Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for BRP RORAX V-810

- Page 2 2006 Engine Shop Manual ROTAX® V-810 ENGINES � BOMBARDIER.

-

Page 3: Table Of Contents

....Trademarks of Bombardier Recreational Products Inc. (BRP) or its affiliates. FRONT CYLINDER HEAD (NO. 1) ................. 28 Trademark of Bombardier Inc. used under license. -

Page 4: Safety Notice

TECHNICAL SPECIFICATIONS and understand these. It does not include dealer modifications, whether authorized or not by BRP. after ..........· . · · · · · . . . · · . · · · · · · · · · · ..· . ·... -

Page 5: Introduction

The illustrations show the typical construction of f writing. BRP however, maintains a policy of the different assemblies and, in all cases. may not ontinuous improvement of its products without reproduce the full detail or exact shape of the parts 1�... - Page 6 INTRODUCTION INTRODUCTION This Shop Manual uses technical terms wich may be slightly different from the ones in the parts catalog. TYPICAL PAGE TYPICAL PAGE Section 03 ENGINE Section 03 ENGINE Subsection 06 (MAGNETO SYSTEM) 04 (REMOVAL AND INSTALLATION) Title indicates BEARING STATOR AND TRIGGER COIL REMOVA L AND INSTALL ATION...

-

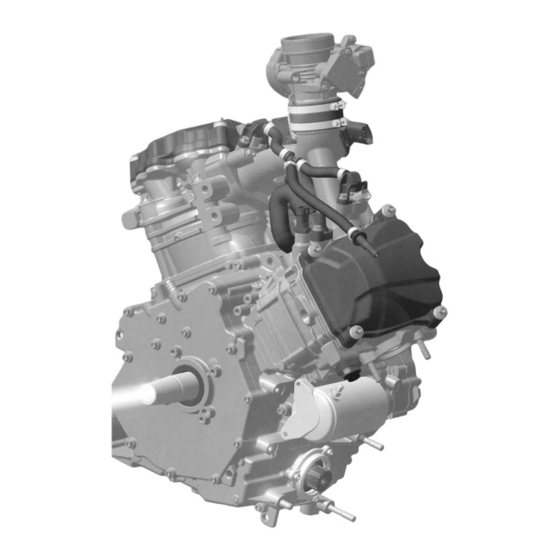

Page 7: V-810 Engine

Section 01 V-810 ENGINE Subsection (LEAK TEST) LEAK TEST SERVICE TOOLS Description Part Number Page camshaft locking tool............529 035 926 ..........2 dial gauge 414 104 700 ..........2 ................GENERAL - any parts to have access to engine cylinder heads. -

Page 8: Reassembly

ENGINE Section 01 V-810 ENGINE Section 01 V-810 Subsection (LEAK TEST) Subsection (LEAK TEST) LEAKAGE ENGINE PERCENTAGE CONDITION 0%to15% Excellent condition 16% to 25% Good condition Fair condition; reduced 26% to 40% engine performance. Poor condition. diagnose % and higher and repair engine. -

Page 9: Cooling System

Section 01 V-810 ENGINE Subsection (COOLING SYSTEM) COOLING SYSTEM SERVICE TOOLS Description Page Part Number installer handle ..............420 877 650 ..........9 oil seal pusher 529 035 757 ..........9 ............... water pump ceramic seal installer ........ - Page 12 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (COOLING SYSTEM) Subsection (LUBRICATION SYSTEM) LUBRICATION SYSTEM SERVICE TOOLS Description Part Number Page disconnect tool ..............529 035 714 ........... 13 hose adapter 529 035 652 ........... 13 ............... . . oil pressure gauge ...............

-

Page 13: General

01 V-810 01 V-810 Section ENGINE Section ENGINE Subsection (LUBRICATION SYSTEM) Subsection (LUBRICATION SYSTEM) GENERAL The engine oil pressure should be within the fol N•m lowing values. LUBRICATION (177 l b f•in) For oil change procedure. refer to VEHICLE SHOP MANUAL. NOTE: Oil pressure switch works between 20 kPa in the appropriate... -

Page 14: Oil Pump

Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (LUBRICATION SYSTEM) Subsection (LUBRICATION SYSTEM) - oil pump shaft with inner rotor and outer rotor. Removal Remove plug screw no. and pull oil pressure regulator out. 1. Pittings on the teeth Using a feeler gauge, measure the clearance of inner and outer rotors as shown. -

Page 15: Engine Oil Strainer

Section ENGINE 01 V-810 Section 01 V-810 ENGINE Subsection (LUBRICATION SYSTEM) Subsection (LUBRICATION SYSTEM) & WARNING Always wear eye protector. Chemicals can cause a rash break out and inju e your eyes. Check engine oil strainer for cracks or other dam age. -

Page 16: 04- Magneto System

Section 01 V-810 ENGINE Subsection 04 (MAGNETO SYSTEM) MAGNETO SYSTEM SERVICE TOOLS Description Part Number Page crankshaft locking bolt ............529 035 617 ........... 23 crankshaft protector ............. 529 036 034 ........... 23 magneto puller 529 035 748 ........... 23 . -

