Summary of Contents for Paccar PX-9

- Page 1 Ope ra t or s M a nua l ’ Ope ra t or’s M a nua l 2021 Emissions 2022 Model Year Warranty...

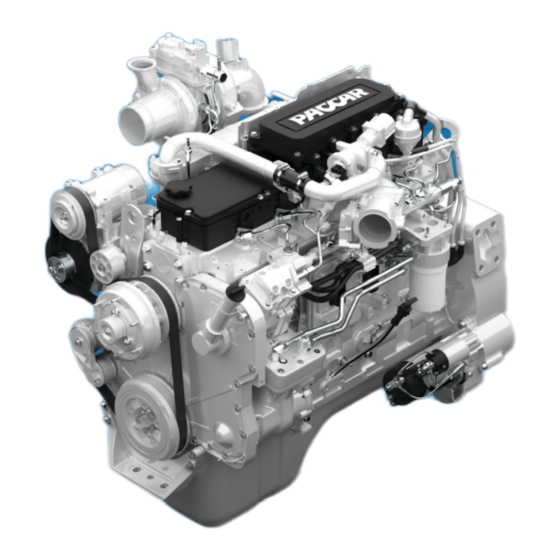

- Page 3 PX Operator Manual PACCAR PX-9 Engine...

- Page 5 Contents Engine Operation........Engine Maintenance........Engine Warranty........

- Page 6 The information contained in this manual is proprietary to PACCAR. Reproduction, in whole or in part, by any means is strictly prohibited without prior written authorization from PACCAR Inc.

- Page 7 ENGINE OPERATION - Chapter 1 | ENGINE OPERATION Safety - Introduction..........................5 Emergency - What To Do If......................... 10 Operating Instructions......................... 13 Y53-1185-1J1 (10/21)

- Page 8 PACCAR dealer. Kenworth This manual contains useful information for Therefore, you should pay careful attention Truck Company reserves the right to make...

- Page 9 WARNING damage. this manual are based on information in effect at the time of printing. PACCAR Hot engine oil can be dangerous. You Notes reserves the right to make changes at any could be burned. Let the engine oil time without obligation.

- Page 10 ENGINE OPERATION - Safety - Introduction Before performing any repair, read and loose tools, parts, ignition sources understand all of the safety precautions and hazardous substances. NOTE and warnings. The following is a list of • Wear protective glasses and general safety precautions that must be protective shoes when working.

- Page 11 ENGINE OPERATION - Safety - Introduction • Before removing or disconnecting • Corrosion inhibitors and lubricating any lines, fittings, or related items, oils may contain alkali. DO NOT WARNING relieve all pressure in the air, oil, get the substance in eyes and fuel, and cooling systems.

- Page 12 State of California to cause cancer. service work. Use only genuine Always wear protective clothing • DO NOT connect the jump starting replacement parts from PACCAR. and eye protection when handling or battery charging cables to any the catalyst assembly. Dispose of •...

- Page 13 Open 24 hours a day, 365 days a year, call toll-free to talk to someone at the PACCAR • Provides these services for FREE. For engines with the engine-protection...

- Page 14 If the oil pressure fails to rise within Add oil if necessary. If the problem 10 seconds after the engine starts, persists, contact an authorized stop the engine and determine the PACCAR engine dealer as soon as cause. possible. • See Engine Oil Specification for the...

- Page 15 ENGINE OPERATION - Emergency - What To Do If seconds from expiring, the ECM begins flashing the check engine warning lamp NOTE NOTE once per second. When the timer expires, the ECM will turn off the warning lamp and The system may also temporarily over- The instrument cluster gauges may shut down the engine.

- Page 16 ENGINE OPERATION - Operating Instructions or if you see any steam or coolant es- This allows the engine to cool WARNING caping. Always remove the cap very gradually and uniformly. slowly and carefully. Be ready to back If overheating came from severe To reduce the chance of personal in- off if any steam or coolant begins to operating conditions, the...

