Table of Contents

Summary of Contents for WinGD X92-B

- Page 1 Operation Manual X92-B Issue 002 2021-11 Winterthur Gas & Diesel Ltd. Schützenstrasse 3 Tel. +41 (0)52 264 8844 Winterthur Gas & Diesel AG P.O. Box 414, 8401 Fax +41 (0)52 264 8866 Winterthur Gas & Diesel S.A. Winterthur, Switzerland www.wingd.com...

- Page 2 Information in this publication is subject to change without notice. NO LIABILITY, WHETHER DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL, IS ASSUMED WITH RESPECT TO THE INFORMATION CONTAINED HEREIN. THIS PUBLICATION IS INTENDED FOR INFORMATION PURPOSES ONLY. www.wingd.com...

-

Page 3: Table Of Contents

X92-B Operation Manual Table of contents Introduction Operation Manual - change record................18 Preface........................20 Technical documentation set..................22 Data module codes (descriptive data)...............24 Data module codes (procedural data)...............26 About this book......................28 About the engine.......................30 List of abbreviations....................34 Safety Safety precautions and safety guidelines..............40... - Page 4 X92-B Operation Manual Group 1 - Engine frame and bearings 5.1.1 Bedplate......................114 5.1.2 Main bearing....................116 5.1.3 Thrust bearing....................118 5.1.4 Monoblock column...................120 5.1.5 rod......................122 Group 2 - Cylinder 5.2.1 Cylinder liner....................124 5.2.2 Lubricating quill....................126 5.2.3 Piston rod gland....................128 5.2.4 Direct controlled injection valve...............130...

- Page 5 X92-B Operation Manual 5.7.1 Cylinder lubrication..................188 5.7.2 Integrated electrical balancer (iELBA).............190 Group 8 - Pipes 5.8.1 Exhaust waste gate..................196 Group 9 - Monitoring instruments 5.9.1 Crank angle sensor unit...................198 5.9.2 Water in oil monitor..................200 5.9.3 Oil mist detector....................202 Control system Engine control system WiCE...................206...

- Page 6 X92-B Operation Manual 8.16 Emergency stop the engine - general..............286 8.17 Emergency stop the engine..................288 8.18 Prepare the engine after stop - general..............290 8.19 Prepare the engine for standstill or for maintenance..........292 Service during operation Do an analysis of the system oil................298...

- Page 7 X92-B Operation Manual 11.1 Engine data......................416 11.2 List of usual values and safeguard settings - general..........418 11.3 List of usual values and safeguard settings.............422 11.4 Section views......................434 Operating media 12.1 General for operating media..................436 12.2 Compressed air.......................438 12.3 Scavenge air......................440 12.4...

- Page 8 X92-B Operation Manual Page left intentionally blank - 8 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

- Page 9 X92-B Operation Manual List of tables Introduction Change record ..................... Data module codes (descriptive data) ............Data module codes (procedural data) ............List of abbreviations and acronyms ............. Design and function of systems LP SCR SYSTEM STATUS (MAIN PAGE) ..........

- Page 10 X92-B Operation Manual 10-16 Piston cooling oil temperature downstream of a piston is too high ..... 10-17 Piston cooling oil flow to a piston is not in the permitted range ....10-18 TC bearing oil temperature at a turbocharger outlet is too high ....

- Page 11 X92-B Operation Manual 10-58 Cylinder liner wall temperature is too high ..........10-59 A fuel pump actuator has a failure ............... 10-60 Power supply to the power supply box E85 has a failure ......10-61 Unwanted engine speed decrease ..............

- Page 12 X92-B Operation Manual Page left intentionally blank - 12 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

- Page 13 X92-B Operation Manual List of illustrations Introduction Side view (generic) ..................Engine numbering (generic) ................ Design and function of the engine Pressure - volume diagram and schematic of the two-stroke diesel cycle .. Operating range ..................Tuning options ..................... Schematic diagram - Relation Speed/Power (FPP) ........

- Page 14 X92-B Operation Manual Monoblock column (generic) ............... Tie rod (generic) ..................Cylinder - cooling water outlet (generic) ............Lubricating quill (generic) ................Piston rod gland (generic) ................Starting valve (example) ................5-10 Exhaust valve (generic) ................5-11 Crankshaft (generic) ..................

- Page 15 X92-B Operation Manual iGPR - schematic diagram ................LDU-20 - overview ..................LDU-20 color display - general items ............iELBA Control ....................MCP page - MAIN locked ................MCP page - MAIN ..................MCP page - Open user parameters ............

- Page 16 X92-B Operation Manual 10-23 Turbocharger cut out procedure: Illustration 5 ........... 10-24 Allowed load during cylinder cut out ............Technical data 11-1 Operating range ..................11-2 Signal codes ....................Operating media 12-1 Viscosity / Temperature diagram ..............Attachments 13-1 Line codes ....................

- Page 17 X92-B Operation Manual 1 Introduction Operation Manual - change record................18 Preface........................20 Technical documentation set..................22 Data module codes (descriptive data)...............24 Data module codes (procedural data)...............26 About this book......................28 About the engine.......................30 List of abbreviations....................34 - 17 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 18: Operation Manual - Change Record

AA00-0000-00AAA-003A-A X92-B Operation Manual Operation Manual - change record Operation Manual - change record Tab 1-1 Change record New issue 002, 2021-11 - Rewritten introductory pages with additional explanations. - Updated safety precautions and safety guidelines. - Updated description of access to engine spaces. - Page 19 AA00-0000-00AAA-003A-A X92-B Operation Manual Operation Manual - change record Page left intentionally blank - 19 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 20: Preface

The data, instructions, graphics and illustrations etc in this manual are related to drawings from WinGD. These data relate to the date of issue of the manual (the year of the issue is shown on the title page and on the footer). All instructions, graphics and illustrations etc can change because of continuous new development and modifications. - Page 21 AA00-0000-00AAA-018A-A X92-B Operation Manual Preface Page left intentionally blank - 21 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 22: Technical Documentation Set

AA00-0000-00AAA-018B-A X92-B Operation Manual Technical documentation set Technical documentation set Because of the continuous development of the engine, the technical documentation for the engine changes and is regularly updated. The change record shows all changes. Important data and changes are given directly to the customer in the service bulletins. - Page 23 External supplier documentation The documentation from external suppliers gives data about the parts of the engine that are not supplied by WinGD, such as turbocharger, automatic filter or damper. Most of this documentation also contains data about spare parts. 1.3.5...

-

Page 24: Data Module Codes (Descriptive Data)

00 = applicable to all engines indepen- acters [0-9] dent of the number of cylinders; ## = ap- plicable only to engines with that specific number of cylinders. #### WinGD design group number 4 numeric char- arbitrary 5551 acters [0-9] Used for sequential numbering of data... - Page 25 AA00-0000-00AAA-018D-A X92-B Operation Manual Data module codes (descriptive data) Page left intentionally blank - 25 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 26: Data Module Codes (Procedural Data)

00 = applicable to all engines indepen- acters [0-9] dent of the number of cylinders; ## = ap- plicable only to engines with that specific number of cylinders. #### WinGD design group number 4 numeric char- arbitrary 5556 acters [0-9] Used for sequential numbering for the... - Page 27 AA00-0000-00AAA-018E-A X92-B Operation Manual Data module codes (procedural data) Code Description Length/type Property Example Shipdex item location code. A = informa- 1 alphabetic Shipdex specif- tion related to items installed on the character [A-D] product; B = information related to items installed on a major assembly removed from the product;...

-

Page 28: About This Book

X92-B Operation Manual About this book About this book In the sections that follow you find the definitions of WinGD for this book. 1.6.1 Definitions for general text For general text in this book the definitions that follow are applicable: •... - Page 29 AA00-0000-00AAA-018C-A X92-B Operation Manual About this book 1.6.2 Warnings Warnings in procedures give data about a hazard. Warnings have the basic structure that follows: Signal word • The signal words that follow are applicable: ○ WARNING ○ CAUTION Hazard •...

-

Page 30: About The Engine

Operation Manual About the engine About the engine In the sections that follow you find the definitions of WinGD for the engine. 1.7.1 Groups of components Each component of the engine has a four-digit material number. WinGD has divided these... -

Page 31: Side View (Generic)

AA00-0000-00AAA-018L-A X92-B Operation Manual About the engine 1.7.2 Engine sides and ends - names The sides and ends of the engine have the names and abbreviations that follow (refer to Figure 1-1: DE - Driving End (end that has a flange to attach the propeller shaft) •... -

Page 32: Engine Numbering (Generic)

LEFT engine. Parts that are applicable for the two engines types (Standard and LEFT) have no mark. 1.7.4 Numbering of items WinGD uses the definitions for the numbering of items as follows (refer to Figure 1-2): In axial direction the numbering starts from the flywheel. - Page 33 AA00-0000-00AAA-018L-A X92-B Operation Manual About the engine Page left intentionally blank - 33 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 34: List Of Abbreviations

AA00-0000-00AAA-005A-A X92-B Operation Manual List of abbreviations List of abbreviations Tab 1-4 List of abbreviations and acronyms Short form Full form, meaning Angle Calculation Module crank Angle Determination Algorithm ahead alarm Alarm and Monitoring System as required astern ASTM American Society for Testing and Materials... - Page 35 AA00-0000-00AAA-005A-A X92-B Operation Manual List of abbreviations Short form Full form, meaning Emission Control Area Engine Control Room Engine Control System eg or e.g. for example (exempli gratia) Exhaust Gas Recirculation ELBA ELectrical BAlancer Exhaust Side Engine Safety System FAME...

