Table of Contents

Advertisement

Quick Links

Operation Manual

"Marine"

Vessel:

Type:

Engine No.:

Document ID: DBAC753771

Winterthur Gas & Diesel Ltd.

Schützenstrasse 1−3

CH-8400 Winterthur

Switzerland

24hrs Support:

Wärtsilä Services Switzerland Ltd.

Zürcherstrasse 12

CH 8400 Winterthur

Switzerland

+41 52 262 80 10

technicalsupport.chts@wartsila.com

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for WinGD W-X82

- Page 1 Operation Manual “Marine” Vessel: Type: Engine No.: Document ID: DBAC753771 Winterthur Gas & Diesel Ltd. 24hrs Support: Schützenstrasse 1−3 Wärtsilä Services Switzerland Ltd. CH-8400 Winterthur Zürcherstrasse 12 Switzerland CH 8400 Winterthur Switzerland +41 52 262 80 10 technicalsupport.chts@wartsila.com...

- Page 2 E 2017-08 Winterthur Gas & Diesel Ltd., Printed in Switzerland – All rights reserved No part of this publication may be reproduced or copied in any form or by any means (electronic, mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written permission of the copyright holder.

- Page 3 Operation Manual “Marine” Vessel: Type: Engine No.: Document ID: DBAC753771 Winterthur Gas & Diesel Ltd. 24hrs Support: Schützenstrasse 1−3 Wärtsilä Services Switzerland Ltd. CH-8400 Winterthur Zürcherstrasse 12 Switzerland CH 8400 Winterthur Switzerland +41 52 262 80 10 technicalsupport.chts@wartsila.com...

- Page 4 E 2017-04 Winterthur Gas & Diesel Ltd., Printed in Switzerland – All rights reserved No part of this publication may be reproduced or copied in any form or by any means (electron- ic, mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written permission of the copyright holder.

-

Page 5: Table Of Contents

New chapter for 9-cylinder engines added 9-cylinder Date of publication 2014-09-16 OM_2015-05 2015-05 Cover page, Disclaimer Data about Winterthur Gas & Diesel (WinGD) and Wärtsilä and all related pages Services Switzerland (WSCH) added; New Layout WinGD; Disclaimer updated (WinGD and WSCH added); 8019-1/A1... - Page 6 13 cSt to 10 cSt; Table 2: Pour point (upper) winter max. value changed from 0 to -6; Carbon residue max. value removed; minor changes in the text; Data about Wärtsilä Service Switzerland Ltd and WinGD added; 0720-1/A1 2015-07 EAAD085468 Operating Media - Fuel Fig.

- Page 7 Modification Service Engine Documentation W-X82 Summary for Operation Manual (OM) Page No. Modification Title Subject Page or Date Manual new exch. 4003-3/A1 2015-01 EAAD085118 Control and Auxiliary Document updated with latest data: Systems -Page 11: PT2041A, PI2041L, 8.11-1 have been removed.

- Page 8 Modification Service Engine Documentation W-X82 Summary for Operation Manual (OM) Page No. Modification Title Subject Page or Date Manual new exch. 6510-1/A1 2017-08 Update Cleaning the Minor text changes (only cleaning of compressor) WinGD Turbocharger during Operation 6606-1/A1 2017-08 Update Operating Instructions Fig.

- Page 9 Operating Descriptions Bedplate and Tie Rod Cylinder Liner and Cylinder Cover Crankshaft, Connecting Rod and Piston Engine Control and Control Elements Supply Unit, Servo Oil Pump and Fuel Pump Scavenge Air System Cylinder Lubrication Piping Systems Engine Monitoring...

- Page 10 Intentionally blank...

-

Page 11: 0020-1/A1

Group0 Operation Operating Descriptions Group 0 For Your Attention ..............0000−1/A1 General Preface... - Page 12 Group0 Operation Operation during Unusual Conditions General Data ............... . 0500−1/A1 Operation with Injection Cut Out (One or More Cylinders) .

- Page 13 The data, instructions, graphics and illustrations etc. in this manual are related to drawings from Winterthur Gas & Diesel Ltd. (WinGD). These data relate to the date of issue of the manual (the year of the issue is shown on the title page). All instructions, graphics and illustrations etc can change because of continuous new development and modifications.

- Page 14 Intentionally blank...

- Page 15 In the code book all parts of the engine are marked with a unique code number. The code number is necessary to order spare parts from Winterthur Gas & Diesel Ltd. (WinGD) or the engine supplier. The spare parts can only be ordered with the code number from the code book.

- Page 16 0010−1/A1 Operation Preface Structure of the Manual The groups with their illustrations are divided into the design groups. Engine type Group No. (Version) Manual type Design variant 0peration 1132−1/A1 W-X62 Title Variant Subtitle − − − − − description Year of issue 2015 Winterthur Gas &...

-

Page 17: Technical Documentation

0010−1/A1 Operation Preface Symbols WARNING This symbol shows that the text is safety related. The signal word WARNING is used to show a hazardous condition. If ignored, these conditions could cause serious injury or death to personnel. CAUTION This symbol shows that the text is safety related. The signal word CAUTION is used to show a potentially hazardous condition. - Page 18 Intentionally blank...

- Page 19 0020−1/A1 Operation Table of Contents Table of Contents Operating Descriptions Group 0 For Your Attention ..............0000−1/A1 General Preface...

- Page 20 0020−1/A1 Operation Table of Contents Operation during Unusual Conditions General Data ............... . 0500−1/A1 Operation with Injection Cut Out (One or More Cylinders) .

- Page 21 0020−1/A1 Operation Table of Contents Crankshaft, Connecting Rod and Piston Group 3 Axial Damper ................3140−1/A1 Connecting Rod and Connecting Rod Bearing .

- Page 22 0020−1/A1 Operation Table of Contents Scavenge Air System Group 6 Scavenge Air Receiver ..............6420−1/A1 Turbocharging .

- Page 23 0030−1/A1 Operation Subject Index Alphabetical Table of Contents Abbreviations ............... 0035−1/A1 Adjustment −...

- Page 24 0030−1/A1 Operation Alphabetical Table of Contents Emergency operation with exhaust valve closed / opened ....... . . 0520−1/A1 Engine, short description of...

- Page 25 0030−1/A1 Operation Alphabetical Table of Contents Leakage and wash-water system ............8345−1/A1 Leakage check of pressure control valve .

- Page 26 0030−1/A1 Operation Alphabetical Table of Contents Pick-up for speed measurement ............4628−1/A1 Piston .

- Page 27 0030−1/A1 Operation Alphabetical Table of Contents Safety measures and warnings (general information) ........0210−1/A1 Scavenge air .

- Page 28 Intentionally blank...

- Page 29 0035−1/A1 Operation Abbreviations See the table below for the the abbreviations used in this manual. Unit of measures are not shown in the list. Abbreviation Word(s) in Full Ahead Alarm ALM−20 Advanced Lubrication Module−20 Alarm and Monitoring System Astern ASTM American Society for Testing and Materials Bottom Dead Center Base Number...

- Page 30 0035−1/A1 Operation Abbreviations Abbreviation Word(s) in Full MARPOL International Convention for the Prevention of Pollution from Ships Main Control Module Modbus Gould-Modicon Fieldbus Maximum Continuous Rating Marine Diesel Oil Main Engine Mean effective pressure Marine Gas Oil Organic Acid Technology Operational Margin Oil Mist Detector Propulsion Control System...

- Page 31 0040−1/A1 Operation General How to Use the Operation Manual Contents The Operation Manual, (Operation), contains data and indications about: The servicing of the engine during operation The necessary media (oil, water, air, fuel) The functions of components and systems. Note: The maintenance and overhaul instructions are found in the Maintenance Manual.

- Page 32 0040−1/A1 Operation How to Use the Operation Manual Cross section 2751−1 2728−1 2124−1 2722−1 3403−1 8017−1 2138−1 6500−1 5562−1 6545−1 8019−1 6420−1 8016−1 1903−1 8018−1 4325−1 7218−1 2303−1 3326−1 6606−1 3603−1 3303−1 8345−1 5556−1 8016−1 5581−1 4104−1 WCH01165 Fig. 1: Cross Section 2014 2/ 3 Winterthur Gas &...

- Page 33 0040−1/A1 Operation How to Use the Operation Manual Longitudinal section 2751−1 2124−1 7218−1 1903−1 2138−1 3403−1 2303−1 3326−1 3140−1 4104−1 3303−1 9223−1 1132−1 1203−1 018.264/09 Fig. 2: Longitudinal Section 2014 3/ 3 Winterthur Gas & Diesel Ltd.

- Page 34 Intentionally blank...

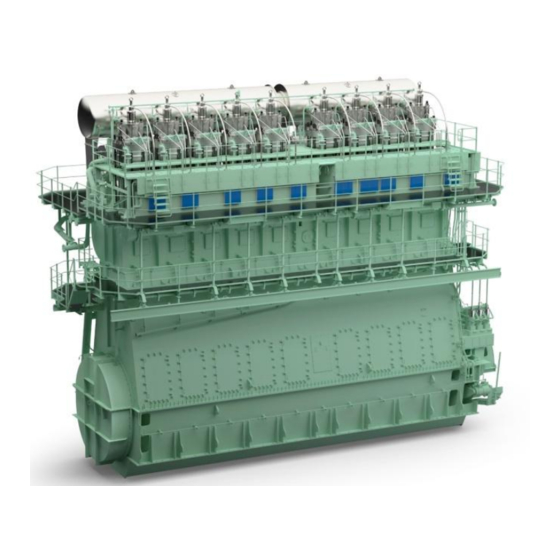

- Page 35 0050−1/A1 Operation General Short Description of the Engine General General data about the engine are given as follows: The W−X engine is a single acting, two-stroke diesel engine of crosshead design with exhaust gas turbocharging and uniflow scavenging. The engine is reversible and is directly connected to the propeller. The W−X concept is based on the Common Rail System, with full electronic control of the fuel injection system and the exhaust valve operation.

