Table of Contents

Advertisement

Quick Links

Maintenance Manual

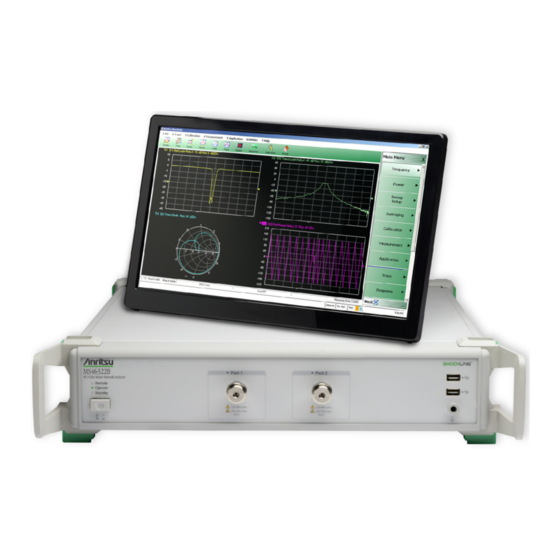

ShockLine™

Vector Network Analyzer

MS46322A

1 MHz to 4 GHz

1 MHz to 8 GHz

1 MHz to 14 GHz

1 MHz to 20 GHz

1 MHz to 30 GHz

1 MHz to 43.5 GHz

MS46322B

1 MHz to 8 GHz

1 MHz to 20 GHz

1 MHz to 43.5 GHz

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

Part Number: 10410-00342

Published: October 2022

Copyright 2018 Anritsu Company. All Rights Reserved.

Revision: J

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Anritsu ShockLine MS46322A

- Page 1 MS46322B 1 MHz to 8 GHz 1 MHz to 20 GHz 1 MHz to 43.5 GHz Anritsu Company Part Number: 10410-00342 490 Jarvis Drive Revision: J Morgan Hill, CA 95037-2809 Published: October 2022 Copyright 2018 Anritsu Company. All Rights Reserved.

- Page 2 NOTICE Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers as a guide for the proper installation, operation and maintenance of Anritsu Company equipment and computer programs. The drawings, specifications, and information contained herein are the property of Anritsu Company, and any unauthorized use or disclosure of these drawings, specifications, and information is prohibited;...

-

Page 3: Table Of Contents

Anritsu Customer Service Centers ........ - Page 4 Table of Contents (Continued) Calibration and Measurement Conditions......... 3-3 Performance Verification.

- Page 5 Table of Contents (Continued) Troubleshooting Test – Power Supply DC Check ........5-2 Equipment Required .

- Page 6 Introduction ..............A-1 ShockLine MS46322A/B System Performance Test Record ......A-2 System Performance Verification .

-

Page 7: Chapter 1 - General Information

Description The ShockLine MS46322A/B Vector Network Analyzer is an instrument system that contains a built-in source, test set, and analyzer. Designed for manufacturing applications, the ShockLine MS46322A/B supports remote test programming through LAN communications. Test results can be displayed real time on an external video monitor. -

Page 8: Identification Number

Stability of the system is not guaranteed with all antivirus software. Windows OS Updates Not all Microsoft updates are compatible with the ShockLine MS46322A/B VNA and, if installed, may affect the performance of the instrument. Changing some of the default Windows settings may cause a loss of instrument control or undesired instrument behavior. -

Page 9: Solid State Drive Data Backup

1-5 Anritsu Customer Service Centers Solid State Drive Data Backup Anritsu recommends that you make a backup copy of your critical data stored on the VNA solid state drive as often as possible. Anritsu reserves the right to reformat or replace the VNAs solid state drive as part of the repair. -

Page 10: Recommended Test Equipment

1-6 Recommended Test Equipment General Information Recommended Test Equipment The following test equipment is recommended for use in testing and maintaining the ShockLine MS46322A (Table 1-1) and MS46322B (Table 1-2). Table 1-1. Recommended Test Equipment for MS46322A (1 of 2) - Page 11 Recommended Test Equipment for MS46322B (1 of 2) Recommended Equipment Critical Specification Manufacturer/Model Codes Calibration Tee Frequency: DC to 8 GHz Anritsu Model OSLN50A-8 or (For Opt. 10) Connector: N(m) TOSLN50A-8 Calibration Tee Frequency: DC to 8 GHz Anritsu Model OSLN50A-8 or (For Opt. 10)

- Page 12 (For Opt. 43) Adapter Connector: K(f) to K(f) Anritsu Model 33KFKF50C P, A (For Opt. 43) Ethernet: RJ45, cross-over, Cat.5E Anritsu Part Number 3-806-152 Interface Cable Ethernet: RJ45, Cat.5E Anritsu Part Number 2000-1371-R Operating System: Windows 7 or higher Personal Computer...