- Page 36 AA00-0000-00AAA-005A-A X92-B Operation Manual List of abbreviations Short form Full form, meaning Injection Control Unit ie or i.e. that is (id est) iELBA integrated ELectrical BAlancer iGPR integrated Gas Pressure Regulation International Maritime Organization Ind. Indenture Input Output Module International Standard Organization...

- Page 37 Top Dead Center UNIC UNIfied Controls Universal Serial Bus exhaust Valve Control Unit Variable Exhaust valve Closing Variable Exhaust valve Opening Variable Injection Timing WECS-9520 WinGD Engine Control System 9520 - 37 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

- Page 38 AA00-0000-00AAA-005A-A X92-B Operation Manual List of abbreviations Short form Full form, meaning Waste Heat Recovery WiCE WinGD Integrated Control Electronics WinGD Winterthur Gas & Diesel Ltd. Work Load Limit - 38 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 39: Safety

X92-B Operation Manual 2 Safety Safety precautions and safety guidelines..............40 Contamination and fire in the scavenge air spaces...........46 Fire-fighting in the scavenge air space..............48 Explosions in the crankcase..................50 Prevent explosions in the crankcase.................52 Access to engine spaces...................54 - 39 - Issue 002 2021-11 Winterthur Gas &... -

Page 40: Safety Precautions And Safety Guidelines

AA00-0000-00AAA-012A-A X92-B Operation Manual Safety precautions and safety guidelines Safety precautions and safety guidelines 2.1.1 General safety precautions The aim of this book is to give correct information about operation and maintenance of the engine. It is important to take the maximum safety in the engine room. All the engine room staff must follow these general safety precautions and safety guidelines given below as usual procedure. - Page 41 AA00-0000-00AAA-012A-A X92-B Operation Manual Safety precautions and safety guidelines Tools • Make sure that hand tools are available on tool panels and easy to access when required. Keep the special tools near the work area in the engine room. Make sure that all tools have protection from corrosion.

- Page 42 AA00-0000-00AAA-012A-A X92-B Operation Manual Safety precautions and safety guidelines Turning Gear and Slow turning • Before you engage the turning gear, make sure that the starting air supply is shutoff and the indicator cocks are open. When turning gear is engage, make sure that the indicator lamp “Turning gear in” is change to local.

- Page 43 AA00-0000-00AAA-012A-A X92-B Operation Manual Safety precautions and safety guidelines WARNING Injury hazard: The removal of fuel valves or other valves in the cylinder cover can cause the oil to fall on the piston crown. If the piston is hot this can cause explosion. Make sure that the engine is cool down before maintenance.

- Page 44 AA00-0000-00AAA-012A-A X92-B Operation Manual Safety precautions and safety guidelines Work card • Cotton boiler suite. • • Safety shoes. Hand gloves. • Safety goggles. • Safety harness • 2.1.5 General safety guidelines for Hot work If you do hot work at or near the engine, obey the guidelines that follow to prevent risks of harm or damage to personal, to equipment, or to environment.

- Page 45 AA00-0000-00AAA-012A-A X92-B Operation Manual Safety precautions and safety guidelines Guidelines for hot work: inside the engine room • Stop the engine before proceed any hot work in the engine room. Set the engine room fire extinguisher to Manual mode. Isolate the work area.

-

Page 46: Contamination And Fire In The Scavenge Air Spaces

AA00-0000-00AAA-012B-A X92-B Operation Manual Contamination and fire in the scavenge air spaces Contamination and fire in the scavenge air spaces 2.2.1 Causes of contamination The primary cause of contamination is when combustion materials are blown between the piston and cylinder into the scavenge air spaces (blow-by). The contamination will be more if the fuel is not fully burned, which causes exhaust smoke. - Page 47 AA00-0000-00AAA-012B-A X92-B Operation Manual Contamination and fire in the scavenge air spaces 2.2.2 Causes of fire The causes of fires are as follows: If sealing rings of the piston rod gland are defective, system oil and cylinder oil will collect •...

-

Page 48: Fire-Fighting In The Scavenge Air Space

AA00-0000-00AAA-140B-A X92-B Operation Manual Fire-fighting in the scavenge air space Fire-fighting in the scavenge air space Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 49 AA00-0000-00AAA-140B-A X92-B Operation Manual Fire-fighting in the scavenge air space PROCEDURE If you think there is no fire, do the steps as follows: Decrease the engine power. Cut out the injection of the related cylinder. Increase the feed rate of the lubricating oil in the related cylinder to the maximum, although there is high temperature in the related cylinder.

-

Page 50: Explosions In The Crankcase

AA00-0000-00AAA-012C-A X92-B Operation Manual Explosions in the crankcase Explosions in the crankcase Examples of explosions in the crankcase of diesel engines have shown that they can only occur in special conditions, and thus do not occur frequently. The cause of crankcase explosions is oil mist. Oil mist comes from components that have become unusually hot. - Page 51 AA00-0000-00AAA-012C-A X92-B Operation Manual Explosions in the crankcase Page left intentionally blank - 51 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 52: Prevent Explosions In The Crankcase

AA00-0000-00AAA-012D-A X92-B Operation Manual Prevent explosions in the crankcase Prevent explosions in the crankcase Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 53 AA00-0000-00AAA-012D-A X92-B Operation Manual Prevent explosions in the crankcase PROCEDURE If an oil mist detector activates an alarm, do as follows: Decrease immediately the engine speed (power). Stop the engine if possible. Let the engine temperature decrease for a minimum of 20 minutes.

-

Page 54: Access To Engine Spaces

AA00-0000-00AAA-012E-A X92-B Operation Manual Access to engine spaces Access to engine spaces Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 0.5 man-hours Duration for performing the requirements after job completion 0.0 man-hours Personnel... - Page 55 AA00-0000-00AAA-012E-A X92-B Operation Manual Access to engine spaces PROCEDURE Make sure that there is always a safety person on the outer side of the engine. Use the correct personal protection equipments. For a DF engine, obey the safety rules for natural gas, refer to section...

- Page 56 AA00-0000-00AAA-012E-A X92-B Operation Manual Access to engine spaces Page left intentionally blank - 56 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 57: Design And Function Of The Engine

X92-B Operation Manual 3 Design and function of the engine Short description of the engine..................58 Use of the engine......................60 The relation between engine and propeller...............64 - 57 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. -

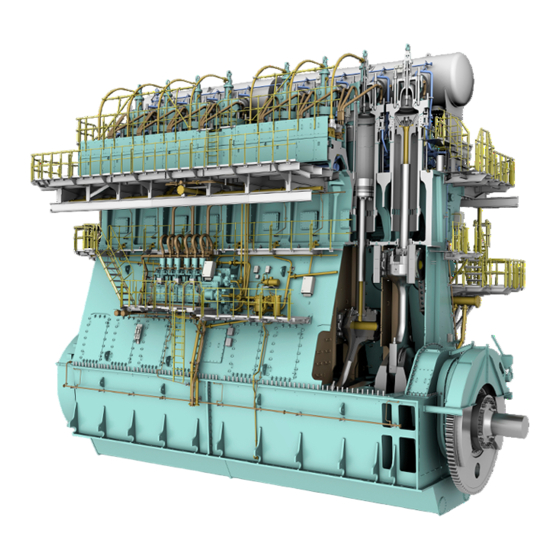

Page 58: Short Description Of The Engine

The engine control system (ECS) electronically controls all important engine functions (eg • speed control, overspeed protection and fuel injection). The engine control can have different remote controls, which are related to the WinGD specifications from recommended manufacturers. - 58 - Issue 002 2021-11 Winterthur Gas &... -

Page 59: Pressure - Volume Diagram And Schematic Of The Two-Stroke Diesel Cycle

AA00-0000-00AAA-020A-A X92-B Operation Manual Short description of the engine 3.1.1 Cycle of a two-stroke diesel engine The sequences of a two-stroke diesel engine are as follows (refer to Figure 3-1): Sequence 1 - 2 • The piston moves up and thus compresses the scavenge air. This increases the temperature of the air above the self-ignition temperature of the fuel. -

Page 60: Use Of The Engine

AA00-0000-00AAA-020C-A X92-B Operation Manual Use of the engine Use of the engine 3.2.1 Intended use The engine is intended to drive a propeller of a vessel. The engine changes the chemical energy of the fuel to mechanical energy. The engine must only be used in the operating range as given in the data sheets, refer to chapter 11. - Page 61 AA00-0000-00AAA-020C-A X92-B Operation Manual Use of the engine 3.2.2 Incorrect use Incorrect use of the engine can result in personal injury and in damage to physical properties. Personal injury or damage to physical properties caused by incorrect use will be the responsibility of the operating company.

