BRP ROTAX 914 Series Operator's Manual

Hide thumbs

Also See for ROTAX 914 Series:

- Service bulletin (13 pages) ,

- Service bulletin (24 pages) ,

- Service bulletin (149 pages)

Summary of Contents for BRP ROTAX 914 Series

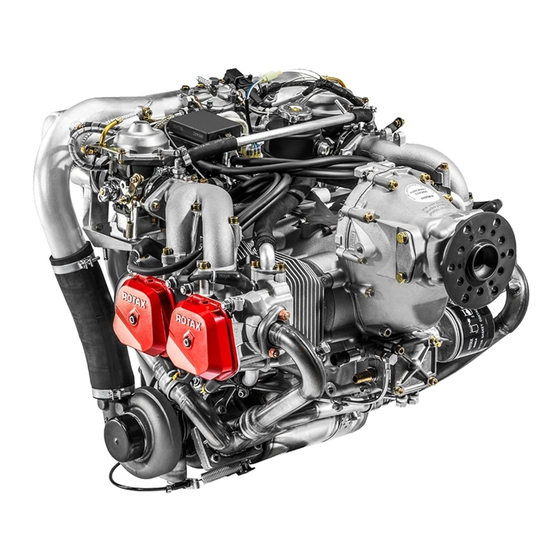

- Page 1 AIRCRAFT ENGINES OPERATORS MANUAL FOR ROTAX® ENGINE TYPE 914 SERIES ref. no.: OM-914 | part no.: 899706 picture: ROTAX® 914 UL with options...

- Page 2 These technical data and the information embodied therein are the property of BRP-Rotax GmbH & CO KG, Austria, acc, BGBI 1984 no. 448, and shall not, without prior written permission of BRP-Rotax GmbH & Co KG, be disclosed in whole or in part to third parties.

-

Page 3: Table Of Contents

5 – Performance and Fuel consumption Chapter 6 – Weights Chapter 7 – System Description Chapter 8 – Preservation and storage Chapter 9 – Supplement Chapter 10 – Proper disposal BRP-Rotax Page Content-1 Effectivity: 914 Series Rev. 0 August 01 2019... - Page 4 INTENTIONALLY LEFT BLANK BRP-Rotax Effectivity: 914 Series Page Table of Content-2 August 01 2019...

- Page 5 INTRO) Introduction Topics in this chapter Foreword BRP-Rotax GmbH & Co KG (hereinafter “BRP-Rotax”) provides “Instructions for Continued Airworthiness”, which are based on the design, tests and certification of the engine and its components. These instructions apply only to engines and components supplied by BRP-Rotax.

- Page 6 INTENTIONALLY LEFT BLANK BRP-Rotax Effectivity: 914 Series Page INTRO-2 August 01 2019...

- Page 7 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 Effectivity: 914 Series BRP-Rotax Page LEP-1 Rev. 0 August 01 2019...

- Page 8 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 August 01 2019 Index rear August 01 2019 page August 01 2019 Page LEP-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 9: Toa) Table Of Amendments

Date of Sig- change approval inclusion appro- from ture authorities INTRO Aug. 01 2019 DOA* Aug. 01 2019 DOA* Aug. 01 2019 DOA* 1 up to Aug. 01 2019 DOA* BRP-Rotax Page TOA-1 Effectivity: 914 Series Rev. 0 August 01 2019... - Page 10 Summary of the relevant amendments in this context, but without any claim to completeness. Rev. no. Chapter Page Date of Comments change 1 up to 10 Aug. 01 2019 new layout and change of company name, also changes in chapter structure BRP-Rotax Effectivity: 914 Series Page TOA-2 August 01 2019 Rev. 0...

