Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for System Sensor PDRP-2001E

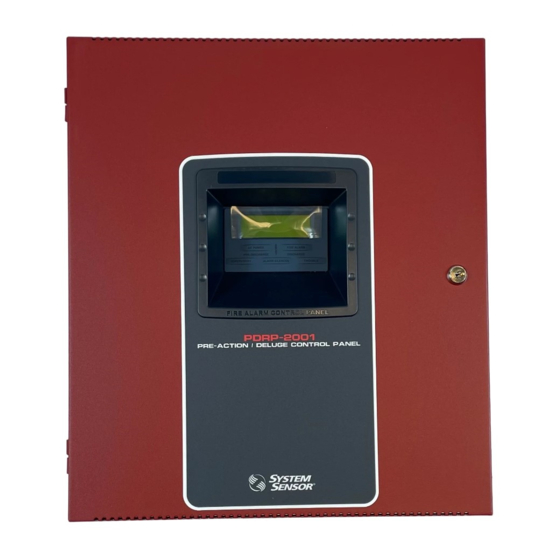

- Page 1 3825 Ohio Avenue St. Charles, IL 60174 1-800-SENSOR2 Fax: (630) 377-6495 PDRP-2001 Series Deluge • Preaction Control Panel Instruction Manual Document #53043 5/08/07 Revision: PN 53043:A ECN 07-157 Downloaded from Elcodis.com electronic components distributor...

- Page 2 While a fire alarm system may lower insurance Fire Alarm System Limitations rates, it is not a substitute for fire insurance! An automatic fire alarm system–typically made up of age of flammable materials, etc.). smoke detectors, heat detectors, manual pull stations, Heat detectors do not sense particles of combustion and audible warning devices, and a fire alarm control panel with alarm only when heat on their sensors increases at a...

- Page 3 Adherence to the following will aid in problem-free Installation Precautions installation with long-term reliability: WARNING - Several different sources of power can be Like all solid state electronic devices, this system may connected to the fire alarm control panel. Disconnect all operate erratically or can be damaged when subjected to sources of power before servicing.

-

Page 4: Table Of Contents

Table of Contents Table of Contents SECTION 1: Product Description .........................11 1.1: Product Features ............................11 1.2: Specifications ..............................13 1.3: Controls and Indicators..........................14 1.4: Components..............................15 1.5: Optional Modules and Accessories ......................16 SECTION 2: Installation ............................17 2.1: Backbox Mounting ............................17 2.2: Operating Power............................20 2.3: Input Circuits ...............................21 2.4: Output Circuits ............................23 2.4.1: Outputs/Notification Appliance/Releasing Circuits................23... - Page 5 Table of Contents 3.2: Initial Power-up ............................47 3.3: Programming Screens Description......................47 3.4: Programming and Passwords ........................48 3.5: Master Programming Level.........................49 3.5.1: FACP CONFIG (Application Templates) ..................50 3.5.2: Input Zones............................50 3.5.3: Output Circuits ..........................57 3.5.3.1 Enabled ............................58 3.5.3.2 Type ............................58 3.5.3.2.1 Release Circuit 1 or Release Circuit 2 .................58 3.5.3.2.2 Release Stage NAC ......................59 3.5.3.3 Silence .............................59 3.5.3.4 Auto Silence ..........................60...

- Page 6 Table of Contents 4.1.4: Reset ..............................85 4.2: Indicators ..............................86 4.3: Normal Operation............................86 4.4: Trouble Operation............................87 4.5: Alarm Operation............................88 4.6: Supervisory Operation..........................89 4.7: Disable/Enable Operation..........................89 4.8: Waterflow Circuits Operation........................89 4.9: 2nd-Shot Water Switch..........................90 4.10: Detector Functions.............................90 4.11: Time Functions: Real-Time Clock......................90 4.12: Coded NAC Operation ..........................90 4.13: Release Stages ............................91 4.14: Special System Timers ..........................91...

- Page 7 APPENDIX F: Maximum Number of Detectors per Zone ................127 APPENDIX F: Four-Wire Smoke Detectors/Devices (UL Listed) ..............128 APPENDIX F: Notification Appliances (UL Listed)..................129 •: System Sensor - 24VDC .........................129 •: Releasing Applications ...........................130 •: Door Holders (UL Listed) ..........................130 •: Relays (UL Listed) ............................130...

- Page 8 Notes PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com electronic components distributor...

- Page 9 It is imperative that the installer understand the requirements of the Authority Having Jurisdiction (AHJ) and be familiar with the standards set forth by the following regulatory agencies: • Underwriters Laboratories Standards • NFPA 72 National Fire Alarm Code • CAN/ULC - S527-99 Standard for Control Units for Fire Alarm Systems Before proceeding, the installer should be familiar with the following documents.

- Page 10 Main Circuit Board PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com electronic components distributor...

-

Page 11: Section 1: Product Description

The PDRP-2001E offers the same features as the PDRP-2001 but allows connection to 220/240 VAC. Unless otherwise specified, the information in this manual applies to both the 110/120 VAC and 220/240 VAC versions of the panels. - Page 12 • Outputs Programmable for: Releasing Solenoids NACs programmable for: Silence Inhibit Auto-Silence Strobe Synchronization (System Sensor, Wheelock, Gentex, Faraday, Amseco) Selective Silence (horn-strobe mute) Temporal or Steady Signal Silenceable or Nonsilenceable Release Stage Sounder • Designed for sprinkler standards NFPA 13, 15 and 16 •...

-

Page 13: Specifications

Product Description 1.2 Specifications AC Power PDRP-2001: 120 VAC, 60 Hz, 3.66 amps PDRP-2001E: 240 VAC, 50 Hz, 2.085 amps Wire size: minimum #14 AWG (2.0 mm ) with 600V insulation Supervised, nonpower-limited Battery (sealed lead acid only) - J12 Maximum Charging Circuit - Normal Flat Charge: 27.6 VDC @ 1.4 amp... -

Page 14: Controls And Indicators

Product Description Controls and Indicators Special Application Resettable or Nonresettable Power - TB9 Operating Voltage: Nominal 24 VDC Maximum Available Current: 500 mA (see note 1) Power-limited Circuitry Jumper selectable by JP31 for resettable or nonresettable power: Jumper pins 1 & 2 on JP31 for nonresettable power Jumper pins 2 &... -

Page 15: Components

Components Product Description Local Piezo Sounder A piezo sounder provides separate and distinct pulse rates for alarm, trouble and supervisory conditions. Indicators Indicators are provided to annunciate the following conditions: • Fire Alarm - red indicator • Supervisory - yellow indicator •... -

Page 16: Optional Modules And Accessories

Product Description Optional Modules and Accessories 1.5 Optional Modules and Accessories CAC-5X Class A Converter Module The CAC-5X Module can be used to convert the Style B (Class B) Initiating Device Circuits to Style D (Class A) and Style Y (Class B) Output Circuits to Style Z (Class A). The modules connect to J2 and J7 on the FACP main circuit board. -

Page 17: Section 2: Installation

Backbox Mounting Installation Installation SECTION 2 The cabinet can be surface mounted or semi-flush mounted. The door is removable during the installation period by opening and lifting it off the hinges. The cabinet mounts using two key slots at the top of the backbox and two additional securing holes located at the bottom. Carefully unpack the system and check for shipping damage. - Page 18 Installation Backbox Mounting Semi-Flush Mounting Do not recess box more than 3.875” into wall to avoid covering venting Hinge Slot for holes on top of box. optional Dress Panel Mounting slots for optional Trim Ring Semi-Flush mounting hole Hinge Slot for optional Dress Panel Figure 2.2 Cabinet Dimensions PDRP-2001 Series PN 53043:A 5/08/2007...