-

Page 62: Tuning Options

AA00-0000-00AAA-020C-A X92-B Operation Manual Use of the engine 3.2.3 Tuning Related to the contract the engine has one of the tuning options that follow (refer to Figure 3-3): Standard tuning • The standard tuning gives a good fuel consumption over the full engine power range. - Page 63 AA00-0000-00AAA-020C-A X92-B Operation Manual Use of the engine Page left intentionally blank - 63 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 64: The Relation Between Engine And Propeller

AA00-0000-00AAA-042B-A X92-B Operation Manual The relation between engine and propeller The relation between engine and propeller 3.3.1 General There is a specified relation between the propeller speed and the absorbed power in ships that have fixed pitch propellers. The relation is between the propeller and the speed at which it turns. -

Page 65: Schematic Diagram - Relation Speed/Power (Fpp)

AA00-0000-00AAA-042B-A X92-B Operation Manual The relation between engine and propeller 3.3.2 Fixed pitch propeller (FPP) 3.3.2.1 Continuous service rating Point A (Figure 3-4) shows the power and speed of a ship that operates at contractual speed in calm seas with a new clean hull and propeller. A power / speed combination at point D is necessary for the same ship at the same speed during service conditions with aged hull and average weather. -

Page 66: Operation

AA00-0000-00AAA-042B-A X92-B Operation Manual The relation between engine and propeller Line 2 is the overload limit. This is a constant MEP line from 100% power and 93.8% speed • to 110% power and 103.2% speed. 103.2% speed is the intersection point between the nominal propeller property and 110% power. -

Page 67: Design And Function Of Systems

X92-B Operation Manual 4 Design and function of systems General for systems....................68 Cooling water system....................70 Wash-water system....................72 System oil system......................74 Servo oil system......................76 Cylinder oil system....................78 Starting air system.....................80 Scavenge air system....................82 Control air system......................84 4.10 Exhaust gas system....................86 4.11 Fuel system.......................88... -

Page 68: General For Systems

AA00-0000-00AAA-043U-A X92-B Operation Manual General for systems General for systems In the chapters that follow you can find a short description of the systems of the engine. The descriptions and figures are generic and simplified. You can find an overview of the used line codes in Figure 4-1. - Page 69 AA00-0000-00AAA-043U-A X92-B Operation Manual General for systems Page left intentionally blank - 69 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 70: Cooling Water System

AA00-0000-00AAA-043A-A X92-B Operation Manual Cooling water system Cooling water system The cooling water system supplies the items that follow with cooling water: Cylinder liner • Cylinder cover • Exhaust valve cages • • Scavenge air cooler (SAC). For the schematic diagrams, refer to section 13.1 Schematic diagrams -... -

Page 71: Cooling Water System (Generic And Simplified)

AA00-0000-00AAA-043A-A X92-B Operation Manual Cooling water system Fig 4-2 Cooling water system (generic and simplified) Cyl. 1 Cyl. n Legend Automatic venting unit Drain valve Shut-off valve cooling water outlet Orifice Shut-off valve, if supply 02 is installed Optional vent valve (usually closed) -

Page 72: Wash-Water System

AA00-0000-00AAA-043P-A X92-B Operation Manual Wash-water system Wash-water system The wash-water system supplies the scavenge air cooler (SAC) with wash-water. This lets you wash the SAC, refer to 9.5 Clean the scavenge air cooler during operation. To regularly wash the SAC increases the service life of the cooler and keeps the performance in the specified range. - Page 73 AA00-0000-00AAA-043P-A X92-B Operation Manual Wash-water system Fig 4-3 Wash-water system (generic and simplified) 11 12 Legend Wash-water tank Cyclone separator Scavenge air cooler (SAC) Turbocharger Auxiliary blower - 73 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 74: System Oil System

AA00-0000-00AAA-043B-A X92-B Operation Manual System oil system System oil system The system oil system supplies the items that follow with system oil: Bearings • Gear wheels • Vibration dampers • • Pistons Crosshead assemblies • iELBA (optional) • Other running parts •... -

Page 75: System Oil System (Generic And Simplified)

AA00-0000-00AAA-043B-A X92-B Operation Manual System oil system Fig 4-4 System oil system (generic and simplified) PLANT ENGINE ENGINE PLANT 23 22 22 23 Legend Turbocharger Crosshead iELBA (optional) Thrust bearing Torsional vibration damper (optional) Oil sample valve Axial vibration damper... -

Page 76: Servo Oil System

AA00-0000-00AAA-043Q-A X92-B Operation Manual Servo oil system Servo oil system The servo oil system supplies the items that follow with servo oil: Exhaust valve control units (VCU) • Cylinder lubricating pumps • Injection control units, if applicable. • For the schematic diagrams, refer to section 13.1 Schematic diagrams -... -

Page 77: Servo Oil System (Generic And Simplified)

AA00-0000-00AAA-043Q-A X92-B Operation Manual Servo oil system Fig 4-5 Servo oil system (generic and simplified) Cyl. 1 Cyl. 2 Cyl. n Legend Injection control unit (ICU) for X82 and X92 Oil pipe to exhaust valve Exhaust valve control unit (VCU) -

Page 78: Cylinder Oil System

AA00-0000-00AAA-043R-A X92-B Operation Manual Cylinder oil system Cylinder oil system The cylinder oil system supplies cylinder oil onto the cylinder liners. The engine control system (ECS) controls the adjustable load-related supply rate of cylinder oil to each lubrication point. The engine has an automatic pre-lubrication sequence. At each engine start the ECS automatically starts this sequence. -

Page 79: Cylinder Oil System (Generic And Simplified, With And Without Icat)

AA00-0000-00AAA-043R-A X92-B Operation Manual Cylinder oil system Fig 4-6 Cylinder oil system (generic and simplified, with and without iCAT) iCAT Cyl. 1 Cyl. n Legend Oil sample valve Square collector pipe Lubricating quill Rail unit Cylinder lubricating pump Change-over valve... -

Page 80: Starting Air System

AA00-0000-00AAA-043C-A X92-B Operation Manual Starting air system Starting air system The starting air system turns the crankshaft before the usual combustion cycle of the engine is started. For the schematic diagrams, refer to section 13.1 Schematic diagrams - general. The starting air system has the engine connections as interface to the plant as follows (in... -

Page 81: Starting Air System (Generic And Simplified)

AA00-0000-00AAA-043C-A X92-B Operation Manual Starting air system Fig 4-7 Starting air system (generic and simplified) Cyl. 1 Cyl. n Legend Solenoid valve Disengaging device turning gear Flame arrestor Starting air supply pipe Safety valve Valve unit for start E Drain valve... -

Page 82: Scavenge Air System

AA00-0000-00AAA-043S-A X92-B Operation Manual Scavenge air system Scavenge air system The scavenge air system replaces the exhaust gas in the cylinder with fresh air. For the schematic diagrams, refer to section 13.1 Schematic diagrams - general. The scavenge air comes in from the outside through a duct or from the engine room. The scavenge air enters at the silencer of the turbocharger. - Page 83 AA00-0000-00AAA-043S-A X92-B Operation Manual Scavenge air system Fig 4-8 Scavenge air system 00148 Legend Exhaust gas manifold Drains Exhaust gas outlet Auxiliary blower Scavenge air inlet Piston underside Turbine Piston Compressor Scavenge air receiver Scavenge air cooler Cylinder liner Water separator...

-

Page 84: Control Air System

AA00-0000-00AAA-043T-A X92-B Operation Manual Control air system Control air system The control air system supplies the air spring of the exhaust valves and the starting air system with control air. For the schematic diagrams, refer to section 13.1 Schematic diagrams - general. -

Page 85: Control Air System (Generic And Simplified)

AA00-0000-00AAA-043T-A X92-B Operation Manual Control air system Fig 4-9 Control air system (generic and simplified) Cyl. 1 Cyl. n Legend Air bottle Starting air shut-off valve Control air supply Valve unit for start Air tank Collector for leakage oil from the air spring... -

Page 86: Exhaust Gas System

AA00-0000-00AAA-043D-A X92-B Operation Manual Exhaust gas system 4.10 Exhaust gas system The exhaust gas system collects the exhaust gas of the cylinders in a manifold. The remaining energy of the exhaust gas is used to operate the turbine of the turbocharger (002,... - Page 87 AA00-0000-00AAA-043D-A X92-B Operation Manual Exhaust gas system Fig 4-10 Exhaust gas system (generic and simplified) Cyl. 1 Cyl. 2 Cyl. 3 Cyl. 4 Cyl. n Legend Turbocharger bypass pipe Exhaust gas manifold Turbocharger Exhaust valve - 87 - Issue 002 2021-11...

-

Page 88: Fuel System

AA00-0000-00AAA-043E-A X92-B Operation Manual Fuel system 4.11 Fuel system The fuel system supplies the injection valves of the cylinders with the applicable quantity of fuel. For the schematic diagrams, refer to section 13.1 Schematic diagrams - general. The fuel system has the engine connections as interface to the plant as follows (in... - Page 89 AA00-0000-00AAA-043E-A X92-B Operation Manual Fuel system Pressure control valve • The pressure control valve (001) has different functions to control the flow and the pressure in the fuel rail. Relief valve • The relief valve (002) is a safety device. If the fuel pressure increases to more than the set value, the relief valve opens.