-

Page 11: General Note

Topics in this chapter 1.1 General ....................2 1.2 Abbreviations and terms ................ 3 1.3 Safety ....................7 1.4 Safety information ................. 9 1.5 Technical documentation..............12 1.6 Type description.................. 14 Effectivity: 914 Series BRP-Rotax Page 1-1 Rev. 0 August 01 2019... -

Page 12: General

The engine serial number is located on the top of the crank- case, magneto side. Cyl.1 Cyl.3 Cyl.2 Cyl.4 10041 Figure 1: Pos. 1: Engine serial number Page 1-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 13: Abbreviations And Terms

American Society for Testing and Materials Air Transport Association American Wire Gauge Controller Area Network Coil 1–4 Ignition coils 1–4 CPS 1+2 Crankshaft Position Sensor 1+2 Constant Speed Actuator Cooling Temperature Sensor clockwise Effectivity: 914 Series BRP-Rotax Page 1-3 Rev. 0 August 01 2019... - Page 14 Harness Interface Connector A HIC B Harness Interface Connector B Indicated Air Temperature Instructions for Continued Airworthiness Instrument Flight Rules IFSD In-flight-shutdown INJ 1–8 Injector 1–8 Illustrated Parts Catalog Page 1-4 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 15 Operators Manual Oil Pressure Sensor Oil Temperature Sensor Pitch Circle Diameters Pressure Control Valve Permanent magnet alternator Production Organisation Approval Power supply PTFE Polytetrafluoroethylene (Teflon) Power Take Off Rev. Revision Effectivity: 914 Series BRP-Rotax Page 1-5 Rev. 0 August 01 2019...

- Page 16 ROTAX® is a trademark of BRP-Rotax GmbH & Co KG Research Octane Number RON 424 ROTAX® Standard 424 s.v. still valid (only Illustrated Parts Catalog) Serial Number Society of Automotive Engineers Single Engine Piston Service Bulletin Service Instruction SI-PAC Service Instruction Parts and Accessories...

-

Page 17: Safety

The information and descriptions of components and systems contained in this Manual are correct at the time of publication. BRP-Rotax maintains a policy of continuous improvement of its products without imposing upon itself any obligation to retrofit products previously manufactured. - Page 18 ENVIRONMENTAL NOTE Environmental notes give you tips on environmental protection. A revision bar outside the page margin indicates a change to text or graphic. Page 1-8 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 19: Safety Information

• Due to the varying designs, equipment and types of aircraft, BRP-Rotax grants no warranty on the suitability of its en- gine’s use on any particular aircraft. Further, BRP-Rotax grants no warranty on this engine’s suitability with any other... - Page 20 ROTAX® aircraft engine distributor or their independent serv- ice center. BRP-Rotax requires that any service or mainte- nance work be carried out and verified by a technician that has a current iRMT rating.

- Page 21 • This engine may be equipped with a vacuum pump. The safety warning accompanying the vacuum pump must be giv- en to the owner/operator of the aircraft into which the vacuum pump is installed. Effectivity: 914 Series BRP-Rotax Page 1-11 Rev. 0 August 01 2019...

-

Page 22: Technical Documentation

Reference Any reference to a document refers to the latest edition issued by BRP-Rotax if not stated otherwise. This symbol informs you of additional references (data sheets, Manuals, etc.) associated with the given subject. - Page 23 The Illustrations in this Manual are stored in a graphic data base system and are provided with a consecutive irrelevant number. This number (e.g. AE 5iS001) is of no significance for the content. Effectivity: 914 Series BRP-Rotax Page 1-13 Rev. 0 August 01 2019...

-

Page 24: Type Description

2 for configura- tion 3 NOTE Conversion of the configuration 2 to configuration 3 and vice versa may be accomplished by BRP-Rotax Authorized Distribu- tors or their independent Service Centers. Page 1-14 BRP-Rotax Effectivity: 914 Series August 01 2019... -

Page 25: Operating Instructions

This chapter of the Operators Manual contains the operating limits that must be observed and adhered to while operating this type of engine. Effectivity: 914 Series BRP-Rotax Page 2-1 Rev. 0 August 01 2019... - Page 26 TCU controlled airbox pressure and may be therefore subject bigger deviations. 914 F starting with engine 4420200 (TCU part no. 966741) 914 UL starting with engine 4417598 (TCU part no. 966741) Page 2-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 27 72 °C (160 °F) temperature * 88 °C (190 °F) * 914 F starting with S/N 4420200 (TCU part no. 966741) * 914 UL starting with S/N 4417598 (TCU part no. 966741) Effectivity: 914 Series BRP-Rotax Page 2-3 Rev. 0 August 01 2019...

