Summary of Contents for Alaris Medical Systems Signature IVAC 710 Series

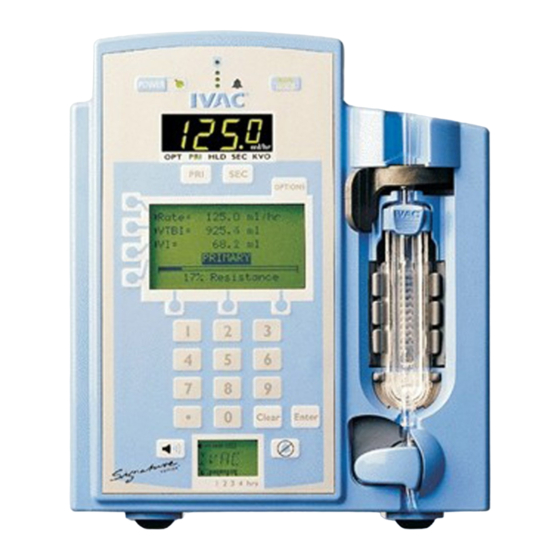

- Page 1 ™ M E D I C A L S Y S T E M S IVAC ® MODEL 710X 720X S E R I E S Signature Edition ® Volumetric Pump TECHNICAL SERVICE MANUAL...

- Page 2 1,743,342. SWITZERLAND: +EP 0,121,931; 0,328,163; 0,328,162; 0,248,632; 122,210; 122,211and 122,212. Other U.S. and foreign patents issued and pending. This document contains proprietary information of ALARIS Medical Systems, and its receipt or possession does not convey any rights to reproduce its contents, or to manufacture or sell any product described.

- Page 3 Phone Numbers for Reference USA Only CUSTOMER SERVICE (800) 482-4822 For placing an order for parts, accessories, etc., and checking status of an order. TECHNICAL SUPPORT (619) 458-6003 (800) 854-7128, EXT. 6003 For technical, troubleshooting and preventive main- tenance information. QUALITY ASSURANCE (800) 854-7128 EXT.

- Page 4 ALARIS Medical Systems, and ALARIS Medical Systems does not give or grant, directly or indirectly, the authority to any representative or other person to assume on behalf of ALARIS Medical Systems any other liability in connection with the sale or use of ALARIS Medical Systems products.

-

Page 5: Table Of Contents

TABLE OF CONTENTS Chapter 1 General Information Introduction ............................1-1 Expanded Pump Specifications ......................1-3 Battery Management System ......................1-5 1.3.1 Fan ..............................1-5 1.3.2 Battery and Charging Process ......................1-5 1.3.3 Refresh Cycle .............................1-6 1.3.4 Battery Gauge ...........................1-6 1.3.5 Power On/Off ............................1-7 1.3.6 Lower LCD Display ..........................1-7 1.3.7 Clock ..............................1-7 1.3.8... - Page 6 TABLE OF CONTENTS 2.4.4 Setting Air-in-Line Threshold ......................2-5 2.4.5 Setting Dose Rate Drugs ........................2-6 2.4.6 Setting Maximum Rate ........................2-8 2.4.7 Setting Computer Link ........................2-8 2.4.8 Setting Optional Modes ........................2-9 2.4.9 Setting Optional Features ........................2-10 2.4.10 Setting KVO Rate ..........................2-12 2.4.11 Setting Dynamic Monitoring™ Options ...................2-13 2.4.12 Setting Audio Volume ........................2-14 2.4.13 Setting Configuration Name ......................2-14 Transferring Settings to Another Pump ....................2-15...

- Page 7 TABLE OF CONTENTS 4.4.1 Processor Kernel ..........................4-4 4.4.2 COMBO IC ............................4-4 4.4.3 EEPROM ............................4-4 4.4.4 RAM ..............................4-4 4.4.5 EPROM ..............................4-5 4.4.6 RS-232 Interface ..........................4-5 4.4.7 RS-232 Interface (7101/7201 only) ....................4-5 Power System ............................4-6 4.5.1 Battery Manager ..........................4-6 4.5.2 AC Off Line Switcher .........................4-7 4.5.3 Battery Charge Regulator ........................4-7 4.5.4...

- Page 8 TABLE OF CONTENTS 4.7.2 Backup Audio Buzzer and Test Circuit ....................4-19 LED Module .............................4-20 Lower LCD Display ...........................4-21 4.10 Main LCD Module ...........................4-21 4.10.1 Main LCD Back Light ........................4-21 4.10.2 Graphic LCD Contrast ........................4-21 4.11 Nurse Call Circuit ..........................4-21 4.12 Panel Lock Switch ..........................4-21 4.13 ECD Board ............................4-21...

- Page 9 TABLE OF CONTENTS Chapter 6 Troubleshooting Introduction ............................6-1 Technical Troubleshooting Guide .......................6-1 Error Messages ..........................6-4 Diagnostics Mode ..........................6-9 6.4.1 Entering Diagnostics Mode ........................6-9 6.4.2 Setting Preventive Maintenance Interval ...................6-10 6.4.3 Viewing Alarm or Error History ......................6-11 6.4.4 Clearing Diagnostic History ......................6-12 6.4.5 Viewing Battery Status ........................6-13 6.4.6...

- Page 10 TABLE OF CONTENTS List of Figures Figure 1-1 Lower LCD Display Layout ......................1-7 Figure 1-2 Resistance Graph ........................1-10 Figure 1-3 Pressure and Resistance Graph ....................1-10 Figure 2-1 Map of Configuration Screens ....................2-19 Figure 3-1 Cleaning the Mechanism Area ....................3-2 Figure 3-2 Setup for Rate Verification Test ....................3-5 Figure 3-3 Pressure Test Setup ........................3-6...

- Page 11 TABLE OF CONTENTS List of Tables Table 1-1 Battery Trip Points ........................1-6 Table 1-2 Common Abbreviations ......................1-15 Table 1-3 Reference Designators ......................1-16 Table 1-4 Symbol Definition ........................1-16 Table 2-1 Configuration Options and Defaults ....................2-2 Table 2-2 Drug List .............................2-7 Table 2-3 Record of Configured Instruments ....................2-17 Table 3-1 PM Inspections ...........................3-7...

