Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for DANA BREVINI D Series

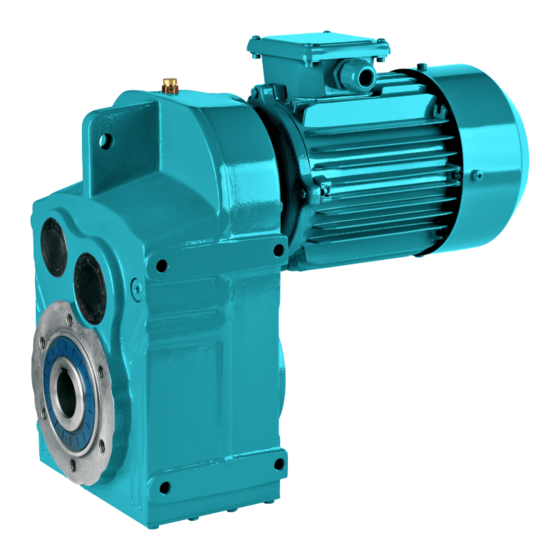

- Page 1 ® Installation and Maintenance Manual Gearmotors D Series IMM-0016EN October 2022...

- Page 2 © Copyright 2022 Dana Incorporated All content is subject to copyright by Dana and may not be reproduced in whole or in part by any means, electronic or oth- erwise, without prior written approval.

-

Page 3: Table Of Contents

USE THE BREATHER PLUG ......................27 CHECK THE OIL LEVEL ........................27 CHECK SHAFT ENDS AND MOUNTING FACES ................27 COVER ABRASIVE AMBIENT ......................27 7.10 CHECK ACCESSIBILITY TO FILLING, BREATHER AND DRAIN PLUGS .......... 27 IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... - Page 4 D SERIES 5-6 STAGE OIL LEVEL PLUGS: ..................52 11 TROUBLESHOOTING GUIDE ......................53 12 DISPOSAL ............................56 12.1 DISPOSAL OF OIL ..........................56 12.2 DISPOSAL OF SEALING ........................56 12.3 DISPOSAL OF METAL ........................56 Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

-

Page 5: Version Tracking

1 VERSION TRACKING File name Revision Date Changes description IMM-0016EN_Rev.00 Gearmotors D 17/10/2022 - Changed layout Series 1.1 MANUAL APPLICABILITY AND SUPPORTED MODELS Models Gearmotors D Series IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 6: How To Use This Manual

Dana Motion Systems Italia S.r.l. for the operating instructions of that type. This instruction can be used only for standard type geared units of Dana Motion Systems Italia S.r.l.. For special application and modified gear units ask Dana Motion Systems Italia S.r.l. for validity. -

Page 7: Unit Designation

5 Stages 6 Stages 4 Stages Revision Number Housing Size 1...9 Input Type :With Motor :IEC B5 / B14 Flanged without Motor :IEC B5 / B14 Flanged with Motor Gearbox Type D Serie IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 8: Nameplate Unit Designation

M.Pos.: Mounting Position Type Designation; DR473 - 3E71M/4C Type Motor Size Type: DR - With motor DT - With input shaft DV - With Motor and IEC Flange DN - IEC Flange without Motor Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 9: Part List Of Standard Type Gear Units

Spacer Bearing Plug Circlip Spacer Cover Plate Seal Bearing Screw Closing Cap Gear Oil Seal Circlip Circlip Spacer Gear Spacer Spacer Bearing Bearing Bearing Circlip Hollow Shaft Shaft Gear Closing Cap Gear IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... - Page 10 Spacer Bearing Cover Plate Circlip Spacer Bolt Oil Seal Bearing Oil Seal Closing Cap Gear Circlip Circlip Bearing Spacer Shaft Gear Bearing Spacer Bearing Output Shaft Bearing Circlip Shaft Gear Closing Cap Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

- Page 11 Spacer Spacer Cover Plate Circlip Bearing Bolt Seal Spacer Oil Seal Flange Bearing Circlip Bolt Gear Spacer Closing Cap Bearing Circlip Shaft Gear Solid Shaft Spacer Bearing Spacer Circlips Bearing Closing Cap IMM-0016EN - Installation and Maintenance Manual Dana Incorporated...