Page 17: General

Section ENGINE Section ENGINE 01 V-810 01 V-810 Subsection 04 (MAGNETO SYSTEM) Subsection 04 (MAGNETO SYSTEM) GENERAL Always perform the electric tests before removing or installing whatever component. During assembly/installation, use the torque val ues and service products as 1n the exploded views. -

Page 18: Stator

Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (MAGNETO SYSTEM) Subsection (MAGNETO SYSTEM) ROTOR NOTE: Use grease to place protector on crank shaft end prior to screw on the magneto puller. Removal Lock crankshaft with crankshaft locking bolt (P/N 529 035 617) (refer to CYLINDER AND HEAD). -

Page 19: Sprag Clutch

Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (MAGNETO SYSTEM) Subsection (MAGNETO SYSTEM) Inspection STARTER DRIVE GEARS Oil sprag clutch no. in sprag clutch housing Inspect sprag clutch and sprag clutch housing for The starter drive gears are located on the engine Slide rotor onto crankshaft. -

Page 20: Cylinder And Head

Section 01 V-810 ENGINE (CYLINDER AND HEAD) Subsection 05 CYLINDER AND HEAD SERVICE TOOLS Description Page Part Number camshaft locking tool ............529 035 926 ......34-35, 37-38 circlip installer 529 035 921 ........... 53 ............... crankshaft locking bolt ............ -

Page 21: Front Cylinder Head (No. 1)

Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (CYLINDER AND HEAD) Subsection (CYLINDER AND HEAD) REAR CYLINDER HEAD (NO. 2) NOTE: For cylinder head, cylinder and piston removal. it is not necessary to remove engine from vehicle. FRONT CYLINDER HEAD (NO. 1) l b f . -

Page 22: Cylinders And Pistons

Section ENGINE Section 01 V-810 ENGINE 01 V-810 Subsection (CYLINDER AND HEAD) Subsection (CYLINDER AND HEAD) GENERAL CYLINDERS AND PISTONS When disassembling parts that are duplicated in the engine, (e.g.: valves), it is a strongly recom NOTE: Components which are identical for both mended to note their position (PTO/MAG side, cylinders/cylinder heads are identified in the two front/rear cylinder) and to keep them as a "group". -

Page 23: Valve Adjustment

Section 01 V-810 ENGINE ENGINE Section 01 V-810 Subsection (CYLINDER AND HEAD) Subsection (CYLINDER AND HEAD) CHAIN TENSIONER VALVE ADJUSTMENT Remove valve covers. Refer to procedure else Removal where in this section. & WARNING CRANK Turn crankshaft to ignition TDC. see SHAFT LOCKING PROCEDURE CAMSHAFT Chain tensioner is spring loaded. -

Page 24: Crankshaft Locking And Camshaft Timing Procedure

Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (CYLINDER AND HEAD) Subsection (CYLINDER AND HEAD) Clean mating surface and threads of camshaft pri Install pick up gear no. prevent timing chain stretching during removal on timing gear of cylinder or to assemble camshaft timing gear. - Page 25 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (CYLINDER AND HEAD) Subsection (CYLINDER AND HEAD) 1. Screwdriver 1. Allen key 14 mm Crank position tri g ger Screw Lock crankshaft with crankshaft locking bolt There are two possibilities to find TDC of the rear 529 035 926).

-

Page 26: Rocker Arm

Section ENGINE 01 V-810 Section ENGINE 01 V-810 Subsection (CYLINDER AND HEAD) ction 05 (CYLINDER AND HEAD) ROCKER ARM Removal Turn crankshaft to ignition TDC, see CRANK SHAFT LOCKING PROCEDURE CAMSHAFT TIMING PROCEDURE above. Remove: - valve cover - chain tensioner - camshaft timing gear no. - Page 28 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection 05 (CYLINDER AND HEAD) Subsection 05 (CYLINDER AND HEAD) Measure camshaft bearing journal diameter and Each camshaft is different in design. Thus, it is lobe height using a micrometer. important not to mix up any parts of the camshaft assembly with that of the other cylinder.

- Page 29 Section ENGll 01 V-810 Section ENGINE 01 V-810 Subsection (CYLINDER AND HEA Subsection (CYLINDER AND HEAD) VALVE Removal Remove valve spring, see VALVE SPRING abO\ Push valve stem, then pull valves no. (inta and no. (exhaust) out of valve guide. A.

- Page 30 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection 05 (CYLINDER AND HEAD) (CYLINDER AND HEAD) Subsection 05 Inspection Replace valve guide out of cylinder head if valve If valve seat contact width is too wide or has dark VALVE GUIDE REPLACEMENT guide is out of specification or has other damages spots, replace the cylinder head.

- Page 31 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (CYLINDER AND HEAD) Subsection (CYLINDER AND HEAD) Remove: VALVE GUIDE DIAMETER - INTAKE AND CYLINDER TAPER IN DIAMETER EXHAUST VALVE - chain tensioner (see CHAIN TENSIONER Maximum New 0.038 mm (.0015 1n) above) Minimum New 5.006 mm (.1971...