-

Page 12: Chapter 1 General Information

ALARIS Medical Systems equipment including nurse call system and/or Warranty. ALARIS Medical Systems offers a variety of repair computer monitoring system. agreements for post-warranty service. Call toll-free (800) 482-4822 (ALARIS Medical Systems) for information. - Page 13 GENERAL INFORMATION Specifications RATE RANGE: 0.1 to 999.9 ml/hr in 0.1 ml/hr increments (primary) 0.1 to 270.0 ml/hr in 0.1 ml/hr increments (secondary) 0.1 to 9999.9 ml in 0.1 ml increments (primary) VOLUME TO BE INFUSED RANGE: 0.1 to 999.9 ml in 0.1 ml increments (secondary) VOLUME INFUSED RANGE: 0.0 to 9999.9 ml in 0.1 ml increments KVO RANGE:...

-

Page 14: Expanded Pump Specifications

GENERAL INFORMATION 1.2 Expanded Pump Specifications Administration Set: Use only IVAC 72 Series administration sets. When used for Max. Gravity Flow Rate: gravity infusion: >4200 ml/hr with 16 gauge catheter x 2.25” Teflon Air-in-Line Accuracy: Configured Threshold Air Volume Detections Range 50µL 15µL - 85µL 100µL... - Page 15 GENERAL INFORMATION Mode: Hi Resistance/Resistance/Pressure Only Alert: On/Off Restarts: 0 (Off), 1-9 Resistance Display: On/Off Resistance Trend Graph: On/Off Instrument ID: 9 digits KVO rate: 0.1 - 20.0 ml/hr Loading Dose: On/Off Panel lock: On/Off Preventive maintenance interval 1-52 weeks Preventive maintenance reminder: On/Off Maximum rate: 0.1- 999.9 ml/hr Multi-Dose Alert: On/Off...

-

Page 16: Battery Management System

GENERAL INFORMATION 1.3 Battery Management System The battery pack (10 to 18V) has a built-in temperature sensor which allows the Battery This section contains general information on the Manager to monitor the temperature of the battery. battery management system. Included is information The pack also includes a temperature limiting on how the Battery Manager monitors and maintains thermostat which opens the circuit if the battery... -

Page 17: Refresh Cycle

GENERAL INFORMATION c. Float Charge: The float charge phase begins at the capacity is loaded and the OK button is pressed, the end of the top-up phase and helps maintain a fully original rated capacity must be reloaded to preserve charged battery. -

Page 18: Power On/Off

141777 FAA Page of 150 GENERAL INFORMATION 1.3.5 Power On/Off 1.3.7 Clock “relative The Battery Manager provides the interface between The Battery Manager provides a time” power on/off switch(es) and the main processor. clock which the main processor can set and When the instrument is off, the Battery Manager read. -

Page 19: Nicd Battery Capacity Information

GENERAL INFORMATION lower LCD goes blank. Reconnect the battery. Plug most practical impact on battery capacity delivered in instrument into AC. A refresh cycle will be initiated. this instrument. Repeat this procedure at 24 hour intervals, 2 or 3 a. TEMPERATURE DURING CHARGE - As the effective times to increase capacity or use a battery ambient temperature of the battery increases, the conditioner. -

Page 20: Dynamic Monitoring™ System

GENERAL INFORMATION d. CHARGE RATE - The ideal charge rate requires 15 NOTE: In the future, ALARIS Medical Systems may provide different battery packs. The replacement battery may have a hours to get to full charge, which is undesirable different rated capacity. Therefore, the Battery Manager of from the user’s perspective. -

Page 21: Resistance Graph

GENERAL INFORMATION Features include: • Alarm setting is based on dynamic system impedance (pressure changes, not absolute pressure). • Detection of complete occlusions. • Reduced nuisance alarms by minimizing artifact effects such as head height and patient movement. • Faster time to alarm at low rates. •... -

Page 22: Data Communications Function

ALARIS Medical Systems No operating features of the pump are changed. The Warranty. ALARIS Medical Systems offers a variety of repair agreements for post-warranty service. Call toll-free (800) pump will alarm with or without the nurse call. The 482-4822 for information. - Page 23 Refer to Section 2.5.2 “Pop-Up Displays” for further explanation. NOTE: In the future, ALARIS Medical Systems may provide different battery packs. The replacement battery may have a NOTE: Must have 4 characters in configuration name, use different rated capacity.

- Page 24 182 to 214, return 24 hours if the instrument is turned on. the instrument to ALARIS Medical Systems or replace the mechanism. NOTE: If replacing battery, ensure battery run time is cleared in Diagnostic Mode.

-

Page 25: Cautions

GENERAL INFORMATION CAUTION: NOTE: Selected Tc=0.0 with software is 2.02 or higher. If Use only ALARIS Medical approved not, will get Perform Temp Cal message when in pressure batteries due to Battery Manager requirements and calibration (soft). the thermostat contained in the battery assembly NOTE: As a result of continuing product development, the part number you receive may not match the one you 1.8.3 Warnings... -

Page 26: Table 1-2 Common Abbreviations

GENERAL INFORMATION Table 1-2 Common Abbreviations liquid crystal display “active Low” logic signal light emitting diode ampere long analog to digital converter megahertz as required µA microamp alternating current µF microfarad ampere-hour µsec microsecond air-in-line milliampere centimeter minute cmH2O centimeters of Water milliliter CMOS complimentary symmetry metal oxide... -

Page 27: Compliance To Standards

GENERAL INFORMATION Table 3 Reference Designators Table 4 Symbol Definition capacitor diode/zener diode Attention, consult accompanying documents. display RS 232 fuse RS-232 Connector ferrite bead connector, terminal header Nurse Call inductor plug connector transistor/FET resistor RESN ceramic resonator switch SPKR speaker transformer thermistor... -

Page 28: Declaration Of Conformity

• Draft IEC 60601-2-24 “Applicable EMC Limits” Authorized EU Representative: Issued by: ALARIS Medical Systems, Inc. V.P. Quality and Regulatory, Tony Thorne, Manager, International QA/RA ALARIS Medical Systems, Inc. Intec 2 Wade Road San Diego, California U.S.A. Basingstoke, UK Hants RG24 8NE ™... -