- Page 17 ENGINE OPERATION - Operating Instructions Engine, Check Engine WARNING CAUTION If the Stop Engine warning lamp illumi- The installation of electronic devices to nates, it means you have a serious en- the On Board Diagnostics (OBD) con- gine system problem. This should be nector, the vehicle Controller Area Net- considered an emergency.

- Page 18 ENGINE OPERATION - Operating Instructions (HEST), diesel particulate filter (DPF), and State Condition and Actions Diesel Exhaust Fluid (DEF) warning lights. DPF Warning Light States The EAS will further derate the engine. The DPF can no longer be NOTE State Condition and Actions regenerated and must now be removed and cleaned.

- Page 19 ENGINE OPERATION - Operating Instructions High Exhaust System Temperature During a regeneration, some EAS plosion and cause serious injury to by- components can reach temperatures (HEST) standers. greater than 1202°F (650°C). Therefore, it is important to WARNING Pay attention to the HEST warnings prior to, during, and immediately When the High Exhaust System Tem- following a regeneration.

- Page 20 An engine compression brake is standard trailer. Failure to comply may result in the ambient temperature. The lower on the PX-9 engines. Optionally, this death, personal injury, equipment, or the ambient temperature, the longer engine may be equipped with an exhaust property damage.

- Page 21 ENGINE OPERATION - Operating Instructions The brake switch is located on the could cause severe damage to the en- accessory dash panel. It controls whether WARNING gine. Idle the engine four minutes at the brake is ON (ready to slow the vehicle approximately 1,000 rpm to warm the down) or OFF (no braking action).

- Page 22 ENGINE OPERATION - Operating Instructions This feature, if the vehicle is equipped, service information or contact a Cummins® erned speed causes additional strain allows the VGT to act as an exhaust brake. Authorized Repair Location. on valve train and internal engine com- An engine exhaust brake retards the speed ponents.

- Page 23 ENGINE OPERATION - Operating Instructions Engine Compression Brake Level Engaging conditions for the engine Switch Operation compression brake: NOTE For the three-position engine compression • Engine speed must be above 1,000 brake level switch, there will be 100 rpm. Typically, on vehicles equipped with percent engine braking when the switch is •...

- Page 24 Follow the daily maintenance checks listed Engine Maintenance on page 35. The new PACCAR engine associated with this manual does not require a “break-in” procedure. This section of the manual Y53-1185-1J1 (10/21)

- Page 25 ENGINE OPERATION - Operating Instructions Engine Operation Symbols NOTE If the engine is running, increase en- gine speed (rpm) or operate the vehi- cle until the low oil pressure warning High exhaust system temperature (HEST); lamp turns off. amber in color. Check engine lamp;...

- Page 26 (N). PACCAR recommends the installation of DO NOT operate your vehicle in an For automatic transmissions that an air intake shutoff device or a similar...

- Page 27 ENGINE OPERATION - Operating Instructions starter motor to cool, then try stances should external heat staring the engine again. WARNING source be applied directly or indirectly Once the engine has started, wait to the lubricating oil pan. for the oil pressure to rise, and the Do not use starting fluids with this en- low oil pressure warning lamp to If you have not already, begin by...

- Page 28 ENGINE OPERATION - Operating Instructions During cold weather, the use of winter fuel blends can significantly improve the ease CAUTION of starting performance, and overall dependability of your vehicle. Winter fuel The use of starting aids, such as ether, blends are designed to reduce wax gelling may result in damage to the engine in the fuel filter and lines.

- Page 29 ENGINE OPERATION - Operating Instructions Manual Transmission Variable Idle Engine Operating Range PACCAR engines are designed to operate Control at full throttle under momentary conditions Proper Engine Operating Range down to peak torque engine speed. This is consistent with recommended operating NOTE practices.

- Page 30 Long periods of idle-time (3 hours or more) PACCAR engines, an idle shutdown damage. may accelerate the build-up of soot in the feature can be programmed to shut...

- Page 31 Locate the accessory receiving electronically controlled fuel system. Under away from the cylinder head, valves, antenna further away. these conditions, PACCAR is not liable for pistons, cylinder liners, turbocharger, and Check with the accessory supplier any performance problems with either the bearings.