-

Page 90: Fuel System With Flv (Generic And Simplified)

AA00-0000-00AAA-043E-A X92-B Operation Manual Fuel system Fig 4-11 Fuel system with FLV (generic and simplified) Cyl. 1 Cyl. n Legend Pressure control valve Injection valve Relief valve Supply unit Flow limiting valve (FLV) Fuel pump Fuel rail Pressure retaining valve... -

Page 91: Fuel System With Icu (Generic And Simplified)

AA00-0000-00AAA-043E-A X92-B Operation Manual Fuel system Fig 4-12 Fuel system with ICU (generic and simplified) Cyl. 1 Cyl. 2 Cyl. 3 Cyl. 4 Cyl. n 60 50 49 Legend Pressure control valve Injection valve Relief valve Supply unit Injection control unit (ICU) -

Page 92: Lp Selective Catalytic Reduction System

The LP SCR system is installed after the turbocharger. The system design and the supply of components is divided between the LP SCR system supplier, the shipyard and WinGD/engine builder. The LP SCR system adds a urea water solution to the exhaust gas flow. Chemical reactions change nitrogen oxides to molecular nitrogen and water, which are not dangerous. -

Page 93: Lp Scr Temperature Controlled (Example)

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system Valves • The valves in the LP SCR system are used for the different operation modes. The LP SCR system has the valves that follow: ○ V1 - reactor inlet valve ○... -

Page 94: Lp Scr Bypass Rate Controlled (Example)

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system Fig 4-14 LP SCR bypass rate controlled (example) 002 003 Legend Engine Burner Urea dosing unit LP SCR reactor Decomposition unit Turbocharger 4.12.2 Operation modes The LP SCR system can be operated if the exhaust gas temperature is in the permitted limits. - Page 95 AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system 4.12.2.2 LP SCR system - preparation In this operation mode, exhaust gas causes the temperature of the LP SCR reactor to slowly increase. Urea solution is not injected. The valves have the conditions that follow: •...

-

Page 96: Lp Scr Control System Layout

LP Selective catalytic reduction system 4.12.3 LP SCR control system The main tasks of the WinGD control system for the LP SCR system are as follows: Calculate the setpoint position for the turbine bypass valve (V4) to control the exhaust gas •... -

Page 97: Lp Scr System - Principal Control Configuration

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system Fig 4-16 LP SCR system - principal control configuration Engine room Signals External main control panel (E73) 4.12.3.1 Messages of the LP SCR control system The LP SCR control system gives three messages to the alarm and monitoring system (AMS). -

Page 98: Control Box E70 With Option Spc

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system 4.12.3.2 Control box E70 The control box E70 is installed on the engine and has switches and visual indicators. Fig 4-17 Control box E70 with option SPC Legend SCR bypass switch... -

Page 99: Control Box E71 With Option Spc

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system 4.12.3.3 Control box E71 The control box E71 is installed on the engine or in the engine room and has switches below the LDU-20. Fig 4-18 Control box E71 with option SPC... -

Page 100: Control Boxes E72 And E73

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system 4.12.3.4 Control box E72 or E73 The control box E72 (without SPC) or E73 (with SPC) is installed in the engine control room and has switches below the LDU-20. Fig 4-19... -

Page 101: Lp Scr System Status (Main Page)

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system 4.12.4 LDU-20 pages The LDU-20 panel has the pages that follow (examples). Fig 4-20 LDU-20 page - LP SCR SYSTEM STATUS (MAIN PAGE) Tab 4-1 LP SCR SYSTEM STATUS (MAIN PAGE) -

Page 102: Lp Scr System Overview

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system Fig 4-21 LDU-20 page - LP SCR SYSTEM OVERVIEW Tab 4-2 LP SCR SYSTEM OVERVIEW Item Function Effect INTERFACES button Opens the interfaces page INDEX button Opens the index page SCREENSHOT button... -

Page 103: Lp Scr Interfaces

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system Fig 4-22 LDU-20 page - LP SCR INTERFACES Tab 4-3 LP SCR INTERFACES Item Function Effect OVERVIEW button Opens the SCR system overview page INDEX button Opens the index page SCREENSHOT button... -

Page 104: Lp Scr Software Info

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system Fig 4-23 LDU-20 page - LP SCR SOFTWARE INFO Tab 4-4 LP SCR SOFTWARE INFO Item Function Effect INDEX button Opens the index page SCREENSHOT button Makes a screenshot of the current screen... -

Page 105: Lp Scr Page Index

AA00-9270-00AAA-043B-A X92-B Operation Manual LP Selective catalytic reduction system Fig 4-24 LDU-20 page - LP SCR PAGE INDEX Tab 4-5 LP SCR PAGE INDEX Item Function Effect INDEX button Opens the index page SCREENSHOT button Makes a screenshot of the current screen... -

Page 106: Steam Production Control System

AA00-9270-00AAA-043C-A X92-B Operation Manual Steam production control system 4.13 Steam production control system The steam production control system (SPC) supplies the steam production of the ship with exhaust gas, which has a higher temperature. SPC is an optional system. NOTE: The engine obeys the IMO NOx limits, with and without steam production. -

Page 107: Ldu-20 Page - Steam Production Control

AA00-9270-00AAA-043C-A X92-B Operation Manual Steam production control system Fig 4-26 LDU-20 page - STEAM PRODUCTION CONTROL Tab 4-6 STEAM PRODUCTION CONTROL (SPC) Item Function Effect ON/OFF button Starts or stops the SPC system INDEX button Opens the index page SCREENSHOT button... - Page 108 AA00-9270-00AAA-043C-A X92-B Operation Manual Steam production control system Item Function Effect PressCtrl mode 1 button Starts the PressCtrl mode 1 This mode is applicable only, if the steam pressure signal from the steam plant is correct. SPC compares the setpoint and the actual steam pressure. If there is a difference, it opens or closes the EWG to change the steam pressure.

-

Page 109: Ldu For The Steam Boost Mode

AA00-9270-00AAA-043C-A X92-B Operation Manual Steam production control system 4.13.4 LDU screen for steam boost mode Fig 4-27 LDU for the steam boost mode - 109 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. - Page 110 AA00-9270-00AAA-043C-A X92-B Operation Manual Steam production control system 4.13.5 Activate the steam boost mode Before activating the steam boost mode, make sure the LDU-Screen (Figure 4-27) shows the following: Firing Pressure Gas Mode indicates (5) “OK”. • Servo Oil (6) indicates “OK”.

-

Page 111: Design And Function Of Components

X92-B Operation Manual 5 Design and function of components Group 1 - Engine frame and bearings 5.1.1 Bedplate......................114 5.1.2 Main bearing....................116 5.1.3 Thrust bearing....................118 5.1.4 Monoblock column...................120 5.1.5 rod......................122 Group 2 - Cylinder 5.2.1 Cylinder liner....................124 5.2.2 Lubricating quill....................126 5.2.3 Piston rod gland....................128... - Page 112 X92-B Operation Manual 5.6.5 Scavenge air cooler..................184 5.6.6 Water separator....................186 Group 7 - Cylinder lubrication and balancer 5.7.1 Cylinder lubrication..................188 5.7.2 Integrated electrical balancer (iELBA).............190 Group 8 - Pipes 5.8.1 Exhaust waste gate..................196 Group 9 - Monitoring instruments 5.9.1 Crank angle sensor unit...................198...

- Page 113 X92-B Operation Manual Page left intentionally blank - 113 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 114: Group 1 - Engine Frame And Bearings Bedplate

AA00-1115-00AAA-043A-A X92-B Operation Manual Bedplate Group 1 - Engine frame and bearings 5.1.1 Bedplate The bedplate is the basic structure of the engine. The bearing girders (001, Figure 5-1) are attached in the bedplate and hold the crankshaft. The bottom part of the bedplate is the crankcase and collects lubricating oil. This oil flows back to the oil supply system through oil drains (002). - Page 115 AA00-1115-00AAA-043A-A X92-B Operation Manual Bedplate Page left intentionally blank - 115 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 116: Main Bearing

AA00-1132-00AAA-043A-A X92-B Operation Manual Main bearing 5.1.2 Main bearing The main bearings hold the crankshaft (007, Figure 5-2) and transmit the forces through the bearing girders (008) into the bedplate. The bottom bearing shell (006) is installed in the bearing girder (008) of the bedplate and the top bearing shell (004) in the bearing cover (003). - Page 117 AA00-1132-00AAA-043A-A X92-B Operation Manual Main bearing Page left intentionally blank - 117 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 118: Thrust Bearing

AA00-1203-00AAA-043A-A X92-B Operation Manual Thrust bearing 5.1.3 Thrust bearing The thrust bearing is installed on the crankshaft at the driving end of the engine. The thrust bearing flange (014, Figure 5-3) transmits the axial thrust from the propeller through the thrust pads into the bedplate: •... -

Page 119: Thrust Bearing (Generic)