-

Page 13: Replaceable Parts And Assemblies

Assembly, all installed instrument options must be declared on the order. The installed options are listed on a label on the rear panel of the MS46322A/B. They can also be viewed in the ShockLine application About box display (Select 9 Help | 1.About Anritsu). Table 1-3 Table 1-4 below summarize the available replaceable parts and assemblies. - Page 14 1-7 Replaceable Parts and Assemblies General Information Table 1-3. MS46322A Replaceable Parts and Assemblies (2 of 2) Part Number Description 3-806-283 RF Cable, BNC(f) to MCX(m), 10 MHz Ref In or Trigger TTL 3-806-288 Interface Cable, USB Mini B to 4 pin header, VNA Module Assembly to CPU Module RF Cable, K(f) to K(m), K male Test Port Adapter to VNA Module Assembly 3-806-315 (For Revision 1 Instruments with Options 14.

- Page 15 General Information 1-7 Replaceable Parts and Assemblies Table 1-4. MS46322B Replaceable Parts and Assemblies (2 of 2) Part Number Description 3-ND80991 5V Power Supply Cable Assembly 3-ND80992 12V and 3.3V Power Supply Cable Assembly 3-ND81711 VNA Module 12V Power Cable 3-513-122 N female Test Port Adapter (For Instruments with Option 10) 3-71353...

- Page 16 1-7 Replaceable Parts and Assemblies General Information 1-10 PN: 10410-00342 Rev. J MS46322A/B MM...

-

Page 17: Chapter 2 - Ms46322A Performance Verification

While there are many ways of verifying VNA performance, sometimes simpler procedures are desired. The use of verification kit, available from Anritsu, is a simpler method of verifying the measurement capabilities of the instrument by analyzing the measurement of artifacts that are traceable to International System of Units (SI) via national metrology institutes. -

Page 18: Second Tier Of Uncertainty Systematic Measurement Errors

Reference Standards Verification Kit Verification Kit Verification Kit Working Standards Reference Standards Traveling Standards Users Anritsu National Standards Calibrated VNA - Without error-correction (accuracy enhancement) by calibration kit System Verification - S-parameter measurements with error-correction Figure 2-1. VNA Traceability PN: 10410-00342 Rev. J... -

Page 19: Electrostatic Discharge Prevention

MS46322A Performance Verification 2-3 Electrostatic Discharge Prevention Electrostatic Discharge Prevention A VNA is a precision electronic instrument consisting of components and/or circuitries that are sensitive to electrostatic discharge (ESD). In order to prevent intrusion of electrostatic charge and mitigate risk of costly ESD damage, it is important to take preventive measures to protect against ESD before and during usage. -

Page 20: System Verification

The procedures are automated by using the automated System Verification Software (PVS), in conjunction with the appropriate Anritsu Calibration and Verification Kits listed in the table below. -

Page 21: Verification Result Determination

The Factory Standard Vector Network Analyzer system is traceable to International System of Units (SI) through the impedance Standards of the Anritsu Calibration laboratory. These standards are traceable to International System of Units (SI) through precision mechanical measurements, microwave theory impedance derivation methods, and electrical impedance comparison measurements. -

Page 22: System Verification Procedure

10410-00740, for instructions. 3. Use a Cat5-E Ethernet cable to connect the ShockLine MS46322A to a Local Area Network port that is close to the PC controller using DHCP server of the LAN for obtaining an IP address. Alternatively, use a Cat5-E Ethernet Crossover cable to connect the ShockLine MS46322A directly to the PC Controller Ethernet port using static IP address. - Page 23 K(m) to K(f) connection so it does not work itself loose during the test. b. Install the female end of the Thru Cable to Port 2 of the ShockLine MS46322A. c. Install the 33KFKF50B adapter to Port 1 of the ShockLine MS46322A.

- Page 24 These files can be found in the following folder on the hard drive of the PC controller: C:\Anritsu ShockLine Verification\VNA_Reports\MS46322A_xxxxxxx [where xxxxxxx is the serial number of the ShockLine MS46322A being tested] If Verification Fails If the verification fails, then check the quality, cleanliness, and installation methods for the calibration and verification components.

-

Page 25: Chapter 3 - Ms46322B Performance Verification

While there are many ways of verifying VNA performance, sometimes simpler procedures are desired. The use of verification kit, available from Anritsu, is a simpler method of verifying the measurement capabilities of the instrument by analyzing the measurement of artifacts that are traceable to International System of Units (SI) via national metrology institutes. -

Page 26: Second Tier Of Uncertainty Systematic Measurement Errors

Reference Standards Verification Kit Verification Kit Verification Kit Working Standards Reference Standards Traveling Standards Users Anritsu National Standards Calibrated VNA - Without error-correction (accuracy enhancement) by calibration kit System Verification - S-parameter measurements with error-correction Figure 3-1. VNA Traceability PN: 10410-00342 Rev. J... -

Page 27: Electrostatic Discharge Prevention

MS46322B Performance Verification 3-3 Electrostatic Discharge Prevention Electrostatic Discharge Prevention A VNA is a precision electronic instrument consisting of components and/or circuitries that are sensitive to electrostatic discharge (ESD). In order to prevent intrusion of electrostatic charge and mitigate risk of costly ESD damage, it is important to take preventive measures to protect against ESD before and during usage. - Page 28 The procedures are automated by using the automated System Verification Software, in conjunction with the appropriate Anritsu Calibration and Verification Kits listed in the table below.