- Page 32 ENGINE OPERATION - Operating Instructions • Determine the optimum Remove Foot from Accelerator personal injury, equipment or property antenna location by obtaining damage. antenna reflective energy data measurements. • Ensure that the optimum WARNING antenna type and mounting arrangement is being used. DO NOT operate the engine compres- •...

- Page 33 ENGINE OPERATION - Operating Instructions the three-position selector switch in the Do Not Exceed Governed Engine Speed "HI" position. CAUTION 40 50 40 50 Operating on Grades and Dry The engine ECM maintains a record of Pavement 2100 2300 maximum rpm. Exceeding the maxi- mum rpm will be considered driver WARNING abuse and will affect the engine war-...

- Page 34 ENGINE OPERATION - Operating Instructions Slow Down Around Curves on valve train and internal engine com- WARNING ponents. Operate the engine within governed engine speed. DO NOT operate the engine compres- sion brake or exhaust brake when driv- NOTE ing/operating your vehicle bobtail or with a loaded or unloaded trailer on road surfaces with poor traction (wet, After you have determined what the...

- Page 35 ENGINE OPERATION - Operating Instructions Tips for Operation on Slick Roads drivetrain. Use the service brakes for quick stops. NOTE WARNING Braking Truck on Grade The longer or steeper the hill, the more To reduce the possibility of personal important it is to use your engine injury or property damage, always al- brake.

- Page 36 ENGINE OPERATION - Operating Instructions two-position selector switch to the “LOW” position and activate the engine WARNING compression brake or exhaust brake by switching the “ON/OFF” switch to the “ON” DO NOT use the vehicle’s engine position. If the vehicle’s drive wheels begin compression brake or exhaust brake in to skid or there is a fishtailing motion, any situation that requires an immedi-...

-

Page 37: Table Of Contents

ENGINE MAINTENANCE - Chapter 2 | ENGINE MAINTENANCE Maintenance Requirements........................ 35 Maintenance Schedule Intervals......................38 Preventative Maintenance Schedule....................39 Engine Specifications..........................42 Engine Lubricating Oil Recommendations and Specifications............43 Engine Oil Capacities and Pressures....................45 Engine Lubrication and Filter Intervals....................46 Cooling System Maintenance......................48 Engine Coolant Specifications...................... -

Page 38: Chapter 2 | Engine Maintenance

PACCAR Inc, refer to the component the cab. Entry of carbon monoxide into manufacturer's maintenance the cab is also possible from other ve- recommendations. - Page 39 ENGINE MAINTENANCE - Maintenance Requirements Fuel Filter / Water Separator When operating the engine, listen This procedure should be followed as part for any unusual system noises CAUTION which can indicate service is of daily and refueling maintenance checks. required. Drain trapped water (if equipped).

- Page 40 ENGINE MAINTENANCE - Maintenance Requirements How to Drain Moisture from Air cooling system may result in cooling Tank NOTE system plugging and overheating problems. Locate the various air tanks on the This procedure should be followed as part The pressure cap (on the rear-top of vehicle of daily and refueling maintenance checks.

-

Page 41: Maintenance Schedule Intervals

12,000 15,000 24,000 30,000 48,000 1,000 12 (1 year) 60,000 96,000 2,000 24 (2 years) 150,000 241,500 4,500 48 (4 years) 200,000 321,500 6,000 PX-9 SEVERE DUTY Maintenance Intervals Maintenance Interval Miles Kilometers Hours 3,500 6,000 7,000 11,000 Y53-1185-1J1 (10/21) -

Page 42: Preventative Maintenance Schedule

NOTE time found in the following schedules maintenance tasks and intervals that by one half (50%). should be performed for PACCAR PX Due to the design of the crankcase series engines. ventilation module, routine service of Perform maintenance at whichever interval NOTE this component is not required. - Page 43 ENGINE MAINTENANCE - Preventative Maintenance Schedule PX-9 Preventative Maintenance Schedule Maintenance Task Recommended Component Preventative Maintenance Interval Emissions Components Diesel Particulate Filter (DPF) - Clean • Diesel Exhaust Fluid (DEF) Filter Access on page 69 - • Replace Exhaust System - Check for Leaks •...