AA00-1203-00AAA-043A-A X92-B Operation Manual Thrust bearing Fig 5-3 Thrust bearing (generic) Legend Column Crankshaft Oil pipe 2-part oil baffle Nozzle Flywheel Arbor support Bedplate Bedplate Thrust pad (engine side) Thrust pad (driving end) Thrust bearing flange Bearing cover Column Crankshaft gear wheel... -

Page 120: Monoblock Column

AA00-1406-00AAA-043A-A X92-B Operation Manual Monoblock column 5.1.4 Monoblock column The monoblock column is the middle part of the engine. The monoblock column is installed on the bedplate and holds the cylinders. On the exhaust side (ES) the monoblock column has one relief valve (001, Figure 5-4) per cylinder. - Page 121 AA00-1406-00AAA-043A-A X92-B Operation Manual Monoblock column Page left intentionally blank - 121 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 122: Tie Rod

AA00-1903-00AAA-043A-A X92-B Operation Manual Tie rod 5.1.5 Tie rod The tie rods (004, Figure 5-5) keep the cylinder block (002), column (003) and bedplate (005) together at four locations around each cylinder. Fig 5-5 Tie rod (generic) Legend Protection cover... - Page 123 AA00-1903-00AAA-043A-A X92-B Operation Manual Tie rod Page left intentionally blank - 123 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 124: Group 2 - Cylinder Cylinder Liner

AA00-2124-00AAA-043A-A X92-B Operation Manual Cylinder liner Group 2 - Cylinder 5.2.1 Cylinder liner The cylinder liner is one of the primary parts of the engine. The cylinder liner is on the cylinder jacket and holds the cylinder cover and the water guide jackets. The nuts and the elastic bolts hold these parts together. - Page 125 AA00-2124-00AAA-043A-A X92-B Operation Manual Cylinder liner Page left intentionally blank - 125 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 126: Lubricating Quill

AA00-2138-00AAA-043A-A X92-B Operation Manual Lubricating quill 5.2.2 Lubricating quill The lubricating quills spray oil onto the cylinder liner wall. The lubricating quills are installed on the circumference of the cylinder liner. The cylinder lubricating pump supplies a specified quantity of cylinder oil at high pressure through... - Page 127 AA00-2138-00AAA-043A-A X92-B Operation Manual Lubricating quill Page left intentionally blank - 127 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 128: Piston Rod Gland

AA00-2303-00AAA-043A-A X92-B Operation Manual Piston rod gland 5.2.3 Piston rod gland The piston rod gland keeps the dirty cylinder oil in the scavenge space and thus prevents contamination of the bearing oil in the crankcase. Also, the piston rod gland seals the scavenge air from the crankcase. - Page 129 AA00-2303-00AAA-043A-A X92-B Operation Manual Piston rod gland Page left intentionally blank - 129 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 130: Direct Controlled Injection Valve

AA00-2722-00AAA-043A-A X92-B Operation Manual Direct controlled injection valve 5.2.4 Direct controlled injection valve The injection valves are installed in the cylinder cover of each cylinder. The injection valves spray the fuel into the combustion chamber. The ECS controls the pilot valve of the injection valves indirectly through the solenoid valve. - Page 131 AA00-2722-00AAA-043A-A X92-B Operation Manual Direct controlled injection valve Page left intentionally blank - 131 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 132: Starting Valve

AA00-2728-00AAA-043A-A X92-B Operation Manual Starting valve 5.2.5 Starting valve The starting valve in each cylinder cover supplies pressurized air into the combustion chamber in the two situations that follow: To start the engine before combustion starts • • To decrease the engine speed when combustion has stopped. - Page 133 AA00-2728-00AAA-043A-A X92-B Operation Manual Starting valve Page left intentionally blank - 133 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 134: Exhaust Valve

AA00-2751-00AAA-043A-A X92-B Operation Manual Exhaust valve 5.2.6 Exhaust valve The exhaust valve in each cylinder cover releases the exhaust gas of the combustion into the exhaust gas manifold. The hydraulic oil pressure from the exhaust valve control unit (VCU) opens the exhaust valve. - Page 135 AA00-2751-00AAA-043A-A X92-B Operation Manual Exhaust valve Air spring • When the exhaust valve is closed, compressed air flows through an air inlet connection into the air spring (011). When the exhaust valve opens, this air is compressed to a higher value.

-

Page 136: Group 3 - Crankshaft, Connecting Rod And Piston Crankshaft

AA00-3103-00AAA-043A-A X92-B Operation Manual Crankshaft Group 3 - Crankshaft, connecting rod and piston 5.3.1 Crankshaft The crankshaft turns as it gets the power from the pistons. The crankshaft transmits the power to the attached propeller shaft of the ship. Main bearings on the two sides of each crank (002, Figure 5-11) hold the crankshaft in position. - Page 137 AA00-3103-00AAA-043A-A X92-B Operation Manual Crankshaft Page left intentionally blank - 137 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 138: Torsional Vibration Damper

AA00-3130-00AAA-043A-A X92-B Operation Manual Torsional vibration damper 5.3.2 Torsional vibration damper The torsional vibration damper decreases the torsional vibrations in the shafting system and in other components of the engine. If a torsional vibration damper is necessary for the engine, one of the two damper types that follow can be used. - Page 139 AA00-3130-00AAA-043A-A X92-B Operation Manual Torsional vibration damper 5.3.2.1 Steel spring damper A steel spring damper (Figure 5-12) is a tuned torsional vibration damper. It consists of two main parts: The inner part (inner star (005) and spring pack (004)) is attached to the crankshaft flange •...

- Page 140 AA00-3130-00AAA-043A-A X92-B Operation Manual Torsional vibration damper 5.3.2.2 Viscous damper A viscous damper (Figure 5-13) is a tuned torsional vibration damper. It consists of two main parts: The housing (002) is fully sealed and is attached to the crankshaft flange at the free end.

- Page 141 AA00-3130-00AAA-043A-A X92-B Operation Manual Torsional vibration damper Page left intentionally blank - 141 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 142: Axial Vibration Damper

AA00-3140-00AAA-043A-A X92-B Operation Manual Axial vibration damper 5.3.3 Axial vibration damper The axial vibration damper decreases the axial vibrations of the crankshaft. The axial vibration damper is attached with bolts to the last bearing girder at the free end of the engine. - Page 143 AA00-3140-00AAA-043A-A X92-B Operation Manual Axial vibration damper 5.3.3.1 Function Oil flows from the oil inlet (012) through the top cylinder half (002) into the two annular spaces (003). When the crankshaft (004) moves in an axial direction, the pressure of the oil in the compressed annular space (003) increases.

-

Page 144: Turning Gear

AA00-3206-00AAA-043A-A X92-B Operation Manual Turning gear 5.3.4 Turning gear The turning gear slowly turns the crankshaft and thus moves the pistons, if the pinion (002, Figure 5-16) is engaged on the flywheel (003). The electric motor (001) turns the pinion (002) and is attached on the driving end of the engine. - Page 145 AA00-3206-00AAA-043A-A X92-B Operation Manual Turning gear Page left intentionally blank - 145 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 146: Connecting Rod And Connecting Rod Bearing

AA00-3303-00AAA-043A-A X92-B Operation Manual Connecting rod and connecting rod bearing 5.3.5 Connecting rod and connecting rod bearing The connecting rod connects the crosshead with the crankshaft and converts the linear movement of the piston into a circular movement of the crankshaft. - Page 147 AA00-3303-00AAA-043A-A X92-B Operation Manual Connecting rod and connecting rod bearing Page left intentionally blank - 147 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 148: Crosshead And Guide Shoe

AA00-3326-00AAA-043A-A X92-B Operation Manual Crosshead and guide shoe 5.3.6 Crosshead and guide shoe The crosshead guides the piston rod (009, Figure 5-18) and absorbs the lateral forces that come from the connecting rod (005). The piston rod (009) is attached to the compression shim (007) and the crosshead pin (006) with screws. - Page 149 AA00-3326-00AAA-043A-A X92-B Operation Manual Crosshead and guide shoe Page left intentionally blank - 149 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 150: Piston

AA00-3403-00AAA-043A-A X92-B Operation Manual Piston 5.3.7 Piston The piston moves in each cylinder. The piston rings seal the combustion chamber. The piston transmits the force from the gas that expands in the cylinder to the crankshaft through the connecting rod. - Page 151 AA00-3403-00AAA-043A-A X92-B Operation Manual Piston Page left intentionally blank - 151 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 152: Group 4 - Supply Unit Drive And Control Components Supply Unit Drive

AA00-4104-00AAA-043A-A X92-B Operation Manual Supply unit drive Group 4 - Supply unit drive and control components 5.4.1 Supply unit drive The supply unit drive is installed at the driving end of the engine on the fuel side. The crankshaft gear wheel (003, Figure 5-20) moves the intermediate wheel (001). - Page 153 AA00-4104-00AAA-043A-A X92-B Operation Manual Supply unit drive Fig 5-20 Supply unit drive (generic) Legend Intermediate wheel Gear wheel (servo oil pumps) Flywheel Intermediate wheel Crankshaft gear wheel Crankshaft Gear wheel (servo oil pump) - 153 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 154: Starting Air Shut-Off Valve

AA00-4325-00AAA-043A-A X92-B Operation Manual Starting air shut-off valve 5.4.2 Starting air shut-off valve The starting air shut-off valve supplies the starting air pipe with starting air. The starting air shut- off valve has a hand-wheel with three positions: CLOSED •... - Page 155 AA00-4325-00AAA-043A-A X92-B Operation Manual Starting air shut-off valve During the start sequence the MCM-20 / IOM-20 module operates the solenoid valves (014) and (016). The control air from the control air inlet (017) opens the control valve (001) through the solenoid valve CV7014C (014) and releases the pressure in the valve space (002).