- Page 19 Backbox Mounting Installation Figure 2.3 Backbox PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com electronic components distributor...

-

Page 20: Operating Power

120 VAC, 60 Hz, 3.66 amps for the PDRP-2001 or 240 VAC, 50 HZ, 2.085 amps for the PDRP-2001E. Run a pair of wires (with ground conductor) from the protected premises main breaker box to the AC terminal block TB1 on the main power supply. As per the National Electrical Code, use 14 AWG (2.00 mm... -

Page 21: Input Circuits

2.3 Input Circuits The PDRP-2001 has six programmable IDCs (Initiating Device Circuits). Each circuit is compatible with System Sensor’s i smoke detectors which generate a maintenance signal when the detector becomes dirty and a separate supervisory ‘freeze’ signal when ambient temperature falls below the detector rating of approximately 45 F. - Page 22 Installation Input Circuits Combination Waterflow/Supervisory Zone A combination Waterflow/Supervisory circuit allows an FACP to distinguish between an Alarm switch (waterflow device) and a Supervisory switch (tamper) installed on the same circuit. Any circuit can be programmed as a Combo Type zone. The following figure illustrates the wiring of Zone 2 as a Style B (Class B) Waterflow/Supervisory circuit.

-

Page 23: Output Circuits

Output Circuits Installation 2.4 Output Circuits 2.4.1 Outputs/Notification Appliance/Releasing Circuits Each of the four Style Y (Class B) Notification Appliance Circuits can output a maximum of 3.0 amps of current. Total current drawn from these as well as other DC power outputs cannot exceed 7.0 amps (refer to battery calculations section). -

Page 24: 2: Special Application Dc Power Output Connections

Installation Output Circuits 2.4.2 Special Application DC Power Output Connections Special Application Resettable and Nonresettable 24 VDC power is available on the PDRP-2001 control panel. Special Application 4-Wire Smoke Detector Power (500 mA) 24 VDC filtered, resettable power for 4-wire smoke detectors can be obtained from these terminals (power-limited) Special Application Resettable or Nonresettable Power (500 mA) -

Page 25: Power-Limited Wiring Requirements

Power-limited Wiring Requirements Installation 2.5 Power-limited Wiring Requirements Power-limited and nonpower-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring must remain at least 0.25” (6.35 mm) away from any nonpower- limited circuit wiring. Furthermore, all power-limited and nonpower-limited circuit wiring must enter and exit the cabinet through different knockouts and/or conduits. -

Page 26: Installation Of Optional Modules

Installation Installation of Optional Modules 2.6 Installation of Optional Modules CAUTION: Remove all power (AC and DC) before installing or removing modules or wiring. 2.6.1 CAC-5X Class A Converter Module 2.6.1.1 Installation The CAC-5X Module can be used to convert five Style B (Class B) Initiating Device Circuits to Style D (Class A) and the two Style Y (Class B) Notification Appliance Circuits to Style Z (Class A). -

Page 27: Wiring Nacs And Idcs For Class A

Installation of Optional Modules Installation 2.6.1.2 Wiring NACs and IDCs for Class A Wire the Style Z (Class A) Notification Appliance Circuits using TB5 of the FACP main circuit board and TB2 of the CAC-5X module. Wire the Style D (Class A) Initiating Device Circuits using TB4 of the FACP main circuit board and TB1 of the CAC-5X. -

Page 28: 2: 4Xtm Municipal Box Transmitter Option Module

Installation Installation of Optional Modules 2.6.2 4XTM Municipal Box Transmitter Option Module The 4XTM module can be plugged into connectors J4 and J5 on the main circuit board. The following steps must be followed when installing the 4XTM module: 1. Remove all power (AC and DC) from the FACP before installing the modules 2. -

Page 29: 4Xtm Transmitter Module Installation

Installation of Optional Modules Installation 2.6.2.1 4XTM Transmitter Module Installation The 4XTM provides a supervised output for a local energy municipal box transmitter in addition to alarm and trouble reverse polarity. A jumper option allows the reverse polarity circuit to open with a system trouble condition if no alarm condition exists. A disable switch allows disabling of the transmitter output during testing to prevent accidental calling of the monitoring service. -

Page 30: Ann-Bus Devices

Installation ANN-BUS Devices 2.7 ANN-BUS Devices WARNING! Disconnect all sources of power (AC and DC) before installing or removing any modules or wiring. A variety of optional devices can be connected to the FACP ANN-BUS communication circuit. Compatible devices include: •... - Page 31 ANN-BUS Devices Installation After calculating the total worst case current draw, Table 2.1 specifies the maximum distance the modules can be located from the FACP on a single wire run. The table ensures 6.0 volts of line drop maximum. In general, the wire length is limited by resistance, but for heavier wire gauges, capacitance is the limiting factor.

-

Page 32: Wiring Configuration

Installation ANN-BUS Devices Wiring Distance Calculation Example: Suppose a system is configured with the following ANN-BUS modules: • 2 ANN-80 Remote LCD Annunciators • 1 ANN-S/PG Serial/Parallel Printer Interface Module • 1 ANN-I/O LED Driver Module The total worst case current is calculated as follows: ANN-80 Current Draw = 2 X 0.040 amps = 0.080 amps... -

Page 33: Powering Ann-Bus Devices From Auxiliary Power Supply

ANN-BUS Devices Installation 2.7.1.3 Powering ANN-BUS Devices from Auxiliary Power Supply Figure 2.16 illustrates the powering of ANN-BUS devices from an auxiliary power supply such as the FCPS-24S6/8, when the maximum number of ANN-BUS devices exceeds the ANN-BUS power requirements. Cut Ground Fault Detection jumper JP1 (FACP monitors for ground faults) FACP ANN-BUS... -

Page 34: 3: Ann-80 Remote Lcd Annunciator

Installation ANN-BUS Devices 2.7.3 ANN-80 Remote LCD Annunciator The ANN-80 LCD Annunciator is a compact, 80 character, backlit LCD remote fire annunciator which mimics the FACP display. It also provides system status indicators for AC Power, Alarm, Trouble, Supervisory and Alarm Silenced conditions. Communication between the ANN-80 and FACP is accomplished over a two wire serial interface employing the ANN-BUS communication format. -