- Page 29 The Factory Standard Vector Network Analyzer system is traceable to International System of Units (SI) through the impedance Standards of the Anritsu Calibration laboratory. These standards are traceable to International System of Units (SI) through precision mechanical measurements, microwave theory impedance derivation methods, and electrical impedance comparison measurements.

- Page 30 • The pin depths of all connectors and the proper torquing of connections. These same factors also affect the VNA measurement quality. Consult the reference manual supplied with Anritsu Calibration Kits and Verification Kits for proper use, care, and maintenance of the devices contained in these kits.

-

Page 31: Special Precautions

MS46322B Performance Verification 3-7 System Verification Procedure Special Precautions When performing the procedures, observe the following precautions: • Minimize vibration and movement of the system, attached components, and test cables. • Clean and check the pin depth and condition of all adapters, test port cables, calibration components, and impedance transfer standards. - Page 32 3-7 System Verification Procedure MS46322B Performance Verification After all tests have been completed, print the test results and attach the printouts to the test record in Appendix A, “ShockLine MS46322A/B System Performance Test Record”. If Verification Fails If the verification fails, then check the quality, cleanliness, and installation methods for the calibration and verification components.

-

Page 33: Instrument Key Parameter Performance Tests

MS46322B Performance Verification 3-8 Instrument Key Parameter Performance Tests Instrument Key Parameter Performance Tests The Instrument Key Parameter Performance tests verify the key performance parameter of the MS46322B Vector Network Analyzer as an independent instrument. The Instrument Key Performance tests consist of the following: •... -

Page 34: Frequency Accuracy

Equipment Critical Specification Manufacturer/Model Symmetricom Model Frequency Reference Frequency: 10 MHz RubiSource T&M Anritsu Model MF2412B or Frequency Counter Frequency: 10 MHz to 20 GHz MF2412C with Option 3 Frequency: DC to 18 GHz Adapter Anritsu Model 34NK50 Connector: N(m) to K(m) - Page 35 MS46322B Performance Verification 3-9 Frequency Accuracy f. Select Frequency and then turn CW Mode to ON (Note: CW Frequency is defaulted to 10 MHz) i. Change # of Points to 801 ii. Change Start Frequency to 1 GHz (This changes the CW Frequency to 1 GHz.) 8.

-

Page 36: Output Power (Operational Test)

Equipment Required for Output Power Characterization Recommended Equipment Critical Specification Manufacturer/Model Power Meter Power Range: -70 to +20 dBm Anritsu Model ML2438A Power Sensor Frequency: 100 kHz to 18 GHz Anritsu Model SC7400 (For Opt. 10) Connector Type: N(m) Power Sensor... - Page 37 MS46322B Performance Verification 3-10 Output Power (Operational Test) 6. On the VNA, set the Start Frequency to the test frequency in Table 3-4. (e.g. Set Start Frequency to 1 MHz when it is the first time that this step is executed). The CW Frequency will match the Start Frequency after the change.

- Page 38 3-10 Output Power (Operational Test) MS46322B Performance Verification Low Power Characterization 13. Select Home, Power and then Low Power. 14. Change the VNA display as follows: a. Click on Tr1 on the top of the S22 trace on the screen. b.

-

Page 39: System Dynamic Range

Equipment Required for System Dynamic Range Test Recommended Equipment Critical Specification Manufacturer/Model Adapter Frequency: DC to 18 GHz Anritsu Model 34NK50 (For Opt. 10) Connector: N(m) to K(m) Adapter Frequency: DC to 18 GHz Anritsu Model 34NKF50 (For Opt. 10) - Page 40 3-11 System Dynamic Range MS46322B Performance Verification 3. Prepare the Thru Cable or the MS46322Bas follows: a. For ShockLine MS46322B with Option 10: Install the 34NK50 and 34NKF50 Adapters to the 3670K50-2 Thru Cable. Use torque wrench to tighten the K connectors to ensure that the connections do not work themselves loose during the test.

- Page 41 MS46322B Performance Verification 3-11 System Dynamic Range h. Disconnect the Thru Cable from Port 1. i. Select Isolation (Optional). j. Install Loads to Port 1 and Port 2 (at the end of the Thru Cable). k. Select Isolation 1-2 and then allow the VNA to complete the measurements. l.

- Page 42 3-11 System Dynamic Range MS46322B Performance Verification e. Set up Cell K2 to calculate the rms value in Log Mag by entering the following formula into the Cell: = 20*LOG(J2,10) f. Copy the formula to the next cell on Column K until it reaches the last frequency point. g.

-

Page 43: High Level Noise (Operational Test)

Equipment Required for High Level Noise Test Recommended Equipment Critical Specification Manufacturer/Model Adapter Frequency: DC to 18 GHz Anritsu Model 34NK50 (For Opt. 10) Connector: N(m) to K(m) Adapter Frequency: DC to 18 GHz Anritsu Model 34NKF50 (For Opt. 10) - Page 44 3-12 High Level Noise (Operational Test) MS46322B Performance Verification 5. Set up the VNA for segmented sweep as follows: a. Select Sweep Setup. b. Select Freq-based Seg. Sweep Setup. c. Enter the data from the first row of Table 3-8 into the setup table on the bottom of the VNA display.