-

Page 156: Control Air Supply

AA00-4605-00AAA-043A-A X92-B Operation Manual Control air supply 5.4.3 Control air supply The control air supply supplies control air to the engine. The plant supply systems supply compressed air with the specified properties at the two engine connections that follow: Connection 45 (control air supply inlet) for usual supply •... - Page 157 AA00-4605-00AAA-043A-A X92-B Operation Manual Control air supply Page left intentionally blank - 157 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 158: Local Maneuvering Stand For Unic

AA00-4618-00AAA-043A-A X92-B Operation Manual Local maneuvering stand for UNIC 5.4.4 Local maneuvering stand for UNIC The local maneuvering stand has the local control panel (001, Figure 5-23) and is attached to the engine at the free end. The local control panel has the components necessary for engine operation. - Page 159 AA00-4618-00AAA-043A-A X92-B Operation Manual Local maneuvering stand for UNIC 5.4.4.1 Local control panel NOTE: If a fault occurs in the remote control, which prevents engine control from the control room, you can operate the engine from the local control panel.

-

Page 160: Pick-Up For Speed Measurement

AA00-4628-00AAA-043A-A X92-B Operation Manual Pick-up for speed measurement 5.4.5 Pick-up for speed measurement To measure the engine speed (rpm), proximity sensors are installed in a speed pick-up unit, attached to the support near the flywheel. For safety, there are three electrically isolated proximity sensor groups as follows: Speed identification in the remote control system (RCS) •... - Page 161 AA00-4628-00AAA-043A-A X92-B Operation Manual Pick-up for speed measurement Page left intentionally blank - 161 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 162: Group 5 - Supply Unit, Pumps And Control Valves Servo Oil Pump

AA00-5551-00AAA-043A-A X92-B Operation Manual Servo oil pump Group 5 - Supply unit, pumps and control valves 5.5.1 Servo oil pump The servo oil pumps (004, Figure 5-25) supply the servo oil system with oil during usual operation. The number of servo oil pumps is related to the engine. - Page 163 AA00-5551-00AAA-043A-A X92-B Operation Manual Servo oil pump Page left intentionally blank - 163 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 164: Supply Unit

AA00-5552-00AAA-043A-A X92-B Operation Manual Supply unit 5.5.2 Supply unit The supply unit includes the servo oil pumps and the fuel pumps. The supply unit is installed on the column at the driving end of the engine. The gear wheels and intermediate wheels in the supply unit operate the fuel pumps and servo oil pumps, refer to section 5.4.1 Supply unit... - Page 165 AA00-5552-00AAA-043A-A X92-B Operation Manual Supply unit Page left intentionally blank - 165 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 166: Fuel Pump

AA00-5556-00AAA-043A-A X92-B Operation Manual Fuel pump 5.5.3 Fuel pump The fuel pumps (001, Figure 5-27) supply the fuel rail with fuel at high pressure. The number of fuel pumps is related to the engine. Fig 5-27 Fuel pump (generic) Legend... -

Page 167: Fuel Pump - Cross Section (Example)

AA00-5556-00AAA-043A-A X92-B Operation Manual Fuel pump Fig 5-28 Fuel pump - cross section (example) Legend HP fuel to fuel rail Guide piston Fuel inlet Driver (of pump plunger) Pump plunger Regulating sleeve Compression spring Toothed rack Bottom spring carrier Fuel outlet... -

Page 168: Pressure Control Valve

AA00-5562-00AAA-043A-A X92-B Operation Manual Pressure control valve 5.5.4 Pressure control valve The pressure control valve (PCV) (002, Figure 5-29) is attached to the fuel rail (007) and has the functions that follow: Usual operation • During usual operation the engine software controls the fuel flow and thus the fuel pressure. -

Page 169: Pressure Control Valve - Location (Example)

AA00-5562-00AAA-043A-A X92-B Operation Manual Pressure control valve Fig 5-29 Pressure control valve - location (example) Legend Solenoid valve (ZV7061S) Fuel return pipe Pressure control valve (10-5562_E0_5) Rail unit Relief valve Fuel rail Fuel return pipe Drain pipe - 169 - Issue 002 2021-11 Winterthur Gas &... -

Page 170: Flow Limiting Valve

AA00-5565-00AAA-043A-A X92-B Operation Manual Flow limiting valve 5.5.5 Flow limiting valve For each cylinder there is one flow limiting valve installed on the fuel rail. The position of the piston (003, Figure 5-30) gives the quantity of fuel for the injection. When the injection valves open, the piston (003) moves to the right until the injection stops. - Page 171 AA00-5565-00AAA-043A-A X92-B Operation Manual Flow limiting valve Page left intentionally blank - 171 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 172: Exhaust Valve Control Unit

AA00-5612-00AAA-043A-A X92-B Operation Manual Exhaust valve control unit 5.5.6 Exhaust valve control unit The exhaust valve control units (VCU) control the servo oil to the exhaust valve of the related cylinders. The exhaust valve control units are attached to the servo oil rail. - Page 173 AA00-5612-00AAA-043A-A X92-B Operation Manual Exhaust valve control unit Page left intentionally blank - 173 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 174: Fuel Pump Actuator

AA00-5583-00AAA-043A-A X92-B Operation Manual Fuel pump actuator 5.5.7 Fuel pump actuator The fuel pump actuator moves the regulating sleeve of the fuel pump and thus controls the fuel quantity, refer to section 5.5.3 Fuel pump. Each fuel pump is connected to its related actuator (for an X92 engine two fuels pumps are connected to there related actuator). - Page 175 AA00-5583-00AAA-043A-A X92-B Operation Manual Fuel pump actuator Page left intentionally blank - 175 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 176: Group 6 - Scavenge Air Components Scavenge Air Receiver

AA00-6420-00AAA-043A-A X92-B Operation Manual Scavenge air receiver Group 6 - Scavenge air components 5.6.1 Scavenge air receiver The scavenge air receiver (005, Figure 5-32) supplies the cylinders with the applicable quantity of air. The scavenge air receiver is a welded assembly attached to the cylinder block on the exhaust side. -

Page 177: Scavenge Air Receiver - Cross Section (Example)

AA00-6420-00AAA-043A-A X92-B Operation Manual Scavenge air receiver Fig 5-33 Scavenge air receiver - cross section (example) Legend Air space Outlet to piston underside Longitudinal wall Flap Receiver space - 177 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. -

Page 178: Turbocharger

8.3 Start the engine - general. WinGD recommends to regularly clean the turbochargers and the silencers, refer to section Clean the turbocharger during operation. This prevents or decreases contamination of the turbochargers and thus increases the time between overhauls. - Page 179 AA00-6500-00AAA-043A-A X92-B Operation Manual Turbocharger Page left intentionally blank - 179 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 180: Auxiliary Blower

AA00-6545-00AAA-043A-A X92-B Operation Manual Auxiliary blower 5.6.3 Auxiliary blower The auxiliary blowers supply air from the engine room through the duct into the scavenge air receiver during the engine start and operation at low load. The flaps prevent the back flow of air to the scavenge air receiver during usual operation of the turbochargers and during engine stop. - Page 181 AA00-6545-00AAA-043A-A X92-B Operation Manual Auxiliary blower Page left intentionally blank - 181 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 182: Auxiliary Blower Switch Box

AA00-6547-00AAA-043A-A X92-B Operation Manual Auxiliary blower switch box 5.6.4 Auxiliary blower switch box The auxiliary blower switch box is used to operate the auxiliary blowers in Auto mode or Manual mode. When the auxiliary switch box is in Auto mode, the first auxiliary blower will start and second will start after few seconds. - Page 183 AA00-6547-00AAA-043A-A X92-B Operation Manual Auxiliary blower switch box Page left intentionally blank - 183 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 184: Scavenge Air Cooler

Air flow Cooling water inlet Cooling water outlet Cover WinGD recommends to regularly clean the scavenge air coolers, refer to section 9.5 Clean the scavenge air cooler during operation. This prevents or decreases contamination of the scavenge air coolers and thus increases the time between overhauls. - Page 185 AA00-6606-00AAA-043A-A X92-B Operation Manual Scavenge air cooler Page left intentionally blank - 185 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 186: Water Separator

AA00-6708-00AAA-043A-A X92-B Operation Manual Water separator 5.6.6 Water separator The water separator removes water from the scavenge air. This prevents damage and gives better combustion in the cylinders. Water occurs when the scavenge air cooler (SAC) decreases the temperature of wet air. Water also occurs during the wash procedure of the SAC. - Page 187 AA00-6708-00AAA-043A-A X92-B Operation Manual Water separator Page left intentionally blank - 187 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 188: Group 7 - Cylinder Lubrication And Balancer Cylinder Lubrication