Page 29: Chapter 2 Checkout And Configuration

141345 FAA Page of 146 Chapter 2 — CHECKOUT AND CONFIGURATION CAUTION 2.1 Introduction : Keep latch closed when instrument is not in use. This chapter describes the initial setup and configuration of the instrument. Included in this chapter is a reproducible form (Record of Configured Instruments, Table 2-3) available for recording and tracking configurations for instruments located in different areas. -

Page 30: Table 2-1 Configuration Options And Defaults

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION Table 2-1. Configuration Options and Defaults** FEATURES OPTIONS FACTORY DEFAULTS 7100/7200 7101/7201 7100/7200 7101/7201 Air-in-Line: Threshold 50, 100, 200, or 500 µl 50, 100, 200, or 500 µl 100 µl 100 µl Reset On/Off On/Off... -

Page 31: Start-Up Defaults

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION 2.3 Start-Up Defaults A hospital biomedical technician has the capability to set all configuration parameters to their start- POWER HOLD ® up defaults in a single operation. The terms “configuration parameters” and “programmable OPT PRI SEC KVO features”... -

Page 32: Entering Configuration Mode

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION 2.4.1 Entering Configuration Mode The instrument must be off (both channels must be off for Model 7200 instruments). The procedure for the single and dual channel pump is the same. Any configuration in the dual channel pump sets the same value for both channels. -

Page 33: Setting Language

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION 2.4.3 Setting Language OPTIONS The language choices are English and Canadian Set To Defaults French. All operating displays will be in the Language language selected. Diagnostic and configuration Air In Line modes, however, will remain in English. Dose Rate Drugs Language 1. -

Page 34: Setting Dose Rate Drugs

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION OPTIONS 2.4.5 Setting Dose Rate Drugs Drug? NOTE: In Models 7101/7201, is used instead Set To Defaults of a drug list option. There is no tick mark next to Language Dose Rate. Air In Line The Dose Rate Drugs feature allows the selection Dose Rate Drugs... -

Page 35: Table 2-2 Drug List

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION Table 2-2. Drug List (7100/7200 only) Methylprednisolone ® Alfentanil (Alfent Milrinone ® Alprostadil(Prostin (PGE-1) ® Morphine Alteplase (Activase ® Nitroglycerin (Tridil Aminophylline ® ® Nitroprusside (Nipride Amrinone (Inocar ® Norepinephrine (Levophed ® Atracurium (Tracrium Oxytocin ®... -

Page 36: Setting Maximum Rate

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION 2.4.6 Setting Maximum Rate OPTIONS This sets the maximum rate selectable by the Maximum Rate clinician. The range for Maximum Rate is 0.1 to Computer Link 999.9 ml/hr. Optional Modes 1. Advance to the C3 page. Optional Features Maximum Rate 2. -

Page 37: Setting Optional Modes

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION OPTIONS Enabling of the monitoring and control modes will automatically place them in the user's options Maximum Rate menu. Computer Link Optional Modes Computer Link 1. On the C3 page, press the Optional Features soft key. -

Page 38: Setting Optional Features

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION Loading Dose 2. Press and release soft key to select for editing. Press again to cycle between OPTIONS . This feature allows the clinician to set up an initial infusion rate for a specific Loading Dose volume, automatically followed by a Dose Rate=... - Page 39 141345 FAA Page of 146 CHECKOUT AND CONFIGURATION When the Resistance Trend feature is on, a graph is displayed on main LCD via Options Menu. When the Multi-Dose Alert feature is on, the clinician will get the option to set an alert at the end of every dose when in Multi-Dose Mode.

-

Page 40: Setting Kvo Rate

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION 2.4.10 Setting KVO Rate OPTIONS The pump will automatically operate at the KVO rate (or the current rate, whichever is less) once KVO Rate the primary VTBI has counted down to zero. The Monitoring Options KVO rate range is 0.1 to 20.0 ml/hr. -

Page 41: Setting Dynamic Monitoring™ Options

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION 2.4.11 Setting Monitoring Options NOTE: Resistance trend graph data is lost when: 1) Clear is pressed, 2) Pump is off for more than 6 The graphical resistance display (appearing in the Main hours. -

Page 42: Setting Audio Volume

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION 2.4.12 Setting Audio Volume The volume settings determine which range of audio volume is available to the clinician. For example; “Low” may be too low for your OPTIONS institution, therefore you would choose “Med Hi”. KVO Rate A transition tone, if enabled, will sound upon Monitoring Options... -

Page 43: Transferring Settings To Another Pump

The instrument ID number and the periodic maintenance settings from the diagnostics mode will not be transferred. Connect a standard 9-pin Null Modem RS-232 cable (also available from ALARIS Medical Systems, P/N 133450) to the RS-232 ports on the pumps. ™ 2-15 IVAC Signature Edition™... -

Page 44: Teacher/Learner Pump Procedure

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION OPTIONS 2.5.1 Teacher/Learner Pump Procedure 1. Access the Configuration Mode for both Learn: Rev. 00.06 “teacher” and “learner” instruments and Teach: Rev. 00.06 advance to page C5. Teach 2. Press and release the soft key of the <... -

Page 45: Table 2-3 Record Of Configured Instruments

141345 FAA Page of 146 CHECKOUT AND CONFIGURATION Duplicate the following table for additional entries. Table 2-3. Record of Configured Instruments Serial # Serial # Serial # Serial # Serial # *Instrument ID # Config Name (Instr Label) Location Language Air-in-Line: Threshold µl... - Page 46 141345 FAA Page of 146 CHECKOUT AND CONFIGURATION RECORD OF CONFIGURED ALARIS Medical Systems SE INSTRUMENTS Hospital: Unit: DRUG NAME/OPTION TRADE NAME NOT SELECTED SHORT LIST EXTENDED LIST Extended List Access DRUG? Alfentanil Alfenta ® Alprostadil Prostin ® (PGE-1) Alteplase Activase ®...

- Page 47 CHECKOUT AND CONFIGURATION 141345 FAA Page 50 of 146 OPTIONS OPTIONS OPTIONS OPTIONS OPTIONS CONFIGURATION MODE Set To Defaults Maximum Rate KVO Rate Learn: Rev. 00.06 ID No. : 001234567 Language Monitoring Options 4 Computer Link Teach: Rev. 00.06 SW Rev.: 2.44 Air In Line Optional Modes Audio...