Page 35: Wiring Ann-80 To Facp

ANN-BUS Devices Installation 2.7.5.3 Wiring ANN-80 to FACP The following steps can be used as a guide to wire the annunciator. Make certain all power has been removed from the FACP prior to annunciator installation. 1. Route wires from hole in backplate, through wiring channel and then to ANN-80 terminal block TB1 wiring channel wires... - Page 36 Installation ANN-BUS Devices FACP 4 3 2 1 ANN-BUS and power wiring are supervised and power-limited ANN-80 Figure 2.17 ANN-80 Wiring to FACP The following table shows the ANN-80 connections to the FACP. FACP (TB3) ANN-80 (TB1) Terminal 4 GND (-) Terminal 1 (-) Terminal 3 PWR (+) Terminal 2 (+)

-

Page 37: 6: Ann-S/Pg Serial/Parallel Printer Interface Installation

ANN-BUS Devices Installation 2.7.6 ANN-S/PG Serial/Parallel Printer Interface Installation The ANN-S/PG Serial/Parallel Interface module allows the ancillary connection of a serial or parallel printer to the FACP for a real-time log of system events, detector status reports and event history. Note that either a serial or parallel printer may be installed, not both. Proceed with the installation as described in the following: 1. -

Page 38: Connecting Prn-6 Printer

Installation ANN-BUS Devices 2.7.6.2.1 Connecting PRN-6 Printer Remote printers require a primary AC power source. If required for the fire alarm system configuration (for example, a Proprietary Fire Alarm System), a remote printer requires a secondary power source (battery backup). Since a secondary power source is not provided as a standard feature, a separate UL-listed Uninterruptible Power Supply (UPS) should be used. -

Page 39: 7: Ann-I/O Led Driver Module

ANN-BUS Devices Installation 2.7.7 ANN-I/O LED Driver Module The ANN-I/O is an LED driver module that can be used in a wide variety of applications, including as an interface with most customized graphic annunciators. The ANN-I/O can drive up to 40 LEDs. -

Page 40: Ann-I/O Connection To Facp

Installation ANN-BUS Devices 2.7.7.3 ANN-I/O Connection to FACP The ANN-I/O connects to the FACP via the ANN-BUS as illustrated in Figure 2.20. After the ANN-I/O is connected to the panel, it must be added to the system via FACP programming. ANN-I/O Module FACP ANN-BUS and power wiring are... -

Page 41: Ann-I/O Module Led Wiring

ANN-BUS Devices Installation 2.7.7.4 ANN-I/O Module LED Wiring There are four 12-pin connectors on the ANN-I/O module for connecting LEDs. Each set of 10 LEDs get their power from Pin 11 of the corresponding connector. Internal resistors are sized so that there is approximately 10 mA of current for each LED. No series resistors are required. LED outputs are mapped to output circuits. -

Page 42: Ann-Led Board Layout

Installation ANN-BUS Devices 2.7.8.1 ANN-LED Board Layout Figure 2.22 illustrates the ANN-LED board showing locations of screw terminals for connection to the FACP and the DIP switches for selecting the ANN-BUS ID number. ANN-BUS (ID#) Address DIP switch ANN-BUS Connector Figure 2.22 ANN-LED Board Layout 2.7.8.2 Specifications •... -

Page 43: Ann-Led Connection To Facp

ANN-BUS Devices Installation 2.7.8.4 ANN-LED Connection to FACP Figure 2.23 illustrates the ANN-LED board showing locations of screw terminals for connection to the FACP and the DIP switches for selecting the ANN-BUS ID number. FACP ANN-LED -24 VDC +24 VDC ANN-BUS Figure 2.23 ANN-LED Connection to FACP PDRP-2001 Series PN 53043:A 5/08/2007... -

Page 44: 9: Ann-Rly Relay Module

Installation ANN-BUS Devices 2.7.9 ANN-RLY Relay Module The ANN-RLY relay module provides 10 programmable Form-C relays when used with a compatible FACP. 2.7.9.1 ANN-RLY Board Layout Figure 2.22 illustrates the ANN-RLY board showing locations of screw terminals for connection to the FACP and the DIP switches for selecting the ANN-BUS ID number. ANN-BUS (ID#) Address DIP switch ANN-BUS Connector... -

Page 45: Ann-Rly Connection To Facp

ANN-BUS Devices Installation 2.7.9.4 ANN-RLY Connection to FACP Figure 2.23 illustrates the ANN-RLY board showing locations of screw terminals for connection to the FACP and the DIP switches for selecting the ANN-BUS ID number. FACP ANN-RLY -24 VDC +24 VDC ANN-BUS Figure 2.25 ANN-RLY Connection to FACP PDRP-2001 Series PN 53043:A 5/08/2007... -

Page 46: Section 3: Programming

Programming User Programming Programming SECTION 3 NOTICE TO USERS, INSTALLERS, AUTHORITIES HAVING JURISDICTION AND OTHER INVOLVED PARTIES This product incorporates field-programmable software. In order for the product to comply with the requirements in the Standard for Control Units and Accessories for Fire Alarm Systems, UL 864, certain programming features or options must be limited to specific values or not used at all as indicated below. -

Page 47: Initial Power-Up

Initial Power-up Programming Pressing 2 will select user Programming Mode which may only be accomplished by an authorized person. After pressing 2, a screen will prompt for a password. After entering the correct password, the user may select from a list of programming options. Exit Programming and Read Status Mode The programmer can exit any mode by repeatedly pressing the keypad ESC (Escape) key until the display reads System All Normal. -

Page 48: Programming And Passwords

Programming Programming and Passwords 3.4 Programming and Passwords There are two factory set programming passwords which will access the Programming screens as indicated in the following examples. From either of the screens, access to specific system and device features or programming may be obtained. All user programming entries are stored in nonvolatile memory. -

Page 49: Master Programming Level

Master Programming Level Programming 3.5 Master Programming Level When the Master Program Level password is entered, the control panel will enter user Programming mode. In this mode, the piezo sounder remains off, the trouble relay is activated and the system Trouble indicator flashes until Programming mode is exited. The following display will appear: PROGRAMMING 1=FACP CONFIG... -

Page 50: 1: Facp Config (Application Templates)

Programming Master Programming Level 3.5.1 FACP CONFIG (Application Templates) For a detailed description of each Template, refer to "FACP Configuration Templates" on page 108. The FACP Configuration option allows the user to program the FACP with one of seven factory preprogrammed templates or one custom template which can be programmed by the user. The templates have been provided to allow the user to quickly program the panel with typical job- site configurations. - Page 51 Master Programming Level Programming To change the programming for the displayed zone, press the keyboard ‘down’ arrow key to view the Edit Zone screens. The following examples show the editing of Input Zone 1: INPUT ZONE 1 1=ENABLED 2=TYPE PULL STATION 3=OUTPUT CIRCUIT MAP Edit Input Zone Screen #2 INPUT ZONE 1...

