH 923CSE001 - 08/03 ® 1.6.4.5 Preventing sparks Temperature limit of liquid handled (* Maximum Temperature depending on To prevent a potential hazard from surface class to material and mechanical contact, the coupling guard must be temperature...

-

Page 9: Warning Label

CS USER INSTRUCTIONS ENGLISH 923CSE001 - 08/03 ® 1.7 Warning label 1.8 Specific machine performance Performance data has been supplied separately to the purchaser and should be obtained and retained with these User Instructions if required. 1.9 Noise level When pump noise level exceeds 85 dB... -

Page 10: Transport And Storage

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® 2 TRANSPORT AND STORAGE Shipping documents should be checked to determine satisfactory arrival of any special tools, loose parts, and/or spare parts (if provided), which 2.1 Consignment receipt and unpacking are usually preserved and packed in a box attached Immediately after receipt of the equipment it must to the skid. -

Page 11: Storage

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® It should be noted, that unless otherwise agreed to, Make sure that any equipment used to lift the full responsibility and costs associated with the pump or any of its components is capable of... - Page 12 CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® 2.4.2.3 Storage preferred (dry) inspection, dismantling, restoration, replacement of parts, and re-assembly will be the responsibility of 2.4.2.3.1 Customer Inspection and Maintenance the customer. The customer will supply all The stored equipment is to be placed on a periodic necessary labour, tools, and cranes.

-

Page 13: Recycling And End Of Product Life

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® 2.4.2.4 Storage non-preferred (wet) It is not recommended that the rotor be subjected to extended periods of submergence or wetting prior to start-up. However, it is recognized that in some cases, a long period of time may lapse from installation until commercial operation. -

Page 14: Performance And Operating Limits

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® absolute concentricity with all diametric fits 3.3.7 Balancing device [6210 and 6220] machined at one setting. Flowserve ring section pumps are maintained in complete axial balance during operation by a self- 3.3.3 Shaft [2100]... -

Page 15: Installation

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® • ASTM C-580. Minimum Flexural Strength 26.2 4 INSTALLATION N/mm (3800 psi) • ASTM C-580. Minimum Flexural Secant Modulus It is strongly recommended the 1.2X10 N/mm (1.8X10 psi) installation and commissioning of this equipment be •... -

Page 16: Arrangement Of Foundation Bolt In Foundation

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® 4.4 Arrangement of foundation bolt in There are many methods of installing foundation pump units to their foundations. The correct method Foundation bolts should be located using dimensions depends on the size of the pump unit, its location as shown on General Arrangement drawing. -

Page 17: Equipment Mounting

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® Establish the equipment elevations as shown on the 4.6.2 Soft foot check General Arrangement drawing. The equipment train The pump feet shall be checked for soft feet. The must be leveled prior to grouting to verify final hold down bolts should be torqued to the values alignment can be achieved. - Page 18 CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® Shafts alignment must be correct for successful operation. Rapid wear, noise, vibration and actual damage to the equipment may be caused by shafts misalignment. The shafts must be aligned within the limits given within this section.

-

Page 19: Checking Coupling Alignment

CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® 4.8.3.2 Before alignment The stainless steel shims between the equipment feet and mounting surface should be clean and dry. It is recommended that the pump hold This is especially critical for pumps that have been in down bolting be torqued and the pump be fixed service for some time and need to be realigned. - Page 20 CS USER INSTRUCTIONS ENGLISH 10.06.77.10986 - 12/05 ® 4.11 Rim and Face data sheet Page 21 of 66...

Need help?

Do you have a question about the CS and is the answer not in the manual?

Questions and answers