-

Page 48: Chapter 3 Preventive Maintenance

Regular inspections are not covered under any contract or agreement offered by ALARIS Medical Systems and must be performed before each use of the instrument by the user. Use Table 3-1 “PM Inspections” to record the completion of preventive maintenance inspections. -

Page 49: Cleaning

141345 FAA Page of 146 PREVENTIVE MAINTENANCE 3.2.2 Cleaning Figure 3-1 Cleaning the Mechanism Area It is good practice to routinely clean the pump, especially if spillage has occurred. Do not use solutions containing phosphoric acid (Foamy Q&A ) or aromatic solvents (naphtha, paint thinner, latch etc.), chlorinated solvents* (Trichloroethane, MEK, Toluene, etc.) or alcohol. -

Page 50: Preventive Maintenance Inspections

Regular inspections are not are free of foreign matter. covered under any contract or agreement offered by ALARIS Medical Systems and must be performed by c. Proper operation of latching mechanism. Cam the user. followers should retract and extend smoothly. -

Page 51: Flow Stop Test

141345 FAA Page of 146 PREVENTIVE MAINTENANCE 4. Clamp off IV line just above pump to simulate NOTE: Do not use 70RCS more than 40 times. an upstream occlusion. Verify the pump stops a. Fill the solution container with clean tap water. running, alarms, and displays OCCLUSION Take a 70 RCS rate calibration set and close the UPSTREAM within 60 seconds. -

Page 52: Pressure Calibration

141345 FAA Page of 146 PREVENTIVE MAINTENANCE o. Press the channel’s RUN/HOLD to start the primary 3.3.5 Pressure Calibration infusion. a. Place instrument on bench or other flat surface and connect to AC power. p. The pump will run approximately 360 seconds to deliver 40 ml, then go into KVO mode. -

Page 53: Ground Current Leakage Test

141345 FAA Page of 146 PREVENTIVE MAINTENANCE f. Select Cal Pressure (A or B for dual channel). 3.3.7 Ground Resistance Test Use a BIO-TEK Model 260 (or equivalent ground g. Allow 1 hour warmup. resistance testing equipment) to measure resistance h. -

Page 54: Table 3-1 Pm Inspections

141345 FAA Page of 146 PREVENTIVE MAINTENANCE Table 3-1. PM Inspections I.D Number_________________________ Instrument Serial Number____________ Ref. Date Date Section Frequency Completed Completed Regular Inspection (record every 12 months) 3.3.1 Every Use Functional Test 3.3.2 12 Months Flow Stop Test 3.3.3 12 Months Rate Accuracy Verification Test... -

Page 55: Chapter 4 Functional Description

Mount Technology (SMT) board. If a board is determined to have failed, it can be replaced or the unit can be returned to ALARIS Medical Systems for repair. ALARIS Medical Systems does not provide replacement components for repair of SMT boards nor does ALARIS Medical Systems recommend attempting field service of the instrument’s SMT... -

Page 56: Overview

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION The pump will alarm at signs of internal problems required for the instrument. The board can be and at preset thresholds for external problems (for broken down into four main sections; kernel, power example, when battery charge falls below a critical system, motor drive and sensor control, and user level, or pump output pressure exceeds a... -

Page 57: Table 4-1 Definition Of Terms

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION Table 4-1. Definition of Terms 80C188 Microprocessor that controls all instrument operations. A/D (A2D) Analog to digital converter. Battery Temperature Sensor Monitors the temperature inside battery to ensure optimum battery capacity. Battery Assembly Contains battery, battery temperature sensor, and thermal cutout. -

Page 58: Main Pcb

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION 4.4 Main PCB circuit provides redundant storage and error 4.4.1 Processor Kernel detection of RAM data. The local serial interface control logic is used to interface with serial accessed The processor kernel is responsible for controlling peripherals such as the A/D converter, EEPROM, LED the motor actuation, sensing and responding to user Module(s), and Battery Manager. -

Page 59: Eprom

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION preserving the contents of the RAMs. The second level signals to RS232 levels. The system can support chip select line, CS2, of the RAMs is tied to up to 9600 baud rate. RST_CPU*, so that the RAMs can not be selected 4.4.7 RS-232 Interface (7101/7201 only) during power down sequence. -

Page 60: Power System

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION Figure 4-3 Electrical Partitioning RS232 PCB 4.5 Power System 4.5.1 Battery Manager For general information, also refer to Chapter 1. The Battery Manager has the following functions: • Instrument on/off The Battery Manager, U34 (U40), is a custom •... -

Page 61: Ac Off Line Switcher

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION Figure 4-4 Battery Manager Block Diagram ON/OFF DC-DC AC SUPPLY CONTROL CONVERTER LOWER LCD CHARGER DISPLAY VOLTAGE BATTERY ANALOG CURRENT WATCHDOG MANAGER CIRCUITS TEMPERATURE AC POWER SENSOR MAIN CPU ON/OFF SWITCH 4.5.2 AC Off Line Switcher and sent to the feedback input of the switching regulator U20 (U28). -

Page 62: Refresh Cycle Load

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION has decreased to approximately 9.75V, the Battery NOTE: The charger will turn off if the battery gets too hot (>37º C) to let the battery cool down. Cool down time is not Manager has the ability to remove these supplies included in the 180 minute charge time. -

Page 63: Battery Voltage Monitor

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION is plugged into AC. The Battery Manager disconnects 4.5.10 Voltage Reference 4.1V the AC source during the battery refresh cycle. The 4.1V reference is used in the voltage monitor circuit, the battery temperature sensor circuit, the When the Battery Manager asserts PWR_ON high, ambient temperature sensor circuit, and is the Q24 (Q41) will turn on. -

Page 64: Always On Supply (+5Vao)

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION 4.5.12 Always On Supply (+5VAO) from a positive supply (9V-24V). The supply can provide about 100mA. The IC ground pin is The always on supply, U39 (U43), is used to power bootstrapped to the negative output voltage. devices that remain powered when the instrument is Then, referencing the feedback signal to ground off e.g., Battery Manager circuitry and VRAM. -

