Table of Contents

Advertisement

Quick Links

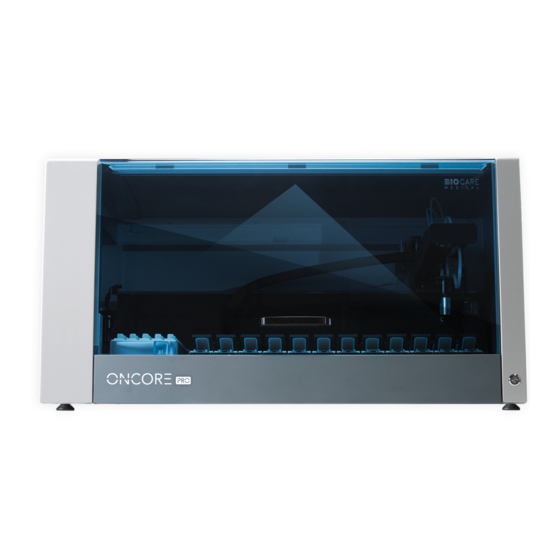

ONCORE™ PRO

Operating Manual

PathCom Systems Corporation

6400 Sierra Court, Suite E

Dublin, CA 94568

Document Number Form 751-02-03 Revision K4

2022-04-12 For In Vitro Diagnostic Use

Tel. 800-799-9499

|

www.biocare.net

|

Fax: 925-603-8080

Distributed

by: Biocare Medical

60 Berry Drive

Pacheco, CA 94553

Advertisement

Table of Contents

Summary of Contents for BioCare Medical PATHCOM ONCORE PRO

- Page 1 ONCORE™ PRO Operating Manual Distributed by: Biocare Medical PathCom Systems Corporation 60 Berry Drive 6400 Sierra Court, Suite E Document Number Form 751-02-03 Revision K4 Pacheco, CA 94553 Dublin, CA 94568 2022-04-12 For In Vitro Diagnostic Use Tel. 800-799-9499 www.biocare.net...

-

Page 2: Table Of Contents

Table of Contents Section 1. Introduction ............................7 Section 2. System Specifications ..........................8 2.1. Instrument Overview ............................8 2.2. Module Overview............................. 11 2.3. Technical Specifications ........................... 12 2.4. Accessories Included with the Oncore Pro Slide Stainer ................. 13 2.5. Staining Area Range ............................14 Slide Dimensions .............................. - Page 3 Clean Z1/Z2 Tubing ............................46 (Optional) Access the Tubing Clean Log ......................47 (Optional) Reset the Module/Chamber Usage Counter..................47 Generate Reports ............................... 48 Move Robot XYZZ Arm Aside ..........................48 Perform System Initialization ..........................48 Check for Module Malfunction .......................... 48 Flush Tubing with Prime Pump Z1 and Z2 Function ...................

- Page 4 Section 7. System Maintenance ........................... 84 7.1. Daily Maintenance Recommendation ......................84 Modules ................................84 Chamber ................................84 Tubing and Pumps .............................. 84 7.2. Weekly Maintenance Recommendation ......................85 Modules and Deck Plate............................. 85 Wash Station and Z1/Z2 Probes ......................... 85 Tubing and Pumps ..............................

- Page 5 Oncore Pro Slide Stainer Information Oncore Pro Slide Stainer Model: ONCPRO0001 Software Version: 3.0 Computer Configuration: Laptop or Desktop Computer with Mouse Instrument Communications Interface: USB 2.0 USB Cable has to be less than 3 meters (10 feet) The use of this instrument is fully licensed under U.S. Patent no. 5,839,091; U.S. Patent no. 7,476,543; U.S. Patent no.

- Page 6 Safety Report any serious incidents related to this device to your local Oncore Pro representative and the state's competent authority. Contact Customer Service if you have any questions or concern regarding safety. Protection from High Temperatures The instrument is equipped with a safety interlock system so that the door remains locked during instrument operation.