- Page 12 Cover Plate Oil Seal Spacer Bolt Flange Bearing Oil Seal Bolt Gear Circlip Closing Cap Spacer Circlip Gear Bearing Spacer Bearing Hollow Output Shaft Spacer Circlip Bearing Closing Cap Gear Shaft Gear Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

- Page 13 Spacer Spacer Plug Circlip Bearing Cover Plate Oil Seal Gear Bolt Closing Cap Oil Seal Circlip Shaft Gear Circlip Spacer Bearing Spacer Spacer Circlip Bearing Bearing Closing Cap Output shaft Shaft Gear IMM-0016EN - Installation and Maintenance Manual Dana Incorporated...

- Page 14 4.6 D...0E... TYPES FOR 3 STAGED GEAR UNITS NOTE: Standard D...0E... type basic part diagram. Parts may differ for special applications. Standard Part List Circlip Spacer Flange Bolt Extruder Neck Bolt Seal Bearing Hollow Shaft Output Spacer Seal Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

-

Page 15: Series Additional Stage For 4 Stage Types

Standard D..4 type additional stage basic part diagram. Parts may differ for special applications. Parts List Parts List Screw Pin Circlips Bearing Gear Oil plug Bearing Circlips Shaft Seal Gear Circlips Bolt Additional Housing IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 16: D Series 5-6 Stages Types

Output Shaft Bearing Gear Spacer Seal Bearing Gear Circlips Circlips Bearing Bearing Oil plug Spacer Bolt Gear Gear Eye bolt Bearing Bearing Oil plug Circlips Circlips Top side cover Cover Cover Screw Pin Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 17: D Series Motor Flange For Direct Coupled Types

Parts List Shaft Circlips Bearing Circlips B5 / B14 Flange Seal Gear Circlips 4.11 DT... TYPES INPUT BEARING HOUSING WITH SOLID INPUT SHAFT Parts List Seal Flange Shaft Bearing Bearing Circlips Gear Circlips IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 18: Safety

The speed range will be provided on the name plate if Dana Motion Systems Italia S.r.l. is informed that the gear unit will be used with frequency inverter. If not informed the nameplate will have a single fixed speed and only this speed is allowed. -

Page 19: Safety Instructions

WARNING Even a brief running of the machine during maintenance work can lead to accidents if the safety devices are not operating. Make sure that all safety devices are mounted and active. IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... - Page 20 Using the gear unit out of this range can cause damage to the gear unit or environment. Over +40 ºC ambient conditions the gear unit surface temp could be so high causing burns when touched. Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

-

Page 21: Tightening Torques

Always keep suitable extinguishing, protective equipment like carbon dioxide, powder, foam, fog easily accessible around the gear unit. WARNING -High temperature produce irritating steam. Use a protective breathing apparatuses. 5.5.2 UNSUITABLE EXTINGUISHING AGENTS WARNING Do not spray with water! IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 22: Thinks To Check Before The Gear Unit Or Geared Motor Is Installed

When the goods arrive, first check for any damage. If some damage observed, immediately contact the transport company and inform about the damage. Contact Dana Motion Systems Italia S.r.l. for the damage and do not start to install the unit until it is agreed that the damage has no affect of operation. -

Page 23: Storage

If the gearbox is stored without packing it is recommended not to store more than 2 years and regular check during this time is recommended. If stored in open protect against insect damage. IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 24: Installing The Gear Unit

+0.01 -0,03 7.3 CHECK THE AMBIENT TEMPERATURE The ambient temperature must be between +5 ºC to +40 ºC for standard type gear units. If different contact Dana Motion Sys- tems Italia S.r.l. for special solutions. Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 25: Check The Voltage Supply

In case of only gear unit is supplied from Dana Motion Systems Italia S.r.l. please observe the name plate of the electric motor and the instructions of the supplier. Check the basic electric connection diagrams below. Use experienced electric technician. - Page 26 The gearbox and the motor must be grounded to prevent potential differences of earth and gearbox/motor. Delayed Running Brake ( 220 V) Sudden Brake (220 V) R S T R S T N Delayed Running Brake ( 24 V) Sudden Brake (24 V) R S T Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

-

Page 27: Check The Mounting Position

The mounting position must be in accordance with the mounting position mentioned on the name plate. If different please con- tact Dana Motion Systems Italia S.r.l. for possibilities of using in a different mounting position. Refer to the mounting positions and oil quantities on this manual and adjust the oil level accordingly with the recommended oil types given on this manuel. -

Page 28: Mechanical Installation

Secure the gear unit using 8.8 or higher quality bolts. DANGER Cover all the turning parts from human entering or touching. Turning parts can cause severe or fatal injuries. CAUTION For different kind of basic installations refer to the following illustrations. Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 29: Installing Customer Shaft With Shoulder