- Page 36 0050−1/A1 Operation Short Description of the Engine The exhaust gases flow from the cylinders through the exhaust valves into the exhaust gas manifold. The turbocharger uses the pressure of the exhaust gas to operate the compressor. The scavenge air from the turbocharger flows through the air cooler and water separator into the air receiver.

- Page 37 0060−1/A1 Operation General Two-stroke Diesel Engine − Operation Piston Movement First Stroke (Compression) The sequence of piston movements during the compression stroke is as follows: The piston is at BDC (see Fig. 1). The scavenge ports and exhaust valve are open. Scavenge air flows into the cylinder and pushes the exhaust gas through the exhaust valve into the exhaust gas manifold and then to the turbocharger.

- Page 38 Intentionally blank...

- Page 39 0070−1/A1 Operation General The Relation between Engine and Propeller General ............Fixed Pitch Propeller (FPP) .

- Page 40 0070−1/A1 Operation The Relation between Engine and Propeller Fixed Pitch Propeller (FPP) Continuous Service Rating (CSR) Point A (see Fig. 1) shows the power and speed of a ship that operates at contractual speed in calm seas with a new clean hull and propeller. A power / speed combination at point D is necessary for the same ship at the same speed during service conditions with aged hull and average weather.

- Page 41 0070−1/A1 Operation The Relation between Engine and Propeller Load Range Limits When the engine has the best values at CMCR (Rx), the limits that follow give the load range of the engine: Line 1 is a constant mep or torque line through CMCR from 100% speed and power down to 95% speed and power.

- Page 42 0070−1/A1 Operation The Relation between Engine and Propeller Controllable Pitch Propeller (CPP) Load Ranges After engine start, the engine is operated at an idle speed of up to 70% of the rated engine speed with zero pitch. From idle speed, the propeller pitch must be increased with constant engine speed to the minimum at point E, the intersection with Line 9.

- Page 43 0070−1/A1 Operation The Relation between Engine and Propeller Control System The CPP control functions are usually part of the engine control system and include the functions in the paragraphs that follow. 3.2.1 Combinator Mode 1 Combinator mode for operation without a shaft generator. A combinator curve that includes an applicable light running margin can be set in the permitted operation area, Line 7 (see Fig.

- Page 44 Intentionally blank...

-

Page 45: 0080-1/A1

0080−1/A1 Operation General Basic Engine Data General Turbocharger 1 Turbocharger 2 DRAWN FOR 7 CYLINDERS Cylinder Numbering DRIVING FREE Thrust Bearing Main Bearing Pads Numbering Turbocharger 2 Turbocharger 1 DRAWN FOR 9 CYLINDERS Cylinder Number DRIVING FREE 11 12 WCH02734 Thrust Bearing Main Bearing Pads... - Page 46 0080−1/A1 Operation Engine Numbering and Designations Rail Unit FUEL EXHAUST SIDE SIDE DRAWN FOR 6 CYLINDERS TO 8 CYLINDERS Servo Pump Unit Fuel Pump Unit Clockwise Rotation 017.921/08 Rail Unit FUEL EXHAUST SIDE SIDE DRAWN FOR 9 CYLINDERS Servo Pump Unit Fuel Pump Unit (Exhaust Side) Fuel Pump Unit...

- Page 47 0080−1/A1 Operation Engine Numbering and Designations Flex Parts DRAWN FOR 6 CYLINDERS TO 8 CYLINDERS Servo Oil Pump 2 Servo Oil Pump 1 Fuel Pump A1 Fuel Pump A2 Fuel Pump A3 EXHAUST SIDE Fuel Pump A4 Actuator A1 Actuator A2 Actuator A3 Actuator A4 FUEL SIDE...

- Page 48 0080−1/A1 Operation Engine Numbering and Designations Crank Angle Sensors Sensor 1 Sensor 2 (GT5127C) (GT5126C) FUEL SIDE 013.150/05 FREE END Fig. 4: Flex Parts 2014 4/ 4 Winterthur Gas & Diesel Ltd.

- Page 49 0110−1/A1 Operation Prepare the Engine for Operation Prepare for Engine Start after a Short Shut-down Period (One or More Days) Start Position For the start position, the engine must be in the condition that follows: All components that had an overhaul are correctly assembled and installed. All components that had an overhaul have had tests or checks to make sure that they operate correctly.

- Page 50 0110−1/A1 Operation Prepare for Engine Start after a Short Shut-down Period (One or More Days) 19) Open the indicator valve on all cylinder covers. WARNING Injury Hazard: Before you operate the turning gear, make sure that no personnel are near the flywheel. 20) Use the turning gear to turn the engine a minimum of one full turn to make sure that all the running gears will operate correctly.

- Page 51 0110−1/A1 Operation Prepare for Engine Start after a Short Shut-down Period (One or More Days) WARNING Injury Hazard: Before you operate the engine make sure that no personnel are near the flywheel. 39) In WECS−9520 manual control panel (on the local control panel), push the SLOW TURNING button (4618−1, Local Control Panel, paragraph 2.1).

- Page 52 Intentionally blank...

- Page 53 0120−1/A1 Operation Prepare the Engine for Operation 6-cylinders to 8-cylinders Prepare the Fuel System for Operation Prepare the Fuel System Diesel Operation See 0720−1, Fig. 1. Set the three-way valve (16) in the suction line of the low pressure feed pump (19) to let diesel oil flow from the daily tank (6) to the pump and to the mixing unit (21).

- Page 54 0120−1/A1 Operation Prepare the Fuel Oil System for Operation 6-cylinders to 8-cylinders High Pressure Circuit 8019−1 Fuel System Fig. 1. Make sure that the drain valve 3.65 (21) is closed. At the driving end of the fuel rail 3.05 (13), make sure that the drain screw 3.82 (22) is closed.

- Page 55 0120−1/A2 Operation Prepare the Engine for Operation 9-cylinders Prepare the Fuel System for Operation Prepare the Fuel System Diesel Operation See 0720−1, Fig. 1. Set the three-way valve (16) in the suction line of the low pressure feed pump (19) to let diesel oil flow from the daily tank (6) to the pump and to the mixing unit (21).

- Page 56 0120−1/A2 Operation Prepare the Fuel Oil System for Operation 9-cylinders High Pressure Circuit 8019−1 Fuel System Fig. 1. Make sure that the drain valve 3.65 (30) is closed. At the driving end of the fuel rail 3.05 (15), make sure that the drain screw 3.82 (31) is closed.

- Page 57 0130−1/A1 Operation Prepare the Engine for Operation Prepare the Servo Oil System Servo Oil System − Checks 6-cylinder to 8-cylinder engines For more data, see 8016−1 Fig. 3 and Fig. 4 and 4003−2, Control Diagram. Do the checks that follow: Make sure that the stop valve 4.37 (14), upstream of the automatic filter 4.20 (1) is open.

- Page 58 Intentionally blank...

- Page 59 0140−1/A1 Operation Prepare the Engine for Operation Prepare the Cylinder Lubricating System For more data, see 7218−1 Cylinder Lubrication, Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 8. Make sure that: The WECS−9520 engine and remote control systems are set to on. The servo oil service pump 4.88 operates.

- Page 60 Intentionally blank...

- Page 61 0200−1/A1 Operation Operation during Usual Conditions General Data The data that follow are about engine operation during usual conditions e.g. all cylinders operate correctly: 0210−1 Safety Precautions and Warnings 0220−1 Slow Turning 0230−1 Starting 0240−1 Usual Operation. During maneuvering, it is possible to operate the engine from the control room, the bridge or the local maneuvering stand.

- Page 62 Intentionally blank...

- Page 63 0210−1/A1 Operation Operation Safety Precautions and Warnings (General Data) General ............Warnings .

-

Page 64: Safety Precautions And Warnings (General Data)

0210−1/A1 Operation Safety Precautions and Warnings (General Information) Lighting There must be good permanent lighting. Also, hand lamps must be available at different locations in the engine room. Clean Areas CAUTION Damage Hazard. Do not use water or cleaning fluids to clean the UNIC electronic control boxes on the rail unit. -

Page 65: Tools

0210−1/A1 Operation Safety Precautions and Warnings (General Information) Tools Put hand-tools in locations where you can easily get access to them. Put special tools and devices in positions in the engine room near the area where you use them. All tools must be prevented from unwanted movement and must have protection from corrosion. -

Page 66: Temperature

0210−1/A1 Operation Safety Precautions and Warnings (General Information) Temperature WARNING Danger: If you think that parts of the running gear or bearings have become too hot, it is possible that the engine must be shut down. Before you open the crankcase doors, you must wait for a minimum of 20 minutes. -

Page 67: 13. Turning Gear

0210−1/A1 Operation Safety Precautions and Warnings (General Information) 13. Turning Gear The lubricating oil pump must operate if possible, but the oil pressure cannot fully increase when the exhaust valves are open. WARNING Injury Hazard: After an air run the crankshaft can turn suddenly when the pressurized air in the cylinder releases. - Page 68 Intentionally blank...

-

Page 69: General

0220−1/A1 Operation Operation during Usual Conditions Slow Turning General To make sure that the running gear turns freely, it is recommended (as long as the classification society did not make more primary specifications) to turn the crankshaft a minimum of one full turn before start-up. Note: This does not apply if the engine was stopped during a maneuvering period. - Page 70 Intentionally blank...

- Page 71 0230−1/A1 Operation Operation during Usual Conditions Engine Start General Before you start the engine (also, before trials and using starting air to turn the engine) see: 0110−1 Prepare the Engine for Engine Start 0120−1 Prepare the Fuel Oil System for Operation 0130−1 Prepare the Servo Oil System 0140−1...