-

Page 7: Section 1. Introduction

Intended Use of the Equipment The Oncore Pro Slide Stainer is a fully-automated slide processing system for staining paraffin-embedded and frozen tissue sections, cytospins, cell smears and fine needle aspirates. This universal system is designed to automate the manual staining methods routinely used in immunohistochemistry, in situ hybridization and related applications. -

Page 8: Section 2. System Specifications

The Oncore Pro Slide Stainer system employs a unique integration of hardware, software, and reagent chemistry to provide full automation of immunohistochemical staining methods. This section provides an overview of the instrument and details the technical specifications. Figure 1 1. Slide Deck holds 36 modules, a reagent rack, and 2 probe wash stations. 2. - Page 9 Figure 2 1. 2D Barcode Reader scans the labelled slides on the slide deck to assign protocols for the staining run. 2. RFID Reader scans the RFID-tagged reagent vials to determine the reagents’ positions on the rack and updates the reagent usage information to the RFID tags during the run. 3.

- Page 10 Figure 3 1. Feet adjusted to level the instrument on the work surface. 2. Main Power Supply connects to the wall outlet and provides power to the instrument. 3. Power Supply Switch turns the power supply on/off. 4. AC Power Port is the position to plug in the power cord. 5.

-

Page 11: Module Overview

1. Side Retainer Clips (2) secure the module onto the instrument deck plate. 2. LED Light displays heater status green (inactive) or orange (active). 3. Hinge secures the slide at the back. 4. Chamber Chimney reagent dispensation/waste extraction point. 5. Slip Holder holds the chamber. Moves to controlled angles to facilitate incubation and reagent dispensation/waste extraction. -

Page 12: Technical Specifications

Dimensions W x H x D Weight 36.5in x 22in x 24in/93cm x 56cm x 61cm 125lb (57kg) (with door closed) 36.5in x 36in x 24in/93cm x 91cm x 61cm (with door open) Electrical requirements Normal operating temperature 120V 110/120V (±10%) 60Hz (±2Hz) 850 watts 18°C-26°C (64°F-79°F) 220V 220/240V (±10%) 50Hz (±2Hz) 850 watts Mains Connection: IEC320... -

Page 13: Accessories Included With The Oncore Pro Slide Stainer

Reagent Rack Two removable reagent racks. Each reagent rack holds a maximum of 40 reagent vials. Removable Vial Holder Installed on the reagent rack for programming RFID-tagged reagent vials. Buffer Container 2L plastic bottle with quick disconnect fittings. Stores the in-line wash buffer. Waste Container Set of two 4L plastic bottles with cap. -

Page 14: Staining Area Range

To ensure staining quality and reliability, slides should be prepared following the guidelines of the Oncore Pro system. Slide Dimensions Standard slide dimensions are 25mm x 75mm x 1mm Material Glass, ISO 8037/1 Dimensions (mm) Width 25–26.0 mm (0.98–1.02 in) Length 74.75–75.5 mm (2.94–2.97 in) Thickness... -

Page 15: Section 3. Installation Requirements And Instructions

This section provides an overview of the installation of the Oncore Pro Slide Stainer to be performed by the field service engineer. The following requirements should be met to ensure proper instrument function. Location Place the system in an area where it is easy to operate and easy to connect to the instrument. Surface Prior to unpacking, ensure that the work area for the instrument is a solid, level surface that can safely support the weight of the system. -

Page 16: Contacts For Assistance

Starting up Turn on the instrument and computer. Power on the power supply switch on the back of the instrument. Power on the Slide Stainer by pushing on the power button at the front of the instrument. Log in to the computer with the default User Name: PathCom and Password: 6747l Note: The user may change the computer user name and password after initial log in. -

Page 17: Section 4. Instructions For Use

This section provides the instructions for daily routine operation of the Oncore Pro Slide Stainer. Please check all Requirements p.7 before beginning instrument operation. Turn on the Slide Stainer using the power button and then turn on the computer. Note: It is important to follow this exact power on sequence. Double-click the shortcut for the Oncore Pro Slide Stainer UI to access the login screen. - Page 18 An interactive slide map corresponding to the 36 slide positions is displayed on the Main screen, displaying the status of the modules. Figure 10 All routine functions are readily accessed from the Main screen. To perform a typical run, click: Prepare Labels to print labels for slides.