- Page 28 Cylinder head temperature Max. 135 °C (275 °F) Permanent monitoring of coolant temperature and cylinder head temperature is necessary. 914 F up to S/N 4420085 914 UL up to S/N 4417665 Page 2-4 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 29 Airbox pressure + 0.25 bar (3.63 psi) Propeller governor Power consumption of the hydraulic propeller governor Max. 600 W Vacuum pump Power consumption of the vacuum pump Max. 300 W Effectivity: 914 Series BRP-Rotax Page 2-5 Rev. 0 August 01 2019...

- Page 30 1200 W Static roll angle The dry sump lubrication system warrants lubrication in every flight situation below maximum static roll angle. Parameter Min. Max. Static roll angle ß 40° Page 2-6 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 31 Applicable for engine S/N with Suffix -01. Mixture ratio % Designation Concentrate Water conventional e.g. BASF Glysantine anticorrosion * coolant component can be increased up to max. 65 %. Effectivity: 914 Series BRP-Rotax Page 2-7 Rev. 0 August 01 2019...

- Page 32 Usage/Description AVGAS 914 F/UL Aviation standard AVGAS 100 LL (ASTM D910) Page 2-8 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 33 Oil specification • Use only oil with RON 424 classification NOTE The ROTAX® Norm 424 (RON 424) is a BRP-Rotax internal standard, which is only available on special request via the ROTAX® authorized distributor and will not be disclosed to third parties without prior consent.

- Page 34 Since the temperature range of neighboring SAE grades over- Table of lubrication lap, there is no need for change of oil viscosity at short duration of ambient temperature fluctuations. AE 2_0064 Figure 1: Temperature range Page 2-10 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 35: Standard Operation

The control elements mentioned in this chapter are only symbolic and should support the understanding of the procedures. The execution of control elements is in the responsibility of the aircraft manufacturer. Effectivity: 914 Series BRP-Rotax Page 3-1 Rev. 0 August 01 2019... -

Page 36: Daily Checks

The coolant level must be between max. and min. mark. ENVIRONMENTAL NOTE Protect the environment! Do not harm the environment by spilling coolant. Dispose coolant in an environmentally friendly manner. Page 3-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... - Page 37 Expansion tank 08523 Figure 1: Expansion tank Radiator cap Expansion tank Overflow bottle coolant AE 5iS_0139 Figure 2: Overflow bottle Overflow bottle Coolant Effectivity: 914 Series BRP-Rotax Page 3-3 Rev. 0 August 01 2019...

- Page 38 (lower than 25 Nm (19 ft.lb)), further inspection is required. Carburetor Step Procedure Verify free movement of throttle cable and starting car- buretor over the complete range. Check from the cockpit. Page 3-4 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 39: Before Engine Start

It is essential to build up compression in the combustion chamber. Maintain the pressure for a few seconds to let the gas flow via the piston rings into the crankcase. The Effectivity: 914 Series BRP-Rotax Page 3-5 Rev. 0 August 01 2019... -

Page 40: Engine Start

Engine start Step Designation Procedure open Fuel valve. Starting carb. activated Then start the engine without engine in operat- choke. ing temperature. Throttle lever. Set to idle position. Master switch. Page 3-6 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... - Page 41 Check if oil pressure has risen within 10 seconds and monitor oil pressure. Increase of en- gine speed is only permitted at steady oil pressure readings above 2 bar (30 psi). Effectivity: 914 Series BRP-Rotax Page 3-7 Rev. 0 August 01 2019...

-

Page 42: After Engine Start

Start warming up period at approx. 2000 rpm for approx. 2 minutes. Continue at 2500 rpm, duration depending on ambient temperature, until oil temperature reaches 50 °C (120 ° Check temperatures and pressure. Page 3-8 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... - Page 43 Check control of the hydraulic propeller governor to specifica- tions of the manufacturer. NOTE Cycling the propeller governor puts a relatively high load on the engine. Unnecessary cycling or additional checks should be avoided. Effectivity: 914 Series BRP-Rotax Page 3-9 Rev. 0 August 01 2019...

