Summary of Contents for Paccar PX-9

- Page 1 Operator s Manual ’ Operator’s Manual 2017 Emissions 2016-2017 Model Years Warranty...

- Page 3 The information contained in this manual is proprietary to PACCAR. Reproduction, in whole or in part, by any means is strictly prohibited without prior written authorization from PACCAR Inc.

- Page 5 Contents Engine Operation........Engine Maintenance........Engine Warranty........

- Page 6 Contents...

- Page 7 Chapter 1 | ENGINE OPERATION In this Chapter: Safety - Introduction..........................6 Emergency - What To Do If........................10 Operating Instructions.......................... 15...

- Page 8 ENGINE OPERATION - Safety - Introduction indicate that in a cross-reference like this: (See Driver’s Check List on page xx). You NOTE Safety - Introduction won’t have to go searching for more information. Finally you’ll find a helpful After you’ve read this manual, it should Subject Index.

- Page 9 Hot engine oil can be dangerous. You effect at the time of printing. PACCAR could be burned. Let the engine oil reserves the right to make changes at any cool down before changing it.

- Page 10 ENGINE OPERATION - Safety - Introduction • Wear protective glasses and protective shoes when working. WARNING! NOTE • DO NOT wear loose-fitting or torn clothing. Tie back and/or tuck in Improper practices, carelessness, or Warranty information including the long hair. Remove all jewelry when ignoring any warnings may cause EPA and California Emission Warranty working.

- Page 11 ENGINE OPERATION - Safety - Introduction • Before removing or disconnecting • Corrosion inhibitors and lubricating any lines, fittings, or related items, oils may contain alkali. DO NOT get WARNING! relieve all pressure in the air, oil, the substance in eyes and avoid fuel, and cooling systems.

- Page 12 • DO NOT connect the jumper contact, immediately contact a service work. Use only genuine starting or battery charging cables physician. replacement parts from PACCAR. to any ignition or governor control wiring. This can cause electrical • Always use the same fastener part CAUTION damage to the ignition or governor.

- Page 13 For engines with the engine-protection shutdown feature enabled, the stop engine • The PACCAR Customer Center service is FREE. lamp will begin to flash 30 seconds before the engine automatically shuts down. The...

- Page 14 Stop Engine Lamp will come ON. shifting and parking brake regeneration or addition of diesel exhaust information.) fluid (DEF) is required. For PACCAR PX Engines, this icon may also illuminate if the 4. Turn OFF the engine. CAUTION crankcase breather element needs 5.

- Page 15 ENGINE OPERATION - Emergency - What To Do If if you have any other reason to suspect the engine coolant temperature engine may be overheating, DO NOT light, immediate action is re- CAUTION TURN OFF THE ENGINE unless a low quired to correct the condition.

- Page 16 An idle shutdown 4. Increase the engine speed to about steam by covering the cap with feature, available on PACCAR one-half of full operating speed, or a large, thick rag. DO NOT try engines, can be programmed to...

- Page 17 ENGINE OPERATION - Operating Instructions incorrect. Check the coolant level at is not permitted. Doing so can ad- must be serviced and the problem cor- the cooling module surge tank. versely affect vehicle performance rected before driving again. Failure to Check the coolant level after each trip and/or cause fault codes to be record- comply may result in death, personal...

- Page 18 ENGINE OPERATION - Operating Instructions safely driven. Vehicle should be serviced to Diesel Particulate Filter (DPF) correct the problem but the situation should Warning Lamp WARNING! not be considered an emergency. This warning symbol will appear when the Temperature of the tail pipe, exhaust DPF needs to be regenerated and then Malfunction Indicator Lamp pipe, the diesel particular filter (DPF) /...

- Page 19 An engine compression brake is standard DEF Warning Lamp in Instrument Cluster 2. DEF Gauge Warning Lamp on the PX-9 engines. Optionally, this The DEF lamp(s) will illuminate when the engine may be equipped with an exahust fluid in the DEF tank reaches a low level. If brake.

- Page 20 ENGINE OPERATION - Operating Instructions vehicle, nor is it an emergency brake. be interrupted if the ABS system de- WARNING! The engine compression brake only tects wheel-slip due to operation on helps the service brakes by using en- slippery surfaces. Do not operate the engine compres- gine back pressure to slow the drive- sion brake when driving/operating your...