- Page 52 Programming Master Programming Level Pressing the down arrow key displays additional zone types as indicated in the following table. Table 3.1 Zone Types Zone Type Action When Activated Pull-Station Fire Alarm Fire Alarm Manual Release Normally Open Contact Fire Waterflow Fire Waterflow NS (nonsilenceable) Fire, nonsilenceable...

- Page 53 Master Programming Level Programming Output Circuit MAP Output Mapping (per input zone) allows the programmer/operator to assign the Output Circuits that will be activated when a particular Input Zone or cross-zoned releasing group goes active. Pressing 3 for Output Circuit Map while viewing Edit Input Zone Screen #2 will display screens which show the Output Circuits programmed to activate when the selected Input Zone (or cross-zoned releasing group) is activated.

- Page 54 Programming Master Programming Level Pressing 1 while viewing the Noun/Adjective Screen will cause the following screen(s) to be displayed. Note that the keyboard down arrow key must be pressed to see all the Adjective screens. Press the number corresponding to the adjective that is to be used as a descriptor for the location of the detector currently being programmed.

- Page 55 Master Programming Level Programming Pressing 2 while viewing the Noun/Adjective Screen will cause the following screen(s) to be displayed. Note that the keyboard down arrow key must be pressed to see all the Noun screens. Press the number corresponding to the noun that is to be used as a descriptor for the location of the detector currently being programmed.

- Page 56 Programming Master Programming Level A maximum of 20 characters (including spaces) can be entered. To enter alphanumeric characters from the keypad, repeatedly press the appropriate key until the desired character is displayed in the first position. For example, to enter the letter B, press the 2 (ABC) key three times to toggle through the characters 1, A and B.

-

Page 57: 3=Output Circuits

Master Programming Level Programming 3.5.3 Output Circuits The options for the Output Circuits on the control panel main circuit board can be configured by pressing 2 while viewing Programming Screen #2. The following screens will be displayed: OUTPUT CIRCUITS 1=OUTPUT 1 2=OUTPUT 2 3=OUTPUT 3 PROGRAMMING... -

Page 58: Enabled

Programming Master Programming Level 3.5.3.1 Enabled Pressing 1 while viewing Output Screen #1 will cause the display to change to Enabled No. This will prevent the selected main circuit board NAC from activating its devices. Each press of the 1 key will cause the display to toggle between Enabled Yes and Enabled No. Note that if a circuit is disabled, a trouble will be logged on the FACP until the circuit is enabled. -

Page 59: Release Stage Nac

Master Programming Level Programming 3.5.3.2.2 Release Stage NAC If Release Stage NAC is selected as the Output Type, the following subscreen will be displayed: RELEASE STAGES 1=RELEASE 1 ONLY 2=RELEASE 2 ONLY An NAC can be used to signal the two stages of a release operation. This screen allows the programmer to select the NAC output that will indicate the release stages for Release Circuit 1 or Release Circuit 2. -

Page 60: Auto Silence

Programming Master Programming Level 3.5.3.4 Auto Silence The Auto Silence feature, when enabled, automatically silences all main circuit board silenceable notification appliances after a programmed length of time. To enable this feature and program the time delay before Auto Silence activation, press 2 while viewing Output Screen #2. -

Page 61: Coding

Coding Screen #1 Output Screen #3 CODING 1=TEMPORAL 2=FUTURE USE 3=FUTURE USE Coding Screen #2 CODING 1=CROSS ZONE 2=SYNC SYSTEM SENSOR 3=SYNC WHEELOCK Coding Screen #3 CODING 1=SYNC GENTEX 2=SYNC FARADAY 3=SYNC AMSECO Coding Screen #4 PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com... -

Page 62: Synchronized Nac Operation

Circuit to perform a release and the programmed NAC output to turn on steady • Synchronized output for System Sensor, Wheelock, Gentex, Faraday or Amseco - Refer to "Synchronized NAC Operation" on page 62 for additional information Selection of one of the above options will cause the control panel to store the information in memory and return the display to Output Screen #1, which will display the new coding choice. -

Page 63: 4: Cross Input Zones

Master Programming Level Programming 3.5.4 Cross Input Zones An application may require that two or more input zones become active at the same time before a particular releasing output activates. This is referred to as cross-zoning. For example, an installer may want four particular zones to become active at the same time before a releasing circuit is activated. -

Page 64: 5: On-Board Relays

Programming Master Programming Level In this example, since the cross-zoning for Release Circuit 1 (Zone 1) is being displayed, Yes is shown for Zone 1 which is cross-zoned with Zone 2. Zone 2 displays Yes since it is cross-zoned with Zone 1. The remaining zones display NO or N/A for no cross-zoning to Zone 1. By pressing the number key corresponding to the desired zone, the display for that zone will toggle between Yes and No indicating cross-zoning to Zone 1 or no cross-zoning to Zone 1. -

Page 65: Timers

Master Programming Level Programming Pressing 3 for System Setup, while viewing Programming Screen #2, will cause the following screens to be displayed: SYSTEM SETUP 1=FUTURE USE 2=TIMERS PROGRAMMING 1=CROSS INPUT ZONES 3=BANNER 2=ON-BOARD RELAYS 3=SYSTEM SETUP System Setup Screen #1 Programming Screen #2 SYSTEM SETUP 1=TIME-DATE... -

Page 66: Soak 1 Or Soak 2

Programming Master Programming Level 3.5.6.1.1 Soak 1 or Soak 2 The factory default setting for Soak Time is 10 minutes. To select a Soak Time delay of 10 to 30 minutes, press 1 for Soak 1 (Release Circuit 1) or 2 for Soak 2 (Release Circuit 2) while viewing Timer Screen #1. -

Page 67: Ac Loss Delay

Master Programming Level Programming 3.5.6.1.3 AC Loss Delay The reporting of a loss of AC power can be delayed by programming the length of the desired delay. Press 1 while viewing Timer Screen #2 to display the following: AC LOSS DELAY RANGE 00-24 HOURS TIMER 1=AC LOSS DLAY 2 HR... -

Page 68: Time-Date

Programming Master Programming Level Pressing 2 while viewing the Select Banner Screen will display the following screen: USER BANNER-LINE 1 PRESS ENTER IF OK User Defined Banner Screen This screen allows the programmer to enter a custom banner. A flashing cursor will appear in the bottom left corner of the display. -

Page 69: Time

Master Programming Level Programming 3.5.6.3.1 Time To change the time, press 1 while viewing the Time-Date Screen. The following screen will be displayed: ENTER TIME AS 12HRS 10:00 1=AM 2=PM Time Screen A flashing cursor is located toward the top left of the display. Below the cursor is the current time. -