- Page 44 ENGINE MAINTENANCE - Preventative Maintenance Schedule Maintenance Task Recommended Component Preventative Maintenance Interval Cooling System on page 65 - Check • Coolant/Antifreeze Condition on page 66 • Radiator Hoses Radiator Pressure Cap - Check • Change Extended Life Coolant on page 51 •...

-

Page 45: Engine Specifications

This work should be performed by a Cummins® authorized service facility. Engine Specifications PACCAR PX-9 Horsepower See the EPA label on top of the front timing gear cover. -

Page 46: Engine Lubricating Oil Recommendations And Specifications

Filter Specifications CAUTION life due to factors such as corrosion, PACCAR is not responsible for problems deposits, and wear. caused by non-genuine filters that do not Use of non-genuine PACCAR oil filters See "Engine Lubrication and Filter meet PACCAR performance or durability can cause severe engine damage. - Page 47 New Engine Break-in Oils • 0W-40, 0W-30 synthetic oils that meet CK-4 certification can be PACCAR does not approve the use of For severe duty applications the use used in operations where the special “break-in” engine lubricating oils for of 15W-40 is advised.

-

Page 48: Engine Oil Capacities And Pressures

The use of a synthetic-base oil does Aftermarket Oil Additive Usage Pressures not justify extended oil change inter- PACCAR does not recommend the use of aftermarket oil additives. Today's high- Engine Oil Capacity and Acceptable Pressures PACCAR PX-9 At Low Idle (minimum allowable) -

Page 49: Engine Lubrication And Filter Intervals

ENGINE MAINTENANCE - Engine Lubrication and Filter Intervals Lubricating oil filter capacity 4 qts. (3.8 liters) Pan only 16-20 qts. (15.1-18.9 liters) Standard oil pan Lubricating oil capacity, low to Cylinder block stiffener plate 19-23 qts. (18-21.8 liters) high (U.S. qts.) High capacity oil pan 20-24 qts. - Page 50 If the type/oil capacity of each lubricat- rates, regardless of the drain ing oil pan is not known: interval. • Contact a PACCAR Inc. Author- • Maintaining the correct oil and filter ized Repair Location change interval is a vital factor in •...

-

Page 51: Cooling System Maintenance

(quickserve.cummins.com) or for ISX and PX engines, and MAT74002 for to freezing, boiling, corrosion, pitted call 1-800-CUMMINS PACCAR MX-11 and MX-13 engine cylinder liners. This information is (1-800-286-6467) requirements. Maintaining coolant found in the engine manufacturers chemistry and freeze protection is critical to owner’s manual. - Page 52 ENGINE MAINTENANCE - Cooling System Maintenance corrosion protection. If you are concerned volume (a 60:40 coolant mixture). The about possible coolant quality, NOTE minimum recommended concentration contamination, or mechanical problems, is 40%. submit a coolant sample for analysis. Coolant is harmful to the environment. Improper maintenance may cause coolant Unused coolant must be stored as a degradation and could result in damage to...

-

Page 53: Engine Coolant Specifications

36. Level CAUTION Engine Coolant Specifications for CAUTION PACCAR PX-9 The use of sealing additives or soluble oils in the cooling system can cause When adding coolant, avoid mixing dif- damage to the engine. These additives Coolant Capacity 16.5 qt (15.6 liters) -

Page 54: Extended Life Coolant

Coolant volumes are dependent on for ISX and PX engines, and MAT74002 for overheat, and corrosion protection. chassis model and cab/sleeper heater PACCAR MX-11 and MX-13 engine The use of supplemental coolant options. requirements. Maintaining coolant additives (SCAs) is not... -

Page 55: Fuel Recommendations

ENGINE MAINTENANCE - Fuel Recommendations hicle. Failure to comply may result in may result in equipment or property Fuel Recommendations equipment or property damage. damage. WARNING CAUTION CAUTION The use of diesel fuel that has been Unapproved fuel can reduce economy DO NOT use high-sulfur diesel fuel as mixed with other fuels may cause an or possibly damage fuel system com-... -