-

Page 19: Preparing And Printing Labels

From the Main screen, click “Prepare Labels” to open the Slide Label Editor: Figure 11 Labels available for printing are listed on the screen under New Slides. A. Select New Slides to create or view new labels. B. Select Printed Slides to review or reprint a label. C. - Page 20 To add protocols to the Selected Protocols, select protocol(s) from the list of Available Protocols and click “Add”. Tip: The user may search the list of protocols by typing the first few letters of the protocol name. Click “Save” to generate new labels for each protocol in the list of Selected Protocols.

-

Page 21: Print Labels In The Slide Label Editor

(Optional) To add an entire panel of protocols to the Selected Protocols, select the custom panel from the list of Available Panels and click “Add”. All protocols assigned to the panel (including positive and negative controls) will be added. Click “Save” to generate new labels. The user must first create a custom panel before the Available Panels field is made visible in Barcode Editor. -

Page 22: Move Slides To Printed Slides (For Use With Lis Only)

To delete a label from the Slide Label Editor, select the checkbox and click “Delete”. Note: Once the slide label(s) have been printed, slide processing is initiated and the slide information will be distributed to all Oncore Pro systems on the Network. The label entry can no longer be deleted. Refer to 2D Barcode Format, p. -

Page 23: Install/Remove Chambers

Transfer the slide to a slide rack and rinse it with distilled water before post treatment. Dry the hinge slot and module surfaces with an absorbent paper towel. Install/Remove Chambers Chambers are installed individually onto each module. They should be removed from the module for routine cleaning and inspection to maintain optimal staining quality. -

Page 24: Assigning Protocols: Scan Slides And Manually Assign Protocols

To automatically assign protocols by scanning labeled slides, close the door and click “Scan Slides” on the Main screen. The system will automatically scan all 36 slide positions and assign the protocol(s) of labeled slides to the appropriate position on the slide map. Tip: Click + drag on the slide map to select specific slide positions to scan. - Page 25 Click “Assign Protocol” to open the Select Protocol screen. A. Click to select Normal to access the list of normal protocols. B. Click to select Negative to access the list of negative control protocols. C. Click to select All to access the list of all protocols. Scroll through the protocol list, highlight the desired protocol, and click “Select”...

-

Page 26: Loading Reagents

Oncore Pro detection kits, ancillary reagents and antibody/probe products are shipped ready-to-use. Refer to the manufacturer’s Datasheet and SDS for specific instructions. Prepare all other reagent solutions following the manufacturer’s instructions. Note: Only Oncore Pro reagent vials are compatible with the Oncore Pro Slide Stainer system. Refer to the vialing specifications in Reagent Vialing Specifications p.27, for additional information on vialing and recommended reagent volumes. -

Page 27: Reagent Vialing Specifications

The Oncore Pro Slide Stainer system provides user-fillable reagent vials for special reagents, uncommon antibodies, and custom ab titers. Each vial is packaged with an RFID tag, cap, and a blank label. Use of unauthorized reagents on the system may cause damage to instrument components and will revoke the manufacturer’s warranty. -

Page 28: Instructions For Use

Instructions for Use Fill the reagent vial with the appropriate amount of reagent solution. Label the reagent vial and cap. Program the RFID tag. Refer to Preparing RFID Tags with the RFID Tag Editor, p. 59 , for more details. Note: Some reagents are listed under multiple reagent types i.e.: AP and HRP. -

Page 29: Refill Buffer And Empty Waste

The system will prompt the user to verify the required Wash Buffer and Waste Container volumes before proceeding with the staining run. Refill the Wash Buffer Bottle The standard Wash Buffer Container has a maximum capacity of 2000mL. 1. Click System Utilities>Tools>”Move Arm Aside” to access the Wash Buffer Container located on the inner left side of the instrument. -

Page 30: Reagent Check: Scan Reagents

Remove all reagent vial caps before proceeding. From the Main screen, click “Scan Reagents” to open the Reagent Check screen. The reagent map is displayed on the left and a table of reagents required for the run is displayed on the right. Tip: Click “Print Required Reagents”... - Page 31 The scanned reagent assignments are displayed on the reagent map on the left. Each scanned reagent vial will be displayed with the following: A. Reagent name. B. Number of tests remaining. Updates during the staining process each time reagent is aspirated. C.

- Page 32 Figure 34 The manual assignments will be saved until the reagent rack is scanned again. G. All manually added reagents are highlighted in dark green. Always verify that the manually assigned reagent is placed in its corresponding position on the Reagent Rack and that it has sufficient volume before proceeding.