- Page 21 ENGINE OPERATION - Operating Instructions 3. After the engine is started, warmed • Throttle sensor the engine if the compression brake up and you are ready to get under • Service brake pressure switch will not deactivate. Failure to comply way, turn the engine compression ®...

- Page 22 ENGINE OPERATION - Operating Instructions will engage to maintain the cruise set The new PACCAR engine associated with speed. this manual does not require a “break-in” procedure. This section of the manual Compression on\off provides all of the necessary information required for proper engine operation.

- Page 23 NOTE IT IS THE RESPONSIBILITY OF THE OWNER AND OPERATOR TO OPER- ATE THE VEHICLE IN A SAFE ENVI- PACCAR recommends the installation of Do Not Use Combustible Gas in Turbo RONMENT. an air intake shutoff device or a similar...

- Page 24 ENGINE OPERATION - Operating Instructions Allow the Wait to Start warning lamp to turned off. Engine, Wait To Start on page CAUTION Follow this engine starting procedure when Engaging the starter motor for more Diesel particulate filter (DPF) status the outside temperature is above 50° F than 30 seconds in any five minute pe- indicator;...

- Page 25 ENGINE OPERATION - Operating Instructions gauge fluctuation under certain until the engine coolant has reached source be applied directly or indirectly engine temperature conditions (both operating temperature. Do not let to the lubricating oil pan. warm and cold). This cycling the engine idle longer than operation is caused by the post-heat necessary.

- Page 26 ENGINE OPERATION - Operating Instructions Starting Procedure After Extended Proper Engine Operating Range Shutdown or Oil Change Guideline on starting the engine after prolonged shutdown or oil change. After extended shutdown or an oil change follow the Normal Starting Procedure page 22.

- Page 27 ENGINE OPERATION - Operating Instructions PACCAR engines are designed to operate shutting it off. You will greatly increase at full throttle under momentary conditions CAUTION its service life. down to peak torque engine speed. This is consistent with recommended operating...

- Page 28 Under 1. Locate the accessory receiving surface. You could lose control of the these conditions, PACCAR is not liable for antenna further away. vehicle and/or jackknife if the wheels any performance problems with either the 2.

- Page 29 ENGINE OPERATION - Operating Instructions Remove Foot from Accelerator the three-position selector switch in the "HI" position. WARNING! Operating on Grades and Dry Pavement Do not operate the engine compres- sion brake when driving/operating your Tips for driving on grades and dry roads. vehicle bobtail or with a loaded or un- loaded trailer on road surfaces with 40 50...

- Page 30 ENGINE OPERATION - Operating Instructions "Control speed" is the speed at which the erned speed causes additional strain forces pushing a vehicle down a grade are CAUTION on valve train and internal engine com- equal to the forces holding it back. ponents.

- Page 31 ENGINE OPERATION - Operating Instructions Vehicle service brakes must be used when Braking Truck on Grade additional braking power is required. NOTE Slow Down Around Curves The longer or steeper the hill, the more important it is to use your engine brakes.

- Page 32 ENGINE OPERATION - Operating Instructions Tips for Operation on Slick Roads When driving on slick roads, start with the “ON/OFF” switch in the “OFF” position and the two-position selector switch in the WARNING! “LOW” position. If your tractor is equipped with a twin-screw rear axle, position the power divider switch in the “unlocked”...

- Page 33 Chapter 2 | ENGINE MAINTENANCE In this Chapter: Maintenance Requirements......................... 33 Maintenance Schedule Intervals......................36 Preventative Maintenance Schedule....................37 Engine Specifications...........................40 Engine Lubricating Oil Recommendations and Specifications.............41 Engine Oil Specifications........................43 Engine Lubrication and Filter Intervals....................44 Cooling System Maintenance......................45 Engine Coolant Specifications......................48 Extended Life Coolant..........................48 Fuel Recommendations........................