AA00-7218-00AAA-043A-A X92-B Operation Manual Cylinder lubrication Group 7 - Cylinder lubrication and balancer 5.7.1 Cylinder lubrication For information about the cylinder lubrication oil, refer to section: 12.1 General for operating media For information about the cylinder oil system in general, refer to section: 4.6 Cylinder oil system... - Page 189 AA00-7218-00AAA-043A-A X92-B Operation Manual Cylinder lubrication Page left intentionally blank - 189 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 190: Integrated Electrical Balancer (Ielba)

AA00-7752-00AAA-043A-A X92-B Operation Manual Integrated electrical balancer (iELBA) 5.7.2 Integrated electrical balancer (iELBA) The optional integrated ELectrical BAlancer (iELBA) decreases second order vertical mass moments (M2v) of the engine, refer to Figure 5-39. NOTE: For the engine itself it is not necessary to install a balancer. But a balancer decreases the exitation forces of the engine. -

Page 191: Ielba - Function

AA00-7752-00AAA-043A-A X92-B Operation Manual Integrated electrical balancer (iELBA) Fig 5-40 iELBA - function Legend Gear wheel Housing Counterweight Column Bearing - 191 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. -

Page 192: Control System

AA00-7752-00AAA-043A-A X92-B Operation Manual Integrated electrical balancer (iELBA) 5.7.2.2 Control system Each iELBA has two control cabinets (E38 and E39). The control system monitors the speed of the electric motor and the rotating speeds and phases of the counterweights (002) and of the flywheel of the engine. -

Page 193: Ielba - Control Cabinet

AA00-7752-00AAA-043A-A X92-B Operation Manual Integrated electrical balancer (iELBA) 5.7.2.4 Control cabinet Figure 5-41 shows the buttons and indications on the control cabinet of the iELBA. Fig 5-41 iELBA - control cabinet - 193 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. - Page 194 AA00-7752-00AAA-043A-A X92-B Operation Manual Integrated electrical balancer (iELBA) Tab 5-1 iELBA - control cabinet Item Function Effect Drive Power Consumption indica- Shows the electric motor current (in Ampere) tion Manual Start button Starts the iELBA (in manual mode) Manual Stop button...

-

Page 195: Ielba - Error Indication

AA00-7752-00AAA-043A-A X92-B Operation Manual Integrated electrical balancer (iELBA) Table 5-2 - iELBA - error indication shows the possible iELBA error indications related to the number of flashes of the indicator light. NOTE: The error indications are active in automatic mode and in manual mode. -

Page 196: Group 8 - Pipes Exhaust Waste Gate

AA00-8135-00AAA-043A-A X92-B Operation Manual Exhaust waste gate Group 8 - Pipes 5.8.1 Exhaust waste gate The optional exhaust waste gate is a by-pass pipe to the turbine (006, Figure 5-42) of the turbochargers. The valve (007) in this pipe controls the flow of exhaust gas through the turbines (006). - Page 197 AA00-8135-00AAA-043A-A X92-B Operation Manual Exhaust waste gate Page left intentionally blank - 197 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 198: Group 9 - Monitoring Instruments Crank Angle Sensor Unit

AA00-9223-00AAA-043A-A X92-B Operation Manual Crank angle sensor unit Group 9 - Monitoring instruments 5.9.1 Crank angle sensor unit The crank angle sensor unit is installed on the supply unit drive at the driving end. There are two crank angle systems that monitor the teeth on the intermediate wheel. The two sets... -

Page 199: Crank Angle Sensor Unit On Flywheel (Example)

AA00-9223-00AAA-043A-A X92-B Operation Manual Crank angle sensor unit Two more proximity sensors (002, Figure 5-44) are used to find the crank angle marks (004) for TDC and BDC on the flywheel (003). All proximity sensors are connected as follows: First sensor pair to MCM-20 and CCM-20#1 •... -

Page 200: Water In Oil Monitor

AA00-9313-00AAA-043A-A X92-B Operation Manual Water in oil monitor 5.9.2 Water in oil monitor The optional water in oil monitor continuously monitors the concentration of water in the oil supply pipe. The water in oil monitor continuously sends a signal to the alarm and monitoring system (AMS). - Page 201 AA00-9313-00AAA-043A-A X92-B Operation Manual Water in oil monitor Page left intentionally blank - 201 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 202: Oil Mist Detector

AA00-9314-00AAA-043A-A X92-B Operation Manual Oil mist detector 5.9.3 Oil mist detector The oil mist detection system continuously monitors the concentration of oil mist in the crankcase, in the supply unit drive and in the supply unit. If there is a high oil mist concentration, the oil mist detector activates an alarm. -

Page 203: Oil Mist Detector - Schematic Diagram (Example)

AA00-9314-00AAA-043A-A X92-B Operation Manual Oil mist detector Fig 5-47 Oil mist detector - schematic diagram (example) Legend Control panel Control unit E15.1 Power supply Supply unit Data cable Crankcase and gear box To alarm system Sensor To safety system Data communication is between the control unit (006, Figure 5-47) and the control panel (001). - Page 204 AA00-9314-00AAA-043A-A X92-B Operation Manual Oil mist detector Page left intentionally blank - 204 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 205: Control System

X92-B Operation Manual 6 Control system Engine control system WiCE...................206 Intelligent combustion control..................210 Integrated gas pressure regulation................214 Local display unit (LDU-20) - general..............218 LDU-20 page - iELBA Control (optional)..............220 Manual Control Panel (MCP) - Option for WiCE 6.6.1 Operate the manual control panel (MCP)............222... -

Page 206: Engine Control System Wice

The optional angle calculation modules (ACM #1 and #2) are installed in the terminal boxes E96.1 and E96.2. Redundant system buses connect all these modules. Software updates must be done only with the supervision of a WinGD service engineer and in accordance with regulations that WinGD has set. - 206 - Issue 002 2021-11 Winterthur Gas &... - Page 207 AA00-0000-00AAC-043K-A X92-B Operation Manual Engine control system WiCE 6.1.2 Functions of the engine control system The main functions of the engine control system are as follows: Starting valve control • Servo oil pressure control • Exhaust valve control • •...

- Page 208 AA00-0000-00AAC-043K-A X92-B Operation Manual Engine control system WiCE 6.1.3 External control systems The Diesel Engine CoNtrol and OptImizing Specification (DENIS) and the engine control system (ECS) are designed so that different remote controls can be used. All nodes are fully specified.

- Page 209 AA00-0000-00AAC-043K-A X92-B Operation Manual Engine control system WiCE 6.1.3.2 Alarm and monitoring system The alarm and monitoring system (AMS) is an external system and monitors the engine. The AMS gives the operator alarms and status data of the engine to make sure of safe and satisfactory engine operation.

-

Page 210: Intelligent Combustion Control

AA00-9308-00AAA-043A-A X92-B Operation Manual Intelligent combustion control Intelligent combustion control The intelligent combustion control (ICC) permanently monitors and automatically controls the combustion process. The ICC is part of the engine control system (ECS). All ICC modifications of the engine control parameters obey the IMO regulations and are related to the IMO certificate of the vessel. -

Page 211: Icc - Pressure Diagram

AA00-9308-00AAA-043A-A X92-B Operation Manual Intelligent combustion control 6.2.1 Pressure calculation In the ICC system, the compression pressure of each cycle is calculated with the polynomial formula and the data of the piston position. The ICC uses the values that follow for calculation,... -

Page 212: Icc - Control Schematic

AA00-9308-00AAA-043A-A X92-B Operation Manual Intelligent combustion control 6.2.2 ICC control A pressure transmitter is installed on each cylinder cover. The cylinder pressure data of each cylinder is taken as an analogue input signal from the pressure transmitter into the ECS. - Page 213 AA00-9308-00AAA-043A-A X92-B Operation Manual Intelligent combustion control Page left intentionally blank - 213 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 214: Integrated Gas Pressure Regulation

AA00-8904-00AAA-043A-A X92-B Operation Manual Integrated gas pressure regulation Integrated gas pressure regulation The integrated gas pressure regulation (iGPR) controls the gas pressure of the gas that is supplied to the engine inlet. The iGPR control system has also other functions as follows: It removes contamination of the supplied gas with a gas filter. - Page 215 AA00-8904-00AAA-043A-A X92-B Operation Manual Integrated gas pressure regulation Starts step 1 (FGSS preparation): • ○ Waits for the signal FGSS is ready. NOTE: All valves are in diesel operation position. ○ Activates the FGSS ready signal from PCS to iGPR.

- Page 216 AA00-8904-00AAA-043A-A X92-B Operation Manual Integrated gas pressure regulation Closes the shut-off valves (CV7285C, CV7291C, CV7292C). • Opens the vent valves (CV7289C, CV7286C, CV7287C). • • Opens the pressure regulating valve (CV7288C). NOTE: The pressure in the engine gas piping decreases to atmospheric pressure.

- Page 217 AA00-8904-00AAA-043A-A X92-B Operation Manual Integrated gas pressure regulation The inert valve in the FGSS closes again after 25 seconds, when the pipes are filled with • inert gas. If the inerting sequence was successful, the iGPR control system activates the inerting •...

