Subscribe to Our Youtube Channel

Summary of Contents for Enerpac W22000X Series

- Page 1 Instruction Sheet W22000X Series W35000X Series Hydraulic Torque Wrench L4136 English (EN) Rev. B 05/2021...

-

Page 3: Table Of Contents

5 Maintenance and troubleshooting ......12 6 Technical specifications - W22000X Series ....15 7 Technical specifications - W35000X Series . -

Page 4: Introduction

If damage is found the carrier General Bolting Safety Precautions should be notified at once. Shipping - Make sure you have completed safety damage is not covered by the Enerpac induction training, specific to the work warranty. surroundings. The operator should be... - Page 5 - The torque required to loosen a nut is - Always use Enerpac pumps and variable and may exceed the torque hoses. capacity of the tool. Never operate...

- Page 6 Use of Torque Wrenches in Explosive be certain to use the W-Series torque Atmospheres wrench only in the specific explosive In addition to the CE mark, the Enerpac atmospheres for which it has been W-Series torque wrenches carry the tested and certified. Refer to the...

- Page 7 • Enerpac has designed and Electrostatic Discharge constructed the W-Series torque • Electrostatic discharge is a potential wrench to minimize the possibility source of ignition and can result in of an incendive spark that may be electrostatic build-up on isolated caused by the impact of aluminum conductive parts.

-

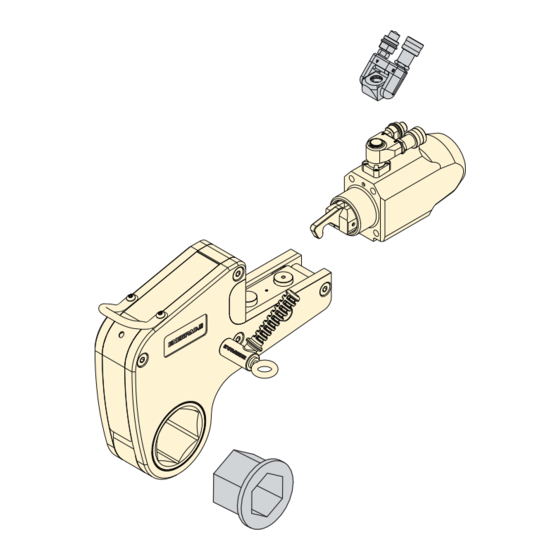

Page 8: Assembly And Adjustments

3 Assembly and adjustments Overview and features (fig. A or B) Hexagon ratchet Cassette 3A Swivel coupling or 3B TSP-Pro swivel coupling (optional) Advance hose connection Return hose connection Hydraulic drive unit Cassette release lever Reaction foot To attach the positioning handle Fig. - Page 9 Make sure the quick connect couplings are securely attached before operating the tool. Fig. D The tool is fitted with male and female quick-connect couplings. Use Enerpac twin safety hoses only. Refer to the table below: Enerpac hose Description model number...

-

Page 10: Operation

Fig. G abutment surface. Ensure that the spanner is secured. - Contact Enerpac if a suitable reaction point is not available. To set the torque Adjust the pressure on the pump as necessary to set the torque. - Page 11 4.3.2 To loosen a nut or bolt (fig. I & J) • Apply penetrating oil to the threads. Allow the oil to soak. • Position the tool on the nut or bolt with the anti-clockwise (-) side facing upwards. • Position the reaction foot (17) against a suitable reaction point (18).

-

Page 12: Maintenance And Troubleshooting

• Check tightness of swivel post maintenance must be carried out retaining screws (see 5.2.1) and by an approved and authorized gland. technician appointed by Enerpac. • Pressurize the drive unit to maximum Recommended service intervals pressure (Advance and Retract), and are: check for any signs of leakage. - Page 13 Full maintenance • Reverse the procedure to reassemble • Pressurize the assembled drive 5.2.1 The hydraulic drive unit unit to max pressure (Advance and • Remove the circlip from the swivel Retract), and check for any signs of coupling. leakage. •...