- Page 34 ENGINE MAINTENANCE - Maintenance Procedures........................53 Engine Identification..........................64 Y53-1185-1D1 (09/16)

- Page 35 If your engine is equipped with a the cab is also possible from other ve- component or accessory not manufactured hicles nearby. Failure to properly main- by PACCAR Inc, refer to the component tain your vehicle could cause carbon Y53-1185-1D1 (09/16)

- Page 36 ENGINE MAINTENANCE - Maintenance Requirements 5. Worn or damaged belts How to Drain Moisture from Air Tank 6. Worn or damaged wiring harnesses page 35 CAUTION 7. Any change in system appearance Diesel Exhaust Fluid on page 36 8. Odor of fuel Do not direct water onto electrical 9.

- Page 37 ENGINE MAINTENANCE - Maintenance Requirements Air Intake Piping 2. Inspect for clearance to other 4. Check coolant level. It should be components. visible through the clear plastic Daily and refueling maintenance check for surge tank. Coolant Level engine air intake piping. 5.

- Page 38 ENGINE MAINTENANCE - Maintenance Schedule Intervals 4. Continue pulling until the air comes Operator’s Manual for DEF in- out free of water. formation. Diesel Exhaust Fluid Daily and refueling maintenance check of Maintenance Schedule diesel exhaust fluid (DEF). Intervals This procedure should be followed as part of daily and refueling maintenance checks.

- Page 39 List of recommended maintenance tasks and intervals that should be performed for This maintenance schedule is for a Due to the design of the crankcase PACCAR PX series engines. normal duty cycle engine operation. ventilation module, routine service of Severe...

- Page 40 ENGINE MAINTENANCE - Preventative Maintenance Schedule Component Maintenance Task Recommended Preventative Maintenance Interval Exhaust System - Replace Flex Pipe(s) • Air System & Compressor Air Compressor on page 63 - Replace • Air Cleaner on page 63 • Charge Air System Charge Air Piping on page 63 •...

- Page 41 ENGINE MAINTENANCE - Preventative Maintenance Schedule Component Maintenance Task Recommended Preventative Maintenance Interval Crankshaft - Vibration Damper on page 64 - • Viscous Type Check Drive Belts Engine Belt Checks on page 60 • Fan Belt Tensioner on page 61 •...

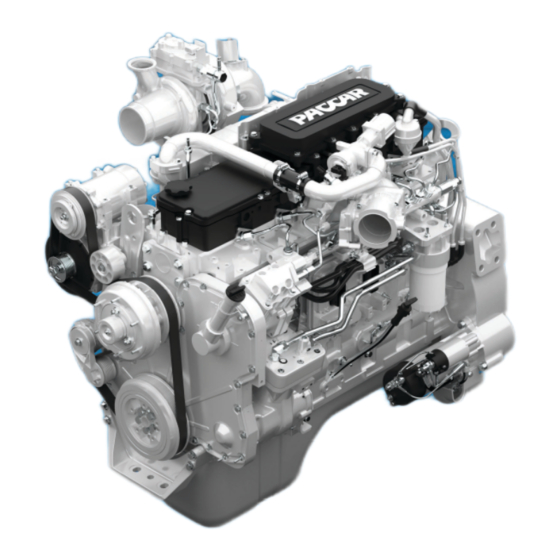

- Page 42 ENGINE MAINTENANCE - Engine Specifications Engine Specifications Engine specifications including horsepower, firing order, displacement, weight, and other engine characteristics. PACCAR PX-9 Horsepower See EPA Label on top of the valve cover or on the mixer manifold. Firing Order 1-5-3-6-2-4 Crankshaft Rotation (viewed from front of engine)

- Page 43 Engine Lubricating Oil Use of non-genuine filters. Recommendations and PACCAR is not responsible for problems The primary PACCAR recommendation is Specifications caused by non-genuine filters that do not for the use of SAE 10W-30 API CK-4 or...

- Page 44 New Engine Break-In Oils Additional information regarding lubricating oil availability throughout the world is PACCAR does not approve the use of available in the EMA Lubricating Oils Data special “break-in” engine lubricating oils for Book for Heavy-Duty Automotive and new or rebuilt PACCAR engines.

- Page 45 Aftermarket Oil Additive Usage characteristics that conform to the lubricant Engine Oil Specifications industry standards and are sufficient PACCAR does not recommend the use of protection when used according to the aftermarket oil additives. Today's high- recommendations. Aftermarket lubricating Engine oil system specifications.