Page 70: Daylight Savings Time

Programming Master Programming Level 3.5.6.3.4 Daylight Savings Time Pressing 1 while viewing Time-Date Screen #2 will cause the following screens to be displayed: DAYLIGHT SAVINGS 1=ENABLED 2=START MONTH 3=START WEEK WK 2 TIME AND DATE 1=DAYLIGHT SAVINGS Daylight Savings Screen #1 Time &... -

Page 71: 7: Ann-Bus

Master Programming Level Programming 3.5.7 ANN-BUS Optional ANN-BUS devices available for the FACP include annunciators, relay modules and printer connection for acquiring hardcopy printouts of panel data. Pressing 1 while viewing Programming Screen #3 will cause the control panel to display the following screens. PROGRAMMING ANN-BUS 1=ANN-BUS... -

Page 72: Ann-Bus Modules

Programming Master Programming Level 3.5.7.2 ANN-BUS Modules If an ANN-BUS module is installed, press 2 while viewing ANN-BUS screen #1 to select ANN-BUS addresses for the module(s). The following screen will be displayed. ANN-BUS MODULES 1=ADDR. 1 NONE 2=ADDR. 2 NONE 3=ADDR. -

Page 73: Auto-Configure

Master Programming Level Programming 3.5.7.3 Auto-Configure The ANN-BUS Auto-Configure features allows the programmer to quickly bring all installed ANN-BUS modules online. The software will search for all ANN-BUS modules and automatically program the device type and address into the system. Pressing 3 while viewing ANN-BUS Screen #1 will begin the Auto-Configure process and cause the following screen to be displayed: ANN-BUS... - Page 74 Programming Master Programming Level If the Parallel Port option is selected, the user has the option to supervise the printer and select an offline timer for the supervision by pressing 2 for Printer Supervision while viewing Print Options screen #1. Each press of the 2 key will cause the display to toggle between Printer Supv NO for no supervision and Printer Supv YES for printer supervision.

-

Page 75: Ann-I/O Led Zone Assignments

Master Programming Level Programming 3.5.7.5 ANN-I/O LED Zone Assignments The information displayed by LEDs on every ANN-I/O module is not programmable and will therefore be as indicated in the following table. Zone (any address) AC Fault General Alarm General Supervisory General Trouble Alarm Silenced Earth Fault... -

Page 76: Options

Programming Master Programming Level 3.5.7.6 ANN-80 Options Pressing 2 while ANN-BUS screen #2 will display the following screen: ANN-80 OPTIONS 1=PIEZO ENABLE 2=LOCK ENABLE 3=ACK BTN ENABLE ANN-80 Options Screen #1 ANN-80 OPTIONS 1=SIL BTN ENABLE 2=RST BTN ENABLE 3=DRL BTN ENABLE ANN-80 Options Screen #2 The Piezo Enable option allows the programmer to select whether the piezo sounder on any installed ANN-80 annunciator will ever sound. -

Page 77: Ann-Rly Options

Master Programming Level Programming 3.5.7.7 ANN-RLY Options Pressing 1 for ANN-RLY Options while viewing ANN-BUS Screen #3 will cause the following screen to be displayed: ANN-RLY OPTIONS 1=RELAY 1 IN ZONE 1 PROGRAMMING 2=RELAY 2 IN ZONE 2 1=ANN-RLY OPTIONS 3=RELAY 3 IN ZONE 3 2=ANN-LED OPTIONS... -

Page 78: 8: History

Programming Master Programming Level 3.5.8 History The History option allows an authorized user to view or erase events which have occurred in the control panel. Pressing 2 while viewing Programming Screen #3 will display the History options as shown in the following display: HISTORY 1=VIEW EVENTS PROGRAMMING... -

Page 79: 9: Walktest

Master Programming Level Programming 3.5.9 Walktest Walktest allows an individual to test the fire alarm system without the necessity to reset the control panel after each device activation. Pressing 3 while viewing the Programming Screen #3 will cause the following Walktest options to be displayed: WALKTEST 1=SILENT PROGRAMMING... -

Page 80: 10: Clear Program

Programming Master Programming Level 3.5.10 Clear Program Pressing 1 while viewing Programming Screen #4, will select the Clear Program option. The control panel will provide a warning to the user by prompting with the following display: WARNING! SYSTEM CHANGE PROCEED? PROGRAMMING 1=YES 2=NO... -

Page 81: Maintenance Programming Level

Maintenance Programming Level Programming 3.6 Maintenance Programming Level To access Maintenance Programming mode, press the Enter key. The LCD will display the following: 1=READ STATUS 2=PROGRAMMING To enter the Maintenance Programming mode, press 2. The display will read as follows: PROGRAMMING ENTER PASSWORD When the Maintenance level password (default 11111) is entered, the following screen will appear:... -

Page 82: 1: Input Zones - Enable/Disable

Programming Maintenance Programming Level 3.6.1 Input Zones - Enable/Disable The Input Zones option allows the user to enable or disable desired zones. Pressing 1 for Input Zones, while viewing Maintenance Screen #1 will cause the following screens to be displayed: POINT PROGRAM 1=ZONE 1 2=ZONE 2... -

Page 83: 3=Walktest

Maintenance Programming Level Programming Pressing 1 while viewing the History screen will cause the following screen to be displayed: HISTORY 1=VIEW ALL 2=VIEW ALARMS 3=VIEW OTHER EVENTS To view all the events which have occurred in the control panel since the history file was last erased, press 1 while viewing the Events screen. -

Page 84: 4: Time-Date

Programming Maintenance Programming Level 3.6.4 Time-Date To program the time and date into the control panel, press 1 while viewing Maintenance Screen #2. The following display will appear: TIME AND DATE 1=TIME 01:00A PROGRAMMING 2=DATE 01012006 1=TIME-DATE 3=CLOCK FORMAT 12HRS Maintenance Screen #2 Time and Date Screen To change the time, press 1 to display the following screen:... -

Page 85: Section 4: Operating Instructions

Panel Control Buttons Operating Instructions Operating Instructions SECTION 4 Factory programmed Templates have been provided to facilitate the installation and configuration of the Fire Alarm Control Panel. The factory default programming for this panel is Template #7. Refer to "FACP Configuration Templates" on page 108 for a detailed description of the FACP operation for Template #7. -

Page 86: Indicators

Operating Instructions Indicators 4.2 Indicators The eight indicators, which are located on the front panel, operate as follows: AC Power This is a green indicator which illuminates if AC power is applied to the FACP. A loss of AC power will turn off this indicator. Fire Alarm This red indicator flashes when one or more alarms occur. -

Page 87: Trouble Operation

Trouble Operation Operating Instructions Note: To ensure that the system is functioning properly, the FACP will perform a freeze check five minutes after the panel is reset, followed by a maintenance check. If there is no freeze or maintenance condition, the panel will continue to monitor for freeze conditions every hour and maintenance conditions every four hours. -