Page 65: Main Power Supply

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION Figure 4-5 Battery Monitor Figure 4-6 Main Power Supply ™ 4-11 IVAC Signature Edition™ Technical Service Manual ® M E D I C A L S Y S T E M S... -

Page 66: System Watchdog

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION 4.5.17 System Watchdog When 10 Hz* is not oscillating, the one shot, U36-5 (U46-13), will not trigger, therefore, output Q is low The system watchdog provides a monitor on the and Q* is high. The watchdog outputs, WD_OUT* operation of the main processor and the Battery and WD_OUT, are activated until the Battery Manager. -

Page 67: Power Switch

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION 4.5.18 Power Switch Battery Manager, U34 (U40) signal R61 or the lack of the PWR_ON signal being asserted will initiate a The power on/off switch(es) are located on the RST_CPU*. keypad. The switch(es) are not included in the standard keypad matrix. -

Page 68: Lower Lcd Display Backlight Drive

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION 4.5.20 Lower LCD Display Backlight Drive The sequence of operation for a single phase [Phase 1 (A)] of the motor is as follows: The backlight for the Lower LCD display contains 6 LEDs in series. The signal AOD_BKLT is tied to the a. -

Page 69: Table 4-3 Motor Control Signals

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION d.The chopping action results in a steady state regulating the motor current, a bipolar network current in the winding for a given phase duration. has been designed around these switches to keep When the phase is reversed the opposite high side switching times below a microsecond. - Page 70 141345 FAA Page of 146 FUNCTIONAL DESCRIPTION Figure 4-9 Motor Drive Circuit, Phase 1(A) Figure 4-10 Motor and Mechanism Sensors Block Diagram ™ 4-16 IVAC Signature Edition™ Technical Service Manual ® M E D I C A L S Y S T E M S...

-

Page 71: Air-In-Line Sensor

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION 4.6.2 Air-In-line Sensor 4.6.3 Transducer The transducer assembly is a silicon based resistor The Air-in-Line (AIL) Detector System consists of a: bridge producing a linear output. The sensing area is • Transmitter arm that also loads the set in in the front of the assembly and directly in contact position to monitor for air. -

Page 72: User Interface

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION with auto zero disabled). Drift is checked periodically the dual channel pump. The keyboard is scanned to ensure the transducer is accurate. If not, a “Cal approximately every 10 ms and key data updated Reqd”... -

Page 73: Main Speaker Driver

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION alarm indication. The Graphic LCD Module provides window comparator, U38 (U16). The speaker is user information on a 128x64 dot matrix display with tested when an alarm or error occurs, while the test LED back light. -

Page 74: Led Module

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION off properly. Additional logic is provided to allow the output (BKUP_SPKR_TST*) drives a digital input on power switch(es) to turn off the backup audio if the the COMBO IC. main CPU or battery processor no longer have 4.8 LED Module control over the instrument. -

Page 75: Lower Lcd Display

141345 FAA Page of 146 FUNCTIONAL DESCRIPTION 4.9 Lower LCD Display filtered PWM input voltage BKLT_LED. The backlight intensity is not user adjustable. The Lower LCD Display is visible whether the pump is 4.10.2 Graphic LCD Contrast on or off, AC or battery operation. It shows the current battery run time available along with the The graphic LCD contrast is controlled by varying the current audio level selected, communications... - Page 76 141345 FAA Page of 146 FUNCTIONAL DESCRIPTION drop detectors for independent Model 180 flow 2.8V. The integrator output signal is controlled by sensors along with common timing and control drive enable FET Q1/Q2 to drive the LED constant logic. The board assembly is common to both current sink U1/Q4 and related components.

- Page 77 141345 FAA Page of 146 FUNCTIONAL DESCRIPTION 2.2V with a flow sensor attached and driven at maximum current. Figure 4-17 Flow Sensor Interface Block Diagram Drop_A/B 2.8V +5 V Model 180 Flow Sensor U7B/U8B U1/U6 U1/Q4 U9A/B Sample Constant Sense Drop ECD _SIG_A/B Capacitor...

-

Page 78: Chapter 5 Corrective Maintenance

141345 FAA Page of 146 Chapter 5 — CORRECTIVE MAINTENANCE 5.1 Introduction This chapter contains procedures required to proper- ly disassemble, repair, and replace parts as well as to test, calibrate, and reassemble an instrument if a problem is detected. Included in this chapter is a list of test equipment required to perform these func- tions. -

Page 79: Repair Or Replacement

NOTE: Instrument configuration will not be lost when dis- connecting power. However, error history and infusion pro- In the future, ALARIS Medical Systems may provide gram settings may be lost. If you want to save error history, record before proceeding. - Page 80 141345 FAA Page of 146 CORRECTIVE MAINTENANCE Handle Cover (removed to access 2 case screws) Tamper Switch Flow Sensor Plugs RS232 Cover and Connector Power Cord Power Cord Retainer Power Cord Retainer/Battery Cover Screw Battery Cover Pole Clamp Case Screws (9) Battery Battery Cover ™...

-

Page 81: Disassembling Pump

141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5.4 Disassembling the Pump WARNING: Disconnect pump from AC power Gaining access and removing various components of before disassembling. Hazardous voltages are present the pump for replacement is simple. It may not be when AC power is connected regardless of the setting of the POWER switch. - Page 82 141345 FAA Page of 146 CORRECTIVE MAINTENANCE 1. Using a Phillips screw driver, remove screw from Power Cord Retainer on the rear case, then remove the power cord and power cord retainer. 2. Lift and remove the battery cover. Power cord Power cord retainer Power cord retainer/battery cover screw Battery cover...

- Page 83 141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5. Remove the battery to get the hidden case screw inside the battery compartment. Remove the screw. Battery compartment Hidden case screw 6. Remove remaining case screws (6 for dual, 4 for single). Case Screws 7.

-

Page 84: Disassembly Of Rear Case

141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5.4.1 Disassembly of the Rear Case 1. Disconnect power supply board connector/battery cable. Lift up the locking bar and remove the RS- 232 flex cable from front case. Disconnect ground wires (1 for single channel) from under motor. •... - Page 85 141345 FAA Page of 146 CORRECTIVE MAINTENANCE 3. To replace ECD board assembly (if installed): a. Remove screw on ECD board using Phillips screw driver, then remove the RS-232 board. 4. To replace RS-232 board assembly: a. Pull the RS-232 cover away from the connector then remove two hex nuts using 3/16”...

