Subscribe to Our Youtube Channel

Summary of Contents for Paccar MX-11

- Page 1 Operator s Manual ’ Operator’s Manual 2017 Emissions 2017-2018 Model Years Warranty...

-

Page 3: Operation

Contents Engine Operation........Engine Maintenance........Engine Warranty........ - Page 5 The information contained in this manual is proprietary to PACCAR. Reproduction, in whole or in part, by any means is strictly prohibited without prior written authorization from PACCAR Inc.

- Page 6 ENGINE OPERATION - Chapter 1 | ENGINE OPERATION In this Chapter: Safety - Introduction..........................5 Emergency - What To Do If......................... 10 Operating Instructions......................... 14 Y53-1166-1F1 (11/2017)

-

Page 7: Safety - Introduction

ENGINE OPERATION - Safety - Introduction indicate that in a cross-reference like this: (See Safety Alerts on page 5). You won’t Safety - Introduction NOTE have to go searching for more information. Finally you’ll find a helpful Subject Index. After you’ve read this manual, it should Using this Manual It’s in the back of the manual and be stored in the cab for convenient ref-... -

Page 8: Maintenance

PACCAR age. that is not safety related but should be reserves the right to make changes at any followed. -

Page 9: Warranty

Preventive Maintenance section. This will needed, we recommend using only help preserve your investment. genuine parts from PACCAR. Make sure your vehicle is in top working WARNING condition before heading out on the road, it NOTE is the responsible driver's duty to do so. - Page 10 ENGINE OPERATION - Safety - Introduction • Before beginning any repair, • Always use wheel chocks or proper • When moving or lifting any heavy disconnect the battery (negative [-] jack stands to support the vehicle equipment or parts, make sure to cable) and discharge any or vehicle components before use proper techniques and...

- Page 11 State of California to cause cancer. service work. Use only genuine or battery charging cables to any Always wear protective clothing replacement parts from PACCAR. ignition or governor control wiring. and eye protection when handling • Always use the same fastener part This can cause electrical damage the catalyst assembly.

-

Page 12: Emergency - What To Do If

Failure to assistance information. who can. comply may result in death, personal • The PACCAR Customer Center Call toll-free to talk to someone at the injury, equipment or property damage. service is FREE. PACCAR Customer Center: For engines with the engine-protection •... - Page 13 Add oil if necessary. If the problem • If the oil pressure fails to rise within persists, contact an authorized 10 seconds after the engine starts, PACCAR engine dealer as soon as stop the engine and determine the possible. cause. •...

- Page 14 ENGINE OPERATION - Emergency - What To Do If the check engine lamp is to warn the transmission in neutral (N) and set result in equipment or property dam- operator of an impending idle shutdown. the parking brake. Keep the engine age.

- Page 15 ENGINE OPERATION - Emergency - What To Do If Increase the engine speed to about atures can decrease engine tempera- WARNING one-half of full operating speed, or ture and could cause engine damage from inadequate lubrication. The nor- 1,100 to 1,200 rpm, maximum for 2 Removing the fill cap on a hot engine mal torsional vibrations generated can or 3 minutes.

-

Page 16: Operating Instructions

ENGINE OPERATION - Operating Instructions Stop Engine Lamp the engine automatically shuts down. The warning lamp alerts the operator to the Operating Instructions impending shutdown. The lamp will also illuminate when the DEF Engine Warning Lamps tank is almost empty or the soot level in the DPF is at full capacity. - Page 17 ENGINE OPERATION - Operating Instructions Malfunction Indicator Lamp Diesel Particulate Filter (DPF) Keep vehicle a safe distance from combustible items. Warning Lamp This warning symbol will appear when the DPF needs to be regenerated and then WARNING also during the regeneration cycle. This icon may also appear if the system is Temperature of the tail pipe, exhaust Illuminates when an engine emissions...