-

Page 33: Starting The Run

To immediately start the run, close the door and click “Start Staining Process” from the Reagent Check screen. Verify that all caps have been removed from the reagent vials before starting the staining process. Close the door before starting the run. The door will lock and block unsafe access to the instrument while it is in operation. - Page 34 As the instrument prepares to start the run, the system will prime each pump three times over the wash stations to fill the in-line tubing. A run timer will appear at the top of the screen, counting down the expected time remaining until the end of the run.

-

Page 35: Gantt Chart

Gantt Chart The current run schedule is displayed on the Gantt chart. This may aid in tracking the progress of the run and determining the wait time for loading/unloading slides. To view the Gantt chart, expand the AutoStainer Server window from the taskbar and click the Gantt tab. Figure 40 The purple line tracks the progress of the staining run. -

Page 36: Auto Start

The Auto Start feature may be used to start the staining process directly from the Main screen. The system will automatically proceed from scan slides to scan reagents and skip the buffer and waste verification step to immediately start the run. This may reduce instrument startup time. This feature requires certain setup conditions for use: A. -

Page 37: Runtime Monitoring

Runtime Monitoring While the instrument is running, the user may track the progress of the run from the Main screen. The slide map displays all 36 slides and displays the protocol, time, and the current step at each slide position. A system log is displayed at the bottom of the screen. -

Page 38: End Of Run

Hazardous Waste to prevent further overflow. The user is advised to verify that the waste tubing is draining properly and/or empty the waste container(s). End of Run The system will highlight the slides that have successfully completed staining in light green and mark them as “Finished”. -

Page 39: Aborting A Run

Aborting a Run If the system encounters an irrecoverable error, it will immediately abort the staining process. The aborted slides will be highlighted in orange and the system will prompt the user: “Run Aborted”. The staining run progress cannot be recovered upon system abort. Contact service/support to verify that the system abort is not caused by a serious issue on the instrument. -

Page 40: Continuous Loading

The Continuous Loading feature allows users to load more slides after the staining process has already started. Note: Using this feature may significantly increase the total run time and delay the finish time for all remaining slides in the run. This feature should not be used for time sensitive reagents such as Fluorescence In-situ Hybridization (FISH). -

Page 41: Restart The Run

Restart the Run Prepare and load new slides. The system will automatically lift the lids of all available slide positions, including empty positions and positions marked as “Finished”. The positions marked as “Stopped” will be set at the lid Down position and those slides cannot be unloaded from the instrument. - Page 42 Re-start the staining process. The system will reschedule the run to incorporate the new slides. The new slides will take priority and will run separately until they catch up with the Stopped slides. The Stopped slides will resume progress when the new slides have reached the same point as the Stopped slides. Figure 51 Continuous loading can be repeated on successive steps in the new run schedule;...

-

Page 43: Shutting Down The Slide Stainer

From the Main screen, double click “Exit” to close the program. Click “Yes” to confirm. Figure 52 This process may take a few minutes as the system waits for all module lids to go the extract position and for all sub-applications to close. -

Page 44: Section 5. System Utilities

From the Main screen, click “System Utilities” to access additional utility functions and advanced features. Some features may be restricted depending on user’s security access level. Refer to Security, p. 65, for more information. Perform manual operations with the system using the functions found under the “Tools” tab. 1. -

Page 45: Prepare Slides With Baking Slides Function

Prepare Slides with Baking Slides Function Click “Baking Slides” to select slides for baking. Check the boxes to select an entire row or select individual slides by module position. Refer to Baking Slide Settings, p. 67, for more information. Figure 54 Click “Start”... -

Page 46: Verify The Calibration Of The Barcode Reader

Verify the Calibration of the Barcode Reader Click “Barcode Calibration” to move the Barcode Reader to module #1 and verify the XY position of the barcode reader. Clean Z1/Z2 Tubing Click “Tubing Clean” to open the tubing cleaning feature. Use the Tubing Cleaning Kit or fill two 15mL vials with an appropriate cleaning solution. Place Z1 cleaning solution in reagent rack position #1. -