- Page 72 0230−1/A1 Operation Engine Start Engine Start Procedure Push the button AUX. BLOWER PRESEL. Push the button FUEL CONTROL MODE. Turn the rotary knob to set the fuel injection quantity to approximately 15%. Push the button START AHEAD or START ASTERN until the engine operates. Slowly turn rotary knob to adjust the fuel injection quantity until the engine operates at the necessary speed.

- Page 73 0240−1/A1 Operation Operation Usual Operation General To get the best performance, operate the engine at constant power. You must only change the engine load and / or speed slowly, unless there are unusual conditions. Checks and Precautions During usual operation, you must do regular checks and use precautions. This lets you operate the engine without problems.

- Page 74 0240−1/A1 Operation Usual Operation Keep the correct scavenge air temperature downstream of the air cooler with the usual water flow (see 0250−1 Operating Data Sheet). A higher scavenge air temperature will give an unsatisfactory quantity of scavenge air in the cylinder. This will cause more fuel to be used and higher exhaust gas temperatures.

- Page 75 0240−1/A1 Operation Usual Operation When you listen to the engine, unusual noises will show that there is a possible defect. Hand-drawn diagrams give data about the combustion process and pressures in the cylinder (see 0420−1 Indicator Diagrams). When the quality of the fuel used changes (diesel oil, HFO from different bunkerings), the maximum pressure in the cylinder at service power must be found as soon as possible.

- Page 76 Intentionally blank...

- Page 77 0250−1/A1 Operation Operating Data Sheet Pressure and Temperature Ranges at Continuous Service Power MCR Medium System Location of Gage Pressure Temperature [bar] [_C] Measurement Min. Max. Min. Max. Diff. Fresh water Cylinder cooling Inlet − max. Outlet each cylinder − −...

- Page 78 Intentionally blank...

- Page 79 0250−2/A1 Operation Operating Data Sheet Alarms and Safeguards at Continuous Service Power Media Unit Location Signal No. Func- Type of Setting Time tion signal value Interval [sec] [bar or _C] Cylinder cooling water Pressure Engine inlet PT1101A 3.0 bar 2.8 bar PS1101S 2.5 bar Temperature...

- Page 80 0250−2/A1 Operation Alarms and Safeguards at Continuous Service Power Media Unit Location Signal No. Func- Type of Setting Time tion signal value Interval [bar or _C] [sec] Turbocharger oil Pressure Inlet PT2611−12A 1.0 bar (ABB, A100-L type) 0.8 bar PS2611−12S 0.6 bar Temperature Housing outlet...

- Page 81 0250−2/A1 Operation Alarms and Safeguards at Continuous Service Power Media Unit Location Signal No. Func- Type of Setting Time tion signal Value Interval [bar or _C] [sec] ( 3) Condensate Level Water separator LS4071−72A max. max. before LS4075−76A max. water separator max.

- Page 82 0250−2/A1 Operation Supply from the starting air pipe upstream the shut-off valve for control and air spring air through the pressure reducing valve 19HA (from starting air bottles 9.01). (10) Signal designation changes downstream of the amplifier (on the engine) from TExxxxA to TTxxxxA.

- Page 83 0260−1/A1 Operation Operation Manoeuvring General Correct maneuvering, with a subsequent increase in engine load up to service power and a decrease in load from service power, is very important. Engine loads in the higher power ranges that are changed too quickly can cause increased wear and contamination, specially on piston rings and cylinder liners.

- Page 84 0260−1/A1 Operation Manoeuvring When HFO is used for maneuvering, the fuel must be heated sufficiently. This keeps the viscosity at the fuel pump inlets in the range given in 0710−1, Fig. 1 Viscosity-Temperature Diagram. The heating of the fuel oil system must stay set to on. Keep the temperature of the cooling media as close as possible to the higher limits given for usual service (see 0250−1 Operating Data Sheet).

- Page 85 0260−1/A1 Operation Manoeuvring Reversing Turn the rotary button to 15% fuel injection quantity (see display). Push the button START AHEAD or START ASTERN until the engine runs in the applicable direction. Note: On ships under way, this procedure can be some minutes, because the flow of water has an effect on the propeller.

- Page 86 Intentionally blank...

- Page 87 Specially make sure that during the procedures HFO never can flow into the MDO tank and pipe system. Note: WinGD recommends to do a manual change−over only, if an automatic change−over system is not installed or if the automatic change−over system is unserviceable.

- Page 88 BN. For more data refer to 0750−1, Lubricating oils. WinGD recommends to monitor the change−over of the cylinder lubricating oil. Do a calculation of the cylinder lubricant quantity and make sure that you know cylinder lubricating feed rate.

- Page 89 0270−1/A1 Operation Change-over from Heavy Fuel Oil to Marine Diesel Oil and Back Change-over from HFO to MDO 0720−1 Fuel Treatment and Fuel System, Fig. 1. To change−over from HFO to MDO, do as follows: Make a full time schedule for the change−over to obey the ECA rules. If you operate the engine with MDO for a long period, you must change the cylinder lubricating oil to the applicable BN at the related time, refer to paragraph Set to OFF the trace heating of the fuel pipes and fuel rail approximately one...

- Page 90 0270−1/A1 Operation Change-over from Heavy Fuel Oil to Marine Diesel Oil and Back Change-over from MDO to HFO 0720−1 Fuel Treatment and Fuel System, Fig. 1. To change−over from MDO to HFO, do as follows: Make a full time schedule for the change−over to obey the ECA rules. Make sure that you have changed the cylinder lubricating oil to the applicable BN, refer to paragraph 5.

- Page 91 0280−1/A1 Operation Operation Operation at Low Load General See the data that follow: 0240−1 Usual Operation, paragraph 2 Checks and Precautions Trace heating of the fuel system during operation Temperature of the cooling medium in the usual range (see 0250−1 Operating Data Sheet) Careful treatment of the fuel (see 0720−1, Fuel Treatment and Fuel System)

- Page 92 Intentionally blank...

- Page 93 0290−1/A1 Operation Operation Operation at Overload General Usually, the engine is only operated at overload (110% of CMCR power) during sea trials when there is an authorized representative of the engine builder on board the ship. The limit for operation of the engine at overload is a maximum of one hour each day (see also 0070−1 The Relation between Engine and Propeller).

- Page 94 Intentionally blank...

- Page 95 0310−1/A1 Operation Engine Shutdown General Engine Load Decrease When possible, it is recommended that the engine load is decreased slowly, see 0260−1 Maneuvering. Engine Stop Usual Procedures 2.1.1 Engine Stop from the Control Room − Remote Control Because different types of remote control can be connected to the engine controls, the operation procedure from the manoeuvring stand in the control room is not given.

- Page 96 Intentionally blank...

- Page 97 0320−1/A1 Operation Engine Shutdown Procedures after Engine Stop Procedures for Short Service Breaks (some days to some weeks) Engine is Maneuverable If the engine must still be maneuvered after it has stopped, see the conditions that follow: The WECS−9520 must stay set to on. All the pumps for coolant water, lubricating oil and fuel must operate.

- Page 98 0320−1/A1 Operation Procedures after Engine Stop Do the steps that follow: Open the indicator valves in the cylinder covers. Engage the turning gear. Set the WECS−9520 to on. At frequent intervals and with the indicator valves open, use the turning gear to turn the engine as necessary (possibly done daily in damp climates).

- Page 99 0320−1/A1 Operation Procedures after Engine Stop WCH01073 Fig. 1: Starting Air System 1 Shut-off valve for starting air 5 Venting valve 2.27 2 Handwheel for shut-off valve 6 Starting air manifold 3 Drain and test valve 2.06 7 Starting air valve 4 Venting valve 2.21 8 5/2-way solenoid valve Procedures for Service Breaks for a Longer Period...

- Page 100 Intentionally blank...

- Page 101 The procedure includes a temporary higher feed rate, refer to Fig. 1. WinGD recommends an inspection of the cylinder liners and of the piston rings after 24 operation hours and after 72 operation hours (1, Fig. 1). For this running−in procedure there is no limit for the engine load.

-

Page 102: Running-In New Cylinder Liners And Piston Rings

0410−1/A1 Operation Running-in of New Cylinder Liners and Piston Rings Before Engine Start Prepare the engine for start, see 0110−1. Do a check of the condition of the piston rings. Do a check of the condition of the cylinder liners from the piston underside and for signs of condensation or leakage (if the engine has not started for some time). -

Page 103: Fuel

0410−1/A1 Operation Running-in of New Cylinder Liners and Piston Rings 15) For the running-in of one cylinder, you can temporarily decrease its load. See step a) and step b): In the remote control, get in the MAINTENANCE SETTINGS in the ADJUST page (see 4002−3, User parameters and Maintenance Settings, paragraph 1.2). - Page 104 Intentionally blank...

- Page 105 0420−1/A1 Operation Operation − Special Procedures Indicator Diagrams General Indicator diagrams must only be drawn with a serviceable indicator at constant power and speed, and ships sailing in calm sea and deep water. To give you data about the indication diagrams, record the related cylinder number, engine speed, the positions of the load indicator and VIT.

- Page 106 0420−1/A1 Operation Indicator Diagrams Maximum Firing pressure Example A Too High at Correct Compression Pressure Possible causes: Ignition (start of injection) too advanced for the fuel type in use. You must adjust the FQS as follows: 004.758/00 In the remote control, get the user Example B parameters page (see 4002−3...

- Page 107 0420−1/A1 Operation Indicator Diagrams Example A Compression Pressure and Maximum Firing Pressure Too High Possible causes: Engine has too much load. VEC timing is incorrect. 004.752/00 Example B 004.751/00 2014 3/ 3 Winterthur Gas & Diesel Ltd.