Page 56: Warranty And The Use Of Biodiesel Fuel

If ultra-low-sulfur diesel (ULSD) fuel is recommended cetane number can cause not used, the engine may not meet PACCAR Inc. approves the use of hard starting instability, and excessive emission regulations, and damage biodiesel fuel blends up to 20 percent by white smoke. -

Page 57: Recommendations To Avoid Fuel Gelling

Recommendations and are not considered as defects of parts or workmanship by PACCAR and therefore Specifications To avoid fuel gelling in cold weather: will not be covered by the PACCAR engine warranty. • Use appropriate fuel grade/blend PACCAR recommends that customers... - Page 58 CAUTION recommended that the DEF used be certified by the American Petroleum Diesel Exhaust Fluid (DEF) contains PACCAR Inc requires the use of DEF Institute (API). urea. DO NOT get the substance in meeting ISO 22241-1 (DIN 70070) spec- your eyes. In case of contact, immedi- ifications.

-

Page 59: Maintenance Procedures

ENGINE MAINTENANCE - Maintenance Procedures dealers. For assistance locating Twist the dipstick handle to unlock DEF, contact your local PACCAR it, then pull the dipstick out of the Maintenance Procedures authorized repair location. holder. • If your vehicle is out of DEF and... - Page 60 If checking the engine oil just after stopping NOTE the engine, wait 15 minutes for the oil to Use of non-genuine PACCAR oil filters drain back into the oil pan before checking On the engine oil dipstick, the differ- can cause severe engine damage.

- Page 61 ENGINE MAINTENANCE - Maintenance Procedures sump is then used as a tool to remove the jury or damage. Always disconnect the primary sump plug. CAUTION battery at the negative terminal when performing service procedures. Failure WARNING to comply may result in death, person- Before beginning to remove and/or al injury or equipment damage.

- Page 62 ENGINE MAINTENANCE - Maintenance Procedures Oil filter Installation • Container that can hold at least 30 qt. (29 lt) of lubricating oil CAUTION Use clean engine oil to coat the gasket surface of the filter. Operate the engine until the coolant temperature reaches 60°C Mechanical overtightening can distort Fill the filter with clean engine oil.

- Page 63 Replace fuel filters with parts of the approximately 10 minutes to let the provides fine-particle filtration, water same part number. PACCAR periodi- oil drain from the upper parts of the separation, water-in-fuel sensing, 12V cally changes its filter design, and fil- engine.

- Page 64 ENGINE MAINTENANCE - Maintenance Procedures Biodiesel the system. The DEF system purges WARNING For information on alternative fuels, such to prevent damage from freezing. Fail- as biodiesel, and additional information for ure to comply may result in equipment fuel recommendations and specifications or property damage.

- Page 65 ENGINE MAINTENANCE - Maintenance Procedures Fuel Filter Installation Clean the fuel filter cap and Follow the steps below to install a new fuel surrounding area to ensure dirt CAUTION does not fall into the fuel module. filter: If clean fuel is available, pre-fill new DO NOT replace the engine oil filter filters, both pressure-side and CAUTION...

- Page 66 ENGINE MAINTENANCE - Maintenance Procedures Tighten the fuel filter another ¾ of a • A container that is safe to collect 1 NOTE turn after the gasket makes contact gallon of diesel fuel with the filter head. If the engine has been allowed to run out of Crank the engine in 15 second inter- If required, connect the wiring fuel or the fuel system has been serviced...

- Page 67 ENGINE MAINTENANCE - Maintenance Procedures To assist in fuel system priming is complete. It may be necessary to Shut the engine OFF and observe and removing air from the fuel repeat this process two or three the orificed diagnostic fuel line. system, an orificed diagnostic fuel times.

- Page 68 Handle coolant and antifreeze careful- make sure to flush the coolant system. maintenance interval. It ly. Ethylene glycol antifreeze is poison- Contact a PACCAR® Authorized Re- should have no cloudiness, floating ous. Store in original fluid container pair Location for flushing the coolant debris, or oils.