-

Page 218: Local Display Unit (Ldu-20) - General

AA00-0000-00AAA-043H-A X92-B Operation Manual Local display unit (LDU-20) - general Local display unit (LDU-20) - general 6.4.1 Local display unit (LDU-20) The LDU-20 (Figure 6-4) is a multi-purpose module that has an LCD color display (009), ten multi- function buttons (004 to 008) and a rotary button (003). -

Page 219: Ldu-20 Color Display - General Items

AA00-0000-00AAA-043H-A X92-B Operation Manual Local display unit (LDU-20) - general 6.4.2 Color display The color display (009) of the LDU-20 shows different pages for each application. After boot-up, or when you push the HOME button, the MAIN page is shown. -

Page 220: Page - Ielba Control (Optional)

AA00-9606-42AAA-043B-A X92-B Operation Manual LDU-20 page - iELBA Control (optional) LDU-20 page - iELBA Control (optional) Fig 6-6 iELBA Control - 220 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. - Page 221 AA00-9606-42AAA-043B-A X92-B Operation Manual LDU-20 page - iELBA Control (optional) Tab 6-1 iELBA Control Item Function Effect START AST button Starts the engine in astern direction (for reversible engine) STOP button Stops the engine START AHD button Starts the engine in ahead direction CTRL.

-

Page 222: Manual Control Panel (Mcp) - Option For Wice Operate The Manual Control Panel (Mcp)

AA00-4618-00AAC-131A-A X92-B Operation Manual Operate the manual control panel (MCP) Manual Control Panel (MCP) - Option for WiCE 6.6.1 Operate the manual control panel (MCP) Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 0.5 man-hours... -

Page 223: Mcp Page - Main Locked

AA00-4618-00AAC-131A-A X92-B Operation Manual Operate the manual control panel (MCP) PROCEDURE Fig 6-7 MCP page - MAIN locked Legend UNLOCK button Navigation field To unlock the function buttons, do the steps that follow: Touch the UNLOCK button (001, Figure 6-7) with your finger. - Page 224 AA00-4618-00AAC-131A-A X92-B Operation Manual Operate the manual control panel (MCP) To change the speed command setting, do the steps that follow: To increase the speed command setting, turn the fuel dial knob clockwise. To decrease the speed command setting, turn the fuel dial knob counterclockwise.

- Page 225 AA00-4618-00AAC-131A-A X92-B Operation Manual Operate the manual control panel (MCP) Page left intentionally blank - 225 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 226: Mcp Page - Main

AA00-4618-01AAA-043B-A X92-B Operation Manual MCP page - MAIN 6.6.2 MCP page - MAIN Fig 6-8 MCP page - MAIN - 226 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. - Page 227 AA00-4618-01AAA-043B-A X92-B Operation Manual MCP page - MAIN Tab 6-2 MAIN Item Function Effect Indication field Shows data for start interlocks and for limiters Start interlock Info: Turning Gear Engaged, Main Start Air Valve Closed, Exhaust Venting Request, Shaft Locking Device En-...

-

Page 228: Mcp Page - Adjust User Parameters

AA00-4618-05AAA-043B-A X92-B Operation Manual MCP page - Adjust user parameters 6.6.3 MCP page - Adjust user parameters Fig 6-9 MCP page - Open user parameters Item Name Effect when touched Navigation field: MENU Opens the sub-navigation fields: INFO • TRENDING •... -

Page 229: Mcp Page - Select User Parameter

AA00-4618-05AAA-043B-A X92-B Operation Manual MCP page - Adjust user parameters Fig 6-10 MCP page - Select user parameter Item Name Effect when touched User parameter Makes the related user parameter ad- justable. - 229 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. -

Page 230: Mcp Page - Adjust User Parameter

AA00-4618-05AAA-043B-A X92-B Operation Manual MCP page - Adjust user parameters Fig 6-11 MCP page - Adjust user parameter Item Name Effect when touched Adjustable user parameter. Makes the related adjustable user pa- rameter option non-adjustable. User parameter regulators Two possible effects: •... - Page 231 AA00-4618-05AAA-043B-A X92-B Operation Manual MCP page - Adjust user parameters Page left intentionally blank - 231 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 232: Mcp Page - System Info - Option For Wice

AA00-4618-03AAA-043B-A X92-B Operation Manual MCP page - SYSTEM INFO - Option for WiCE 6.6.4 MCP page - SYSTEM INFO - Option for WiCE Fig 6-12 MCP page - SYSTEM INFO Tab 6-3 SYSTEM INFO Item Function Effect Engine Shows data for the engine... - Page 233 AA00-4618-03AAA-043B-A X92-B Operation Manual MCP page - SYSTEM INFO - Option for WiCE Page left intentionally blank - 233 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 234: Mcp Page - Trend - Option For Wice

AA00-4618-04AAA-043B-A X92-B Operation Manual MCP page - TREND - Option for WiCE 6.6.5 MCP page - TREND - Option for WiCE Fig 6-13 MCP page - TREND Tab 6-4 TREND Item Function Effect Selection field Highlights the selected parameters Diagram field... - Page 235 AA00-4618-04AAA-043B-A X92-B Operation Manual MCP page - TREND - Option for WiCE Page left intentionally blank - 235 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 236: Mcp Page - Instruments

AA00-4618-02AAA-043B-A X92-B Operation Manual MCP page - INSTRUMENTS 6.6.6 MCP page - INSTRUMENTS Fig 6-14 MCP page - INSTRUMENTS Tab 6-5 INSTRUMENTS Item Function Effect Indication field Shows the values of the displayed instruments NOTE: The number of the displayed instruments is related to the engine. - Page 237 AA00-4618-02AAA-043B-A X92-B Operation Manual MCP page - INSTRUMENTS Page left intentionally blank - 237 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 238: Mcp Page - Fuel / Lubrication System

AA00-4618-08AAA-043B-A X92-B Operation Manual MCP page - FUEL / LUBRICATION SYSTEM 6.6.7 MCP page - FUEL / LUBRICATION SYSTEM Fig 6-15 MCP page - FUEL / LUBRICATION SYSTEM - 238 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. -

Page 239: Fuel / Lubrication System

AA00-4618-08AAA-043B-A X92-B Operation Manual MCP page - FUEL / LUBRICATION SYSTEM Tab 6-6 FUEL / LUBRICATION SYSTEM Item Function Effect LFO button Changes to LFO (Light Fuel Oil) HFO button Changes to HFO (Heavy Fuel Oil) LOW BN button Changes to low BN cylinder oil... - Page 240 AA00-4618-08AAA-043B-A X92-B Operation Manual MCP page - FUEL / LUBRICATION SYSTEM Page left intentionally blank - 240 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd.

-

Page 241: Installation

X92-B Operation Manual 7 Installation Installation.......................242 - 241 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. -

Page 242: Installation

Engine stays • Extinguishing system • Auxiliary systems. • NOTE: The latest version of the Marine Installation Manual and the installation drawings are available on the WinGD website. https://www.wingd.com/ - 242 - Issue 002 2021-11 Winterthur Gas & Diesel Ltd. -

Page 243: Operation

X92-B Operation Manual 8 Operation Prepare the engine before start - general..............244 Prepare the engine before start................246 Start the engine - general..................254 Start the engine.......................256 Do checks during operation - general..............258 Do checks during operation..................260 Do regular safety checks..................264 Maneuver the ship - general..................268... -

Page 244: Prepare The Engine Before Start - General

AA00-0000-00AAA-120A-A X92-B Operation Manual Prepare the engine before start - general Prepare the engine before start - general If you have done maintenance work on the engine, make sure that you have done the related function tests and the engine is ready for operation. - Page 245 AA00-0000-00AAA-120A-A X92-B Operation Manual Prepare the engine before start - general Control air system • Make sure that the quality of the control air obeys the related specifications in section 12.2 Compressed air. Make sure that control air is available at the engine connection 49 (control air supply inlet).

-

Page 246: Prepare The Engine Before Start

AA00-0000-00AAA-121A-A X92-B Operation Manual Prepare the engine before start Prepare the engine before start Periodicity Description Engine start Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 247 AA00-0000-00AAA-121A-A X92-B Operation Manual Prepare the engine before start PROCEDURE Make sure that there is no alarm indication. Prepare the control system for operation. Set to ON the engine control system (ECS) and the remote control system (RCS). Set to ON all circuit breakers in the power supply box E85.

-

Page 248: Cooling Water System With Bypass Cooling

AA00-0000-00AAA-121A-A X92-B Operation Manual Prepare the engine before start Prepare the cooling water system for operation. For an engine with a bypass cooling water system (refer to Figure 8-1), and when the liner wall temperature is between 60°C and 90°C (for example when the engine... -

Page 249: Cooling Water System Without Bypass Cooling

AA00-0000-00AAA-121A-A X92-B Operation Manual Prepare the engine before start For an engine without a bypass cooling water system (refer to Figure 8-2), and when the liner wall temperature is between 60°C and 90°C (for example when the engine is pre-heated or after engine full stop for a sufficient period), release the... -

Page 250: Cooling Water System With Circulation