- Page 108 Intentionally blank...

-

Page 109: General

0450−1/A1 Operation Operation − Special Procedures Procedures to Prevent Contamination and Fire in the Scavenge Air Spaces General The primary cause of contamination is when combustion materials are blown between the piston and cylinder into the scavenge air spaces (blow-by). The contamination will be more if the fuel is not fully burned, causes exhaust smoke. - Page 110 0450−1/A1 Operation Procedures to Prevent Contamination and Fire in the Scavenge Air Spaces Indications of a Fire The indications of a fire as follows: You can hear the related temperature alarms. A large increase in the exhaust gas temperature of the related cylinder and an increase in piston underside temperature.

- Page 111 0450−1/A1 Operation Procedures to Prevent Contamination and Fire in the Scavenge Air Spaces After a careful check, or if necessary a repair, do the procedure given in steps a) to c): Start the engine. Start the injection and slowly increase the load. Set the lubricating oil feed rate to the applicable value.

- Page 112 Intentionally blank...

- Page 113 0460−1/A1 Operation Special Procedures − Operation Prevention of Crankcase Explosions − Instructions General Examples of crankcase explosions in diesel engines have shown that they can only occur in special conditions,and thus do not occur frequently. The cause of crankcase explosions is oil mist. Oil mist comes from components that have become unusually hot.

- Page 114 Intentionally blank...

- Page 115 0500−1/A1 Operation Operation during Unusual Conditions General Data General The data below give the procedures for engine operation when: The parts cannot be immediately repaired The engine must continue to operate, or When engine operation must continue as soon as possible. Decreased Power Output In an emergency, when the engine must operate (with one or more cylinders out of operation, turbochargers out of operation or decreased coolant flow etc) the power...

- Page 116 Intentionally blank...

- Page 117 0510−1/A1 Operation Operation during Unusual Conditions Operation with Injection Cut Out (One or More Cylinders) Cut Out the Injection If the injection of one or more cylinders must be cut out, do the procedure give in steps 1) to 4): In the remote control, select Inj.

- Page 118 0510−1/A1 Operation Operation with Injection Cut Out (One or More Cylinders) DRIVING END WCH01182 WCH01184 Fig. 1: Rail unit and injection control unit 1 Fuel rail 3.05 6 Drain screw 3.82 2 Servo oil rail 4.11 7 Rail valve 3.76 3 Injection control unit 3.02 8 Electrical connection 4 Fuel pressure control valve 3.06...

- Page 119 0515−1/A1 Operation Operation during Unusual Conditions Faults in High Pressure Fuel System Defective Fuel Pump ..........Fault Identification .

-

Page 120: Faults In High Pressure Fuel System

0515−1/A1 Operation Faults in High Pressure Fuel System Defective Fuel Pump Actuator Fault Identification If an actuator becomes defective, its output stays the same or changes slowly to zero supply. The toothed rack does not change when the load changes. At higher fuel consumption, the serviceable actuator has control of the fuel quantity regulation. -

Page 121: Procedure

0515−1/A1 Operation Faults in High Pressure Fuel System Procedure Minimum Position Maximum Position Max. Max. Min. Min. WCH01185 010.513/02 WCH01185 Fig. 1: Minimum / Maximum Position of the Regulating Linkage 1 Fuel pump 3.14 3 Spacer (tool 94555) 2 Toothed rack 4 Actuator 3.21 2.3.1 One Actuator is Defective... -

Page 122: Defective Injection Control Unit

0515−1/A1 Operation Faults in High Pressure Fuel System Defective Injection Control Unit Fault Identification Alarm indication in WECS−9520 (remote control). The fuel injection is cut off automatically (Inj. CUT OFF) on the related cylinder, and a SLOW DOWN signal will be released. The injection control unit has a leak. -

Page 123: Procedures

0515−1/A1 Operation Faults in High Pressure Fuel System Procedures 3.3.1 Fuel Quantity Sensor It is not necessary to stop the engine. Engine operation is also possible with a defective fuel quantity sensor. Replace the defective fuel quantity sensor as follows: Disconnect the electrical connection from the fuel quantity sensor (2, Fig. - Page 124 0515−1/A1 Operation Faults in High Pressure Fuel System 3.3.3 Rail Valve Replace the defective rail valve as soon as possible. Do the procedure that follows: Note: It is possible to replace a defective rail valve during operation. In the remote control, use the parameter Inj. Cut off to cut out the related cylinder (see 4002−3, paragraphs 1 and 1.1).

-

Page 125: Defective Fuel Pressure Control Valve

0515−1/A1 Operation Faults in High Pressure Fuel System 3.3.4 Injection Control Unit The fuel injection must be cut out immediately if: The injection control unit has cracks The injection control valve or fuel quantity piston cannot move. Note: When the injection is cut out (Inj. CUT OFF) you can can only operate the engine at decreased load. -

Page 126: Procedure

0515−1/A1 Operation Faults in High Pressure Fuel System Procedure WARNING Injury Hazard: Replace the PCV only when the engine has stopped. The oil supply pipe from the bearing oil system and the fuel rail must have zero pressure. Stop the engine. Turn the knurled screw (4, Fig. - Page 127 0520−1/A1 Operation Operation during Unusual Conditions Operation with Exhaust Valve Control Unit Cut Out General ............Emergency Operation with Exhaust Valve Closed .

- Page 128 0520−1/A1 Operation Operation with Exhaust Valve Control Unit Cut Out Replace the defective VCU or the hydraulic pipe (see the Maintenance Manual 5612−1 and 8460−1). Torque the drain screw (2) to 200 Nm. Set to on the bearing oil pump. Cut in the injection (see 0510−1, paragraph 2).

- Page 129 0520−1/A1 Operation Operation with Exhaust Valve Control Unit Cut Out Emergency Operation with Exhaust Valve Open This mode of operation is only necessary if there is water leakage into the combustion chamber (see also 0545−1). Exhaust Valve − Stop Operation Stop the engine.

- Page 130 0520−1/A1 Operation Operation with Exhaust Valve Control Unit Cut Out WCH00700 WCH00699 Fig. 3: Exhaust Valve / Pressure Element 1 Damper 4 Pressure element (tool 94259a) 2 Upper housing 5 Control signal plug 3 Shim VS Maximum exhaust valve stroke 2014 4/ 4 Winterthur Gas &...

- Page 131 0525−1/A1 Operation Operation during Unusual Conditions Faults in Servo Oil System Defective Automatic filter ......... . Identification .

- Page 132 0525−1/A1 Operation Faults in Servo Oil System Defective Servo Oil Pump Identification The flow sensors FS2061A − FS2063A indicate that a pump is defective, i.e. an alarm is activated in the alarm and monitoring system (Servo oil pump n. flow). Causes The servo oil pump has damage.

- Page 133 0525−1/A1 Operation Faults in Servo Oil System Procedures 3.3.1 Rail Valve − Replace Replace the defective rail valve as soon as possible. Stop the engine. Make sure that the servo oil service pump is set to off. Set to off the main bearing oil supply. Carefully loosen the drain screw (7, Fig.

- Page 134 0525−1/A1 Operation Faults in Servo Oil System 3.3.2 Defective Exhaust Valve Control Unit The exhaust valve control unit must be shut off as an immediate procedure if the piston or slide rod in the exhaust valve control unit is seized. 0520−1 Emergency operation with exhaust valve closed, paragraph 2.

- Page 135 0540−1/A1 Operation Operation during Unusual Conditions Operation with Running Gear Partially or Fully Removed General If the engine must operate after a defect in the running gear (of a cylinder), which cannot be immediately repaired, do the related procedures that follow in paragraph 2 or paragraph 3.

- Page 136 0540−1/A1 Operation Operation with Injection Cut Out (One or More Cylinders) Piston, Crosshead and Connecting Rod Removed Breakdown Examples The crosshead or guide shoes are defective. The connecting rod bearing is damaged. The crosshead pin or on the connecting rod are defective. Procedure The exhaust valve stays closed during the emergency operation that follows: Cut out the injection (see...

- Page 137 0540−1/A1 Operation Operation with Injection Cut Out (One or More Cylinders) 016.924/08 016.924/08 016.924/08 Fig. 1: Piston Removed 1 Exhaust valve 7 Blank flange (tool 94831) 2 Crosshead 8 Cover plate (tool 94345D) 3 Toggle lever 9 Cover and lifting plate (tool 94324) 4 Starting air pipe 10 Base (tool 94324B) 5 Elbow...

- Page 138 Intentionally blank...

- Page 139 0545−1/A1 Operation Operation during Unusual Conditions Operation with Water Leakage into the Combustion Chamber General If there is water leakage into the combustion chamber (e.g. a crack in the cylinder cover or cylinder liner) the defective part must be replaced immediately. Procedures If it is not possible to replace the defective parts but the engine must continue to operate, do the procedures on the related cylinder as given in steps 1) to 4):...

- Page 140 Intentionally blank...

- Page 141 0550−1/A1 Operation Operation during Unusual Conditions Defective Scavenge Air Cooler / Defective Auxiliary Blowers Defective Scavenge Air Cooler When a scavenge air cooler (SAC) is defective, water can go into the scavenge air receiver. The water then goes out through the condensate collector of the SAC drain. The related level switch activates an alarm.

- Page 142 Intentionally blank...

- Page 143 0560−1/A1 Operation Operation during Unusual Conditions Defective Remote Control General If a fault occurs in the remote control, which prevents engine control from the control room, you can operate the engine from the local control panel. The data are given in the groups that follow: 0230−1 Engine Start 0260−1...

- Page 144 Intentionally blank...

- Page 145 0570−1/A1 Operation Operation during Unusual Conditions Defective Speed Control System General Defects in the speed control system must be repaired as soon as possible (see the documentation of the manufacturer). If this is not possible, you can control the engine from the local control panel.