Page 47: (Optional) Access The Tubing Clean Log

(Optional) Access the Tubing Clean Log If Tubing Clean Tracking is enabled, the system tracks the number of slides processed since the last tubing clean. If the total number of slides run exceeds the set threshold, the system will block the user from initiating a new staining process. -

Page 48: Generate Reports

Generate Reports Click “Generate Reports” to open the Report Generator utility. Refer to Section 6: Reports, p. 74, for more information. Move Robot XYZZ Arm Aside Close the door and click “Move Arm Aside” to move the robotic arm to the center of the instrument. This will enable the user to gain access to the left side of the instrument to fill the buffer bottle and inspect wash stations, pumps (if applicable) etc. -

Page 49: Flush Tubing With Prime Pump Z1 And Z2 Function

Otherwise, the system will highlight any malfunctioning heater in red on the slide map and mark “Low Temperature” or “Overheating”. Figure 63 2) Select the Motion and Heater option to check for both module motion and heater malfunction. The system will perform both the heater check and the motion check on the selected modules. 3) Select the Motion option to check for module motion malfunction only. -

Page 50: Backup Report Data

Backup Report Data Click “Backup Report Data” to make a backup copy of the report data. Refer to Section 6: Reports, p.74, for more information. Access the protocol, reagent, and RFID editors under the “Editors” tab. Figure 64 ONCORE PRO, Operating Manual, Rev. K... -

Page 51: Editing Protocols In The Protocol Editor

Editing Protocols in the Protocol Editor The Oncore Pro is pre-installed with a set of protocols optimized to run on the system. The user may customize certain key steps for each protocol to suit the individual tissue and staining requirements of the lab. If further optimization is required, Technical Support may modify the existing protocol template or create a special protocol. - Page 52 To customize the Block reagent for an IHC protocol, select from the dropdown list under Block Option. A. Buffer. This is the default option (no blocking step). TR1 is formulated to provide sufficient blocking under most conditions. B. Block. Select this option to apply H block instead of wash buffer.

-

Page 53: Restoring Protocol Customizations In The Protocol Editor

Restoring Protocol Customizations in the Protocol Editor In certain circumstances, the user may need to restore the customizations of certain protocols: 1) Restore protocol(s) using saved customizations after a temporary change was made. 2) Restore protocol(s) using manufacturer’s default to reset the system to default or to evaluate control slides. 3) Regenerate all protocols after changes were made to the assigned protocol template. -

Page 54: Editing Protocols In The Protocol Editor: Ish/Cish/Fish

Editing Protocols in the Protocol Editor: ISH/CISH/FISH Figure 70 To edit the enzyme incubation time and temperature, adjust the Time (hours, minutes, seconds) and Temp ( ̊ C ). Viewing Special Protocols in the Protocol Editor Special protocols are listed under the Special tab. These protocols offer the flexibility to customize any step in the staining protocol. -

Page 55: Changing The Protocol Template

Changing the Protocol Template Each type of detection system is assigned one protocol template. This template is used to generate all protocols listed under that type. The user may change the assigned protocol template by selecting a different protocol template. Click “Change Protocol Template”... -

Page 56: Importing Protocols In The Pr Manager

Importing Protocols in the PR Manager Export packages are periodically released to the user in order to 1) update protocol templates and protocols, 2) add additional applications and products, or 3) add special protocols. These packages may be imported into the system using the PR Manager utility. - Page 57 Click “Import" to import the contents of the export package. A status bar will be displayed to show the progress of the import process. All new protocols, templates and reagents will be added to the system. All existing protocols that share the same name as an imported protocol will be overwritten. All existing templates/special protocols that share the same name or index position as an imported template/special protocol will be overwritten.

-

Page 58: Assigning Negative Controls

Assigning Negative Controls All protocols (except Special) are automatically generated with a corresponding negative control protocol. All steps of the protocols are identical except the primary reagent which is substituted with the negative control reagent. The negative control is set to Universal Negative by default. Click “Negative Control Editor”... -

Page 59: Adding Reagents And Protocols In The Reagent Editor

Adding Reagents and Protocols in the Reagent Editor The user has the option to use third-party antibody products on the system. This may be necessary when certain antibodies are not offered in the Oncore Pro product line. Click “Reagent Editor” to view and manage the system’s reagents and protocols. New antibodies are added in the Reagent Editor to generate new protocols in the Protocol Editor. - Page 60 The system permits one protocol per antibody product for each detection system type. Therefore, if the reagent is run with multiple detection systems, it may only be added once to each applicable Reagent Type. Each protocol must have a unique name. It is recommended to append a short suffix to the end of the protocol name to identify the detection system used.