- Page 45 MS46322B Performance Verification 3-12 High Level Noise (Operational Test) 7. Set up the VNA display as follows: a. Select Trace and then set # of Traces to 2. b. Select Response and then S12. Verify that Tr1 is displaying S12 response. c.

- Page 46 3-12 High Level Noise (Operational Test) MS46322B Performance Verification 3-22 PN: 10410-00342 Rev. J MS46322A/B MM...

-

Page 47: Chapter 4 - Adjustment

Each replacement VNA assembly is fully pre-calibrated / pre-adjusted prior to shipping from the factory. Equipment Required • Anritsu Model MA24118A USB Power Sensor (For Instruments with N(f) test ports) • Anritsu Model SC8268 USB Power Sensor (For Instruments with K(m) test ports) Procedure 1. - Page 48 4-2 Source Level Adjustment Procedure Adjustment Port 1 Source Power Cal 11. Verify that Port Selection: Port 1 is shown on the POWER CAL menu. If not, select the Port Selection button to change to Port 1 as shown in Figure 4-1.

-

Page 49: If Adjustment Procedure

• For Instruments with K(m) test ports: • Anritsu Model 3670K50-2 or 3670K50A-2 (For Opt 43) Thru Cable • Anritsu Model 33KFKF50B or 33KFKF50C (For Opt 43) K(f) to K(f) Adapter Procedure 1. Power on the VNA and allows the instrument to warm up for at least 45 minutes. -

Page 50: Time Base Adjustment Procedure

Equipment Required • For Instruments with N(f) test ports: • Anritsu Model MF2412x Frequency Counter with Option 3 • Anritsu Model 3670K50-2 Thru Cable • Anritsu Model 34NK50 N(m) to K(m) Adapter • Anritsu Model 34NKF50 N(m) to K(f) Adapter •... - Page 51 Adjustment 4-4 Time Base Adjustment Procedure 7. Enter the password ModVna in the Password field and click OK. 8. Select Hardware Cal button, then the Time Base Cal button. 9. Change the DAC Number value in the TIME BASE CALIBRATION dialog box as shown in Figure 4-4 that the frequency displayed on the frequency counter is within 5 GHz ±...

-

Page 52: Factory Rf Calibration (Rf Cal)

Calibration. Equipment Required • For Instruments with N(f) test ports: • Anritsu Model 3653A N Connector Calibration Kit • Anritsu Model 3670K50-2 Thru Cable • Anritsu Model 34NK50 N(m) to K(m) Adapter • Anritsu Model 34NKF50 N(m) to K(f) Adapter •... - Page 53 Adjustment 4-5 Factory RF Calibration (RF Cal) 9. Change the parameters in the dialog box as shown in the table below, then click the Apply button when done. Table 4-1. Parameters Changes for Factory RF Calibration Thru Length (mm) Line Loss (dB/mm) @ Frequency (GHz) 0.009 Actual length of thru including...

-

Page 54: Thru Line Length Determination Procedure

This procedure is used to determine the length of the thru line cable (including adapters) that is used for Factory RF Calibration. Equipment Required • For Instruments with N(f) test ports: • Anritsu Model 3653A N Connector Calibration Kit • For Instruments with K(m) test ports: • Anritsu Model 3652A K Connector Calibration Kit Procedure 1. - Page 55 Adjustment 4-6 Thru Line Length Determination Procedure 14. Uncheck Test Port 2 and change Test Port 1 DUT Connector as follows: a. For Instruments with N(f) Test Ports N-Conn(M) b. For Instrument with K(m) Test Ports K-Conn(F) 15. Click the OK button when done, then click on the Back icon to return to the previous men. 16.

- Page 56 4-6 Thru Line Length Determination Procedure Adjustment 4-10 PN: 10410-00342 Rev. J MS46322A/B MM...

-

Page 57: Chapter 5 - Troubleshooting

Chapter 5 — Troubleshooting Introduction This chapter provides information about troubleshooting tests that can be used to check the MS46322A/B Vector Network Analyzer for proper operation. These tests are intended to be used as a troubleshooting tool for identifying the faulty components and checking the functionality of internal components and sub-assemblies in the MS46322A/B VNA. -

Page 58: Troubleshooting Test - Power Supply Dc Check

5-3 Troubleshooting Test – Power Supply DC Check Troubleshooting Troubleshooting Test – Power Supply DC Check This procedure verifies that the expected DC voltages are present at the Power Supply and the Back Plane PCB Assembly in the MS46322A/B VNA. Equipment Required •... -

Page 59: Procedure

Troubleshooting 5-3 Troubleshooting Test – Power Supply DC Check Frontside Backplane PCB Assembly Figure 5-3. Location of P17 VNA 12V Power Supply Connector Procedure 1. Turn off the MS46322A/B VNA and unplug the AC power cord, mouse, keyboard and external monitor. 2. -