- Page 86 141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5. To replace the line filter: remove screw from Line Filter using Phillips screw driver. Remove two screws from exterior power connec- tor using Phillips screw driver. Remove exterior power connector and Line Filter assembly.

-

Page 87: Disassembly Procedure For Cable Routing

141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5.4.2 Disassembly Procedure for Cable Routing CHANNEL B CHANNEL A LED Flex Latch Cable Back 4-Bar Back 4-Bar Latch Cable Tie #2 Motor Cable Motor Cable Tie #4 Rotation Cable Rotation Cable XDCR Cable Tie #3 Tie #1 XDCR Cable... - Page 88 141345 FAA Page of 146 CORRECTIVE MAINTENANCE Power Supply cable Tamper Switch cable Cable clamp Cable clamp Speaker Cable clamp Cable clamp Battery/Power RS-232 Flex cable Connector B. Rear Case 4. Disconnect battery/power cable from main board. 1. Disconnect flex cable for RS-232 board assem- bly.

-

Page 89: Disassembly Of Front Case

141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5.4.3 Disassembly of Front Case 1. Disconnect all wire connections to the CHANNEL CHANNEL Main PCB. NOTE: When removing flex cables, carefully lift locking bar to remove cable from connector. NOTE: Pay particular attention to wire routing. Wires should be routed back to initial scheme and similar to the example shown. - Page 90 141345 FAA Page of 146 CORRECTIVE MAINTENANCE 3. To replace the LED modules: Lift up on locking bar for flex cable and disconnect. Use fingers to push back snap fittings holding the upper LEDs (only one on single channel), then lift and remove.

- Page 91 141345 FAA Page of 146 CORRECTIVE MAINTENANCE 6. To replace the mechanism: a. First, separate the front and rear case halves following the procedure in Section 5.4, “Disassembling Pump”. NOTE: Pay close attention to cable routing when disassem- bling the instrument. The cables are specifically routed to ensure they are not pinched or stressed when reassembled.

- Page 92 141345 FAA Page of 146 CORRECTIVE MAINTENANCE 7. To replace the key pad assembly: remove the Key Pad only if it is defective. Removing a good Key Pad will ruin it. NOTE: Keypad pictures are for reference only and may not match your instrument.

- Page 93 141345 FAA Page of 146 CORRECTIVE MAINTENANCE e. Adhesive will remain on the surface of the front case. Remove any remaining residue from surface before applying new Key Pad. Alcohol may be used to remove adhesive residue. f. Position the front case so that it faces you. Fold back a small portion of the protective backing along the right side of the Key Pad.

- Page 94 141345 FAA Page of 146 CORRECTIVE MAINTENANCE h. It may be necessary to loosen the Main PCB to gain access to the flex cables from inside the front case. To do so, remove screw from Main PCB using Phillips screw driver. Lift and move the Main PCB to the side to gain access to the flex cables.

-

Page 95: Reassembly Procedure For Cable Routing

141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5.4.4 Reassembly Procedure for Cable Routing NOTE: Cable routing may change over time to ensure wires are not pinched and ease of assembly and disassembly is maintained. When the pump was opened, if the cable rout- ing was different, follow that cable routing scheme. - Page 96 141345 FAA Page of 146 CORRECTIVE MAINTENANCE 9. Route CH B ail receiver cable (black) up over motor assembly and connect to main board. Install tie # 1 to motor cable and CH B ail receiver cable (black). 10. Route CH B rotation sensor cable out to right side and under back 4-bar (mechanism).

-

Page 97: Assembling Pump

141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5.5 Assembling Pump NOTE: Calibration coefficients for the transducer are stored in the EEPROM on the main board assembly. Once they have been calibrated, the Signature Edition mechanism and board assemblies become a matched set. Replacement of either requires pressure and rate calibration. -

Page 98: Test And Calibration

141345 FAA Page 102 of 146 CORRECTIVE MAINTENANCE 5.6 Test and Calibration Install non-check valve set (e.g. 72013) into Additional testing and calibration may be required instrument. after certain repairs are completed. These tests are in addition to the Preventive Maintenance tests. See NOTE: No fluid in set for mechanical leak test. -

Page 99: Test Run Mode

141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5.6.6 Test Run Mode The test run mode enables the instrument to run without fluid after being repaired. To run the instru- ment without fluid, perform the following: 2” Segment 1. Cut AccuSlide segment out of standard set. Leave 2 inches of tubing at the top and bottom. -

Page 100: Hard Pressure Cal Procedure

141345 FAA Page of 146 CORRECTIVE MAINTENANCE 5.6.7 Hard Pressure Cal Procedure front case using the case bosses for alignment. For a dual channel instrument, route the long 1. Ensure warmup of two hours minimum. ground wire into the corner of the case boss. 2. -

Page 101: Rate Calibration Procedure

182 to 214, return This procedure allows the rate calibration value to the instrument to ALARIS Medical Systems or replace the mechanism. be set for each mechanism, using a rate calibration a. -

Page 102: Table 5-2 Level Of Testing Guidelines

141345 FAA Page of 146 CORRECTIVE MAINTENANCE b. Use an IVAC Rate Calibration Set, P/N 70RCS. NOTE: The disposable set (70RCS) cannot be used for more than 40 rate accuracy verification runs (20 rate c. If the rate accuracy falls outside a 40 ml ±4% cal number changes). -

Page 103: Chapter 6 Troubleshooting

141345 FAA Page of 146 Chapter 6 — TROUBLESHOOTING WARNING: 6.1 Introduction Use extreme caution in servicing the instrument when connected to AC power. This chapter contains descriptions of possible Hazardous voltages are present when AC power is connected regardless of the setting of the power operating errors and technical problems that may be switch. -

Page 104: Table 6-1 Technical Troubleshooting Guide

141345 FAA Page of 146 TROUBLESHOOTING Table 6-1. Technical Troubleshooting Guide Problem Remedy Accuracy 1. Try new 70RCS Rate Cal set and repeat test a second time. Verification Fails 2. Check for mechanical damage and proper loading of administration set. 3. - Page 105 141345 FAA Page of 146 TROUBLESHOOTING Table 6-1. Technical Troubleshooting Guide (cont.) Problem Remedy No Power 1. Wait 15 seconds after connecting to AC power. 2. Check/replace battery. 3. Replace power supply board (AC off line switcher). 4. Replace key pad. 5.