- Page 69 ENGINE MAINTENANCE - Maintenance Procedures Radiator Hoses using an ELC-specific test kit or concerned about possible coolant Perform these maintenance procedures test strips. quality, contamination, or mechanical according to the Preventative Maintenance problems, submit a coolant sample to Keep the cooling system full by Schedule.

- Page 70 ENGINE MAINTENANCE - Maintenance Procedures Engine Accessory Drive Belts • Solid line = Belt route with Air Conditioning • Dashed line = Belt route without Air Conditioning HVAC Compressor Idler Fan Hub Engine Crank Pulley Tensioner Arm and Pulley Water Pump Alternator Engine Belt Checks •...

- Page 71 ENGINE MAINTENANCE - Maintenance Procedures • Frayed or exposed belt threads • Tensioner maintains proper belt After removing the belt, carefully tension allow the belt tensioner to spring • Signs of animal activity - gnaw back to the stop (if it had not been marks temporarily blocked).

- Page 72 ENGINE MAINTENANCE - Maintenance Procedures Diesel Exhaust Fluid (DEF) Filter then allow the tensioner to spring Reinstall fan blade using NEW back to its normal position. 5/16-18 UNC-2A on Horton fans, or Access 3/8-24UNF-2A on Borg-Warner Perform these maintenance procedures fans, with nylon patch lock nuts.

- Page 73 ENGINE MAINTENANCE - Maintenance Procedures Charging - Cranking System Replace the aftertreatment DEF • Check hose clamp torque. dosing unit (DEF module) filter Charge Air Piping Electrical Harness / Cables according to the maintenance Perform these maintenance procedures Perform these maintenance procedures schedule.

-

Page 74: Engine Identification

(PX-7) or on Check mount and leg for fractures, the front timing gear cover (PX-9). The breaks or deformation. Replace as engine EPA label must not be changed necessary. unless approved by PACCAR. - Page 75 ENGINE MAINTENANCE - Engine Identification Have the following engine data available when communicating with a PACCAR Authorized Repair Location: Date of manufacture Engine serial number (ESN) Engine model information Fuel rate Control parts list (CPL) Idle speed Valve lash Advertised horsepower and rpm rating...

- Page 76 ECM. The following information is found on Bosch data plate includes: the engine control module dataplate: • Pump serial number • ECM part number (PN) • PACCAR part number • ECM serial number (SN) • Factory code Data plate • ECM date code (DC) •...

- Page 77 ENGINE MAINTENANCE - Engine Identification PACCAR Engine Nomenclature Variable Geometry Turbocharger mation to assist in servicing or re- Dataplate The PACCAR engine nomenclature placement. provides the following information: PX-9 Horsepower rating Engine model The Holset® variable geometry Air Compressor Dataplate turbocharger (VGT) dataplate is located on the turbocharger inlet compressor housing.

- Page 78 ENGINE MAINTENANCE - Engine Identification Y53-1185-1J1 (10/21)

- Page 79 ENGINE WARRANTY - Chapter 3 | ENGINE WARRANTY United States and Canada Engine Warranty..................77 Y53-1185-1J1 (10/21)

- Page 80 This warranty applies to new PACCAR Emissions Systems Warranties on page when an engine repair is performed at the PX-9 engines sold and used in the United site of the failure. States or Canada and operated in on- Owner Responsibilities PACCAR and Owner highway applications with one exception –...

- Page 81 Failures of belts and hoses supplied by cargo damage, fines, all applicable taxes, limited to: damage due to accident; PACCAR are covered for the first year from all business costs and other losses operation without adequate coolants or the date of delivery of the engine to the first resulting from a warrantable failure.

- Page 82 FITNESS FOR A PARTICULAR This warranty applies to new PACCAR lubricants, filters, filter elements, or any PURPOSE. PX-9 engines sold and used in the United PACCAR AND THE SELLING DEALER other part which is considered a States or Canada and operated in fire SHALL NOT BE LIABLE FOR maintenance item.