-

Page 44: Take-Off

Switch on the auxiliary fuel pump at take-off. Move throttle lever to 115 % (take-off performance). Set take-off power until the boost pressure stabilizes within the limits of operation. Page 3-10 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 45: Cruising

• With throttle closed and choke activated (open throttle ren- ders starting carb ineffective) • Be aware, no spark below crankshaft speed of 220 rpm (pro- peller speed of 90 rpm) Effectivity: 914 Series BRP-Rotax Page 3-11 Rev. 0 August 01 2019... - Page 46 • Generously sized water separators • Fuel lines routing inclined and without undrained low points • Prevent condensation of humidity, i. e avoid temperature dif- ferences between aircraft and fuel Page 3-12 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 47: Abnormal Operation

4.9.1 Oil pressure below minimum - on ground ........... 8 4.9.2 Oil pressure above permitted range at low ambient temperatures....................9 4.10 Engine on fire or fire in the engine compartment ..................9 4.11 Troubleshooting .................. 9 Effectivity: 914 Series BRP-Rotax Page 4-1 Rev. 0 August 01 2019... - Page 48 Authorities) trained on this particular engine, is allowed to carry out maintenance and repair work. The following description of procedures depends on the respective type of installation in the aircraft and shall therefore only be seen functionally. Page 4-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 49: Sudden Drop Of Boost Pressure And Speed

Limited flying operation as wastegate may be fully closed and control of the boost pressure is only possible via throttle lever. Effectivity: 914 Series BRP-Rotax Page 4-3 Rev. 0 August 01 2019... -

Page 50: Periodical Rise And Drop Of Boost Pressure And Speed (Boost Pressure Control Is Surging)

Possible cause Remedy Pressure control is not Limited flying operation. Switch off possible. servo motor for a moment (max. 5 sec). After a short regulating time opera- tion should stabilize. Page 4-4 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 51: Caution Lamps

The maximum “take-off“ Reduce speed and boost pressure at time limitation was least to maximum continuous speed. exceeded. NOTE After a short regulating time, the blinking red boost lamp should extinguish. Effectivity: 914 Series BRP-Rotax Page 4-5 Rev. 0 August 01 2019... -

Page 52: Orange Caution Lamp Of Tcu Blinking

Any exceeding of the max. admissible operating limits must be recorded by the pilot in the logbook, stating the duration, exact time and extent of exceeding. Page 4-6 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 53: Re-Start During Flight

4.8.2) Exceeding of max. admissible coolant temperature ATTENTION Reduce engine power setting to the minimum necessary and carry out precautionary landing. Coolant tempera- Applicable for engine S/N with Suffix -01. ture max. Effectivity: 914 Series BRP-Rotax Page 4-7 Rev. 0 August 01 2019... -

Page 54: Exceeding Of Max. Admissible Oil Temperature

Immediately stop the engine and check for reason. Check oil system. • Check oil quantity in oil tank. • Check oil quality. See Chapter: Operating media-Lubricants. • A maintenance inspection should be carried out. Page 4-8 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 55: Oil Pressure Above Permitted Range At Low Ambient

The engine must not be operated until the problem is rectified. All checks in accordance with the Maintenance Manual , current issue. Starting problems Engine does not start Effectivity: 914 Series BRP-Rotax Page 4-9 Rev. 0 August 01 2019... - Page 56 Start without start carb (Choke). Engine run Engine keeps running while ignition switch is turned off Possible cause Remedy Overheating of engine. Let engine cool down at idling at ap- prox. 2000 rpm. Page 4-10 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 57 Check fuel. fuel. Cold engine start Engine hard to start at low temperature Possible cause Remedy Starting speed too low. Preheat engine. Faulty or discharged battery. Fit fully charged battery. Effectivity: 914 Series BRP-Rotax Page 4-11 Rev. 0 August 01 2019...

- Page 58 Oil pressure must be measured at idle at an oil temperature of minimum 50 °C (120 °F). Be sure the oil pressure does not go below minimum at idle. Page 4-12 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 59 The indicated power can be achieved by following the procedures laid out in the Operators Manual and ensuring that the engine is well-maintained. Effectivity: 914 Series BRP-Rotax Page 5-1 Rev. 0 August 01 2019...

- Page 60 5.1) Performance data and fuel consumption Performance Performance graphs for standard conditions (ISA) graphs Figure 1: Performance graphs Continuous full throttle Take-off performance performance Power requirement of propeller Page 5-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 61 1180 hPA (34.9 in Hg) Propeller curve (Power requirement of pro- peller) 914 F starting with engine 4420200 (TCU part no. 966741) 914 UL starting with engine 4417598 (TCU part no. 966741) Effectivity: 914 Series BRP-Rotax Page 5-3 Rev. 0 August 01 2019...

