Summary of Contents for Maruyama BSM300

- Page 1 BOOM SPRAYER BSM300 Instruction Manual Conpletely read and understand this manual before using this product...

- Page 2 READ AND SAVE THIS MANUAL BSM300 INSTRUCTION MANUAL Preface Thank you for purchase of this product. This manual explain how to use, maintain properly for safety & comfortable operation. Before operation, please read this manual carefully and utilize this manual to optimize this products at best performance.

-

Page 3: Table Of Contents

CONTENTS 3 1 For safety operation ………………………………………………………………………… 5 2 Portion’s name & accessories …………………………………………………………… 7 3 Specification ………………………………………………………………………………… 8 4 Caution label ……………………………………………………………………………… 9 5 How to mount tractor ……………………………………………………………………… 12 6 Explanation of each portion ……………………………………………………………… 12 ■Stand ………………………………………………………………………………… 13... -

Page 4: 1 For Safety Operation

1. For safety operation (1) Please read and follow the instruction manual of chemical, optional device, and operate correctly. ①Please operate tractor with boom sprayer at the area within 5°slope. ②Please wear safety gear, such as helmet, glove and mask, and wear the suitable cloths. - Page 5 turn. Please drive & operate safely. ③ When you travel to plot, be sure to close the side boom. (Refer to P.18) ④ When you get in and get out plot, or cross the dike or ditch, or pass through mad area, ⑤...

-

Page 6: 2 Portion's Name & Accessories

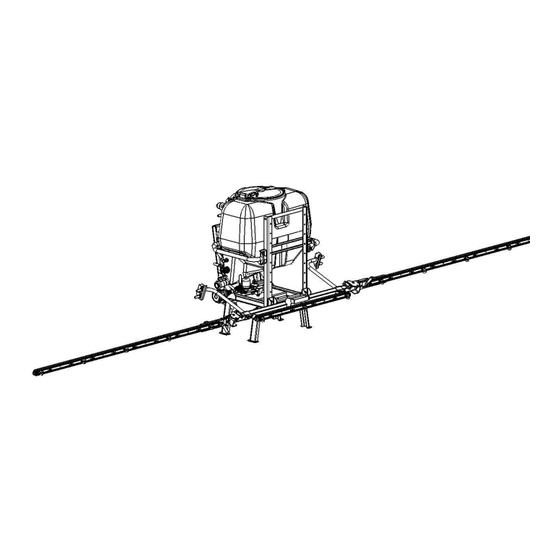

2. Portion name & accessories ② ④ ⑤ ⑥ Front Right ① Inside in tank Left Rear ③ ⑧ ⑨ ⑦ ⑭ ⑬ ⑮ ⑲ ⑩ ⑪ ⑫ ⑯ ⑰ ⑱ ⑯... - Page 7 ■PORTION’S NAME Page ITEM NAME ① LEFT BOOM (SIDE BOOM) 9, 17, 18 ② RIGHTBOOM(SIDE BOOM) 9, 17, 18 ③ CENTER BOOM 17, 19 ④ CHEMICAL TANK 13, 14, 15 ⑤ CHEMICAL TANK LID ⑥ MAST FRAME ⑦ STAND ⑧ STEP ⑨...

- Page 8 ※1. Please install front weight. Please ask dealer shop nearby. ※2. Even though dry weight is less than 1,100kg, some tractor is applicable for this sprayer. Please ask dealer shop. ※3.Spray height at 300mm is adjusted by lower link operation. BSM300 Dimension(mm) W(1850) L(2850)...

-

Page 9: 4 Caution Label

4. Caution label WARNING ●Please wipe mud on label to make it visible. ●In case caution label is torn, please replace to new one. ●Please attach new label at same space where old label was attached. ※On the chemical tank, there are following caution label. So please read carefully and understand before operation. -

Page 10: 5 How To Mount Tractor

5. How to mount on tractor WARNING ●For safety, be sure to attach boom sprayer with tractor alone. ●When you attach & remove boom sprayer with tractor, be sure that the chemical tank is empty and boom is open for 20°.Otherwise gravity is not stable and it may cause accident. - Page 11 (4) Pull down shaft lock pin arm to lock it. (5) Please do the same procedure for another boom as well. ②Install universal joint with pump’s crank shaft (input shaft) (1)Put parallel key on crank shaft’s key groove and coat grease on it then install universal joint until end.