- Page 18 Information on using the engine braking result in death, personal injury, equip- system. ment or property damage. An engine compression brake is standard on the MX-11 engines. Optionally, this engine may be equipped with an exahust brake. When activated, these devices Y53-1166-1F1 (11/2017)

- Page 19 ENGINE OPERATION - Operating Instructions the brake is ON (ready to slow the vehicle warm the engine before activating the down) or OFF (no braking action). WARNING engine brakes. Do not use the engine compression brake to slow the vehicle down The service brakes must be used in an when you are bobtailing or pulling NOTE...

- Page 20 ENGINE OPERATION - Operating Instructions progressively stronger braking to slow the position there will be 33 percent engine vehicle down. braking. CAUTION Engine compression brake controls With the compression brake switch ON, the include: compression brake will be engaged when Operating the engine with a compres- the service brake is applied.

- Page 21 ENGINE OPERATION - Operating Instructions Driving Introduction and important information WARNING about operating your vehicle safely. Combustible vapors near the air intake Correct care of your engine will result in system could be ingested into the en- longer life, better performance, and more gine, causing the engine to suddenly economical operation.

- Page 22 ENGINE OPERATION - Operating Instructions Normal Starting Procedure Steps for starting the engine in normal NOTE temperatures. Follow this engine starting procedure when If the engine is running, do not in- Check engine lamp; yellow in color. the outside temperature is above 50° F crease engine speed (rpm) or operate (10°...

- Page 23 ENGINE OPERATION - Operating Instructions Has Run Dry or After Fuel System Service to allow the oil pressure to • Fuel dilution of the lubricating has been Performed on page 62 stabilize. oil. • Carbon buildup in the com- Cold Weather Starting bustion chamber.

- Page 24 This is electronically controlled fuel system. Under consistent with recommended operating NOTE these conditions, PACCAR is not liable for practices. any performance problems with either the DO NOT shut off the engine immedi- fuel system or the accessory. EMI is not ately.

- Page 25 (wet, icy, or snow cov- ered roads) or in heavy traffic. There Electronic components are required to Operating on Level and Dry may not be enough weight on the rear pass various PACCAR and industry EMI Pavement axle provide traction.

- Page 26 ENGINE OPERATION - Operating Instructions To reduce vehicle speed, put the engine pressure to slow the drive train. You surface. You could lose control of the brake ON/OFF switch in the "ON" position. must use the service brakes for quick vehicle and/or jackknife if the wheels Remove your foot from the accelerator or emergency stops.

- Page 27 ENGINE OPERATION - Operating Instructions The engine brake is NOT intended as the primary brake for the vehicle, nor is it an WARNING NOTE emergency brake. The engine brake only helps the service brakes by using pressure DO NOT use an exhaust brake when Once you have determined what the to slow the drivetrain.

- Page 28 ENGINE OPERATION - Operating Instructions Shift to a Lower Gear on Grade The operation of any vehicle is difficult to predict on slick roads. The first 10 to 15 WARNING minutes of rainfall are the most dangerous, 40 50 40 50 as road dirt and oil mixed with rain create a Do not drive with frequent or continu- very slippery surface.

- Page 29 ENGINE OPERATION - Operating Instructions using the retarding power of the engine alone and more braking power is required, switch the two-position selector switch to the “LOW” position and activate the engine brakes by switching the “ON/OFF” switch to the “ON” position. If the vehicle’s drive wheels begin to skid or there is a fishtailing motion, switch the “ON/OFF”...

-

Page 30: Table Of Contents

ENGINE MAINTENANCE - Chapter 2 | ENGINE MAINTENANCE In this Chapter: Maintenance Requirements........................ 29 Maintenance Schedule........................31 Engine Specifications..........................37 Engine Lubricating Oil Recommendations and Specifications............39 Engine Oil Specifications........................40 Engine Lubrication and Filter Intervals....................40 Cooling System Maintenance......................42 Engine Coolant Specifications......................45 Extended Life Coolant.........................45 Fuel Recommendations........................ -

Page 31: Maintenance Requirements

Engine Fuel Filter / Water Separator component or accessory not manufactured the cab is also possible from other ve- Daily and refueling maintenance check for by PACCAR Inc, refer to the component hicles nearby. Failure to properly main- the engine fuel filter/water separator. manufacturer's maintenance tain your vehicle could cause carbon recommendations. - Page 32 ENGINE MAINTENANCE - Maintenance Requirements Chassis Fuel Filter / Water Inspect for clearance to other system plugging and overheating Separator components (i.e. electrical problems. Daily and refueling maintenance check for harnesses, etc.). This procedure should be followed as part the chassis fuel filter/water separator. of daily and refueling maintenance checks.