-

Page 61: Preparing Rfid Reagent Tags With The Rfid Tag Editor

Preparing RFID Reagent Tags with the RFID Tag Editor The Oncore Pro system offers user-programmable vials for use with the user’s custom reagents and third-party antibodies. Each programmable vial contains an RFID tag which will store all the information associated with that reagent. - Page 62 To read the information in the RFID tag, click “Read Tag”. The programmed information will be displayed in the empty fields to the left. Note: Brand new RFID tags will not be read correctly, as they only contain a randomly generated Tag ID. To write information into the RFID tag, complete the entry fields to the right and click “Write Tag”.

-

Page 63: Creating Custom Groups

Creating Custom Groups Click “Custom Group Editor” to edit/create custom lists of protocols for quick access to protocols in the Barcode Label Editor. Refer to Add New Labels in the Barcode Label Editor p. 19 for more information. Select a custom group from the dropdown list Custom Group Name. Protocols in the custom group will be listed under Selected Protocols. -

Page 64: Creating Custom Panels

Creating Custom Panels Click “Panel Editor” to edit/create custom panels of protocols accessible in the Barcode Label Editor. Refer to Add New Labels in the Barcode Label Editor p. 19. Select a panel from the dropdown list Panel Name. Protocols in the panel will be listed under Selected Protocols. To add a new panel, click “Add New Panel”, enter a new name, and click “Add”. -

Page 65: Security

Manage system security features under the “Security” tab. Figure 87 Change Password Click “Change Password” to change the current user login password. Figure 88 User Administration Click “User Administration” to view the list of users: Figure 89 Users at the Supervisor level will have full access to Tools and Editors, and limited access to Security and Settings. Users at the Technician level will have limited access to Tools, Security, Settings and Editors. - Page 66 To add a new user, click “Add User” to open the “Add User” window. Enter the Name, User ID and Password and set the Access Level. Note: Only users with the Supervisor access level may create additional user accounts. Figure 90 To remove a user, select the user in the grid and click “Delete User.”...

-

Page 67: Baking Slide Settings

Baking Slide Settings Click “Baking Slides Settings” to set the Temperature ( ̊ C ) and Baking Time (Minute). Click “Save” and “Return” when finished. Figure 92 2D Barcode Format Click “2D Barcode Format” to open the “Barcode Label Options” and edit settings for the Barcode Label Editor. Figure 93 Select the option for the Date Format. - Page 68 Click “Label Format” to open the Label Formatter and edit the printable data on the label. The user may change the line order on the label or select new data types to be printed on each line of the label. Note: Some data types are only available for use with an LIS system.

-

Page 69: Save All Customizations

Save All Customizations Click “Save All Customizations” to back-up the protocol customizations for every tab in the Protocol Editor. The previously saved customizations will be overwritten. Therefore, the user should verify all current protocol customizations in the Protocol Editor before proceeding. The user may restore protocols using the saved protocol customizations by clicking “Refresh Protocol with Customizations”... -

Page 70: Tubing Clean Tracking Option

Tubing Clean Tracking Option Figure 99 Check the box Enable Tubing Clean Tracking to track the number of slides run since the last tubing clean. Enter the Maximum Slides Run. The count is incremented after each staining run. When the system detects that the counter has exceeded the set threshold, the system will block the user from starting a new staining process until the tubing cleaning has been performed. -

Page 71: Network

Connect several Oncore Pro Autostainer systems over the local network under the “Network” tab. The systems connected over the network may print from a dedicated printer on a main PC/server and share 2D barcode label records. Slides may be placed and run interchangeably on all systems connected over the network. Contact Technical Support to setup the network and connect existing system(s) to the network. - Page 72 Select the name of the network machine from the list and click “Add the selected network machine”. Note: The name of the network machine is the same as the computer name. Figure 102 Alternatively, if the machine is not detected, click “The machine that I want is not listed” to manually input the name.