- Page 83 3rd, 4th, and 5th recommended maintenance has been years of base engine warranty. The PACCAR will pay for all parts and labor performed. deductible will not be charged during the needed to repair the damage to the engine Before the expiration of the applicable first two years of the base engine warranty.

- Page 84 Failures of belts and hoses supplied by WEAROUT OF COVERED PARTS. limited to: damage due to accident; PACCAR are covered for the first year from THIS WARRANTY AND THE EMISSION WARRANTY SET FORTH HEREINAFTER operation without adequate coolants or...

- Page 85 PACCAR engines marketed dealer. Your vehicle contains air, fuel, and purchaser that the engine is designed, built by PACCAR that are used in the United electrical components that may affect and equipped so as to conform at the time...

- Page 86 ENGINE WARRANTY - United States and Canada Engine Warranty under the manufacturer’s warranty. are not covered by this warranty. PACCAR schedule or when the system indicates that PACCAR does not evaluate all aftermarket is not responsible for failures or damage...

- Page 87 ENGINE WARRANTY - United States and Canada Engine Warranty ATTORNEYS’ FEES; AND ANY by PACCAR. This is your emission control completed in a reasonable amount of time, LIABILITY YOU MAY HAVE IN RESPECT system defects warranty. not to exceed 30 days.

- Page 88 Diesel oxidation catalyst State of California emissions components • Camshaft • Diesel particulate filter (except for statement for the PACCAR PX-9 engine ash maintenance) • Camshaft valve lobe coverage. This list of emission control parts • Diesel particulate filter differential •...

- Page 89 System Component PACCAR will repair any of the emission to the PACCAR engine or OEM vehicle control parts found by PACCAR to be manufacturer’s original part may impair the •...

- Page 90 Replaced parts and paid invoices must be are not covered by this warranty. PACCAR other part which is considered a presented at an authorized PACCAR is not responsible for failures or damage maintenance item.

- Page 91 ENGINE WARRANTY - United States and Canada Engine Warranty DAMAGES INCLUDING, BUT NOT LIMITED TO: LOSS OF INCOME OR LOST PROFITS; ENGINE OR VEHICLE DOWNTIME; THIRD PARTY DAMAGE, INCLUDING DAMAGE OR LOSS TO OTHER ENGINES, VEHICLES OR PROPERTY, ATTACHMENTS, TRAILERS AND CARGO;...

- Page 92 ENGINE WARRANTY - United States and Canada Engine Warranty Y53-1185-1J1 (10/21)

- Page 93 Index Index Crankshaft - Vibration Damper Accessory Drive Additives to Cooling System Aftertreatment Exhaust Piping Diesel Exhaust Fluid Air Cleaner Diesel Exhaust Fluid (DEF) Lamp Air Compressor Diesel Exhaust Fluid filter access Air Intake Piping Diesel Fuel Antifreeze Drive Belts Driving Batteries, Cables, and Connections Belt Routing...

- Page 94 Engine Wait-To-Start Lamp Engine Warning Lamps Engine, Check Engine Engine, identification, PX, PX-7, PX-9, PX7, PX9, data, plate, ESN, serial, number, no, Maintenance Schedule Intervals Engine, identification, PX, PX-7, PX-9, PX7, PX9, horsepower, horse, power, hp, MIL, See Malfunction Indicator Light (MIL)

- Page 95 Index Remove Oil filter Replacing Emissions Related Parts Roadside Assistance Safety Alerts Starting Procedure After Extended Shutdown or Oil Change Stop Engine Lamp 10, Topping Up the Engine Oil ULSD Ultra-Low Sulfur Diesel Using this Manual Visual Inspection of Engine Warning Lights Diesel Particulate Filter (DPF) High Exhaust System Temperature (HEST)

- Page 96 Index...

- Page 97 WARNING Breathing diesel engine exhaust exposes you to chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. • Always start and operate the engine in a well-ventilated area. • If in an enclosed area, vent the exhaust to the outside. •...

Need help?

Do you have a question about the PX-9 and is the answer not in the manual?

Questions and answers