Page 88: Alarm Operation

Operating Instructions Alarm Operation Pressing the Acknowledge/Step or Alarm Silence key will cause the pulsing piezo to silence and the system Trouble indicator to change from flashing to on steady. This block acknowledgment occurs regardless of the number of troubles, alarms and supervisory events active in the system. When the Acknowledge/Step key is pressed and at least one new alarm or trouble exists in the system, the ‘acknowledge’... -

Page 89: Supervisory Operation

Supervisory Operation Operating Instructions • Fourth line in display: Time; the current time in this example is 10:00A which represents 10:00 AM Date; the current month, day and year in this example is 03 for March, 08 for the 8th day of the month and 06 for the year 2006 4.6 Supervisory Operation Supervisory operation is similar to alarm operation but with the following differences:... -

Page 90: 2Nd-Shot Water Switch

Circuit to perform a water release and the programmed NAC output to turn on steady • Synchronized output for System Sensor, Wheelock, Gentex, Faraday or Amseco - Refer to "Synchronized NAC Operation" on page 62 for additional information. PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com... -

Page 91: Release Stages

Release Stages Operating Instructions 4.13 Release Stages Outputs programmed as Release Stage NACs indicate the two stages of a release operation: The activation of an output programmed as a Releasing Circuit will cause the programmed indicating NAC output to turn on steady Upon completion of the release, the programmed indicating NAC output will pulse at a 20 pulse-per-minute rate 4.14 Special System Timers... -

Page 92: Read Status

Operating Instructions Read Status Alarm/Shorted Condition When in audible Walktest, the panel responds to each new alarm and activates its programmed control outputs for four seconds, if those outputs have been programmed for silenceable activation. It also stores each alarm in the walktest history file which can be sent to an optional printer. The stored display will be the same as if the device actually activated except the colon (:) in the time stamp is replaced with an asterisk (*). -

Page 93: 1: Facp Configuration

Read Status Operating Instructions 4.16.1 FACP Configuration Pressing 1 while viewing Read Status Screen #1 will display the type of configuration programmed into the FACP (refer to "FACP CONFIG (Application Templates)" on page 50). As an example, if Template 7 was programmed as the FACP configuration, the following screen will be displayed: READ FACP CONFIG TEMPLATE 7 SINGLE HAZARD... -

Page 94: 3=Output Circuits

Operating Instructions Read Status 4.16.3 Output Circuits Pressing 3 while viewing Read Status Screen #1 will display the following screens: READ OUTPUTS 1=OUTPUT 1 2=OUTPUT 2 3=OUTPUT 3 READ STATUS 1=FACP CONFIG 2=INPUT ZONES Read Outputs Screen #1 3=OUTPUT CIRCUITS Read Status Screen #1 READ OUTPUTS 1=OUTPUT 4... -

Page 95: 5: On-Board Relays

Read Status Operating Instructions 4.16.5 On-Board Relays Pressing 2 while viewing Read Status Screen #2 will display the following screen: ON-BOARD RELAYS RELAY 1 ALARM RELAY 2 TROUBLE RELAY 3 SUPERVSRY This screen allows the operator to view the programmed option for each relay. 4.16.6 System Settings Pressing 3 while viewing Read Status Screen #2 will display the following screens: SYSTEM SETTINGS... -

Page 96: 7: Timers

Operating Instructions Read Status 4.16.7 Timers Pressing 1 while Read Status Screen #3 will display the following screens: TIMERS SOAK 10 MIN SOAK 10 MIN READ STATUS 1=TIMERS WATERFLOW DELAY 2=DAYLIGHT SAVINGS 3=HISTORY Read Status Screen #3 TIMERS AC LOSS DELAY 2 HR These screens allow the operator to view the various timer settings. -

Page 97: 9: History

Read Status Operating Instructions 4.16.9 History Pressing 3 while viewing Read Status Screen #3 will display the following screens: HISTORY 1=VIEW ALL 2=VIEW ALARMS 3=VIEW OTHER EVENTS The operator can view all events which have been stored in the history file, only alarms or other events, such as troubles or supervisories, by pressing the corresponding number key. -

Page 98: 11: Ann-Bus

Operating Instructions Read Status 4.16.11 ANN-BUS Pressing 2 while viewing Read Status Screen #4 will display the settings for the ANN-BUS options as shown in the following screens: ANN-BUS BUS ENABLED 1=BUS MODULES 2=ANN-S/PG OPTIONS ANN-BUS Screen #1 ANN-BUS 1=ANN-80 OPTION 2=ANN-RLY OPTIONS ANN-BUS Screen #2 ANN-BUS Screen #1 indicates whether the ANN-BUS is enabled (Yes/No). -

Page 99: Section 5: Power Supply Calculations

TABLE 5-1:120/240 VAC Branch Circuit Requirements Number of Current Draw Total Current per Device Type Devices (AC amps) Device PDRP-2001 3.66 PDRP-2001E 2.085 Sum Column for AC Branch Current Required PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com electronic components distributor... -

Page 100: Calculating The System Current Draw

Power Supply Calculations Calculating the System Current Draw Calculating the System Current Draw 5.3.1 Overview The control panel must be able to power all internal and external devices continuously during the non-fire alarm condition. To calculate the non-fire alarm load on the system power supply when primary power is applied, use Calculation Column 1 in Table 5-3 on page 101. - Page 101 Calculating the System Current Draw Power Supply Calculations Table 5-3 contains three columns for calculating current draws. For each column, calculate the current and enter the total (in amperes) in the bottom row. When finished, copy the totals from Cal- culation Column 2 and Calculation Column 3 to Table 5-4 on page 102.

-

Page 102: Calculating The Battery Size

Power Supply Calculations Calculating the Battery Size Calculating the Battery Size Use Table 5-4 to calculate the total Standby and Alarm load in ampere hours (AH). This total load determines the battery size (in AH), required to support the control panel under the loss of AC power. -

Page 103: Appendix A Circuit Mapping And Cross-Zoning

Input-to-Output Circuit Mapping and Cross-Zone Operation Circuit Mapping and Cross-Zoning Circuit Mapping and Cross-Zoning APPENDIX A A.1 Input-to-Output Circuit Mapping and Cross-Zone Operation The flexible cross-zoning and input-to-output (I/O) mapping capability of this fire panel provides a powerful toolset to accommodate many site-specific configurations. To simplify initial setup, preconfigured application templates that employ cross-zoning and I/O mapping are included from the factory. -

Page 104: A.1.1: Mapping Input Zones To Output Circuits For Direct Activation

Circuit Mapping and Cross-Zoning Input-to-Output Circuit Mapping and Cross-Zone Operation A.1.1 Mapping Input Zones to Output Circuits for Direct Activation Using the INPUT ZONES menus, you can assign any input zone to directly activate (without cross- zoning) any of the four output circuits provided they are assigned matching operational types (see the OUTPUT CIRCUIT MAP menu within the INPUT ZONES menus). -

Page 105: A.1.2: Mapping Input Zones To Release Circuits For Cross Zone

Input-to-Output Circuit Mapping and Cross-Zone Operation Circuit Mapping and Cross-Zoning A.1.2 Mapping Input Zones to Release Circuits for Cross Zone Activation Using the OUTPUT CIRCUITS menus, this fire panel will allow you to assign a release circuit type of operation to any two of the four output circuits. Up to two releasing circuits (or hazards), called RELEASE 1 and RELEASE 2, may be created. - Page 106 Circuit Mapping and Cross-Zoning Input-to-Output Circuit Mapping and Cross-Zone Operation Example 4: A dual hazard, cross-zoned application using four input zones and two releasing output circuits. Input Zones 1 and 2 are cross-zoned to activate Output Circuit 2, which is programmed as RELEASE 1.