-

Page 33: Maintenance Schedule

ENGINE MAINTENANCE - Maintenance Schedule Visual Inspection of Engine NOTE Daily and refueling visual check of engine. Maintenance Schedule This procedure should be followed as part The pressure cap (on the side of the of daily and refueling maintenance checks. Maintenance Schedule Intervals surge tank) should NEVER be re- Check for any signs of fluid leaks. - Page 34 ENGINE MAINTENANCE - Maintenance Schedule Maintenance Interval Miles Kilometers Hours Months 37,000 60,000 1,125 75,000 120,000 2,250 12 (1 year) 150,000 240,000 4,500 24 (2 years) 225,000 360,000 6,750 36 (3 years) 300,000 480,000 6,750 36 (3 years) 450,000 725,000 13,500 48 (4 years) 600,000...

- Page 35 ENGINE MAINTENANCE - Maintenance Schedule Maintenance Interval Miles Kilometers Hours Months 600,000 965,000 18,000 72 (6 years) 750,000 1,200,000 24,000 96 (8 years) Engine Maintenance Intervals - Severe Duty/Vocational Maintenance Interval Miles Kilometers Hours Months 15,000 24,000 30,000 48,000 12 (1 year) 60,000 96,000 1,600...

- Page 36 ENGINE MAINTENANCE - Maintenance Schedule Maintenance Interval Miles Kilometers Hours Months Vocational vehicle applications include: Agriculture, Concrete Mixers, Construction, Crane, Dumps, Emergency/Fire, Heavy Equipment, Loggers, Mining, Oil Field, Refuse, Pick-up & Delivery, Snowplows, and Wrecker. Preventative Maintenance Schedule List of recommended maintenance tasks NOTE NOTE and intervals that should be performed.

- Page 37 ENGINE MAINTENANCE - Maintenance Schedule Engine Maintenance Schedule Recommended Preventative Maintenance Interval Maintenance Task Component Aftertreatment System Diesel Particulate Filter (DPF) Dry Cleaning • on page 72 - Dry Cleaning Strategy Diesel Particulate Filter (DPF) Wet Cleaning on page 73 - Wet •...

- Page 38 ENGINE MAINTENANCE - Maintenance Schedule Recommended Preventative Maintenance Interval Maintenance Task Component Cooling System Coolant/Antifreeze Condition on page 64 • Radiator Hoses on page 65 • Replace Coolant Filter on page 65 • Change Extended Life Coolant on page • Crankshaft Crankshaft - Vibration Damper on page...