- Page 46 ENGINE MAINTENANCE - Engine Lubrication and Filter Intervals with an hour meter use the last column in prolong the life of internal moving com- the table that fits the application or connect Engine Lubrication and ponents. Follow the oil and filter an electronic service tool.

- Page 47 ENGINE MAINTENANCE - Cooling System Maintenance Vehicles Average Kilometers Miles Hours Months Typical Speed Application(s) 10 to 15 mph 9,650 6,000 Cement Mixer Dump Truck Feedlot Truck Yard Spotter 15 to 20 mph 13,700 8,500 Cement Mixer Dump Truck Truck Crane 20 to 25 mph 16,900 10,500...

- Page 48 ENGINE MAINTENANCE - Cooling System Maintenance listed in the engine manufacturers WARNING! NOTE owner’s manual. Coolant is toxic. DO NOT get the fluid Maximum recommended ELC concen- NOTE in eyes. If contact occurs, flood eyes tration is 60% ELC and 40% water by with large amounts of water for 15 mi- volume (a 60/40 coolant mixture).

- Page 49 ENGINE MAINTENANCE - Cooling System Maintenance NOT add coolant extender to nitrite-free cooling system. The use of sealing ad- coolant. CAUTION ditives can: • Build up in coolant low-flow Coolant Mix Ratio Use of non-genuine coolant filters can areas. cause severe engine damage. •...

- Page 50 ASTM D6210 and Engine Coolant Specifications for Coolant volumes are dependent on Cummins CES 14439. The change interval PACCAR PX-9. chassis model and cab/ sleeper heater for nitrite free coolant is 600,000 miles options. (1,000,000 km) or 6 years, with no Coolant Capacity 16.5 qt (15.6 liters)

- Page 51 Coolant Suppliers Dirt or water in the fuel system can Using diesel fuels blended with lubri- Authorized PACCAR Engine dealer cause severe damage to both the fuel cants may cause damage to your ex- pump and the fuel injectors. Due to the haust aftertreatment system.

- Page 52 PACCAR recommends that the cetane meet emission regulations. Use only PACCAR is not responsible for failures number of diesel fuel be a minimum of ultra-low-sulfur diesel (ULSD) fuel. caused by the use of incorrect fuel, oil or...

- Page 53 Specifications Avoid Fuel Gelling workmanship by PACCAR and therefore will not be covered by the PACCAR engine Information to prevent fuel gelling. warranty. CAUTION • Use appropriate fuel grade/blend for PACCAR recommends that customers conditions.

- Page 54 CAUTION recommended that the DEF used be certified by the American Petroleum Diesel Exhaust Fluid (DEF) contains PACCAR Inc requires the use of DEF Institute (API). urea. Do not get the substance in your meeting ISO 22241-1 (DIN 70070) spec- eyes.

- Page 55 ENGINE MAINTENANCE - Maintenance Procedures dealers. For assistance locating This procedure should be followed as part DEF, contact your local PACCAR of routine maintenance checks. Maintenance Procedures authorized repair location. 1. Twist the dipstick handle to unlock • If your vehicle is out of DEF and you...

- Page 56 ENGINE MAINTENANCE - Maintenance Procedures Oil Level Indication on Dipstick Engine Oil Dip Stick Markings This procedure should be followed when oil level is low and more oil needs to be High and low marks on the dipstick indicate added. level of oil in the oil pan.

- Page 57 ENGINE MAINTENANCE - Maintenance Procedures 1. Disconnect the chassis battery disconnecting the battery clamps. DO cable at the negative battery CAUTION NOT place any tools or other materials terminal. on top of or close to the batteries. This 2. Place an oil collection pan directly can cause a dangerous high current Use of non-genuine oil filters can under the oil filter.

- Page 58 PX-7 and PX-9 extended until the oil drain interval. gine, as viewed from the driver's seat. Procedure for installing the PACCAR PX-7 or PX-9 fuel filter. Follow the steps below to install a new fuel filter:...