-

Page 106: Error Messages

141345 FAA Page of 146 TROUBLESHOOTING 6.3 Error Messages The following hardware error messages can be generated by the instrument. These display messages indicate that the instrument has detected an internal malfunction. The battery manager error codes in Use these tables to diagnose and correct technical problems. Table 6-2. - Page 107 141345 FAA Page of 146 TROUBLESHOOTING Table 6-2. Error Messages (cont.) Message Probable Cause Remedy LCD TURNED OFF LCD Controller is off. 1. Replace LCD module. 2. Replace Main PCB. 3. Return to factory. LED CH TEST LED error. (Start-up) 1.

- Page 108 141345 FAA Page of 146 TROUBLESHOOTING Table 6-2. Error Messages (cont.) Message Probable Cause Remedy PRESSURE ERR Pressure sensor test (test pulse) failed. 1. Try another set. 2. Check for downstream occlusion. 3. Perform pressure cal (soft). 4. Perform pressure cal (hard). 5.

- Page 109 141345 FAA Page of 146 TROUBLESHOOTING Table 6-2. Error Messages (cont.) Message Probable Cause Remedy PERFORM TEMP CAL Channel requires temperature calibration. 1. Check TC=0 in Diagnostic Mode for 7100E/7200E or later. 2. Replace Main PCB. 3. Replace mechanism. 4. Return to factory. Vbackup HIGH VBKUP HIGH over 6.5 1.

-

Page 110: Table 6-3 Battery Manager Error Codes

141345 FAA Page of 146 TROUBLESHOOTING Table 6-3. Battery Manager Error Codes (not in Alarm History) Message Probable Cause Remedy ERR I - ROM CRC Battery manager code failure. 1. Replace Main PCB. 2. Return to factory. ERR 2 - RAM TEST Battery manager code failure. -

Page 111: Diagnostics Mode

141345 FAA Page of 146 TROUBLESHOOTING 6.4 Diagnostics Mode The Diagnostic Mode allows a hospital to manage POWER HOLD periodic preventive maintenance of the instrument and ® view the instrument’s history. It allows testing of functions and entry of the instrument’s ID number. For OPT PRI SEC KVO quick reference, a fold-out map of all diagnostic screens... -

Page 112: Setting Preventive Maintenance Interval

141345 FAA Page of 146 TROUBLESHOOTING 6.4.2 Setting Preventive Maintenance Interval OPTIONS The preventive maintenance reminder is a message that PM Setup appears upon start-up, telling the clinician that the History maintenance cycle has elapsed. The clinician may choose Set Time to bypass the message and operate the pump as normal. -

Page 113: Viewing Alarm Or Error History

141345 FAA Page of 146 TROUBLESHOOTING 6.4.3 Viewing Alarm or Error History (Event Log) OPTIONS History 1. From the D2 page, press the key. The PM Setup History Log will keep all major changes (1000) to the History pump in memory. Entry 01 will be the most recent Set Time and entry 1000(+) will be the oldest. - Page 114 141345 FAA Page of 146 TROUBLESHOOTING page 2. Pressing the soft key enables you to scroll OPTIONS forwards and backwards to the next event screen. 08 Misc. Inst. (Events are listed on a last in, first out basis.) Jun 4, 1997 14:30 return 3.

-

Page 115: Viewing Battery Status

141345 FAA Page of 146 TROUBLESHOOTING OPTIONS 6.4.5 Viewing Battery Status PM Setup Battery Status 1. On the D2 page, press the soft History key. Voltage may range from 10V to 18V. Ampere- Set Time hours may range from 0.0 to 3.0. Battery Status <... -

Page 116: Viewing Dc Voltages

141345 FAA Page of 146 TROUBLESHOOTING OPTIONS 6.4.7 Viewing DC Voltages DC Voltages 1. Advance to the D3 page. Set ID Number Run Times DC Voltages 2. Press the soft key. Self-Check Timer return 3. Press the soft key to return to the D2 page. <... -

Page 117: Viewing Battery And Total Run Times

141345 FAA Page of 146 TROUBLESHOOTING OPTIONS 6.4.9 Viewing Battery and Total Run Times DC Voltages Run Times 1. On the D3 page, press the soft key. Set ID Number Run Times Clear Battery Time 2. Press the soft key to Self-Check Timer clear battery run time. - Page 118 141345 FAA Page of 146 TROUBLESHOOTING If a self-check due message appears, press continue to keep the instrument running. Ensure the instrument is on when the set is removed, wait one to two seconds, and then power off. If the instrument is powered off without following this sequence of steps, it will not run on the Self Check next power up.

-

Page 119: Viewing Rate Calibration Information

141345 FAA Page of 146 TROUBLESHOOTING OPTIONS 6.4.12 Viewing Rate Calibration Information Test A Sensors This page is for viewing only. Use the following procedure A Rate to verify the Cal # setting. Test B Sensors 1. Advance to the D4 page. B Rate Cal A Rate Cal B Rate... -

Page 120: Testing Aux (Lower) Lcd

141345 FAA Page of 146 TROUBLESHOOTING 6.4.14 Testing Aux (Lower) LCD OPTIONS Test Aux. LCD 1. On the D5 page, press the soft Test Main LCD key. Test Aux. LCD • This tests the Lower LCD Display, lighting all Test Switches segments of the display. -

Page 121: Changing Main Lcd Contrast

141345 FAA Page of 146 TROUBLESHOOTING OPTIONS 6.4.16 Changing Main LCD Contrast Test Main LCD Main LCD 1. On the D5 page, press the Test Aux. LCD Contrast soft key. Test Switches 2. Press the soft key next to the contrast number to Main LCD Contrast highlight. - Page 122 FAIL ZERO LOW/HIGH LIMIT • — Pressure reading seen by ADC out of range. Retry soft pressure cal, perform hard cal, or return to ALARIS Medical Systems for repair or replace mechanism. FAIL ZERO LOW/HIGH RANGE • — Pressure reading outside relative limits. Retry soft pressure cal, perform hard cal, or return to ALARIS Medical Systems for repair, or replace mechanism.