-

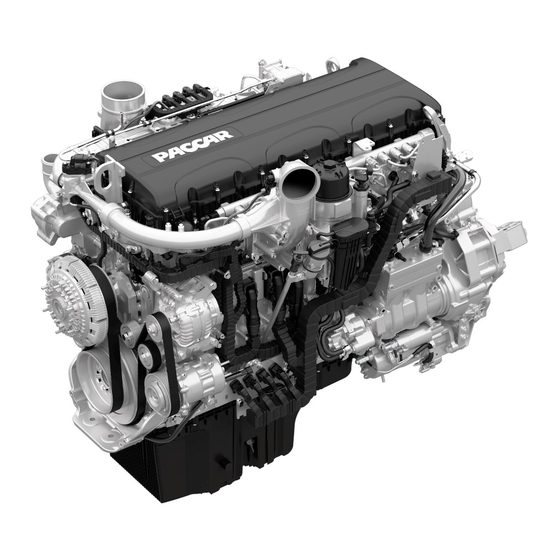

Page 39: Engine Specifications

Engine Specifications Engine specifications including horsepower, firing order, displacement, weight, and other engine characteristics. PACCAR MX-11 Engine Specifications Horsepower See EPA Label on top of the valve cover or on the mixer manifold. Firing Order 1, 5, 3, 6, 2, 4... - Page 40 REPTO Torque Limit (1 o’clock) 738 lb-ft (Max), 590 lb-ft (continuous) REPTO Torque Limit (11 o’clock) 184 lb-ft (continuous) PACCAR is not responsible for problems Contact your local PACCAR authorized caused by non-genuine filters that do not repair location for specific part numbers.

-

Page 41: Engine Lubricating Oil Recommendations And Specifications

New Engine Break-In Oils See Engine Lubrication and Filter Intervals PACCAR does not approve the use of to determine which oil drain interval to use special “break-in” engine lubricating oils for for an application. -

Page 42: Engine Oil Specifications

Aftermarket Oil Additive Usage These oils meet performance the engine. characteristics that conform to the lubricant PACCAR does not recommend the use of industry standards and are sufficient aftermarket oil additives. Today's high- Engine Oil Specifications protection when used according to the quality engine lubricating oils are very recommendations. - Page 43 ENGINE MAINTENANCE - Engine Lubrication and Filter Intervals will decrease the engine life due to ponents. Follow the oil and filter CAUTION factors such as corrosion, deposits, change intervals as recommended in and wear. Engine oil filters capture dirt this section of the manual. Failure to and remove deposits from the oil to comply may result in equipment or Extending the oil and filter change in-...

-

Page 44: Cooling System Maintenance

ENGINE MAINTENANCE - Cooling System Maintenance Engine Oil and Filter Change Intervals Vehicle Application Change Interval 75,000 miles (120,000 km) Normal Duty (Line Haul) - less than 20% idle time 2,250 hours or 12 months Normal Duty (Line Haul) - more than 20% 50,000 miles (80,000 km) idle time Oil Drain and Filter Replacement Interval... - Page 45 Avoid prolonged or repeated meets or exceeds all ASTM D6210 and contact with skin. In case of contact, Caterpillar EC-1 requirements. PACCAR immediately wash skin with soap and Coolant is harmful to the environment. recommends only using a 50/50 mixture of water.

- Page 46 ENGINE MAINTENANCE - Cooling System Maintenance Condition formulations. If the coolant is mixed with more than 25% of a different formulation, NOTE Perform a visual inspection of the coolant. engine corrosion damage could occur. If It should have no cloudiness or floating mixing exceeds 25% of total system debris.

-

Page 47: Engine Coolant Specifications

EGR system and oil cooler. The plug- (ELC). Engine Coolant Specifications for ging of the cooling system can hamper PACCAR MX-11 heat transfer, causing internal engine Perform these maintenance procedures damage. Do not use sealing additives according to the Preventative Maintenance or soluble oils in the cooling system. -

Page 48: Fuel Recommendations

The change interval for extended-life pump and the fuel injectors. Due to the coolant containing nitrite and molybdate is Authorized PACCAR Engine dealer precise tolerances of diesel injection 750,000 miles (1,200,000 km) or 12,000 systems, it is extremely important that... - Page 49 PACCAR requires all permissible fuels to will be reduced. DO NOT use diesel engine emission. ULSD fuel is re- have adequate fuel lubricity. Lubricity can...