Page 60: Troubleshooting Test - Non-Ratio Power Level Check

• For Instruments with K(m) test ports: • Anritsu Model 3670K50-2 or 3670K50A-2 (For Opt 43) Thru Cable • Anritsu Model 33KFKF50B or 33KFKF50C (For Opt 43) K(f) to K(f) Adapter Procedure 1. For instruments with N(f) test ports, install the 34NK50 and 34NKF50 adapters to the 3670K50-2 RF Coaxial Cable to convert both ends into N(m) connector port. -

Page 61: Troubleshooting Turn-On Problems

Troubleshooting 5-5 Troubleshooting Turn-on Problems Troubleshooting Turn-on Problems Unit Cannot Boot Up Unit cannot boot up, no activity occurs when the Operate/Standby key is pressed: 1. Perform Power Supply DC Check as described in “Troubleshooting Test – Power Supply DC Check” on page 5-2. -

Page 62: Troubleshooting Operating Problems

5-6 Troubleshooting Operating Problems Troubleshooting Troubleshooting Operating Problems Frequency Related Problems If the instrument exhibits frequency related problem, do the following: 1. Perform “Adjustment” on page 4-1. If it does not help, go to the next step. 2. Apply external 10 MHz Reference to the rear panel 10 MHz Ref In. 3. -

Page 63: Troubleshooting Measurement Problems

Troubleshooting 5-7 Troubleshooting Measurement Problems Troubleshooting Measurement Problems If the MS46322A/B measurement quality is suspect, the following paragraphs provide guidelines and hints for determining possible quality problems. VNA Measurement Quality The quality of MS46322A/B VNA measurements is determined by the following test conditions and variable: •... - Page 64 5-7 Troubleshooting Measurement Problems Troubleshooting PN: 10410-00342 Rev. J MS46322A/B MM...

-

Page 65: Chapter 6 - Assembly Removal And Replacement

Chapter 6 — Assembly Removal and Replacement Introduction This chapter describes the removal and replacement procedures for the various assemblies. Illustrations (drawings or photographs) in this manual may differ slightly from the instrument that you are servicing, but the basic removal and replacement functions will remain as specified. The illustrations are meant to provide assistance with identifying parts and their locations. - Page 66 6-3 Basic Assembly Overview Assembly Removal and Replacement 1 Top Cover 2 Front Panel Bezel 3, 4, 5 Right Handle, Top Handle Insert and Green screw 6, 7 Bottom Handle Foot 8 Side Cover 9 Rear Panel 10 ...

-

Page 67: Disassembly Procedure

Assembly Removal and Replacement 6-4 Disassembly Procedure Disassembly Procedure Use this procedure to prepare the MS46322A/B for removal and replacement procedures for all of its replaceable components. Other than the front panel cables, all replacement components require this common disassembly procedure. Common Disassembly Procedure 1. - Page 68 6-4 Disassembly Procedure Assembly Removal and Replacement 7. Removing the bottom cover is required when replacing the Power Supply, the Solid State Drive or the high frequency VNA Module Assembly. Refer to Figure 6-2 and use the following steps to remove the bottom cover: a.

-

Page 69: Vna Module Assembly

Assembly Removal and Replacement 6-5 VNA Module Assembly VNA Module Assembly Use this procedure to replace the VNA Module Assembly. It is secured to the chassis by five (5) Phillips screws and five (5) standoffs. Replacement Parts • VNA Module Assembly for MS46322A with Option 4 – ND81295-RFB •... - Page 70 6-5 VNA Module Assembly Assembly Removal and Replacement 1 10 MHz Ref In Cable 2 Trigger TTL In Cable 3 Front Panel USB Interface Cable 4 VNA Module Assembly USB Interface Cable 5 VNA Module Assembly +12V Power Supply Cable Figure 6-4.

- Page 71 Assembly Removal and Replacement 6-5 VNA Module Assembly 1 10 MHz Ref In Cable plugged into J34 on the VNA Module Assembly 2 Test Port Coaxial Cables Figure 6-5. Low Frequency VNA Module Assembly Location Diagram (MS46322B Option 10) MS46322A/B MM PN: 10410-00342 Rev.

- Page 72 6-5 VNA Module Assembly Assembly Removal and Replacement 1 VNA Module Assembly 2 Long Mounting Screw (1) 3 Short Mounting screws (9) 4 Short Standoff (1) 5 Tall Standoffs (4) Figure 6-6. Low Frequency VNA Module Assembly (MS46322A Options 4 and 10 or MS46322B Option 10) PN: 10410-00342 Rev.

- Page 73 Assembly Removal and Replacement 6-5 VNA Module Assembly 1 10 MHz Ref In Cable 2 Trigger TTL In Cable 3 Front Panel USB Interface Cable 4 VNA Module Assembly USB Interface Cable 5 VNA Module Assembly +12V Power Supply Cable Figure 6-7.