- Page 146 Intentionally blank...

-

Page 147: 0590-1/A1

0590−1/A1 Operation Operation during Unusual Conditions Defective Turbocharger General If a turbocharger becomes defective, you must shut down the engine as quickly as possible to prevent damage. If repair or replacement of a turbocharger is not immediately possible, the engine can operate in Emergency Operation at decreased load after the procedures below is completed. - Page 148 0590−1/A1 Operation Defective Turbocharger Condition Two Defective turbocharger on engines without an exhaust bypass pipe. The engine load output is approximately 10% to 15% of the CMCR. This is related to the output of the auxiliary blowers. 2.2.1 Procedure Lock the rotor of the defective turbocharger (see the turbocharger manual).

- Page 149 0610−1/A1 Operation Special Procedures Before and After Operation Prepare for Engine Start after a Long Shutdown Period or an Overhaul General For an engine that that was shut down after a long period or an overhaul, do the special procedures in paragraph 2. Note: If the engine was shut down only for some days, you must do the procedures given in 0110−1...

- Page 150 Intentionally blank...

- Page 151 0620−1/A1 Operation Special Procedures Before and After Operation Prepare the Engine for a Long Shutdown Period General ............Condition One .

- Page 152 0620−1/A1 Operation Prepare the Engine for a Long Shutdown Period Close the stop valves on the fuel tanks. Open the drain valves of the exhaust gas manifold and the exhaust gas pipe to drain the condensate. 10) Close the drain valves of the exhaust gas manifold and the exhaust gas pipe. 11) Put a cover (e.g.

- Page 153 0620−1/A1 Operation Prepare the Engine for a Long Shutdown Period Procedure Intervals WARNING Injury Hazard: Before you operate the turning gear, make sure that no personnel are near the flywheel. Do steps 1) to 12) below each week: Make sure that the indicator valves are open. Use the turning gear to turn the engine until the piston is at 60_ before or after TDC (look on the flywheel).

- Page 154 Intentionally blank...

- Page 155 Gas oils and diesel oils (distillates) can be used in all WinGD engines with some limits. WinGD 2-stroke diesel engines are designed to operate on up to 700 mm (cSt) at 50_viscosity heavy fuel oil (ISO 8217:2010 RMK 700 grade) if sufficient fuel heating and treatment is done.

-

Page 156: 0710-1/A1

0710−1/A1 Operation Diesel Engine Fuels Heavy fuel oil must be treated in an applicable fuel treatment plant. When bunkering, it is possible that the fuel suppliers will report only some of the values given in the Quality Specifications. Frequently, only the density and maximum viscosity is given. - Page 157 0710−1/A1 Operation Diesel Engine Fuels In ISO 8217, foreign substances such as used oil or chemical waste must not be added to the fuel. This is because of the hazards to the crew, machines and the environment. Tests that are done for unwanted substances as acids, solvents and monomers with titrimetric, infrared and chromatographic methods, are recommended.

- Page 158 Note: For data about the parameters given in the table above, see paragraph to paragraph 3.12. CAUTION Damage Hazard: For WinGD 2-stroke engines, the maximum permitted fuel temperature at the engine inlet is 150_C. Always make sure to obey this limit. Damage to the engine can occur. For more data, see also 0250−1...

-

Page 159: Data About Heavy Fuel Oil Specifications

0710−1/A1 Operation Diesel Engine Fuels Data about Heavy Fuel Oil Specifications Viscosity The recommended viscosity range upstream of the engine is between 13 mm /s (cSt) and 17 mm /s (cSt). You get the necessary temperature for a given nominal viscosity from the data in Fig. -

Page 160: Density

Sulphur Sulphur limits are not specified in ISO 8217:2010 because statutory specifications put a limit on this value. The maximum sulphur level that can be used in WinGD 2-stroke engines is 4.5% m/m. The alkalinity (base number (BN)) of the cylinder lubricating oil must be selected in relation to the sulphur level of the fuel in use. -

Page 161: Acid Number

0710−1/A1 Operation Diesel Engine Fuels Acid Number Fuels with high acid numbers have caused damage to fuel injection systems. Most fuels have a low acid number, which is not dangerous, but an acid number above 2.5 mg KOH/g, can cause problems. Some naphthenic fuels can have an acid number of more than 2.5 mg KOH/g, but still be permitted. -

Page 162: 3.12 Used Lubricating Oil And Chemical Waste

0710−1/A1 Operation Diesel Engine Fuels 3.11.2 Aluminum and Silicon Aluminum (Al) and silicon (Si) in the fuel are an indication of catalytic fines (cat fines). These are particles of hard oxides (round particles of material almost the same as porcelain) which cause high abrasive wear to pistons, piston rings and cylinder liners. Cat fines are used as a catalyst in some processes in petroleum refining and can be found in diesel engine fuels. - Page 163 0710−1/A1 Operation Diesel Engine Fuels Distillate Fuel Specifications Note: For data about the parameters given in Table 2, see paragraphs 5.1 to 5.12. Table 2: Fuel Specifications Parameter Unit Bunker Limit Test Method Necessary Fuel Quality at the Engine Inlet /s [cSt] Maximum 11.0 ISO 3104...

-

Page 164: Data About Distillate Fuel Specifications

They are easier to operate than residual fuel, but caution is necessary for some problems. See Service Bulletin RT−82: Distillate Fuel Use. ISO 8217: 2010 specifies DMX, DMA, DMZ and DMB categories. The WinGD engine inlet specification is based on the DMB grade which is the highest viscosity grade. -

Page 165: Hydrogen Sulphide

0710−1/A1 Operation Diesel Engine Fuels Hydrogen Sulphide WARNING Danger: Hydrogen Sulphide (H S) is a very toxic gas and exposure to high concentrations is dangerous and can kill you. Be careful when tanks or fuel lines are opened because there can be H S vapor. -

Page 166: Bio-Derived Products And Fatty Acid Methyl Esters

ISO 8217 standard or for fuels that WinGD has recommended. If you think, that it is necessary to use additives, WinGD recommends to speak to the fuel supplier and to the additive supplier. They can give you the related results of the use of additives. -

Page 167: General

0720−1/A1 Operation Operating Media Fuel Treatment and Fuel System General ............Treatment of HFO and Treatment Plant . - Page 168 0720−1/A1 Operation Fuel Treatment and Fuel System HFO and Diesel Fuel Separation It is recommended that modern centrifuges are used for the treatment of heavy fuels. The separation effect, i.e. the cleaning effect, is related to the flow rate and viscosity of the HFO.

- Page 169 0720−1/A1 Operation Fuel Treatment and Fuel System Configuration of the Fuel System In the recommended standard plant, pressure is kept in the full fuel system to prevent the evaporation of water in the fuel at the temperature necessary for the heavy fuel oil (HFO).

- Page 170 0720−1/A1 Operation Fuel Treatment and Fuel System Key to Fig. 1 1 HFO settling tank 18 Suction filter 2 HFO/LSHFO settling tank 19 Low pressure supply pump 3 HFO daily tank 20 Air overflow pipe 4 LSHFO daily tank 21 Mixing unit, heatable and insulated 5 MDO settling tank 22 Booster pump 6 MDO daily tank...

- Page 171 W-X82 0720−1/A1 Operation Fuel Treatment and Fuel System WCH03254 Fig. 1: Schematic Diagram − Fuel System 2015-07 5 / 5 Winterthur Gas & Diesel Ltd.

- Page 172 Intentionally blank...

-

Page 173: Scavenge Air

0740−1/A1 Operation Operating Media Scavenge Air and Starting Air Scavenge Air The turbocharger compresses the air from the engine room or from outside for the scavenge air and air for the cylinders, (see 6500−1 Turbocharging). The air must be as clean as possible to keep the wear of cylinder liner, piston rings, turbocharger compressor etc. - Page 174 Intentionally blank...

- Page 175 The oil must also have good thermal stability, anti-corrosion and anti-foam properties, and good demulsifying performance. Note: Validated system oils for WinGD 2-stroke engines are shown in paragraph 8.2. For different or new lubricating oils, speak to or send a message to WinGD.

-

Page 176: Lubricating Oils

0750−1/A1 Operation Lubricating Oils Oil Care 2.1.1 System Oil To keep the lubricating oil in good condition for long periods, good oil treatment is necessary. To do this, a self-cleaning centrifugal separator is used. A self-cleaning centrifugal separator is used as a purifier in bypass. The oil flows from the oil tank through the centrifugal separator. - Page 177 0750−1/A1 Operation Lubricating Oils Table 1: Alert Limits of System Oil Parameters Parameter Limit Test Method Viscosity at 40_C Maximum 140 mm /s [cSt] ASTM D 445 Flash point (PMCC) Minimum 200_C ASTM D 92 Total insolubles Maximum 0.70% m/m ASTM D 893b Base Number (BN) Maximum 12 mg KOH/g...

-

Page 178: Particle Size And Count

If there is an important decrease in the flash point below the recommended value shown above, WinGD recommends a replenishment of the oil charge. By a replenishment, an increase in the system oil BN is prevented. A small increase in BN is often an indication that the system oil consumption is low. - Page 179 0750−1/A1 Operation Lubricating Oils Table 3: ISO 4406 Particle Count and Size Classes Number of particles per 100 ml More Than Up To and Includes Class 250 000 000 − Less than 28 130 000 000 250 000 000 64 000 000 130 000 000 32 000 000 64 000 000...

- Page 180 0750−1/A1 Operation Lubricating Oils The (older) NAS 1638 and SAE AS 4059 cleanliness classes for oils are given in Table 4. Table 4: NAS 1638 and SAE AS 4059 Cleanliness Classes Contamination (particles/100 ml) Particle size (mm or microns) Class 5 to 15 15 to 25 25 to 50...