-

Page 73: Lis/Lims

To print from a network printer, go to the “Settings” tab and click “2D Barcode Format”. Select the shared network printer from the Printer dropdown list. The printer name will appear preceded by the system name on the network. Figure 105 Change the label format options as needed. -

Page 74: Section 6. Reports

The Oncore Pro system provides a basic report utility to track slides, run sessions, and reagent consumption From the Main screen, click “System Utilities” and open the Tools tab to access the utility. Click “Generate Reports” to open the Report Generator. Slide Barcode To track a processed slide by 2D barcode, select the Slide Barcode option and click “Start”. - Page 75 From the Run List, the user may choose to: Select a run by clicking the empty grid in the leftmost column (the row will be highlighted in blue). Click “Show All Slides in Selected Run” to generate a Slide List of all slides in the selected run. Click “Reagent Usage Report”...

-

Page 76: Patient Information

Patient Information To manually track a processed slide by patient information, select the Patient Information option and click “Start”. Figure 110 The system will display all processed slides in the Patient Information list. Search the list by entering the Patient ID in the search box, Search Patient ID. -

Page 77: Report Types

Slide Report The Slide Report provides the run summary for an individual slide. The report can be generated by scanning a slide using the Slide Barcode Option or by selecting a slide from a Slide List or Patient Information list. Figure 112 The first line displays the date and time that the report was generated. - Page 78 The first table displays the Instrument Serial Number, Operator name, unique Run ID, and unique Slide ID. Note: The slide may be associated with 2 or more unique Run IDs if its run process was interrupted by the continuous loading feature. The second table displays the Patient ID, Case Number, Block ID, Specimen Type, Additional Information 1, and Additional Information 2.

-

Page 79: Reagent Usage In Run Report

Reagent Usage in Run Report The Reagent Usage in Run Report provides a detailed summary of the reagents used in an individual run. The reagents used in the run can be traced back to individual reagent vials by using the Tag ID, or by batch using the Lot Number. -

Page 80: Reagent Usage Report

Reagent Usage Report The Reagent Usage Report provides an overall summary of total reagents usage for a user-specified time period. This data may be useful for ordering and tracking reagent consumption. The report can be generated from any Run List. Figure 114 The first line displays the date and time the report was generated. -

Page 81: Slide Summary Report

Slide Summary Report The Slide Summary Report provides an overall summary of total slides in a-specified run. The report can be generated from any Run List. ONCORE PRO, Operating Manual, Rev. K... -

Page 82: Staining Runs

Staining Runs To manually track a slide by the run session, select the Staining Runs option and click “Start”. Note: This is the only method for tracking a manually assigned slide. Figure 115 The system will generate a Run List of all run sessions. The number of Total Unique Slides that have been processed on the system is displayed at the bottom of the list. -

Page 83: Print And Save A Report

The system can generate several types of reports. Navigate each report by using the page number, arrows and search box located in the toolbar. To print a report, click the Print icon in the toolbar and select a valid network printer. Do not select the barcode printer. - Page 84 The user should adhere to a routine preventative maintenance schedule to maximize the reliability and lifespan of the Oncore Pro Slide Stainer. Contact Customer Service for a supply of spares and consumable items. Modules The modules should be cleaned routinely (recommended after every run) to prevent the buildup of salt and reagent residues.

- Page 85 Modules and Deck Plate The modules and deckplate should be cleaned and inspected routinely to maintain proper function. 1. Use a damp paper towel to wipe away any salt deposits that have accumulated on the module surfaces. 2. The user may pipette distilled water and/or alcohol into the hinge slot to dissolve any crystallized salt deposits.

- Page 86 Chambers The chambers should be inspected routinely and replaced as needed (estimated after every 50 runs). Tubing The tubing should be inspected and cleaned routinely (recommended after every 500 slides) to prevent buildup of reagent residues. An obstruction in the tubing line may cause inconsistent/negative staining results and premature wear on the pumps.

- Page 87 Make sure the slides are placed securely on the module – the slide should be pushed in against the spring and the spring should push the slide back under the slide clips. Place the reagent rack firmly in its seated position before starting a run on the instrument. Remove caps from reagent vials before starting a run on the instrument.

Need help?

Do you have a question about the PATHCOM ONCORE PRO and is the answer not in the manual?

Questions and answers