- Page 74 6-5 VNA Module Assembly Assembly Removal and Replacement 1 10 MHz Ref In Cable plugged into J34 on the VNA Module Assembly 2 Trigger TTL In Cable Figure 6-8. High Frequency VNA Module Assembly Location Diagram (MS46322B Options 20, 40, or 43) 6-10 PN: 10410-00342 Rev.

- Page 75 Assembly Removal and Replacement 6-5 VNA Module Assembly 1 VNA Module Assembly 2 Long Mounting screw (1) 3 Short Mounting screws (4) 4 Standoff Mounting screws (5) Figure 6-9. High Frequency VNA Module Assembly (MS46322A Options 14, 20, 30 or 40, or MS46322B Options 20, 40, or 43) MS46322A/B MM PN: 10410-00342 Rev.

-

Page 76: Replacement Procedure (For Instruments With Options 4 Or 10)

6-5 VNA Module Assembly Assembly Removal and Replacement Replacement Procedure (For instruments with Options 4 or 10) 1. Remove the top cover as described in the “Common Disassembly Procedure” on page 6-3. 2. Remove the Stiffener Plate. 3. Disconnect the 10 MHz Ref In Cable from J30 of the VNA Module Assembly. 4. -

Page 77: Replacement Procedure (For Instruments With Options 14, 20, 30, 40, Or 43)

Assembly Removal and Replacement 6-5 VNA Module Assembly Replacement Procedure (For Instruments with Options 14, 20, 30, 40, or 43) 1. Remove the top and bottom covers as described in the “Common Disassembly Procedure” on page 6-3. 2. Remove the Stiffener Plate. 3. -

Page 78: Cpu Assembly

6-6 CPU Assembly Assembly Removal and Replacement CPU Assembly Use this procedure to replace the CPU Assembly. The CPU Assembly has the Main Processor and SODIMM modules already installed and has been pre-tested as a single assembly. Replacement Part • MS46322A CPU Assembly – ND80983-RFB •... - Page 79 Assembly Removal and Replacement 6-6 CPU Assembly 1 CPU Assembly Power Supply Cable 2 – Solid State Drive Power Cable 3 – Solid State Drive SATA Interface Cable 4 – Ribbon cables linked to Back Plane Board Figure 6-11. MS46322B CPU Assembly Cable Connections MS46322A/B MM PN: 10410-00342 Rev.

- Page 80 6-6 CPU Assembly Assembly Removal and Replacement 1 CPU Assembly 2 Mounting Screws 3 Silicone block Figure 6-12. CPU Assembly 6-16 PN: 10410-00342 Rev. J MS46322A/B MM...

-

Page 81: Replacement Procedure

Assembly Removal and Replacement 6-6 CPU Assembly Replacement Procedure 1. Remove the top cover as described in the “Common Disassembly Procedure” on page 6-3. 2. Remove the Stiffener Plate. 3. Unplug all the cable harnesses connected to the CPU Assembly. 4. -

Page 82: Solid State Drive

6-7 Solid State Drive Assembly Removal and Replacement Solid State Drive Use this procedure to replace the solid static drive. Replacement Part • MS46322A Revision 1 Instrument Solid State Drive − ND80984 • MS46322A Revision 2 Instrument Solid State Drive − ND80997 •... -

Page 83: Replacement Procedure For Ms46322A Revision 1 Instrument

Assembly Removal and Replacement 6-7 Solid State Drive Replacement Procedure for MS46322A Revision 1 Instrument 1. Remove the top cover as described in the “Common Disassembly Procedure” on page 6-3. 2. Remove the Stiffener Plate. 3. Unplug the SATA cable and Power cable from the solid state drive. 4. -

Page 84: Back Plane Pcb Assembly

6-8 Back Plane PCB Assembly Assembly Removal and Replacement Back Plane PCB Assembly Use this procedure to replace the Back Plane PCB Assembly. Replacement Part • MS46322A Back Plane PCB Assembly – ND80994-RFB • MS46322B Back Plane PCB Assembly – 3-ND87249-RFB Reference Figure •... -

Page 85: Replacement Procedure

Assembly Removal and Replacement 6-8 Back Plane PCB Assembly Replacement Procedure 1. Remove the top cover as described in the “Common Disassembly Procedure” on page 6-3. 2. Remove the stiffener plate. 3. Disconnect the VNA Module 12V Power Supply Cable from P17. 4. -

Page 86: Io Handler Pcb Assembly

6-9 IO Handler PCB Assembly Assembly Removal and Replacement IO Handler PCB Assembly Use this procedure to replace the IO Handler PCB assembly. The IO Handler PCB assembly is being used in the MS46322A Revision 2 and the MS46322B instrument only. Replacement Parts •... -

Page 87: 6-10 Fan Assemblies

Assembly Removal and Replacement 6-10 Fan Assemblies 6-10 Fan Assemblies Use this procedure to replace the Fan Assemblies. Replacement Parts • MS46322A Fan Assembly, Right – ND80986 • MS46322A Fan Assembly, Left – ND80987 • MS46322A Fan Assembly, Rear – ND80989 •... -