-

Page 50: Warranty And The Use Of Biodiesel Fuel

Biodiesel information and warranty Information to prevent fuel gelling. workmanship by PACCAR and therefore precautions. will not be covered by the PACCAR engine • Use appropriate fuel grade/blend warranty. PACCAR Inc. approves the use of for conditions. -

Page 51: Maintenance Procedures

ENGINE MAINTENANCE - Maintenance Procedures • Only use the additive for the Check this carefully on a vehicle with air Reinstall the dipstick and twist to minimum time needed. suspension. lock it in place. Engine coolant should be at or above the •... - Page 52 ENGINE MAINTENANCE - Maintenance Procedures Oil Level Indication on Dipstick High oil level (1) Engine Oil Fill Location High and low marks on the dipstick indicate Low oil level (2) level of oil in the oil pan. Topping Up the Engine Oil Steps for topping up the engine oil.

- Page 53 ENGINE MAINTENANCE - Maintenance Procedures Oil Drain Plug for Composite Pan Oil Pan Drain Plug Installation • The plug/O-ring assembly is What to do after draining oil. damaged. • The retention detent cannot be felt After draining the oil, replace the drain plug during installation.

- Page 54 ENGINE MAINTENANCE - Maintenance Procedures Engine Oil Filter Always use quality engine lubricating oils in ure to comply may result in equipment conjunction with the appropriate oil drain Procedure for replacing engine oil filters. or property damage. and filter change intervals. Refer to the Oil Filter Module “Preventative Maintenance Schedule”...

- Page 55 Place an oil collection pan directly under the oil filter. Oil Filter Removal Procedure for removing the oil filter on PACCAR MX-11 engines. Clean the oil filter cap and surrounding area to ensure dirt does not fall into the oil filter module.

- Page 56 Remove the O-ring from the lower lock the full-flow oil filter in place. cap. Oil Filter Installation Remove the full-flow oil filter from Procedure for installing oil filter on the oil module. PACCAR MX-11 engines. Use the following procedure to install oil filters. Y53-1166-1F1 (11/2017)

- Page 57 ENGINE MAINTENANCE - Maintenance Procedures Install the new centrifugal oil filter Installing and Locking Cap Installing O-rings onto Screw Cap and Insert into Base element onto the centrifuge base. Installing Centrifugal Oil Filter into Base Lightly lubricate the new O-rings (1) with engine oil.

- Page 58 ENGINE MAINTENANCE - Maintenance Procedures After Replacing Engine Oil Filter(s) This engine may be equipped with a Non Serviceable CCV Procedure for what to do after installing servicable Crankcase Ventiflation Module new oil filters. (CCV). This emissions related component separates oil from air coming from the Follow the steps below after installing new crank case vent.

- Page 59 ENGINE MAINTENANCE - Maintenance Procedures Clean the CCV module and Serviceable CCV - MX-11, Front NOTE surrounding area to avoid dirt contaminating the module. Be careful when removing the CCV to prevent an oil spill. Oil may be present NOTE in the CCV-to-engine interface.

- Page 60 ENGINE MAINTENANCE - Maintenance Procedures Module on page 56 before proceeding with Housing housing, and wipe the two gasket disassembling the unit. grooves with a clean, lint-free rag. Motor Follow the steps below to disassemble the Properly dispose of the filter and Mounting Flange CCV to access to the replaceable filter and gaskets.

- Page 61 ENGINE MAINTENANCE - Maintenance Procedures CCV Motor/Filter Assembly Fit onto Shaft Turn to Slide Ensure Shaft Protrudes Install the new O-ring gasket on the position. When reinstalling motor, CCV Filter/Motor Installation motor and the new face gasket on ensure shaft and bottom bearing the CCV-to-engine interface of the are aligned (1).

- Page 62 ENGINE MAINTENANCE - Maintenance Procedures How to Install a CCV Unit to the death, personal injury, equipment or Engine NOTE property damage. Installation instructions for servicable Crankcase Ventilation (CCV) modules. The engine and fuel module should be Follow the steps below to install the CCV. NOTE operated in cold climates with accepta- Install the CCV module on the...

- Page 63 ENGINE MAINTENANCE - Maintenance Procedures Fuel Filter Removal Fuel Filter Installation - PACCAR Clean the fuel filter cap and MX-11 Procedure for removing the PACCAR surrounding area to ensure dirt Procedure for installing the PACCAR MX-11 fuel filter. does not fall into the fuel module.