- Page 14 • As a check, refer to figure M and the tables below for the correct height of the fail safe pin (Y). Fail Safe Pin Height - W22000X Series (fig. M, dimension “Y”) Metric Imperial 7,5 mm 0.296 inch Fail Safe Pin Height - W35000X Series (fig.

-

Page 15: Technical Specifications - W22000X Series

Weight of Drive Unit kg (lbs) 7,7 (16.98) * Important: Hexagon reducer inserts (if used) must meet minimum wall thickness requirements. Refer to Section 6.2 for additional information. Consult your Enerpac distributor regarding the availability of inserts for your cassette model. - Page 16 W22205X - W22404X 9,2 mm W22405X - W22506X 7,75 mm Important: If wall thickness is less than shown in the table above, the insert may experience reduced component life. Consult your Enerpac distributor regarding the availability of inserts for your cassette model.

- Page 17 W22205X - W22404X 0.36 inch W22405X - W22506X 0.31 inch Important: If wall thickness is less than shown in the table above, the insert may experience reduced component life. Consult your Enerpac distributor regarding the availability of inserts for your cassette model.

- Page 18 6.3 Torque settings - W22000X Series 6.3.1 Metric system pressure/torque table - W22000X Series Pump pressure (bar) Torque (Nm) Pump pressure (bar) Torque (Nm) 3.051 17,068 3.670 17,687 3.670 18,306 4.864 18,925 5.483 19,500 6.102 20,119 6.721 20,738 7.340 21,357 7.915...

- Page 19 6.3.2 Imperial system pressure/torque table - W22000X Series Pump pressure (psi) Torque (Ft.lbs) Pump pressure (psi) Torque (Ft.lbs) 1,000 2,250 5,600 12,600 1,200 2,700 5,800 13,050 1,400 3,150 6,000 13,500 1,600 3,600 6,200 13,950 1,800 4,050 6,400 14,400 2,000 4,500...

- Page 20 NOTES:...

-

Page 21: Technical Specifications - W35000X Series

Weight of Drive Unit kg (lbs) 12 (26.4) * Important: Hexagon reducer inserts (if used) must meet minimum wall thickness requirements. Refer to Section 7.2 for additional information. Consult your Enerpac distributor regarding the availability of inserts for your cassette model. - Page 22 W35302X - W35404X 14,50 mm W35405X - W35602X 12,00 mm Important: If wall thickness is less than shown in the table above, the insert may experience reduced component life. Consult your Enerpac distributor regarding the availability of inserts for your cassette model.

- Page 23 W35302X - W35404X 0.57 inch W35405X - W35602X 0.48 inch Important: If wall thickness is less than shown in the table above, the insert may experience reduced component life. Consult your Enerpac distributor regarding the availability of inserts for your cassette model.

- Page 24 7.3 Torque settings - W35000X Series 7.3.1 Metric system pressure/torque table - W35000X Series Pump pressure (bar) Torque (Nm) Pump pressure (bar) Torque (Nm) 4.745 26.546 5.708 27.509 6.671 28.472 7.565 29.434 8.528 30.328 9.491 31.291 10.453 32.254 11.416 33.217 12.310 34.180 13.273...

- Page 25 7.3.2 Imperial system pressure/torque table - W35000X Series Pump pressure (psi) Torque (Ft.lbs) Pump pressure (psi) Torque (Ft.lbs) 1,000 3,500 5,600 19,600 1,200 4,200 5,800 20,300 1,400 4,900 6,000 21,000 1,600 5,600 6,200 21,700 1,800 6,300 6,400 22,400 2,000 7,000 6,600 23,100 2,200...

-

Page 26: Replacement Parts And Recommended Tools

To order replacement parts 3/4" A/F spanner 5/8" spanner For replacement parts information, Circlip pliers refer to the Enerpac repair parts Seal extraction tool sheet for your wrench model. 2" A/F spanner Repair parts sheets are available ø 5 mm x 6 mm LG x 50 mm... - Page 27 NOTES:...

- Page 28 NOTES:...

- Page 29 NOTES:...

- Page 30 © Enerpac 03-2015 - Subject to change without notice.

Need help?

Do you have a question about the W22000X Series and is the answer not in the manual?

Questions and answers