8.1 INSTALLING CUSTOMER SHAFT WITH SHOULDER Use anti-seize assembling paste available on your market. Use a brush to apply the paste. Fasten the bold as shown below. Retaining Bolt Lock Washer Washer Circlip Hollow Shaft Customer Shaft IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 30: Installing Customer Shaft Without Shoulder

8.2 INSTALLING CUSTOMER SHAFT WITHOUT SHOULDER Use anti-seize mounting paste available on your market. Use a brush to apply the paste. Fasten the bold as shown below. Retaining Bolt Lock Washer Washer Circlip Hollow Shaft Customer Shaft Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 31: Disassembling Customer Shaft With Shoulder

Disassemble the bolt and take out the parts as shown Use the disassemble set from Dana Motion Systems Italia S.r.l. and fasten the bold as shown bellow to take out the output shaft. For disassemble sets look the following pages. -

Page 32: Disassembling Customer Shaft Without Shoulder

Disassembly the bolt and take out the parts as shown Use the disassembly set from Dana Motion Systems Italia S.r.l. and fasten the bold as shown bellow to take out the output shaft. For disassembly sets look the following pages. -

Page 33: Shaft Tightening Torques

MECHANICAL INSTALLATION 8.5 SHAFT TIGHTENING TORQUES Use the following table for shaft tightening torques. Table 6: Type Bolt Tightining Torque [Nm] D.072/073 D.172/173 D.272/273 D.282/283 D.372/373 D.472/473 D.572/573 D.672/673 D.772/773 D.872/873 D.972/973 IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 34: Advised Shaft Dimensions And Accessiories

53.5 D.57.. 59.7 17.5 D.67.. 69.7 74.5 19.5 74.5 D.77.. 89.7 24.5 D.87.. 109.7 27.5 D.97.. 119.7 Dismounting Mounting 6 Contour Bolt (DIN ISO 4014 . DIN ISO 4017) (DIN ISO 8765) Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... - Page 35 25.25 M10x30 N30x1,25x30x22x9H 27,5 30,25 M10x30 N35x2x30x16x9H 35,4 M10x30 63,5 N45x2x30x21x9H 45,4 M16x50 N50x2x30x24x9H 50,4 M16x50 N65x2x30x31x9H 65,4 M20x60 N70x2x30x34x9H 70,4 M20x60 N85x3x30x27x9H 139,5 85,6 M20x60 N100x4x30x24x9H 100,8 M24x80 N120x4x30x28x9H 120,8 M24x80 IMM-0016EN - Installation and Maintenance Manual Dana Incorporated...

- Page 36 68,990 / -0,06 (0/-0,06) 4,00 M20x44 W70x2x30x34x8f 74,180 / -0,06 (0/-0,06) 4,00 M20x44 W85x3x30x27x8f 91,020 / -0,05 (0/-0,05) 6,00 M20x44 W100x4x30x24x8f 108,370 / -0,06 (0/-0,06) 8,00 M24x52 W120x4x30x28x8f 127,89 (0/-0,06) 8,00 M24x52 Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

-

Page 37: Assembling Customer Shaft With Shrink Disk

Use a solvent available in your market to clean all the dirt an oil from the shaft and shrink disk hollow. The surfaces must be free from oil or any dirt. The solvent must be removed from the surfaces as well. IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... - Page 38 Customer Shaft Bronze Ring Hollow Shaft Shrink Disk Table 10: Type Bolt Quantity Tightening Torque [Nm] D.07.. D.17.. D.27.. D.28.. D.37.. D.47.. D.57.. D.67.. D.77.. D.87.. D.97.. Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

-

Page 39: Disassembling Customer Shaft With Shrink Disk

MECHANICAL INSTALLATION 8.9 DISASSEMBLING CUSTOMER SHAFT WITH SHRINK DISK Loosen the bolts of the shrink disk and take out the shaft. IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 40: Assembling Gear Unit With Torque Arm

MECHANICAL INSTALLATION 8.10 ASSEMBLING GEAR UNIT WITH TORQUE ARM Use the torque arm connection according the following drawing. Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... - Page 41 MECHANICAL INSTALLATION Assemble the parts as shown bellow Bolt Washer Washer Ring Rubber Buffer Bolt Fixing Plate Bolt IMM-0016EN - Installation and Maintenance Manual Dana Incorporated...

- Page 42 MECHANICAL INSTALLATION For the fixing bold position refer to the following dimensions Ød Table 11: Type D.07. 26.5 D.17. 31.5 D.27. D.28. 40.5 D.37. D.47. D.57. D.67. D.77. D.87. D.97. 82.5 Dana Incorporated IMM-0016EN - Installation and Maintenance Manual...