- Page 64 ENGINE MAINTENANCE - Maintenance Procedures cap to 30 lb-ft (40 N·m) as (closed) position before starting the low the starting instructions below may specified on the filter cap. priming procedure. damage the starter motor. Fuel Filter Module - Priming Pump If vehicle is equipped with a fuel blending valve, rotate the valve to Fuel Filter Module - Priming Pump...

- Page 65 ENGINE MAINTENANCE - Maintenance Procedures Fuel Blending Valve CAUTION CAUTION Operate priming pump at a maximum If the engine is cranked excessively rate of 30 strokes per minute to pre- Starter Protection will be triggered and vent damage to pump. starter engagement will be restricted for 10 minutes.

- Page 66 Your engine may be equipped with a Contact a PACCAR authorized repair of children. Never remove the filler cap coolant filter designed to capture and...

- Page 67 ENGINE MAINTENANCE - Maintenance Procedures Checking Coolant Condition Coolant Shutoff Valve quality, contamination, or mechanical Recommended coolant checks. problems, submit a coolant sample to your dealer for analysis. Improper To ensure the Extended Life Coolant (ELC) maintenance may cause coolant deg- in your vehicle always provides maximum radation and could result in damage to protection, perform the following tests:...

- Page 68 ENGINE MAINTENANCE - Maintenance Procedures Clean the coolant filter and Coolant Filter Removal Apply a small amount of coolant to surrounding area. the sealing ring of the new coolant filter. A small amount of coolant could leak out when the filter is loosened. Install the filter, rotating it clockwise Use a suitable container to catch until the sealing ring makes contact...

- Page 69 Run engine at a higher idle until point) If the coolant frequently needs top- engine fan turns on and allow Pressure ping-up or there are any signs of cool- thermostat to open. cap (never ant leakage, consult a PACCAR Serv- ice dealer. Y53-1166-1F1 (11/2017)

- Page 70 ENGINE MAINTENANCE - Maintenance Procedures Drive Belts Maintenance checks and procedures for engine drive belts. Engine Belts Accessory Belt Fan Belt Water Pump Y53-1166-1F1 (11/2017)

- Page 71 ENGINE MAINTENANCE - Maintenance Procedures Tensioners Engine Dampener A/C Compressor Alternator Check and correct fan belt Your truck may be equipped with an On/Off tensioner. or Viscous Fan Drive. Follow these NOTE guidelines to check your engine fan: • Mounting bolt torque. •...

- Page 72 ENGINE MAINTENANCE - Maintenance Procedures Engine Fan Blade Place a flex-bar with a 15 mm (bore). This facilitates removal socket on the fastener securing the and installation of the poly V- Verify that there is enough fan blade automatic belt tensioner's roller, as belt.

- Page 73 ENGINE MAINTENANCE - Maintenance Procedures back to its normal position. If the Remove the poly V-belt from the Flex Bar on Tensioner - Compressor and Coolant Pump Belt tensioner had been temporarily fan and coolant pump drive as blocked, relieve tensioner pressure described in Poly V-belt and Fan enough to remove the locking pin, Drive Belt Removal.

- Page 74 Clean or back to its normal position. PACCAR dealer may either replace as necessary. continue to use the wet Reinstall the fan drive poly V-belt...

- Page 75 ENGINE MAINTENANCE - Maintenance Procedures If a DPF is wet cleaned, then the does not apply to a unit that has been maintenance intervals may be switched to dry cleaned. See Diesel Particulate Filter NOTE stay on the dry cleaning strategy or start Service Strategy on page 72 and Diesel...

- Page 76 ENGINE MAINTENANCE - Maintenance Procedures Medium and Large DEF Tank Small DEF Tank Filter Access Replace the aftertreatment diesel From the bottom of the tank, Air System exhaust fluid (DEF) dosing unit remove the cover plate by (DEF module) filter according to removing the various fasteners Air Intake System the maintenance schedule.