- Page 59 ENGINE MAINTENANCE - Maintenance Procedures 1. Verify the sealing O-ring that is the full time is required to fully prime the starter is engaged for longer supplied with the filter kit is installed the fuel system. Then tighten the than 20 seconds without starting, on the fuel filter cap and lightly coat knob by rotating it clockwise.

- Page 60 Store in original fluid container maintenance interval. It should be a Contact a PACCAR authorized repair only, and always keep out of the reach bright red with no signs of debris or location for flushing the coolant sys- of children.

- Page 61 ENGINE MAINTENANCE - Maintenance Procedures 50/50 blend, unless a different ratio 3. Clean the coolant filter and 2. Install the filter, rotating it clockwise of water/antifreeze has been surrounding area. until the sealing ring makes contact substituted (depending on operating with the filter housing.

- Page 62 CAUTION coolant through the surge tank fill signs of coolant leakage, con- neck. sult a PACCAR Service dealer. 3. Start the engine and idle at low Follow the procedure below to fill cool- RPM for 2 minutes. ant. Failure to follow this procedure and maintain proper coolant level can 4.

- Page 63 ENGINE MAINTENANCE - Maintenance Procedures • Alignment. 3. Place a flex-bar with a 15 mm 1. Place the new poly V-belt over the socket on the fastener securing the pulleys, making certain the belt falls Fan Belt Tensioner automatic belt tensioner's roller, as into all the belt pulley grooves.

- Page 64 ENGINE MAINTENANCE - Maintenance Procedures 4. Reconnect the electrical ground Medium and Large DEF Tank Rectangle DEF Tank Filter Access wire to the battery. Diesel Exhaust Fluid (DEF) Filter Maintenance tasks for diesel exhaust fluid filter Perform these maintenance procedures according to the Preventative Maintenance Schedule.

- Page 65 ENGINE MAINTENANCE - Maintenance Procedures 1. Check and correct for carbon • Hose/pipe condition – buildup. deterioration/signs of leaking. NOTE • Hose clamps for tightness. Air Intake System • Clearance to other components. The DPF clean/replace interval is based on the use of lubricating oils Charge Air Cooler Air Cleaner that meet the Cummins Engineering...

- Page 66 ENGINE MAINTENANCE - Engine Identification 1. Check the following electrical 1. If equipped with a rubber type CAUTION components: crankshaft damper, perform the following checks of vibration • Inspect for loose connections, damper. Do not re-torque or reuse exist- corrosion, chafing, and broken ing flange head bolts.

- Page 67 The engine dataplate must not be changed unless approved by X.XX X.XX PACCAR Inc. The dataplate is located on rocker lever cover as illustrated. The EPA label provides many details regarding the engine. Some facts that are Engine Identification...

- Page 68 ENGINE MAINTENANCE - Engine Identification Have the following engine data available when communicating with a PACCAR Authorized Repair Location: 1. Engine Serial Number (ESN) 2. Engine model information 3. Control Parts List (CPL) 4. Valve Lash 5. Horsepower and RPM rating...

- Page 69 ECM. The following information is found on Bosch dataplate includes: the engine control module dataplate: • Pump serial number • ECM part number (PN) • PACCAR part number • ECM serial number (SN) 1. Dataplate • Factory code • ECM date code (DC) 2.

- Page 70 ENGINE MAINTENANCE - Engine Identification PACCAR Engine Nomenclature • Date code NOTE Variable Geometry Turbocharger The PACCAR engine nomenclature provides the following information: Dataplate The electronic actuator on the VGT is a serviceable component and has a PX-9 separate dataplate that contains infor- mation to assist in servicing or re- placement.

- Page 71 Chapter 3 | ENGINE WARRANTY In this Chapter: United States and Canada Engine Warranty..................70...

- Page 72 This warranty applies to new PACCAR towing a vehicle disabled by a warrantable PX-9 engines sold and used in the United Additional coverage is outlined in failure to the nearest authorized repair States...

- Page 73 Limitations of engine warranty for standard Before the expiration of the applicable of maintenance of lubricating, cooling or applications. warranty, the owner must notify a PACCAR intake systems; improper storage, starting, authorized engine dealer or an authorized warm-up, run-in or shutdown practices;...