- Page 181 2.3.2 Recommended Limits for NAS and SAE AS Particle Count For particles larger than 21 mm, WinGD recommends the NAS and SAE AS specification for a 100 ml oil sample in the system oil as in Table 5. Table 5: Limits for NAS 1638 and SAE AS 4059 Cleanliness Classes...

-

Page 182: Oil Samples

0750−1/A1 Operation Lubricating Oils Oil Samples At regular intervals, (i.e. at approximately each 300 operation hours), it is recommended that you get a sample of the system oil. Send the the sample of the system oil to a laboratory to make an analysis. The analysis must include ISO 4406 particle counts for samples taken from downstream of the coarse filter or fine filter. -

Page 183: Cylinder Lubricating Oil

0750−1/A1 Operation Lubricating Oils Cylinder Lubricating Oil A high-alkaline cylinder lubricating oil of the SAE 50 viscosity grade that has a minimum kinematic viscosity of 18.5 cSt at 100_C is recommended. But, cylinder lubricating oils of the viscosity grades SAE 40 and SAE 60 can be used in some conditions. - Page 184 0750−1/A1 Operation Lubricating Oils Range 1 (see Fig. 1): When the fuel sulphur content is more than 0.1% m/m and less than 0.5% m/m during operation with BN 15 to BN 25 cylinder lubricating oil, you must do an analysis of the piston underside drain oil from the on-board monitoring system.

- Page 185 Note: Use only the cylinder lubricating oils given in paragraph 8.2. The oil company assumes all responsibility for the performance of the cylinder lubricating oils in service of all WinGD 2-stroke engines to the exclusion of any liability of any WinGD company belonging to the WinGD group.

-

Page 186: Oil Samples − Piston Underside Drain Or Scrape-Down

Operation Lubricating Oils Oil Samples − Piston Underside Drain or Scrape-down WinGD recommends to get piston underside drain oil (scrape-down oil) samples at regular intervals from each cylinder and to make an analysis to monitor the engine condition. These analyses are used to make an estimate of the cylinder liner and piston ring wear and to set the applicable alkalinity and feed rate of the cylinder lubricating oil. - Page 187 0750−1/A1 Operation Lubricating Oils It is necessary to find the safe value for continuous operation on fuel oil with a low sulphur content (of between 0.0% m/m and 0.5% m/m) and a low BN cylinder lubricating oil (between BN 15 and BN 25) for each engine. To find this safe value, you monitor the piston underside samples and do regular checks of the pistons, piston rings and cylinder liners for excessive deposits, corrosion and wear.

-

Page 188: General Recommendations

60% CMCR) and the sulphur content of the used HFO is more than 2.5% m/m, WinGD strongly recommends the use of a BN 100 cylinder lubricating oil, as the cylinder oil feed rate cannot be adjusted to adequately compensate for the lower alkalinity. -

Page 189: Turbocharger Oil

0750−1/A1 Operation Lubricating Oils Turbocharger Oil To select the turbocharger lubricating oil and keep this oil in a satisfactory condition, refer to the recommendations given in the turbocharger instruction manual. The turbocharger lubricating oil is usually system oil or turbine oil. Turning Gear Oil To select the turning gear oil and keep this oil in a satisfactory condition, refer to the recommendations given in the instruction manual of the turning gear manufacturer. -

Page 190: Validated Lubricating Oils

Lubricating Oils Validated Lubricating Oils Lubricating Oil Instruction and Liability The application and handling of lubricating oils must be in compliance with the WinGD general lubricating oil specifications and recommendations given in the Operation Manual (this manual) and the Maintenance Manual. - Page 191 0750−1/A1 Operation Lubricating Oils Pertamina − − − Medripal 570 − − Petrobras − Marbrax Marbrax Marbrax − − CID−54−APN CID−55 CID−57 (BN 50) PetroChina − − − KunLun DCA − − 5070H Premier Six − Opt−Max BoB 300 additives for on−board blended cylinder oils (BN 40 to BN 120) Opt−Max −...

-

Page 192: System Oils

0750−1/A1 Operation Lubricating Oils System Oils Table 7: List of Validated System Oils (Last Update: May 2017) Oil Supplier Brand Base Number (BN) Aegean Alfasys 305 Castrol CDX 30 Chevron Veritas 800 Marine 30 Marilube Oil AC−30 Cladium 50 ExxonMobil Mobilgard 300 C FL Selenia MESYS 3006... -

Page 193: General

0760−1/A1 Operation Operating Media Cooling Water / Cooling Water Treatment General An applicable treatment is used to give the cooling water the correct properties, which will prevent service problems. Cooling water that has not had treatment can soon cause problems in the cooling system from corrosion, sediment and hard particles (crust). - Page 194 0760−1/A1 Operation Cooling Water / Cooling Water Treatment Cleaning the Cooling Water System For new cooling water, the full system must be clean. The system must not contain grease, oil or unwanted particles. During operation oil or sediment can go into the system, which can cause a decrease in the heat transfer and cooling effect.

- Page 195 0800−1/A1 Operation Problems during Operation General General If the operation and maintenance instructions are obeyed, problems during operation can be prevented. If a fault occurs, do not search randomly for the cause. Use a sequence to find possible causes. This applies specially to problems during engine start and engine stop.

- Page 196 0800−1/A1 Operation General Problems and Damage to Engine Parts Hot running of a piston Hot running of the running gear. For more data, see 0840−1 Failures and Defects of WECS Components WECS passive fault WECS common fault WECS cylinder fault WECS pressure fault WECS critical fault (WECS engine fault) Cylinder lubrication has a malfunction.

- Page 197 0810−1/A1 Operation Operation Problems Problems during Engine Start and Stop Problems during Engine Start For the names and part code numbers, see 4003−2 Control Diagram. Problem Possible Cause Procedure The engine does not turn The shut-off valves on the starting air bottles Open the shut-off valves.

- Page 198 0810−1/A1 Operation Problems during Engine Start and Stop Problem Possible Cause Procedure Engine will not start from the The starting air shut-off valve does not open, Do an overhaul of the starting control stand at the engine (cannot move), the non-return valve cannot air shut-off valve.

- Page 199 0810−1/A1 Operation Problems during Engine Start and Stop Problem Possible Cause Procedure The engine turns on starting The fuel booster pressure is not sufficient. Adjust the fuel booster air but gets no fuel Pressure retaining valve is set too low. Booster pressure.

- Page 200 0810−1/A1 Operation Problems during Engine Start and Stop Problem Possible Cause Procedure A cylinder does not fire or does No power supply to FCM−20. Electrical Set to on the power supply. not fire correctly when starting connection disconnected, or incorrectly Connect the electrical (continued).

- Page 201 0820−1/A1 Operation Operating Problems Irregular Operation Load Indications ..........Cylinder Lubrication .

- Page 202 0820−1/A1 Operation Irregular Operation Problem Possible Causes Procedure The exhaust temperature of a The air flaps in the scavenge air receiver are Clean, overhaul or replace cylinder increases dirty or defective. the air flaps. The injection nozzles are worn. Replace with the spare kit. The scavenge ports in the cylinder liner are Clean the scavenge ports.

- Page 203 0820−1/A1 Operation Irregular Operation Problem Possible Causes Procedure There is smoke from the Air supply is not sufficient. Unwanted material Scavenge air pressure exhaust in the exhaust side or air side of the decreases. turbocharger, scavenge air cooler, air flaps in the receiver, scavenge ports in cylinder liners or in the exhaust boiler.

- Page 204 0820−1/A1 Operation Irregular Operation Problem Possible Causes Procedure Irregular operation of the Air collects in the cooling spaces or in the Release the pressure. cylinder cooling water system pipes because pressure release is not sufficient. Pressure increases and There is a decrease of static pressure at the See the plant instructions.

- Page 205 0820−1/A1 Operation Irregular Operation Problem Possible Causes Procedure Cylinder lubrication is The daily tank is empty. The ball valve Fill the daily tank. Open the defective. No lubricating oil downstream of the lubricating oil filter 8.17 is ball valve. Replace or clean closed or the filter element is clogged.

- Page 206 0820−1/A1 Operation Irregular Operation Turbocharger Short, loud noise and at the same time the pressure changes on the air side. Surges do not have a direct effect on the engine when this occurs at irregular intervals, but the air flow rate is decreased. Problem Possible Causes Procedure...

- Page 207 0820−1/A1 Operation Irregular Operation Exhaust Waste Gate The exhaust waste gate is defective, low-load tuning causes too much thermal load on the engine, or a scavenge air pressure that is too high. Problem Possible Causes Procedure The engine has too much The butterfly valve stays in the OPEN Adjust the screw for manual thermal load...

- Page 208 Intentionally blank...

- Page 209 0840−1/A1 Operation Operation Problems Irregular Operation Piston − Hot Operation The possible indications of a piston that operates at a temperature that is too hot, but where combustion is correct are as follows: A temperature increase at the piston cooling oil outlet A temperature increase at the jacket cooling water outlet A temperature increase of the piston underside.

- Page 210 Intentionally blank...

- Page 211 0850−1/A1 Operation Operation Problems Failures and Defects of WECS Components General ............Failure ID and LED Indications on FCM-20 .