- Page 62 47.8 / 64 95 / 70 approx. 55 % 4300 40.4 / 54 90 / 66 NOTE Further essential information regarding engine behavior see Service Letter SL-914-014, latest edition. Page 5-4 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 63 -5 °C (268.15 K) Ambient temperature at 10 000 ft -15 °C (258.15 K) Temperature difference to ISA -10 °C (263.15 K) Max. continuous power as per table 72 kW Effectivity: 914 Series BRP-Rotax Page 5-5 Rev. 0 August 01 2019...

- Page 64 5.2) Fuel consumption Fuel consumption Figure 4: Fuel consumption Engine curve (take-off Engine curve (continuous performance) full throttle performance) Propeller curve (Power requirement of propeller) Page 5-6 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 65: Weights

0.8 kg (1.8 lb) Overload clutch 1.7 kg (3.7 lb) NOTE The overload clutch is installed on all certified aircraft engines and on non-certified aircraft engines of the configuration 3. Effectivity: 914 Series BRP-Rotax Page 6-1 Rev. 0 August 01 2019... - Page 66 INTENTIONALLY LEFT BLANK Page 6-2 BRP-Rotax Effectivity: 914 Series August 01 2019...

-

Page 67: System Description

The design shown in this chapter does not represent a specified execution but should support the understanding of the system. Effectivity: 914 Series BRP-Rotax Page 7-1 Rev. 0 August 01 2019... -

Page 68: General Specification

• Propeller drive thru integrated gearbox with shock absorber and overload clutch (optional on configuration UL2) • Oil tank • External start relay • Drive of hydraulic governor (on configuration 3 only) Page 7-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 69: Auxiliary Equipment (Optional)

Components especially developed and tested for this engine are readily available at BRP-Rotax. Auxiliary equip- The following auxiliary equipment has been developed and ment certified tested for this engine. -

Page 70: Technical Data

1211 cm³ (73.9 in³) Compression ratio. 9.0 : 1 7.1.4) Engine components AE_914_0049_g Figure 1: Engine components Propeller gearbox Airbox Oil pump Oil filter Oil cooler Oil tank Exhaust Exhaust manifold Turbocharger Page 7-4 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 71: Cylinder Arrangement

Figure 2: Cylinder arrangement 7.1.6) Direction of rotation Direction of rotation on propeller shaft: counter clockwise, viewed from the front. 10045 Figure 3: Normal direction of propeller rotation (engine) Effectivity: 914 Series BRP-Rotax Page 7-5 Rev. 0 August 01 2019... -

Page 72: Cooling System

The coolant temperature sensor is located on cylinder head 4 ture measuring (Applicable for engine S/N with Suffix-01). 09152 Figure 4: Cooling system (symbolic) Expansion tank Pressure cap Radiator Overflow bottle Page 7-6 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 73: Fuel System

Otherwise the carburetors could flood. Via the return line surplus fuel flows back to the fuel tank. MAIN 00103 filter/water trap fuel tank electric fuel pumps fuel pressure regulator Effectivity: 914 Series BRP-Rotax Page 7-7 Rev. 0 August 01 2019... -

Page 74: Lubrication System

The oil emerging from the turbocharger collects in a stainless steel oil sump and is sucked back to the secondary oil pump and then pumps back to the main oil tank via the oil line. Page 7-8 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... - Page 75 Oil tank Oil radiator Venting tube Oil pressure sensor Oil line (secondary oil pump Oil line (main oil pump) to oil tank) Oil temperature sensor 10 Oil filter (oil) Effectivity: 914 Series BRP-Rotax Page 7-9 Rev. 0 August 01 2019...

-

Page 76: Electric System

Firing order: 1 - 4 - 2 - 3 Ignition circuit A 10040 Ignition circuit B Charging coils Electronic modules Trigger coils for ignition Dual ignition coils signal Trigger coil for speed signal Figure 7: Ignition circuit Page 7-10 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 77: Turbo Charger And Control System

(115 %) or, on a power reduction, to max. continuous power (100 %). In this range (108 to 110 % throttle position) small changes in throttle position have a big effect on engine performance and Effectivity: 914 Series BRP-Rotax Page 7-11 Rev. 0 August 01 2019... - Page 78 If one of the stated factors exceeds the specified limits, the boost pressure is automatically reduced, thus protecting the en- gine against overload. Page 7-12 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 79: Tcu Caution Lamps