-

Page 107: Release Circuits

Input-to-Output Circuit Mapping and Cross-Zone Operation Circuit Mapping and Cross-Zoning A.1.3 Complex Examples of Cross Zoning and I/O Mapping for Release Circuits Following are some complex examples of cross-zoning for more demanding applications that are possible with this fire panel. Input zone entries in a single cross-zone group are effectively AND’ed together while the cross-zone groups are effectively OR’ed together. -

Page 108: Appendix B: Facp Configuration Templates

FACP Configuration Templates Input-to-Output Circuit Mapping and Cross-Zone Operation FACP Configuration Templates APPENDIX B The PDRP-2001 has been provided with preprogrammed templates which allow the user to quickly configure the FACP [refer to "FACP CONFIG (Application Templates)" on page 50]. The user also has the option to reprogram selected portions of the template for customized applications. -

Page 109: B.1: Template 7: Single Hazard - 3 Zone

Template 7: Single Hazard - 3 Zone FACP Configuration Templates B.1 Template 7: Single Hazard - 3 Zone TEMPLATE 7: SINGLE HAZARD - 3 ZONE INPUT ZONES OUTPUT CIRCUITS 2-WIRE SMOKE FIRE WATERFLOW MANUAL PULL SUPV. RELEASE STATION #1 ALARM NAC #2 WATERFLOW NAC #3 RELEASE SOLENOID 1 #4 SUPV. -

Page 110: B.2: Template 8: Single Hazard - Cross-Zone With Manual Release

FACP Configuration Templates Template 8: Single Hazard - Cross-Zone With Manual Release B.2 Template 8: Single Hazard - Cross-Zone With Manual Release TEMPLATE 8: CROSS-ZONE WITH MANUAL RELEASE SWITCH INPUT ZONES OUTPUT CIRCUITS 2-WIRE SMOKE FIRE WATERFLOW MANUAL PULL SUPV. RELEASE STATION #1 ALARM NAC... -

Page 111: B.3: Template 9: Dual Hazard - Combined Release

Template 9: Dual Hazard - Combined Release FACP Configuration Templates B.3 Template 9: Dual Hazard - Combined Release TEMPLATE 9: DUAL HAZARD - COMBINED RELEASE INPUT ZONES OUTPUT CIRCUITS 2-WIRE SMOKE FIRE WATERFLOW MANUAL PULL SUPV. RELEASE STATION #1 ALARM NAC #2 SUPV BELL NAC #3 RELEASE SOLENOID 1 #4 RELEASE SOLENOID 2... -

Page 112: B.4: Template 10: Dual Hazard - Split Release

FACP Configuration Templates Template 10: Dual Hazard - Split Release B.4 Template 10: Dual Hazard - Split Release TEMPLATE 10: DUAL HAZARD - SPLIT RELEASE INPUT ZONES OUTPUT CIRCUITS 2-WIRE SMOKE FIRE WATERFLOW SUPV. MANUAL PULL RELEASE STATION #1 ALARM NAC #2 SUPV BELL NAC #3 RELEASE SOLENOID 1 #4 RELEASE SOLENOID 2... -

Page 113: B.5: Template 11: Single Hazard - 3 Zones And Low Pressure

Template 11: Single Hazard - 3 Zones and Low Pressure FACP Configuration Templates B.5 Template 11: Single Hazard - 3 Zones and Low Pressure TEMPLATE 11: SINGLE HAZARD - 3 ZONES AND LOW PRESSURE INPUT ZONES OUTPUT CIRCUITS 2-WIRE SMOKE FIRE WATERFLOW MANUAL... -

Page 114: B.6: Template 12: Single Hazard - 2 Zones Cross-Zoned With All Active

FACP Configuration Templates Template 12: Single Hazard - 2 Zones Cross-Zoned With All Active B.6 Template 12: Single Hazard - 2 Zones Cross-Zoned With All Active TEMPLATE 12: SINGLE HAZARD - 2 ZONES CROSS-ZONES WITH ALL ACTIVE INPUT ZONES OUTPUT CIRCUITS 2-WIRE SMOKE FIRE WATERFLOW... -

Page 115: B.7: Template 13: Single Hazard - Dual Zone

Template 13: Single Hazard - Dual Zone FACP Configuration Templates B.7 Template 13: Single Hazard - Dual Zone TEMPLATE 13: SINGLE HAZARD - DUAL ZONE INPUT ZONES OUTPUT CIRCUITS 2-WIRE SMOKE FIRE WATERFLOW PULL MANUAL PRESS. STATION RELEASE #1 ALARM NAC #2 WATERFLOW NAC #3 RELEASE SOLENOID 1 #4 WATERFLOW NAC... -

Page 116: Appendix Cnfpa Standard-Specific Requirements

NFPA Standard-Specific Requirements Template 13: Single Hazard - Dual Zone NFPA Standard-Specific Requirements APPENDIX C This panel has been designed for use in commercial, industrial and institutional applications and meets the requirements for service under the National Fire Protection Association (NFPA) Standards outlined in this Appendix. - Page 117 Template 13: Single Hazard - Dual Zone NFPA Standard-Specific Requirements The following figure illustrates an example of Central Station/Remote Station Reporting using a 411UD. The relay contacts from the PDRP-2001/E may be used to trip any dialer UL-listed for Central Station/Remote Station Reporting Services. 411UD Channel1 Channel 2...

- Page 118 NFPA Standard-Specific Requirements Template 13: Single Hazard - Dual Zone 411UD FACP Alarm TB2-1 TB8-1 TB2-2 TB8-3 Trouble TB2-3 TB8-4 TB2-4 TB8-6 Supervisory TB2-5 TB8-7 TB2-6 TB8-9 Table C.1 411-UD Connections to FACP Notes: 1. Reference the 411UD Manual for additional information. 2.