-

Page 212: Failures And Defects Of Wecs Components

0850−1/A1 Operation Failures and Defects of WECS Components Failure ID and LED Indications on FCM-20 Ó Ó Ó Ó Ó Ó Ó Ó Ó Inject Ó Ó Ó Ó Ó Ó Ó Ó Ó Exhaust Ó Ó Ó Start Vlv Ó... -

Page 213: Led Indication On Alm-20

0850−1/A1 Operation Failures and Defects of WECS Components LED Indication on ALM-20 PART NO : SER. NO : HW REV. : PROD. DATE : 014.537/06 014.538/06 Fig. 2: LED Indications on ALM-20 1 Connector (COMBICON) 3 Screw 2 Control box 41.nn 4 LEDs 2014 3/ 39... -

Page 214: Failure Indications

0850−1/A1 Operation Failures and Defects of WECS Components Failure Indications Failure Groups All WECS failure indications are part of the failure groups that follow and are always shown together with the related group. Failure Groups Failure Effects Procedures WECS passive failures Failures of redundant systems (failure of Find the cause and repair as a redundant component, system or an... -

Page 215: Led On / Off Codes

0850−1/A1 Operation Failures and Defects of WECS Components LED On / Off Codes 4.3.1 Red Fail LED and Two-digit LED Display The red Fail LED shows a failure on the related FCM-20 and if the failure status is active or inactive (see Fig. 1). Type of Failure Failure Effects Procedures... - Page 216 0850−1/A1 Operation Failures and Defects of WECS Components 4.3.5 LED Indication on FCM-20 at Start-up On the right side of the the FCM−20: After the power is set to on, the SSI CA1, CA2 and CAN S1, S2 and M LEDs show red for approximately four seconds.

-

Page 217: Failure Id

0850−1/A1 Operation Failures and Defects of WECS Components Failure ID Display Failure Text Failure Group ME crank angle #1+2 fail. WECS critical WECS critical failure WECS critical WECS pressure failure WECS pressure WECS cylinder failure WECS cylinder WECS common failure WECS common WECS passive failure WECS passive... - Page 218 0850−1/A1 Operation Failures and Defects of WECS Components Display Failure Text Failure Group ME crank angle #1 / TDC low shift WECS common ME crank angle #2 / TDC low shift WECS common ME both CA / TDC low shift WECS cylinder ME excessive engine speed WECS critical...

-

Page 219: Wecs Passive Failure

0850−1/A1 Operation Failures and Defects of WECS Components WECS Passive Failure Failure Text ME scavenge air pressure sensor #1 meas. fail. (ID 8) FCM−20 No. Display Indication Cause Sensor signal < 2mA or > 22mA Procedure ⇒ Do a check of the pressure transmitter PT4043C for damage. ⇒... - Page 220 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME servo oil pressure sensor #1 meas. fail. (ID 16) FCM−20 No. Failure ID Display Indication Cause Sensor signal < 2 mA or > 22 mA (failure signal is released after 3 seconds). Procedure ⇒...

- Page 221 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME fuel rail pressure sensor #1 meas. fail. (ID 27) FCM−20 No. Failure ID Display Indication Cause Sensor signal < 2 mA or > 22 mA (failure signal is released after 3 seconds). Procedure ⇒...

- Page 222 0850−1/A1 Operation Failures and Defects of WECS Components Indication FCM−20 No. Failure ID Display Cause The sensor power supply has a short circuit (red LED) Procedure ⇒ In E95.04, disconnect pressure transmitter PT3462C and plug X25 Remark: ID fault FCM−20 #04 comes on ⇒...

- Page 223 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text WECS Modbus fail. FCM−20 #01 or #02 (ID 39) FCM−20 No. Failure ID Display Indication #01 and #02 Modbus Cause Modbus monitoring, no communication (failure signal is released after 3 seconds). Procedure ⇒...

- Page 224 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME exhaust valve #nn position meas. fail. (ID 71) FCM−20 No. Failure ID Display Indication #01 to #08 Ex.D or Ex.F Cause Sensors ZT5421C to 27C (driving end) signal < 2 mA or > 22 mA (failure signal is released after 3 seconds).

- Page 225 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME crank angle #1 fail. (ID 1.0) FCM−20 No. Failure ID Display Indication #01 to #09 SSI CA1 Cause No data received from sensor #1 (GT5126C). Procedure ⇒ If the failure is shown on all cylinders do a check of the sensor GT5126C for increased clearance on the sensor pulley and bearings.

- Page 226 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text WECS CAN S1-bus fail. (ID 1.2) FCM−20 No. Failure ID Display Indication #01 to #09 Cause CAN system bus #1 monitoring / CAN failure (failure signal is released after 3 seconds). Procedure ⇒...

- Page 227 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text WECS cylinder lubrication passive failure. (ID 2.5) FCM−20 No. Failure ID Display Indication #03 and #04 None Cause Disconnected power supply #1 or #2. Procedure ⇒ In E85, E90 and E41.xx, make sure that the cables have no damage and are connected correctly.

-

Page 228: Wecs Common Failure

0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME waste heat recovery valve #2 not closed (ID 3.4.) FCM−20 No. Failure ID Display Indication None 3.4. Cause Waste heat recovery valve #2 (second valve) is not closed. A command to close the second valve was sent to the valve, but the sensor responses that the valve is in the open position. - Page 229 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME scavenge air pressure meas. fail. diff. high (ID 10) FCM−20 No. Failure ID Display Indication #03 and #04 Cause The pressure transmitters PT4043C and PT4044C have a difference of more than 0.2 bar (failure signal is released after 5 seconds) Procedure ⇒...

- Page 230 0850−1/A1 Operation Failures and Defects of WECS Components Failure text ME servo oil pressure high (ID 19) FCM−20 No. Failure ID Display Indication #01 and #02 Cause Servo oil pressure is 15 bar more than the setpoint, engine speed is more than 8% of nominal speed (failure signal is released after 5 seconds).

- Page 231 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME servo oil pump #2 fail. (ID 26) FCM−20 No. Failure ID Display Indication Cause The setpoint pressure controller of the servo oil pump actuator CV7222C is > 100 mA (failure signal is released after 30 seconds) Procedure ⇒...

- Page 232 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME fuel rail pressure meas. fail. diff. high (ID 29) FCM−20 No. Failure ID Display Indication #03 and #04 Cause The sensors PT3461C and PT3462C have a difference of more than 50 bar (failure signal is released after 7 seconds).

- Page 233 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME fuel rail pressure low (ID 31) FCM−20 No. Failure ID Display Indication #03 and #04 Cause Fuel rail pressure is 100 bar less than the fuel pressure setpoint (failure signal is released after 10 seconds).

- Page 234 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME crank angle #1 and #2 difference (ID 60) FCM−20 No. Failure ID Display Indication #01 and #02 SSI CA1 Cause Crank angle sensor #1 and #2 are serviceable, but the difference between the two systems is more than 1.0_ CA.

- Page 235 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME crank angle #1 / TDC high shift (ID 63) FCM−20 No. Failure ID Display Indication Cause The difference between the TDC pick-up and the crank angle sensor #1 is 4.0_ CA The crank angle sensor or toothed belt has moved.

- Page 236 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME crank angle #2 / TDC high shift (ID 64) FCM−20 No. Failure ID Display Indication Cause The difference between the TDC pick-up and the crank angle measurement system #2 is 4.0_ CA.

- Page 237 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME crank angle #2 / TDC low shift (ID 67) FCM−20 No. Failure ID Display Indication Cause The difference between the TDC pick-up and the crank angle sensor #2 is ± 2.0_ The crank angle sensor or toothed belt has moved Remark: No failure shown at shut-down Procedure ⇒...

- Page 238 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME injection quantity sensor #nn meas. fail. (ID 80) FCM−20 No. Failure ID Display Indication #01 to #09 InjQ Cause The sensor power supply has a short circuit (red LED). Procedure ⇒...

- Page 239 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME exhaust waste gate not closed (ID 5.5) FCM−20 No. Failure ID Display Indication InjQ Cause Butterfly valve stays open at a load range of less than 85%. Connection to the position sensor ZS5372C is broken, or there is a short circuit (failure signal released after 20 seconds) Procedure ⇒...

-

Page 240: Wecs Cylinder Failure

0850−1/A1 Operation Failures and Defects of WECS Components WECS Cylinder Failure Failure Text ME manual injection cutoff cylinder #nn (ID 45) FCM−20 No. Failure ID Display Indication #01 to #09 Cause The fuel injection is cut off manually Procedure ⇒ For more data, see the related alarms (WECS cylinder fail) Remark: This failure is not shown if a cylinder is cut off automatically. - Page 241 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME Exh. Valve Late/Not Opening (slowdown) (ID 75) FCM−20 No. Failure ID Display Indication #01 to #09 Cause The exhaust valve opens 15_CA or more after the crank angle setpoint Procedure ⇒...

- Page 242 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME Exh. Valve Late/Not Closing (slowdown) (ID 77) FCM−20 No. Failure ID Display Indication #01 to #09 Cause The exhaust valve closes 15_CA or more after the crank angle setpoint Procedure ⇒...

- Page 243 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME Inj. Quantity Piston, No Movement (slowdown) (ID 91) FCM−20 No. Failure ID Display Indication #01 to #09 InjQ Cause The fuel quantity piston moves less than 4% during the injection. Remark: This alarm is first transmitted after three revolutions.

-

Page 244: Wecs Pressure Failure

0850−1/A1 Operation Failures and Defects of WECS Components WECS Pressure Failure Failure Text ME Scavenge Air Pressure very HI (ID 11) FCM−20 No. Failure ID Display Indication #03 and #04 Cause The scavenge air pressure is more than 105% (failure signal is released after 2 seconds). The exhaust waste gate has a malfunction. - Page 245 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME fuel rail pressure very low (ID 32) FCM−20 No. Failure ID Display Indication #03 and #04 Cause The fuel rail pressure is 150 bar more than the fuel pressure setpoint (failure signal is re- leased after 10 seconds) Remark: No failure is shown during the conditions that follow: Stop command, shut-down, engine is stopped, fuel rail pressure sensor #1+2 meas.