- Page 77 ENGINE MAINTENANCE - Maintenance Procedures Engine heat, vibration, and age combine to Check and correct for carbon • Clearance to other components. loosen air intake connections and cause buildup. cracks in the tubing and elbows. Leaks in Charge Air Cooler the intake system allow abrasive dust to Air Cleaner Maintenance checks for the charge air...

- Page 78 ENGINE MAINTENANCE - Maintenance Procedures elements when the air inlet restriction Main enclosure indicator locks in the extreme Up position. WARNING Air filter Paper elements require care and proper Housing handling because they are critical to Do not use air cleaner components as Screws engine service life.

- Page 79 ENGINE MAINTENANCE - Maintenance Procedures not push any contaminant into the suction is created when the engine is engine inlet. running. This suction could draw your Visually inspect the new filter and hand or anything else near it into the the filter housing for damage, impeller fan.

- Page 80 ENGINE MAINTENANCE - Maintenance Procedures Batteries, Cables, and Connections Exhaust System Engine Mounting Bolts Maintenance checks for electrical General information on maintaining the Maintenance guidelines for engine components. exhaust system. mounting bolts. Perform these maintenance procedures The exhaust system is part of the noise Perform these maintenance procedures according to the Preventative Maintenance and emission control system.

- Page 81 ENGINE MAINTENANCE - Maintenance Procedures Engine Valves Perform these valve clearance maintenance procedures according to the Procedures and maintenance intervals for following intervals. initial service and routine maintenance of valves. Engine Valve Adjust Intervals Vehicle Application Interval Normal Duty (Line Haul) - less than 20% Initial adjust at 150,000 miles (240,000 km, idle time 6,750 hours), at 450,000 miles (725,000...

-

Page 82: Engine Identification

ENGINE MAINTENANCE - Engine Identification Engine Identification Component Locations Identification of major engine components. Engine - Right Side Coolant Filter Centrifugal Bypass Oil Filter Y53-1166-1F1 (11/2017) - Page 83 ENGINE MAINTENANCE - Engine Identification Full-flow Oil Filter Oil Cooler Torbcharger Engine - Left Side Electronic Control Module (ECM) Dipstick Oil Fill Y53-1166-1F1 (11/2017)

- Page 84 This label is located on top of the engine valve cover or on the mixer manifold. The engine EPA label must not be changed unless approved by XXX.X XXX - XXX PACCAR. XXXX X.XX X.XX XXX/XXX X.XX X.XX...

- Page 85 ENGINE MAINTENANCE - Engine Identification Y53-1166-1F1 (11/2017)

- Page 86 ENGINE WARRANTY - Chapter 3 | ENGINE WARRANTY In this Chapter: United States and Canada Engine Warranty..................85 Y53-1166-1F1 (11/2017)

- Page 87 Warranty coverage for major engine Responsibilites components. This warranty applies to new PACCAR Description of responsibilites for PACCAR MX-11 engines sold and used in the United and the owner of a PACCAR Brand There is an Engine Warranty period of 60 Engine. States...

- Page 88 ENGINE WARRANTY - United States and Canada Engine Warranty PACCAR will pay during the base engine failure, owner must also deliver the engine States and Canadian PACCAR engine warranty period of two years or 250,000 to the repair facility. dealers , or an authorized PACCAR engine...

- Page 89 Failures of belts and hoses supplied by WEAROUT OF COVERED PARTS. LODGING AND/OR MEAL EXPENSES; PACCAR are covered for the first year from THIS WARRANTY AND THE EMISSION FINES; APPLICABLE TAXES OR the date of delivery of the engine to the first WARRANTY SET FORTH HEREINAFTER BUSINESS COSTS OR LOSSES;...

- Page 90 Before the expiration of the applicable This warranty applies to new PACCAR antifreeze, filter elements, belts, hoses, warranty, the owner must notify a PACCAR MX-11 engines sold and used in the United and other maintenance items that are not authorized engine dealer of any States or Canada and operated in fire reusable due to the warrantable failure.