-

Page 119: C.1: Nfpa 72 Auxiliary Fire Alarm System

NFPA 72 Auxiliary Fire Alarm System NFPA Standard-Specific Requirements C.1 NFPA 72 Auxiliary Fire Alarm System All connections are power-limited and supervised. This application is not suitable for separate transmission of sprinkler supervisory or trouble conditions. Notes: 1. 3 ohms maximum loop resistance allowed for wiring from control panel to Municipal Box. 2. - Page 120 NFPA Standard-Specific Requirements NFPA 72 Auxiliary Fire Alarm System NFPA 72 Remote Station Protective Signaling System Notes: 1. Cut Jumper JP30 on the PDRP-2001/E main circuit board to supervise placement of the 4XTM module. 2. Refer to "4XTM Transmitter Module Installation" on page 29 for detailed information. RS82 Remote Station Receiver UL listed.

- Page 121 NFPA 72 Auxiliary Fire Alarm System NFPA Standard-Specific Requirements NFPA 72 Proprietary Protective Signaling Systems Fire Alarm Control Panel FACP Main Circuit Board Form-C Alarm contact programmed to activate on General Alarm. Form-C Trouble contact which will automatically activate on any Trouble condition.

-

Page 122: Connection To Facp Dry Contacts

NFPA Standard-Specific Requirements Central Station/Remote Station Transmitter: Connection to FACP Dry C.2 Central Station/Remote Station Transmitter: Connection to FACP Dry Contacts The dry contacts of the PDRP-2001/E programmable relays can be used to trip a UL-864 Listed Central Station/Remote Station Transmitter. The FACP contacts must be supervised by the Central Station/Remote Station Transmitter module using End-of-Line Resistors (ELRs) with a value determined by the Transmitter manufacturer. -

Page 123: Appendix D: Facp With Keltron

Central Station/Remote Station Transmitter: Connection to FACP Dry Contacts FACP with Keltron FACP with Keltron APPENDIX D The following figure illustrates the connections between the FACP and Keltron Reveiver/ Transmitter. CAUTION! For reasons of wiring diagram clarity, terminal designations of Keltron modules are not shown in actual order. -

Page 124: Appendix E: Testing & Maintenance

End-of-Line device to serve as a dummy load to prevent unwanted water release. Ensure proper wiring and power is applied. After power-up, allow 80 seconds for the detectors to stabilize before testing. Refer to System Sensor’s i Installation and Maintenance Instructions document I56-1800-00 for device specifications and testing procedures. -

Page 125: E.2: Maintenance

If a detector fails any of the above test methods, its wiring should be checked and it should be cleaned as outlined in the Maintenance section of the System Sensor Document. If the detector still fails, it should be replaced. -

Page 126: Appendix F: Compatible Devices

Compatible Two-Wire Smoke Detectors (UL Listed) Detector Detector Base Base Standby Model Type Model Current (uA) System Sensor 2W-B Photoelectric I System Sensor 2WT-B Photoelectric I System Sensor 1100/D Ionization System Sensor 1151 B401 / B110LP / B116LP System Sensor 1400... -

Page 127: Appendix F: Maximum Number Of Detectors Per Zone

Maximum Number of Detectors per Zone Compatible Devices Maximum Number of Detectors per Zone When using two-wire smoke detectors containing supplementary relays or indicators, the operation of more than one detector per zone cannot be ensured Base Number of Model Number Model Devices 2W-B... -

Page 128: Appendix F: Four-Wire Smoke Detectors/Devices (Ul Listed)

0.70 Ionization Duct System Sensor DH400ACDCI Photoelectric Duct System Sensor DH400ACDCP System Sensor 1112/24/D Ionization 0.05 System Sensor 1424 Ionization 0.10 System Sensor 1451 (w/B402B Base) Ionization 0.10 System Sensor 2112/24ATR Photoelectric 0.50 60/70 System Sensor 2112/24AITR Photoelectric 0.50 60/70... -

Page 129: Appendix F: Notification Appliances (Ul Listed)

Refer to manufacturer’s installation instructions for more information. • Contact manufacturer for current draws or additional options System Sensor - 24VDC MODEL NUMBER & NOMENCLATURE (System Sensor) CH12/24 Electronic Chime/Sounder CH2415, CH241575, CH2475, CH24110 SpectrAlert Chime with Strobe MA-12/24D Electronic Sounder... -

Page 130: Releasing Applications

DH158A Surface Mount Rixon Firemark FM-980 Floor Mount, single Rixon Firemark FM-996 Surface Wiring Rixon Firemark FM-998 Concealed Wiring Relays (UL Listed) Current MANUFACTURER MODEL (mA) System Sensor A77-716B PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com electronic components distributor... - Page 131 Index Numerics buttons 2nd-Shot Water Switch 52 see also control buttons 12 4XTM 120 cabinet ANN-BUS mounting 17 wiring distance 30 cabinet dimensions 18 AC Loss Delay 65, 67 cabinet mounting 19 AC power 20 CAC-5X 21 AC power rating 13 California 62 AC power requirements 99 charger capacity 13...

- Page 132 Index DP-51050LED Dress Panel 16 Supervisory 86 dress panel 12, 16 Trouble 86 Drill 12, 14, 85 Indicators 15 indicators 12, 14 earth ground 20 Initiating Device Circuit 11, 13, 21 edit Class A 27 detector screens 51 In-Line resistor IDC combination circuit 22 Enable/Disable 82 zone 51...

- Page 133 Index coded 90 alarm 15 current 23 maintenance 15 End-of-Line resistor 13, 23 see also sounder 12 maximum current 13 supervisory 15 programmable 12 trouble 15 synchronized 62 polarity reversal circuit wiring 23 see also transmitter module 29 NFPA 72 Auxiliary Fire Alarm System 116, 119 power 13, 20, 24 NFPA 72 Central Station Service (Protected Premises primary 20...

- Page 134 Index Release Stage NAC 59 releasing circuit 13 Temporal 62 releasing solenoid 12 Time setting 69 releasing solenoids 11 Time-Date remote LCD annunciator Maintenance Level 84 installation 34 Time-Date setting 64, 68 programming 36, 76 Timers 64, 96 specifications 34 timers 65 wiring 35 Transmitter Module 16...

- Page 135 Index Zone type 51 Zone Setup Maintenance Level 82 zone type inputs 52 PDRP-2001 Series PN 53043:A 5/08/07 Downloaded from Elcodis.com electronic components distributor...

- Page 136 Notes PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com electronic components distributor...

- Page 137 Notes PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com electronic components distributor...

- Page 138 Notes PDRP-2001 Series PN 53043:A 5/08/2007 Downloaded from Elcodis.com electronic components distributor...

- Page 139 Limited Warranty Honeywell International Inc. warrants products manufactured by it to be free from defects in materials and workmanship for eighteen (18) months from the date of manufacture, under normal use and service. Products are date stamped at time of manufacture. The sole and exclusive obligation of Honeywell International Inc.

- Page 140 3825 Ohio Avenue St. Charles, IL 60174-5465 1-800-SENSOR2 Fax: (630) 377-6495 Downloaded from Elcodis.com electronic components distributor...

Need help?

Do you have a question about the PDRP-2001E and is the answer not in the manual?

Questions and answers