-

Page 246: Wecs Critical Failure (Wecs Engine Failure)

0850−1/A1 Operation Failures and Defects of WECS Components WECS Critical Failure (WECS Engine Failure) Failure Text ME crank angle #1+2 fail. (ID 1) Indication FCM−20 No. Display #03 and #04 None Cause The two crank angle sensor measurements fail. Procedure ⇒ Do a check of the crank angle sensor unit and terminal box E96 for damage. ⇒... -

Page 247: 4.10 Malfunction Of Cylinder Lubrication

0850−1/A1 Operation Failures and Defects of WECS Components 4.10 Malfunction of Cylinder Lubrication LEDs on the ALM−20 show malfunctions and defects of the cylinder lubrication control system (see Fig. 2). Data about irregular functions with the lubricating pump components, or in the lubricating and servo oil system are given in 0820−1, paragraph 2 Cylinder lubrication. - Page 248 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME cylinder lubrication malfunction cylinder #nn ALM−20 No. On / Off Code Indication #01 to #09 CAN1 and/or CAN2 None Cause LED indication on one module: a cable is broken on the plug X2 on the related ALM−20. LED indication on all modules: CAN Bus #1 / #2 malfunction.

- Page 249 0850−1/A1 Operation Failures and Defects of WECS Components Failure Text ME cylinder lubrication malfunction cylinder #nn ALM−20 No. On / Off Code Indication #01 to #09 Fail Two times each interval Cause A cable is broken between an ALM−20 (plug X1, terminals 13 and 14) and the pressure trans- mitter (PT3131C to PT3139C).

- Page 250 Intentionally blank...

- Page 251 Group1 Operation Bedplate and Tie Rod Group 1 Main Bearing ................1132−1/A1 Thrust Bearing .

- Page 252 Intentionally blank...

-

Page 253: Main Bearing

1132−1/A1 Operation Main Bearing General The main bearing has a lower bearing shell (7, Fig. 1) and an upper bearing shell (5). The running surfaces of the bearing shells are lined with white metal. The lower bearing shell (7) is installed in the bearing girder (9) of the bedplate and the upper bearing shell (5) in the bearing cover (4). - Page 254 Intentionally blank...

-

Page 255: Thrust Bearing

1203−1/A1 Operation Thrust Bearing General The thrust bearing is installed at the driving end of the engine. The thrust bearing flange (17, Fig. 2) transmits the force from the propeller through the thrust pads (5, 13) into the bedplate. The arbor supports (6, Fig. 1) prevent circular movement of the thrust pads (5, 13, see Fig. - Page 256 1203−1/A1 Operation Thrust Bearing 018.087/09 Fig. 1: Cross Section 1 Column 6 Arbor support 2 Oil pipe 7 Bearing cover 3 Nozzle 8 Intermediate wheel (pump unit) 4 Bedplate 9 Intermediate wheel (supply unit) 5 Thrust pad (free end) OI Bearing oil inlet 2017−08 2/ 3 Winterthur Gas &...

- Page 257 1203−1/A1 Operation Thrust Bearing Lubrication During operation, bearing oil flows through the oil pipe (2, Fig. 2) to the two nozzles (3). The oil flows out of the two nozzles (3) as a spray, which becomes an oil layer between the thrust bearing flange (17) and the thrust pads (5, 13). I - I 018.088/09 Fig.

- Page 258 Intentionally blank...

- Page 259 1903−1/A1 Operation Tie Rod General The tie rods (1, Fig. 1) keep the cylinder block (2), column (3) and bedplate (4) together at four locations around the cylinders. WCH01187 WCH01187 FOR 7-CYLINDER ENGINES Fig. 1: Tie Rod Configuration and Locations 1 Tie rod 3 Column 2 Cylinder block...

- Page 260 1903−1/A1 Operation Tie Rod A two-part bush (2, Fig. 2) is welded on the tie rod (1) as shown in view II. At the bottom of the cylinder block, two set screws (7) tightly hold the two-part bush (2) and prevent vibration of the tie rods (1).

- Page 261 Group2 Operation Cylinder Liner and Cylinder Cover Group 2 Cylinder Liner ................2124−1/A1 Lubricating Quills on Cylinder Liner .

- Page 262 Intentionally blank...

-

Page 263: Cylinder Liner

2124−1/A1 Operation Cylinder Liner General The screws (12, Fig. 1) and holders (6) attach the cylinder liner (1) in the cylinder jacket (4). The nuts of the elastic studs attach the cylinder cover (9) and cylinder liner (1) with the upper and lower water guide jackets (2, 3) to the cylinder jacket (4). The surfaces of the cylinder liner (1) and the cylinder jacket (4) make a metallic seal MS. - Page 264 2124−1/A1 Operation Cylinder Liner WCH01114 Fig. 1: Cylinder Liner 1 Cylinder cover 14 Insulating bandage 2 Top water guide jacket 15 Antipolishing ring 3 Bottom water guide jacket 4 Cylinder jacket AS Annular space in upper water guide jacket 5 Lubricating quill CB Cooling bores in cylinder cover 6 Holder CI Cooling water inlet...

-

Page 265: General

2138−1/A1 Operation Lubricating Quills on Cylinder Liner General Eight lubricating quills (1, Fig. 1) are are installed around the circumference of the cylinder liner (2). The lubricating pump (3) supplies lubricating oil through pipes to each lubricating quill (1). WCH01128 Fig. - Page 266 2138−1/A1 Operation Lubricating Quills on Cylinder Liner Function The lubricating pump supplies a set quantity of lubricating oil at high pressure through the connection (OI) into the lubricating quills (see Fig. 2). The non-return valve (6, Fig. 2) opens and the lubricating oil comes out of the the nozzle tip (5) and the lubricating point (LP) as a spray.

- Page 267 2303−1/A1 Operation Piston Rod Gland General The piston rod gland (1, Fig. 1) keeps the dirty oil in the scavenge space (SS) and prevents contamination of the bearing oil. Also, the piston rod gland box seals the scavenge air from the crankcase (2). Damaged gaskets cause an increase in the quantity of oil in the leakage oil drain.

- Page 268 2303−1/A1 Operation Piston Rod Gland I - I WCH01179 FUEL SIDE WCH01179 Fig. 2: Piston Rod Gland 1 Housing (2-part) 10 Cylinder jacket 2 Support 11 Piston rod 3 Scraper ring (4-part) 4 Ring support (3-part) BD Bearing oil drain 5 Scraper ring (3-part) LD Leakage oil drain 6 Gasket (4-part)

- Page 269 2722−1/A1 Operation Injection Valve (FAST Nozzle) General Three Fuel Actuated Sacless Technology (FAST) injection valves (3, Fig. 1) are installed in each cylinder cover (1). Fuel, which leaks because of the needle clearance, drains through the connection leakage fuel drain (LD, Fig. 2) to the fuel leakage pipe (6) and into the collector block (5) (see 8019−1 Fuel Oil System).

- Page 270 2722−1/A1 Operation Injection Valve (FAST Nozzle) 016.921/08 Fig. 1: Location of Injection Valves 1 Cylinder cover 5 Collector block 2 Fuel leakage pipe 6 Fuel leakage pipe 3.49 3 Injection valve 3.01 7 Injection control unit 3.02 4 Injection pipe 3.47 8 Fuel rail 3.05 2017−08 2/ 3...

- Page 271 2722−1/A1 Operation Injection Valve (FAST Nozzle) II - II I - I WCH00879 Fig. 2: Injection Valve 9 Nozzle holder FS Fuel supply (high pressure) 10 Tappet carrier LO Leakage fuel outlet 11 Nozzle body FB Fuel bore 12 Nozzle tip SF Sealing face 13 Clamping nut LD Leakage fuel drain...

- Page 272 Intentionally blank...

- Page 273 2728−1/A1 Operation Starting Valve General A starting air valve is installed in each cylinder cover (5, Fig. 1). The starting air valves start the engine, or decrease the engine speed for reversing. The Wärtsilä Engine Control System (WECS-9520) monitors and controls the starting air valve operation (see 4002−1, paragraph 4.4).

- Page 274 2728−1/A1 Operation Starting Valve I - I 016.856/08 016.856/08 Fig. 1: Starting Valve 1 Cover SA Starting air 2 Piston RB Relief bore 3 Housing Air space 4 Compression spring Air space 5 Cylinder cover CA Control air from starting air pipe 6 Valve spindle 7 3/2-way solenoid valve 2014...

- Page 275 2751−1/A1 Operation Exhaust Valve General ............Function .

-

Page 276: Exhaust Valve

2751−1/A1 Operation Exhaust Valve The air spring (AS) is below the air spring piston (10, Fig. 2). The valve stroke sensor (18) monitors and transmits the open and closed positions of the valve spindle (6) to the WECS-9520. If there is a large pressure difference between when the exhaust valve opens and the pressure in the air spring (AS), damage can occur to the exhaust valve. - Page 277 2751−1/A1 Operation Exhaust Valve I - I IV - IV 016.874/08 WCH00851 Fig. 2: Exhaust Valve and Leakage Oil Drain 2014 3/ 6 Winterthur Gas & Diesel Ltd.

-

Page 278: Function

2751−1/A1 Operation Exhaust Valve Key to Fig. 2: Exhaust Valve and Leakage Oil Drain 1 Valve cage 12 Thrust piece 2 Lower housing 13 Connection (hydraulic oil) 3 Upper housing 14 Orifice 4 Outside piston 15 Cup spring 5 Inside piston 16 Rotation wing 6 Valve spindle 18 Valve stroke sensor... - Page 279 2751−1/A1 Operation Exhaust Valve Lubrication Leakage oil from the outside piston (4, Fig. 2) and inside piston (5) lubricates the air spring piston (10). Oil in the leakage oil collection space (LS) drains to the leakage oil drain (LD). While the exhaust valve closes, oil flows through the air spring piston (10) and goes into the air spring (AS).