-

Page 123: Viewing Temperature Calibration Information

141345 FAA Page of 146 TROUBLESHOOTING 5. Additional self-check information may also be OPTIONS viewed. Calibrate Pressure a. Press the sensor reading soft key. 0mmHg=1100 Pass Pass will be displayed. Press the soft key again. 500mmHg=2400 Pass • Three numbers will appear in the lower portion of Sensor=+001 Pass the display. - Page 124 141345 FAA Page of 146 TROUBLESHOOTING 3. Four numbers will appear in the lower portion of OPTIONS the display. Temperature Cal • The number on the left represents the Vbridge Measured Tc = ---- value in ADC counts at the last soft pressure Selected Tc = 0.0 cal.

-

Page 125: Configuring Pressure System Auto Zero

141345 FAA Page of 146 TROUBLESHOOTING 6.4.19 Configuring Pressure System Auto Zero OPTIONS 1. Press upper left soft key to access Auto Zero option. Pressure System 2. Press bottom center soft key to access other screens in Diagnostics Mode. 3. Press Auto Zero soft key to highlight settings. Press Auto Zero soft key again to change between “... - Page 126 141345 FAA Page of 146 DIAGNOSTICS OPTIONS OPTIONS OPTIONS OPTIONS OPTIONS OPTIONS OPTIONS DC Voltages PM Setup Test Main LCD Cal A Pressure DIAGNOSTICS MODE Test A Sensors Pressure System Adjust A Tc ID No. : 987654321 1 History Set ID Number Test Aux.

- Page 127 Parts Ordering: • ALARIS Medical Systems designed and built parts. Address: ALARIS Medical Systems, Inc. • ALARIS Medical Systems procured parts built by an Attn: Customer Service outside vendor. 10221 Wateridge Circle San Diego, California 92121...

- Page 128 141345 FAA Page 132 of 146 ILLUSTRATED PARTS BREAKDOWN Start-Up Kits and Other Parts Item Part Number Description* 139070 Kit, Start-Up, 7100G contains the following: (7100G only) Memory Assy, Rev. 2.06, or higher, Item 005 Main Keypad Assy, Item 040 Power Supply, Item 060 Battery Cable Interface, Item 61 LCD Module, Item 80 (lower)

-

Page 129: Case Assembly

141345 FAA Page 133 of 146 ILLUSTRATED PARTS BREAKDOWN Figure 7-1. Case Assembly Item Part Number Description* 141788 Battery Pack, Conditioned (7100F/G or 7200F/G)(7101A/7201A) 141496 Case Front, Single Channel (order keypad, labels and feet separately) 141498 Case Front, Dual Channel (order keypad, labels and feet separately) 141497 Case, Rear, Single Channel (order labels and feet separately) 141499... - Page 130 DOMESTIC ONLY Figure 7-1a Case Assembly, Single Channel IVAC Signature Edition™ Technical Service Manual ® ™ ™ M E D I C A L S Y S T E M S...

- Page 131 DOMESTIC ONLY Figure 7-1b Case Assembly, Dual Channel IVAC ® Signature Edition™ Technical Service Manual ™ ™ M E D I C A L S Y S T E M S...

-

Page 132: Front Case Assembly

141777 FAA Page 142 of 150 ILLUSTRATED PARTS BREAKDOWN Figure 7-2. Front Case Assembly Item Part Number Description* 142215** Memory Assembly, Single Channel, (Rev. 2.44 or higher) 142216** Memory Assembly, Dual Channel, (Rev. 2.44 or higher) 141428 Main Keypad Assembly, Single Channel (7100X) 141429 Main Keypad Assembly, Dual Channel (7200X) 141426... - Page 133 Figure 7-2a Front Case Assembly, Single Channel IVAC ® Signature Edition™ Technical Service Manual 7-11 ™ ™ M E D I C A L S Y S T E M S...

- Page 134 Figure 7-2b Front Case Assembly, Dual Channel 7-13 IVAC ® Signature Edition™ Technical Service Manual ™ ™ M E D I C A L S Y S T E M S...

-

Page 135: Rear Case Assembly

141345 FAA Page 139 of 146 ILLUSTRATED PARTS BREAKDOWN Figure 7-3. Rear Case Assembly Item Part Number Description* 141917 RS-232 Board Assembly with Nurse Call (7100X/7200X) 136593 Isolated RS-232 Board Assembly (7101X/7201X) 141189 ECD Board (Discriminator Board)(7101X/7201X and 7100X/7200X with Flow Sensor Kit added) 140077 Panel Lock Keypad 141371... - Page 136 Figure 7-3a Rear Case Assembly, Single Channel 7-17 ™ ™ IVAC® Signature Edition™ Technical Service Manual M E D I C A L S Y S T E M S...

- Page 137 Figure 7-3b Rear Case Assembly, Dual Channel 7-19 IVAC ® Signature Edition™ Technical Service Manual...

- Page 138 § QC Seal § LABELS NOT SOLD. PLACED ON INSTRUMENT AT ALARIS Medical Systems ONLY NOTE: If model is not specified, the part can be used on all versions. * 7100X = 7100E, 7100F, 7100G 120V VERSION; 7101X = 7101A, 220V VERSION ** TO INSTALL FLOW SENSOR KIT, INSTRUMENT MUST HAVE REV.

- Page 139 141777 FAA Page of 14 Figure 7-4 Label/Literature Assembly 7-23 IVAC ® Signature Edition™ Technical Service Manual ™ ™ M E D I C A L S Y S T E M S...

- Page 140 141345 FAA Page of 146 ILLUSTRATED PARTS BREAKDOWN Figure 7-5. Item Part Number Description 139518 DCM Manual 139784 Foam top, Single Channel 139785 Foam Bottom, Single 139787 Box, Single and Dual Channel 139788 Foam Top, Dual Channel 139789 Foam Bottom, Dual Channel NOTE: If model is not specified, the part can be used on all versions.

Need help?

Do you have a question about the Signature IVAC 710 Series and is the answer not in the manual?

Questions and answers