Page 88: Replacement Procedure For Right Fan Assembly

6-10 Fan Assemblies Assembly Removal and Replacement 1 Rear Fan Assembly 2 Mounting Screw 3 Hex Nut Figure 6-17. Rear Fan Assembly Replacement Procedure for Right Fan Assembly 1. Remove the top cover as described in the “Common Disassembly Procedure”... -

Page 89: Replacement Procedure For Left Fan Assembly

Assembly Removal and Replacement 6-10 Fan Assemblies Replacement Procedure for Left Fan Assembly 1. Remove the top cover as described in the “Common Disassembly Procedure” on page 6-3. 2. Remove the stiffener plate. 3. Disconnect the fan assembly power cables from P9 and P10 of the Back Plane PCB Assembly. 4. -

Page 90: Power Supply Assembly

6-11 Power Supply Assembly Assembly Removal and Replacement 6-11 Power Supply Assembly Use this procedure to replace the Power Supply Assembly. Replacement Part • Power Supply Assembly 3-40-191 Reference Figures • Figure 6-18 shows how the power supply mounting bars are installed to the power supply. •... - Page 91 Assembly Removal and Replacement 6-11 Power Supply Assembly 1 Power Supply 2 IO Handler PCB Mounting Plate 3 Mounting screw Figure 6-19. Power Supply with IO Handler PCB Mounting Plate installed, MS46322A Revision 2 Instrument and MS46322B 1 ...

-

Page 92: Replacement Procedure

6-11 Power Supply Assembly Assembly Removal and Replacement Replacement Procedure 1. Remove the top cover as described in the “Common Disassembly Procedure” on page 6-3. 2. Remove the Stiffener Plate. 3. For MS46322A Revision 2 instrument and MS46322B, do the following: a. -

Page 93: 6-12 Test Port Adapter

Assembly Removal and Replacement 6-12 Test Port Adapter 6-12 Test Port Adapter Use this procedure to replace the Front Panel Test Port Adapters. Replacement Parts • MS46322A/B N(f) Test Port Adapter – 3-513-122 • MS46322A Revision 1 Instrument K(m) Test Port Adapter – 3-75651 •... - Page 94 6-12 Test Port Adapter Assembly Removal and Replacement 1 Front Panel 2 Mounting Screws (8) 3 Nuts (3) 4 Flexible Coaxial Cables (2) Figure 6-22. N(f) Test Port Adapter (For Instruments with Options 4 or 10) 6-30 PN: 10410-00342 Rev.

- Page 95 Assembly Removal and Replacement 6-12 Test Port Adapter 1 Front Panel 2 Mounting Screws (8) 3 Nuts (3) 4 Chassis Figure 6-23. K(m) Test Port Adapter (For Instruments with Options 14, 20, 30, 40, or 43) MS46322A/B MM PN: 10410-00342 Rev.

-

Page 96: Replacement Procedure N(F) Test Port Adapter

6-12 Test Port Adapter Assembly Removal and Replacement Replacement Procedure N(f) Test Port Adapter 1. Remove the top cover as described in the “Common Disassembly Procedure” on page 6-3. 2. Disconnect the flexible coaxial cable from the SMA(f) connector of the test port adapter. See Figure 6-22 on page 6-30. -

Page 97: 6-13 Front Panel Led Pcb Assembly

Assembly Removal and Replacement 6-13 Front Panel LED PCB Assembly 6-13 Front Panel LED PCB Assembly Use this procedure to replace the Front Panel LED PCB Assembly. Replacement Part • Front Panel LED PCB Assembly ND81163 Reference Figure • Figure 6-24, “Front Panel LED PCB Assembly”... -

Page 98: Replacement Procedure Instruments With N(F) Test Ports

6-13 Front Panel LED PCB Assembly Assembly Removal and Replacement Replacement Procedure Instruments with N(f) Test Ports 1. Remove the top cover and handles as described in the “Common Disassembly Procedure” on page 6-3. 2. Disconnect the flexible coaxial cables from the SMA(f) connector of the test port adapters. See Figure 6-22 on page 6-30. - Page 99 Assembly Removal and Replacement 6-13 Front Panel LED PCB Assembly 19. Install the handles. 20. Install the top cover and bottom cover. MS46322A/B MM PN: 10410-00342 Rev. J 6-35...

- Page 100 6-13 Front Panel LED PCB Assembly Assembly Removal and Replacement 6-36 PN: 10410-00342 Rev. J MS46322A/B MM...

