Summary of Contents for CIMLINE Magma 150

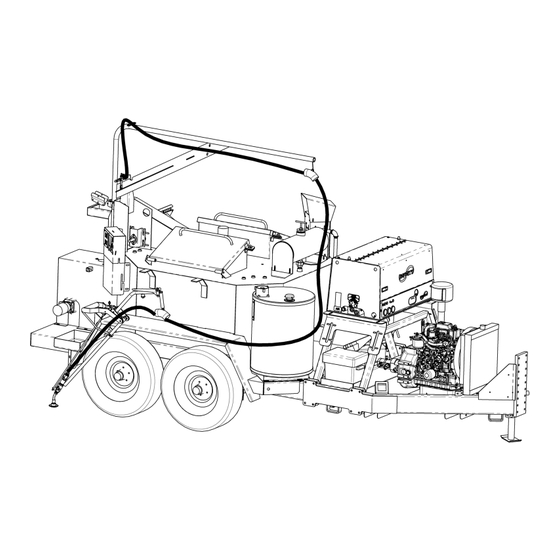

- Page 1 Melter Applicator Magma 150, & 230 Owner/Operator Manual 2601 Niagara Lane · Plymouth, MN 55447 · (763) 557-1982 · (877) 841-0848 · Fax (763) 557-1971 Part # 161439 Revised 2/27/15...

-

Page 2: Table Of Contents

Table of Contents Shipping Papers and Information…………………….…….…3 Safety Notes……………………………………………….………4 Weights and Dimensions………………………………….……5 Controls and Their Functions………………………………..6-7 Start Up…………………………………………………………..8-9 Automatic Temperature Control Setting…………………….10 Loading Empty Tank…………………………………………….11 Cleanout Procedure……………………………………………..12 Cleanout Procedure (Optional Air Cleanout)………………..13 Maintenance…………………………………………………...14-15 Fluid and Components Specs…………………………………16 Heat Transfer Oil Specs………………………………………...17 Material Tank Capacity………………………………………….18 Trouble Shooting Guide………………………………………..19 Parts Section... -

Page 3: Shipping Papers And Information

Burner (Diesel only) IMPORTANT: This manual contains the basic information required to operate, main- tain and repair the CIMLINE Melter you have purchased. The use of this manual in- sures accurate adjustments, operation and proper lubrication of your equipment. Please keep it handy. -

Page 4: Safety Notes

Safety Notes PLEASE READ AND UNDERSTAND ENTIRE OPERATORS MANUAL BEFORE PROCEEDING WARNING: Protective clothing must be worn. Refer to ANSI Regulations: Wear gloves with wristlets. Wear long sleeve shirt with sleeves rolled down and cuffs buttoned. Wear a face shield. Load Melter from ground level. -

Page 5: Weights And Dimensions

Weights and Dimensions Model Number "A" in/cm "B" in/cm "C" in/cm Weight lbs/kg (empty) 84/214 156/396 95/242 4000/1814 81/206 171/435 90/229 4700/2132 Model 230 shown Weights are without options... -

Page 6: Controls And Their Functions

Controls and Their Functions NOTE: This general outline will only familiarize you with the machine. Read through the entire manual before putting this machine into operation. Pump Maintenance Valve: Allows the melted material to not leave the tank to allow maintenance work on the pumping system. - Page 7 Controls and Their Functions...

-

Page 8: Start Up

Start up 1. SETUP: A) Set Flow control to “9” Make sure pump maintenance valve is fully open Counter-Clockwise (Item “1” from page 7). B) Set all control switches to up C) Set switch with switch guard down. 2. START ENGINE: A) Turn key on engine control to “1”... - Page 9 Start up 3. WAND A) Unlock Boom B) Place wand in port. 4. Ready for Work When all 3 GREEN lights are on: A) Set Flow to “0” B) Pin Wand trigger and set handle forward C) Set Flow to desired level D) Start Sealing...