- Page 74 SHALL NOT BE LIABLE FOR This warranty applies to new PACCAR loss resulting from engine horsepower/ INCIDENTAL OR CONSEQUENTIAL PX-9 engines sold and used in the United torque upgrades. DAMAGES INCLUDING, BUT NOT States or Canada and operated in fire LIMITED TO: LOSS OF INCOME OR apparatus truck applications.

- Page 75 The owner is responsible for a $100 (U.S. recommended maintenance has been Dollars) deductible per each service visit PACCAR will pay for all parts and labor performed. under this plan in the 3rd, 4th, and 5th needed to repair the damage to the engine years of base engine warranty.

- Page 76 Failures of belts and hoses supplied by lubricants; overfueling; overspeeding; lack PACCAR are covered for the first year from Limitations of engine warranty for fire truck of maintenance of lubricating, cooling or the date of delivery of the engine to the first applications.

- Page 77 PERSONAL CONTENTS; of sale by PACCAR with all U.S. Federal United States includes American Samoa, the Commonwealth of Northern Mariana Islands, Guam, Puerto Rico, and the U.S. Virgin Islands.

- Page 78 NO OTHER WARRANTIES, EXPRESS parts that are not equivalent to the are not covered by this warranty. PACCAR OR IMPLIED. PACCAR EXPRESSLY PACCAR engine or OEM vehicle is not responsible for failures or damage DISCLAIMS ANY WARRANTY OF manufacturer’s original part may impair the...

- Page 79 Where a warrantable condition exists, telephone number provided with your PACCAR are pleased to explain the PACCAR will repair your engine at no cost vehicle operating instructions or the emission control system warranty on your to you including diagnosis, parts and labor.

- Page 80 • Diesel particulate filter (except for State of California emissions components ash maintenance) • Camshaft valve lobe statement for the PACCAR PX-9 engine • Diesel particulate filter differential • Clean idle sticker coverage. This list of emission control parts pressure sensor EGR may be covered by the Emission Control •...

- Page 81 Cummins replacement parts that are not equivalent • EGR differential pressure sensor Distributor using new or genuine PACCAR to the PACCAR engine or OEM vehicle approved rebuilt parts and assemblies. • EGR mixer/venturi manufacturer’s original part may impair the...

- Page 82 The accrued PACCAR is not responsible for the material warranted parts replaced and labor time, mileage, or hours is calculated when and labor costs of emission control parts...

- Page 83 ENGINE WARRANTY - United States and Canada Engine Warranty DAMAGES INCLUDING, BUT NOT LIMITED TO: LOSS OF INCOME OR LOST PROFITS; ENGINE OR VEHICLE DOWNTIME; THIRD PARTY DAMAGE, INCLUDING DAMAGE OR LOSS TO OTHER ENGINES, VEHICLES OR PROPERTY, ATTACHMENTS, TRAILERS AND CARGO;...

- Page 84 ENGINE WARRANTY - United States and Canada Engine Warranty Y53-1185-1D1 (09/16)

- Page 85 Index Index After Replacing Engine Oil Filter(s) Diesel Exhaust Fluid Aftertreatment Exhaust Piping Diesel Exhaust Fluid (DEF) filter Air Cleaner Diesel Exhaust Fluid (DEF) Lamp Air Compressor Diesel Particulate Filter (DPF) Air Intake Piping Diesel Particulate Filter (DPF) Warning Lamp Antifreeze Drive Belts Driving...

- Page 86 Index Engine, Check Engine Engine, Wait To Start Exhaust Brake Extended Life Coolant Normal Starting Procedure Fan Belt Tensioner Oil Filter Removal Preparation Forward Oil Level Indication on Dipstick Operating on Grades and Dry Pavement Fuel Filter Fuel Filter Installation Operating on Level and Dry Pavement Fuel Recommendations Operating the Engine...

- Page 87 Index Topping Up the Engine Oil Visual Inspection of Engine Warranty and the Use of Biodiesel Fuel...

- Page 88 Index...

- Page 90 PACRI Engines P.O . Box 1518 x 1518 Bellevue , WA 98009 A 98009 Y53-1185-1D1...

Need help?

Do you have a question about the PX-9 and is the answer not in the manual?

Questions and answers