-

Page 101: Appendix A - Test Records

Appendix A — Test Records Introduction This appendix provides test record that can be used to record the performance of the ShockLine MS46322A/B. Make a copy of the following Test Record pages and document the measured values each time performance verification is performed. -

Page 102: Shockline Ms46322A/B System Performance Test Record

A-2 ShockLine MS46322A/B System Performance Test Record Test Records Instrument Information Serial Number: Firmware Revision: Operator: Options: Date: ShockLine MS46322A/B System Performance Test Record System Performance Verification This test is automated using the System Verification software that is included with 3663-x or 3668-x Verification Kits. -

Page 103: Shockline Ms46322B Instrument Performance Test Record

Test Records A-3 ShockLine MS46322B Instrument Performance Test Record Instrument Information Serial Number: Firmware Revision: Operator: Options: Date: ShockLine MS46322B Instrument Performance Test Record Frequency Accuracy Table A-1. Frequency Accuracy Measurement Frequency Measured Value Uncertainty Specification (GHz) (Hz) (Hz) (Hz) Pass/Fail a.Specification is ±... - Page 104 A-3 ShockLine MS46322B Instrument Performance Test Record Test Records Table A-2. High Output Power (2 of 2) Port 1 Port 2 Measurement Frequency Measured Power Measured Power Uncertainty (MHz) (dBm) (dBm) (dB) 0.51 12000 0.51 13000 0.51 14000 0.51 15000 0.51 16000 0.51...

- Page 105 Test Records A-3 ShockLine MS46322B Instrument Performance Test Record (Output Power = Low) Table A-3. Low Output Power (1 of 2) Port 1 Port 2 Measurement Frequency Measured Power Measured Power Uncertainty (MHz) (dBm) (dBm) (dB) 0.38 0.38 0.38 0.48 0.48 1000 0.48...

- Page 106 A-3 ShockLine MS46322B Instrument Performance Test Record Test Records Table A-3. Low Output Power (2 of 2) Port 1 Port 2 Measurement Frequency Measured Power Measured Power Uncertainty (MHz) (dBm) (dBm) (dB) 0.66 30000 0.66 31000 0.66 32000 0.66 33000 0.66 34000 0.66...

-

Page 107: System Dynamic Range

Test Records A-3 ShockLine MS46322B Instrument Performance Test Record System Dynamic Range (High Power, 10 Hz IFBW, RMS) Table A-4. S12 System Dynamic Range Measurement Frequency Measured Value Uncertainty Specification (GHz) (dB rms) (dB rms) (dB rms) Pass/Fail 1 MHz to 10 MHz 0.16 >... -

Page 108: High Level Noise

A-3 ShockLine MS46322B Instrument Performance Test Record Test Records High Level Noise (100 Hz IFBW, RMS) Table A-6. High Level Noise – S12 Magnitude (1 of 2) Frequency Measured Value Measurement Uncertainty (MHz) (dB rms) (dB rms) 0.00059 0.00059 0.0029 0.0029 0.0029 1000... - Page 109 Test Records A-3 ShockLine MS46322B Instrument Performance Test Record Table A-6. High Level Noise – S12 Magnitude (2 of 2) Frequency Measured Value Measurement Uncertainty (MHz) (dB rms) (dB rms) 31000 0.0029 32000 0.0029 33000 0.0029 34000 0.0029 35000 0.0029 36000 0.0029 37000...

- Page 110 A-3 ShockLine MS46322B Instrument Performance Test Record Test Records Table A-7. High Level Noise – S12 Phase (2 of 2) Frequency Measured Value Measurement Uncertainty (MHz) (Deg rms) (Deg rms) 15000 0.0018 16000 0.0018 17000 0.0018 18000 0.0018 19000 0.0018 20000 0.0018 21000...

- Page 111 Test Records A-3 ShockLine MS46322B Instrument Performance Test Record Table A-8. High Level Noise – S21 Magnitude (2 of 3) Frequency Measured Value Measurement Uncertainty (MHz) (dB rms) (dB rms) 0.0029 1000 0.0029 2000 0.0029 3000 0.0029 4001 0.0029 5000 0.0029 6000 0.0029...

- Page 112 A-3 ShockLine MS46322B Instrument Performance Test Record Test Records Table A-8. High Level Noise – S21 Magnitude (3 of 3) Frequency Measured Value Measurement Uncertainty (MHz) (dB rms) (dB rms) 38000 0.0029 39000 0.0029 40000 0.0029 41000 0.0043 42000 0.0043 43000 0.0043 43500...

- Page 113 Test Records A-3 ShockLine MS46322B Instrument Performance Test Record Table A-9. High Level Noise – S21 Phase (2 of 2) Frequency Measured Value Measurement Uncertainty (MHz) (Deg rms) (Deg rms) 22000 0.0018 23000 0.0018 24000 0.0018 25000 0.0018 26000 0.0018 27000 0.0018 28000...

- Page 114 A-3 ShockLine MS46322B Instrument Performance Test Record Test Records A-14 PN: 10410-00342 Rev. J MS46322A/B MM...

-

Page 115: Index

RF calibration procedure ... . . 4-6 repair service, Anritsu ..... .1-3 frequency related troubleshooting . - Page 116 RF power related ..... . .5-6 service center, Anritsu ..... 1-3 turn-on .

- Page 118 Anritsu Company 490 Jarvis Drive Anritsu utilizes recycled paper and environmentally conscious inks and toner. Morgan Hill, CA 95037-2809 http://www.anritsu.com...

Need help?

Do you have a question about the ShockLine MS46322A and is the answer not in the manual?

Questions and answers