- Page 12 ④Insert right lower link and fix it by fastening pin. (Right lower link can be up & down by rotating adjusting handle.) CAUTION ●Balance of right & left can be adjusted to be horizontal by rotating right lower link adjusting handle. (Please refer to tractor manual) ⑤Place parking brake of tractor and confirm whether PTO is OFF, and start engine and lift up lower link slowly, then attach top link to boom sprayer and fix it by linchpin.

-

Page 13: 6 Explanation Of Each Portion

6. Explanation of each portion ■STAND Stand is used when you attach and detach boom sprayer with tractor. WARNING ●When you unfold the stand, hold the stand by hand then pull out the pin and Unfold HOW TO SET STAND ①Please lift up lower link by shift lever then confirm stand is not contacting on ground. -

Page 14: Pump

■PUMP It suctions the chemical liquid in chemical tank, the feed as pressurized. Pump CAUTION ●Tractor’s PTO speed should be at 580-820rpm. If PTO rpm is too high or too low, it will cause unevenness of spray or trouble of pump. ●Please lubricate oil (equivalent to SAE10W-30)to 3holes for 3-5 drops every time Before operation. - Page 15 When you open lid of chemical tank, rotate counter clockwise, then release lock and open it. When you close it, rotate clockwise and surely lock it. Open Lock The strainer of chemical tank will filter rubbish when you feed water or mixed chemical.

-

Page 16: Jet Nozzle

■JET NOZZLE This device agitate the chemical inside chemical tank. Scroll nozzle should be replaced at every 500hours operation. CAUTION ●If the jet nozzle is clogged, chemical will not be agitated smoothly and it may Cause harmful effect of chemical. ●If jet nozzle is worn, sprayer’s performance may get worse such as sprayer’s pressure will not increase or discharge volume will decrease. -

Page 17: Suction Strainer/Water Feeding Valve

■SUCTION STRAINER/WATER FEEDING VALVE Suction strainer filter the rubbish in chemical tank. You can remove it from strainer itself by loosening nut. When there is remained chemical in chemical tank, please clean strainer while water feeding valve is closed. WARNING ●If you remove strainer while feeding valve is open while there is remained chemical in Chemical tank, you will be exposed by chemical or it will flow out accidentally. -

Page 18: Spray Cock

IMPORTANT ●When you pause or finish spraying work, first, please decrease pressure by rotate pressure adjusting dial counter clockwise, then stop PTO. ■SPRAY COCK When you position pump cock on “ OPEN”, chemical will come out from nozzle, and if you position at “CLOSE”, spray will be stopped. - Page 19 HOW TO OPEN SIDE BOOM CAUTION ●When you open or close boom, make sure there is no obstacles within 5m radius. ①Pull out shaft lock pin arm fixing side boom then release lock. ※Please refer to page P9 ②Please hold the side boom so as not to move accidentally, then pull out lock pin by the other hand.

- Page 20 Adjust bolt so that lower side of boom & lower bolt of boom holder contact each other. If they don’t contact, loosen lower bolt to adjust. HOW TO ADJSUTMENT OF SPRAY HEIGHT. Depending on grass height, you can change the spray height by 10cm pitch. Maximum spray height is 1.2m.

-

Page 21: Step

use provided nut for back side of mast, and fix tightly. (Fastening torque: 30[N・m]) ■STEP Please use while feeding water or mixed chemical to chemical tank. Step WARNING ●Please use step when the parking brake is placed and hydraulic is locked. ●Do not travel while person is on the step. -

Page 22: 7 Spray Planning

7. Spray planning Before operation, make a spray plan for the day. IMPORTANT ●Please use manufacturer’s designated nozzle only. ●If you use standard nozzle, please set pressure within 0.5- 2.0MPa. If pressure is too high, it may damage nozzle and if pressure is too low, it will cause uneven spray. HOW TO PLAN ①After you decide spray volume per 10a(area unit) ,spray pressure, select suitable nozzle and decide spray speed. -

Page 23: 8 Inspection Before Operation

SUPPLEMETAL INFORMATION How to seek spraying speed. (1) Decide spray volume & pressure per 10a (2) Please seek spray speed by below formula. Total nozzle discharge volume(Liter/min) Spray speed(km/h) =60 × Spray volume(L per 10a)× spray width (m) (ex.) Spray volume 25Liter per 10a, Total nozzle discharge volume 10.5Liter/mim (at 2MPa), Spray width 7.8m 10.5 V= 60 ×... -