- Page 32 ENGINE Section 01 V-810 ENGINE Section 01 V-810 Subsection 05 (CYLINDER AND HEAD) Subsection 05 (CYLINDER AND HEAD) Remove one piston circlip and discard it. Measuri n g perpendicu�rly (90") to isto n pm A. 8 (.315 m) The measured dimension should be as described in the following table.

- Page 33 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subs 05 (CYLINDER AND HEAD) Subsection 05 (CYLINDER AND HEAD) NOTE: Make sure the cylinder bore gauge indica tor is set exactly at the same position as with the micrometer, otherwise the reading will be false. Piston Pin Using synthetic abrasive woven, clean piston pin from deposits.

- Page 34 ENGINE Section 01 V-810 ENGINE Section 01 V-810 Subsection (CYLINDER AND HEAD) Subsection (CYLINDER AND HEAD) ....� -------·- +--- 2 ---------6 +- -- 3 1. Piston Feeler gauge Upp e r compression ring Ring End Gap Lower compression ring 3.

- Page 35 Section 01 V-810 ENGINE Subsection (BOTTOM END) BOTTOM END SERVICE TOOLS Description Part Number Page crankcase support sleeve ............ 529 036 031 ........... 67 529 036 033 ........... 62 oil seal installer ..............plain bearing remover/installer ..........

- Page 36 01 V-810 ENGINE Section Section 01 V-810 ENGINE Subsection (BOTTOM END) Subsection 06 (BOTTOM END) Engine oil & Engine oil & N•m (18 lbfeft) ,/' - - - Engine oil & Engine oil 20N•m 11 (177 lbf.in) Loctite & 10 N•m (89 lbfein) &...

- Page 37 Section ENGINE Section ENGINE 01 V-810 01 V-810 (BOTTOM Subsection 06 (BOTTOM END) Subsection 06 END) GENERAL During assembly/installation, use the torque val ues and service products as shown in the explod ed view(s). Clean threads before applying a threadlocker. Re fer to SELF-LOCKING FASTENERS LOCTITE...

- Page 38 ENGINE Section 01 V-810 Section 01 V-810 ENGINE (BOTTOM END) Subsection Subsection (BOTTOM END) Removal Remove: - PTO cover (refer to PTO COVER above) - intermediate gear no. OIL PUMP - oil pump gear no. (refer to BRICATION SYSTEM) - water pump gear no. remove water pump gear, pull the shaft assem...

-

Page 39: Timing Chain

Section 01 V-810 ENGINE Section ENGINE 01 V-810 Subsection 06 {BOTTOM END) Subsection 06 {BOTTOM END Removal of Magneto Side Timing Chain Inspection NOTE: At installation replace the V-ring no. the breather gear. Check timing chain guide for wear, cracks or othe Adequately oil the ball bearing of the breather gear. - Page 40 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection 06 (BOTIOM END) Subsection 06 (BOTTOM END) NOTE: Measure plain bearing inside diameter - timing chains and timing chain guides (refer and compare to PTO/MAG side journal diameters to TIMING CHAIN and TIMING CHAIN GUIDE of crankshaft (refer to CRANKSHAFT below).

- Page 41 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (BOTTOM ENO) Subsection (BOTTOM ENO) Crankcase half PTO (inside) 2 Oil bore PUSH PLAIN BEARINGS OUTSIDE 3. Partition Oil bore position marked on crankcase Crankcase half Oil bore position marked on plain bearing remover/insca((er Plain bearing remover/installer NOTE: Use an 0-nng...

-

Page 44: Camshaft

Refer to the appropriate VEHICLE SHOP MANUAL Engine oil pressure M1n1mum 350 kPa (51 PSI) at 6000 Oil filter BRP Rotax paper type, replaceable Intake valve opening 10° BTOC Intake valve closing 45° ABOC 1. Crankcase half MAG side Exhaust va Ive opening... - Page 45 Section 01 V-810 ENGINE Section 01 V-810 ENGINE Subsection (TECHNICAL SPECIFICATIONS) Subsection (TECHNICAL SPECIFICATIONS) ENGINE ENGINE Piston measurement Nominal New to 90.966 mm (3 5807 3 5813 in) Minimum New 42.024 mm (I 6545 0.027 mm (0011 Crankshaft j01Jrnal diameter MAG/PTO side Minimum New Maximum...

- Page 46 Section 01 V-810 ENGINE Subsection 07 (TECHNICAL SPECIFICATIONS) COOLING Type Liquid cooled. Closed loop for engine Ethylene-glycol 50%/50% antifreeze/water. Coolant Coolant containing corrosion inhibitors for internal combustion aluminum enoines Thermostat Opening temperature 65°C (149°F) CAPACITIES Engine oil Refer to the appropriate VEHICLE SHOP MANUAL Cooling system (coolant) vmr2006-045...

Need help?

Do you have a question about the RORAX V-810 and is the answer not in the manual?

Questions and answers