• The TCU registers the time of full throttle operation (boost pressure). Full throttle operation for longer than 5 minutes will make the red boost lamp blink. See Chapter 4) Abnormal operation. Effectivity: 914 Series BRP-Rotax Page 7-13 Rev. 0 August 01 2019... -

Page 80: Exhaust System

Exhaust Gas The sensors for reading the exhaust gas temperature are lo- Temperature cated on the exhaust pipes near the cylinder outlet. Sensors (EGT) Page 7-14 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0... -

Page 81: Propeller Gearbox

3. Figure 11: Overload clutch Fig. shows a propeller gearbox of configuration 2 with the inte- grated overload clutch. Effectivity: 914 Series BRP-Rotax Page 7-15 Rev. 0 August 01 2019... - Page 82 NOTE Transmission ratio between crankshaft and hydraulic governor or vacuum pump is 1.842 i.e. the speed of the hydraulic gover- nor or vacuum pump is 0.54 of engine speed. Page 7-16 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 83: Preservation And Storage

Other useful information for service and airworthiness of your engine you'll find on www.rotax-owner.com. ATTENTION Carry out all directives of Service Bulletins (SB), according to their priority. Observe applicable Service Instructions (SI) and Service Letter (SL). Effectivity: 914 Series BRP-Rotax Page 8-1 Rev. 1 August 01 2019... - Page 84 Close all openings on the cold engine, such as exhaust end pipe, venting tube, air filter etc. against entry of dirt and humidity. Spray all steel external engine parts with corrosion inhibit- ing oil. Drain carburetor float chambers. Page 8-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 85 For longer storage periods repeat preservation annually. Step Procedure Remove all plugs and caps. Clean spark plugs with plastic brush and solvent. Reinstall. Effectivity: 914 Series BRP-Rotax Page 8-3 Rev. 0 August 01 2019...

- Page 86 INTENTIONALLY LEFT BLANK Page 8-4 BRP-Rotax Effectivity: 914 Series August 01 2019...

-

Page 87: Supplement

The form is also available from the official ROTAX® AIRCRAFT ENGINES Website in electronic version. Authorized Overview of ROTAX® authorized aircraft engines distributor or Distributor their independent Service Center. Refer to the official ROTAX® AIRCRAFT ENGINES Website www.FLYROTAX.com. Effectivity: 914 Series BRP-Rotax Page 9-1 Rev. 0 August 01 2019... - Page 88 9.1) Form Figure 1: Form Page 9-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

-

Page 89: Proper Disposal

(coolant, oil) or fuels and the applicable regional waste disposal regulations. ENVIRONMENTAL NOTE Work with the utmost care to ensure that no water pollutants can penetrate into the soil, water or the sewerage system. Effectivity: 914 Series BRP-Rotax Page 10-1 Rev. 0 August 01 2019... - Page 90 ROTAX® aircraft engines F.O.B to ROTAX® Authorized Distributors or their independent Service Centers. Chemical agents Please observe the safety and disposal instructions of the (cleaner, LOCTITE manufacturer. etc.) Page 10-2 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 91 .........7 pressure, speed ......4 Exceeding engine speed ....7 Pre-flight checks ......5 Exceeding of max. admissible Propeller gearbox ......15 coolant temperature .....7 Exceeding of max. admissible cooling system temperature ..7 Effectivity: 914 Series BRP-Rotax Page Index-3 Rev. 0 August 01 2019...

- Page 92 Turbocharger/Exhaust system ..14 Start, as per RTCA DO 178 B ..10 Type description ......14 Start, standard......10 Sudden drop, boost pressure, speed..........3 Sudden rise, boost pressure, speed..........3 Weight, Accessories.......1 Weight, Engine ......1 Page Index-4 BRP-Rotax Effectivity: 914 Series August 01 2019 Rev. 0...

- Page 96 AIRCRAFT ENGINES __________________________________________________________ Engine serial no. __________________________________________________________ Type of aircraft __________________________________________________________ Aircraft registration no. ROTAX® authorized distributor www.flyrotax.com ® and tm are trademarks of BrP-rotax GmbH & co KG. © 2019 BrP-rotax GmbH & co KG. all rights reserved...

Need help?

Do you have a question about the ROTAX 914 Series and is the answer not in the manual?

Questions and answers