-

Page 43: Fitting Outputshaft Elements

8.12 CORRECT POSITION OF OUTPUT SHAFT ELEMENTS The Output Shaft unit (transmission elements) must placed as close as possible to the gear unit so that the radial load is as closest as possible to the gear unit. IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 44: Fitting Couplings

By fitting couplings be sure that there is some clearance between the two elements By fitting couplings be sure that there is no eccentric between the two shafts. By fitting couplings be sure that the two shafts are not angular miss-aligned. Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 45: Maintenance & Inspection

For normal ambient conditions 70 ºC oil bath temperature should be taken as reference * For D series mineral oil is used unless it is differently ordered. For oil type and quantities refer to the following table. IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 46: Lubrication

Carter SH -35 ... +20 -5 ... +20 synth GEM SHC XMP EP-XF 150 4-150 N Klüber- -40 ... +10 -8 ... +10 – – – synth GEM – – – 4-100 N Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 47: Changing The Oil

Extended, intensive contact with oils can lead to skin irritations. Avoid extended contact with oil, and clean oil off skin thorough. WARNING Hot oil can cause scalding. When changing oil, protect yourself against contacting hot oil. IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 48: Mounting Positions

LUBRICATION 10.3 MOUNTING POSITIONS Figured mounting positions of M1 to M6 are determined as reference of directional position of the gearbox. Mounting surfaces are not binding. Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... - Page 49 LUBRICATION Figured mounting positions of M1 to M6 are determined as reference of directional position of the gearbox. Mounting surfaces are not binding. IMM-0016EN - Installation and Maintenance Manual Dana Incorporated...

-

Page 50: Oil Plugs And Oil Quantities

21.0 40.0 33.0 32.5 DR872 53.0 58.0 43.0 67.0 55.0 54.0 DR873 48.5 53.0 39.0 61.0 50.0 49.0 DR972 87.0 113.0 80.5 117.0 97.0 95.0 DR973 84.0 110.0 77.0 112.0 93.0 89.0 Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 51: D Series 4 Stage Oil Level Plugs

53.0 / 3.5 39.0 / 3.5 61.0 / 3.5 50.0 / 3.5 49.0 / 3.5 DR974 84.0 / 5.0 110.0 / 5.0 77.0 / 5.0 112.0 / 5.0 93.0 / 5.0 89.0 / 5.0 IMM-0016EN - Installation and Maintenance Manual Dana Incorporated... -

Page 52: D Series 5-6 Stage Oil Level Plugs

110.0 / 7.5 77.0 / 7.5 112.0 / 7.5 93.0 / 5.5 89.0 / 5.5 DR976 84.0 / 4.0 110.0 / 7.0 77.0 / 7.0 112.0 / 7.0 93.0 / 5.0 89.0 / 5.0 Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... -

Page 53: Troubleshooting Guide

Inform Dana Motion Systems Italia S.r.l. before making any change to the gearbox. Only oil change is allowed to change with- out information. Do not make any think if you are not sure what you are doing and contact Dana Motion Systems Italia S.r.l.. - Page 54 Much than +40 Celsius Dana Motion Systems Italia S.r.l.. Go to ID 100. If not ATEX con- firming check the oil type and oil quantitiy/level according your mounting position and check the nameplate mounting position.

- Page 55 Italia S.r.l.. Goto ID 100 Please contact Dana Motion Systems Italia S.r.l. Service point. See on the back side of this manual. Changing mechanical parts of gearbox can only be done by Dana Motion Systems Italia S.r.l. Service Required No self solution found or with information of Dana Motion Systems Italia S.r.l..

-

Page 56: Disposal

Dispose of the sealings as composite material (metal/plastic) 12.3 DISPOSAL OF METAL Divide up the remainder of the gear reducer into iron, aluminium, non-ferrous havy metal if possible Dispose of it according to the valid national guidelines. Dana Incorporated IMM-0016EN - Installation and Maintenance Manual... - Page 57 IMM-0016EN - Installation and Maintenance Manual Dana Incorporated...

- Page 58 Copyright 2022 Dana Incorporated For product inquiries or support, All content is subject to copyright by Dana and may not visit www.dana.com. be reproduced in whole or in part by any means, ® For other service publications, visit electronic or otherwise, without prior written approval.

Need help?

Do you have a question about the BREVINI D Series and is the answer not in the manual?

Questions and answers