Page 24: 10 Check Spray

10. Check spray CAUTION ●When you check spray status, be sure to use water .(Not chemical) ① Pour pure water into chemical tank. ② Open left & right boom ③ Confirm whether water feeding valve is open or not. Lever ④... -

Page 25: 11 Caution For Spray Work

⑧When you attach nozzle again, please fasten the nozzle cap surely to prevent from leakage. CAUTION ●If you use nozzle for long period, nozzle disc will be worn out and discharge volume will be larger. Rough target replacement period is 500hours ●If you store in winter or long term, please drain out water. -

Page 26: 13 Spray Work

13. Spray work CAUTION ●Before operation, please adjust by tractor ‘s hydraulic lever so that universal joint will be horizontal level. If angle position is beyond above, it will cause damage to pump. ①Travel to the position where to start spraying. ②Stop tractor in front of point which you want to start. -

Page 27: 14 Stop Operation

14. Stop operation ①After finish spraying, positions spray cock to “CLOSE”. ②Rotate pressure adjusting dial fully to counter clockwise, and decrease pressure. CAUTION ●If you finish operation as highly pressurized (not returned to 0 position of pressure dial), pump may not suction chemical when you use next time. ③Run tractor engine at idling. - Page 28 16. Inspection CAUTUION! ●When you inspect, please attach boom sprayer with tractor and unfold stand. ● Stop the engine of tractor, lock the hydraulic and pull out the key, then start inspection ●Do not inspect while tractor engine is running. In case you have to do, please consult with dealer.

-

Page 29: Installation Bolt & Nut

■INSTALLATION BOLT & NUT Regarding Lower link pin, chemical tank, mast frame, pump, center boom, side boom, check whether there is no looseness of bolt & nut. If there is loosened one, fasten again. Walk around the boom sprayer and check each fastening part (bolt, nut, pin). If there is loosened one, fasten again. -

Page 30: Strainer

②Before operation, lubricate to 3points of oil inlet for 3-5drops.(SAE#10W-30) Oil inlet Lubricant ③Check whether there is no gutter or looseness in crank shaft & universal joint. If it is about to disconnect or looseness, put crank shaft of pump until end of universal joint and fix by fastening hexagon bolts(M8×35) and lock by hexagon nut(M8). -

Page 31: Jet Nozzle

■JET NOZZLE Check spraying and whether water is flashing from jet nozzle. (Refer to page 23) If water flow is weak, There maybe stuck in nozzle. Then please ask dealer to wash he jet nozzle by dealer. Please replace it after 500hours operation. 17. - Page 32 ⑤In order to prevent freezing, nozzle(packing, strainer) and pipe connecting part should be removed and drain it out totally. Nozzle should be kept carefully. ⑥Remove rust by sandpaper and coat paint. ⑦Please keep strainer’s lid and chemical tank lid open for venting. ⑧Unfold stand to ground and remove boom sprayer from vehicle.

- Page 33 20. Trouble shooting CAUTION ●When you check trouble shooting, mount boom sprayer on tractor, then unfold stand. ●Stop tractor engine and lock the hydraulic then out the key. ●Do not do trouble shooting while tractor engine is running otherwise ask dealer shop. PHENOMENON CAUSE COUNTERMEASURE...

- Page 34 21. Consumable part list PORTION PARTS NAME PARTS NO Q’ty REMARK SEAL 100015 3 PISTON PACKING 116121 3 OIL FILLER CAP 117420 FELT PACKING 027711 O-RING 014041 O-RING 023170 PUMP 015862 O-RING 023172 CYLINDER PIPE 022929 INLET VALVE SEAT 014122 PISTON RETAINER 118628 DISCHARGE VALVE ASSY...

- Page 35 MEMO...

- Page 36 4-15, Uchi-kanda 3-Chome, Chiyoda-ku, Tokyo 101-0047 JAPAN TEL 81-3-3252-2285 http://www.maruyama.co.jp P/N.567312-01 09.11 PRINTED IN THAILAND...

Need help?

Do you have a question about the BSM300 and is the answer not in the manual?

Questions and answers