- Page 91 Failures of belts and hoses supplied by deductible will not be charged during the limited to: damage due to accident; PACCAR are covered for the first year from first two years of the base engine warranty. operation without adequate coolants or the date of delivery of the engine to the first lubricants;...

- Page 92 WEAROUT OF COVERED PARTS. AND CARGO; LOSS OR DAMAGE TO of sale by PACCAR with all U.S. Federal THIS WARRANTY AND THE EMISSION PERSONAL CONTENTS; emission regulations applicable at the time WARRANTY SET FORTH HEREINAFTER COMMUNICATION EXPENSES;...

- Page 93 PACCAR schedule or when the system indicates that parts that are not equivalent to the is not responsible for failures or damage...

- Page 94 PACCAR must warrant the emission Where a warrantable condition exists, control system on your diesel engine for PACCAR will repair your engine at no cost California Air Resource Board, 9528 the periods of time listed below provided to you including diagnosis, parts and labor.

- Page 95 Emissions Components Statement • NOx Sensor Intake System State of California emissions components • Pressure protection-valve and statement for the PACCAR MX-11 engine • Air intake pipe mixer plumbing to DPF Fuel Injector coverage. • Charge air cooler and associated •...

- Page 96 Exhaust Gas Recirculation System emission controls. The use of non-genuine (EGR) engine or vehicle replacement parts that • Ambient temperature sensor are not equivalent to the PACCAR engine • EGR cooler and associated • Camshaft Speed (CMP) sensor or OEM vehicle manufacturer’s original plumbing •...

- Page 97 ENGINE WARRANTY - United States and Canada Engine Warranty assemblies. PACCAR will repair any of the performed by an authorized PACCAR operation without adequate coolants or emission control parts found by PACCAR engine dealer . lubricants; overfueling; overspeeding; lack to be defective without charge for parts or...

- Page 98 THE EXPRESS COMMERCIAL BUSINESS COSTS OR LOSSES; WARRANTIES ARE THE SOLE ATTORNEYS’ FEES; AND ANY WARRANTIES MADE BY PACCAR IN LIABILITY YOU MAY HAVE IN RESPECT REGARD TO THESE ENGINES. TO ANY OTHER PERSON OR ENTITY. THIS LIMITED EMISSIONS WARRANTY IS THE SOLE WARRANTY MADE BY PACCAR AND THE SELLING DEALER.

- Page 99 ENGINE WARRANTY - United States and Canada Engine Warranty Y53-1166-1F1 (11/2017)

- Page 100 Index Index Cooling Fan Cooling System Cooling system maintenance Additives to Cooling System Cooling System Overheating After Replacing Engine Oil Filter(s) Crankshaft - Vibration Damper Aftertreatment Exhaust Piping Air Cleaner Air Cleaners Air Compressor Air Filter Restriction Indicator Diesel Exhaust Fluid Air Intake Piping Diesel Exhaust Fluid (DEF) filter Air Intake System...

- Page 101 Engine Oil Level Engine Oil Level Check Maintenance Schedule Intervals Malfunction Indicator Lamp Engine Oil Pressure Lamp Turns On Engine Oil Specifications MX-11 46, Engine Operating Range MX-13 46, Engine Shutdown Engine Specifications for operator manual Engine Valves Engine Warning Lamps...

- Page 102 Index Radiator Hoses Recommendations to Avoid Fuel Gelling Replace Coolant Filter Roadside Assistance Safety Safety Alerts Serviceable Crankcase Ventilation (CCV) System 56–58, Starting After the Fuel Tank Has Run Dry Starting Procedure After Extended Shutdown or Oil Change Stop Engine Lamp 10, Topping Up the Engine Oil Turbocharger Under hood air cleaner...

- Page 104 PACRI Engines P.O . Box 1518 x 1518 Bellevue , WA 98009 A 98009 Y53-1166-1F1...

Need help?

Do you have a question about the MX-11 and is the answer not in the manual?

Questions and answers

зазор клапанов