-

Page 10: Automatic Temperature Control Setting

Automatic Temperature Control Setting The control system on your CIMLINE Magma melter has been factory set to run the most com- mon types of materials. These materials have an application temperature of 380 deg F. With some materials, it may be needed to change the controller to achieve the appropriate appli- cation temperature. -

Page 11: Loading Empty Tank

Loading Empty Tank All material must be clean. Keep all foreign matter out of melting tank. Open the material door (1) and place slab or biscuit (2) on the open door against the holder (3). Push door to the closed position. DO NOT DROP MATERIAL INTO THE MELTER WITH DOOR OPEN. -

Page 12: Cleanout Procedure

Cleanout Procedure Contact material supplier for information on how to flush out non-reheatable materials. 1. SETUP: A) Place wand in port. B) Pin wand trigger and set handle for- ward. C) Place toggle switch with guard in down position. D) Set pump control switch to reverse (R). -

Page 13: Cleanout Procedure (Optional Air Cleanout)

Cleanout Procedure (Optional Air Cleanout) 1. Place material pump in neutral (a) 2. Remove sealing tip and return wand to access port (b). 3. Pin wand trigger and set handle forward (c). 4. Close tank maintenance valve (d). 5. Connect air hose and open air cleanout valve (e). 6. -

Page 14: Maintenance

Maintenance Engine: The operation and life of the engine depends on you and your operator. Do not start engine until the engine precheck is complete. The engine precheck consists of checking the oil, the fuel level, the hydraulic oil level and the air filter. The 150/230 Melter Applicator has the op- tion of (2) different engines. - Page 15 Maintenance 1000 Maintenance Operation Daily 25 Hrs Hrs Yearly Check fuel level (add if low) Check engine and heat transfer oil (add if low) Check hydraulic oil (add if low) Check engine air cleaner Inspect pre-cleaner Cleanout material system Inspect sealing hose and cover Inspect sealing hose connection Drain condensation from air compressor option Blow oil cooler on the air compressor option...

-

Page 16: Fluid And Components Specs

Fluid and Components Specifications Model Model 30 Gallons Hydraulic Reserve Capacity Conoco MV32 or equiv Hydraulic Oil Type 30 Gallons Diesel Fuel Capacity ASTM D975 No.2 Diesel Fuel Type Heat Transfer Oil Capacity 21 Gal. 26 Gal. Heat Transfer Oil Type See Specs. -

Page 17: Heat Transfer Oil Specs

YOU MUST CLARIFY with the supplier that the oil is to be used in a heat transfer system to avoid any potential problems. Oil is also available from CIMLINE in 5 and 30 Gallon containers for ship-out. -

Page 18: Material Tank Capacity

Material Tank Capacity MATERIAL CAPACITY (Tank cutaway) MATERIAL VAT MODEL 150 6.8 GALLONS PER INCH MODEL 230 9.37 GALLONS PER INCH INSULATION Model 150 Model 230 Material 1570 Cubic 2165 Cubic Depth Inches Inches 2" 13.6 18.74 4" 27.18 37.48 6"... -

Page 19: Trouble Shooting Guide

Trouble Shooting Guide Problem Cause Solution Fuse burned out. Check fuse Burner relay inoperative. Check for 12VDC at relay. Burner will not ignite Primary control fuse. Check fuse Thermocouple(s) inoperative Replace thermocouple(s) Fuse burned out. Check fuse Sealant material not hot enough. Allow material to heat longer Too many biscuits added at one Continue heat up and reverse agitation... -

Page 20: Parts Section

Parts Section... -

Page 21: Wiring Diagrams

Complete Wiring Diagram... -

Page 22: Engine And Burner Wiring Harness

Wiring Diagrams Engine Harness... -

Page 23: Switch Panel

Wiring Diagram Switch Plate... -

Page 24: Temperature Control Wiring Diagram

Wiring Diagrams Temperature Control Panel... -

Page 25: Relay Panel

Wiring Diagrams Relay Panel... -

Page 26: Main Supply Harness

Wiring Diagrams Main Supply Harness... -

Page 27: Primary Control

Wiring Diagrams Burner... -

Page 28: Hydraulic Schematic

Hydraulic Schematic For Compressor Hydraulics, see Supplement manual... -

Page 29: Hydraulic Manifold Parts List

Hydraulic Manifold Components Item Part # Description 172371 Hyd. Manifold 171597 Guage 172587 Relief Valve (Set at 800 PSI) 172226 Spool and Coil Kit for Matl Pump 172224 Spool for Matl Pump 172225 Coil for Matl Pump (2 req'd) 172589 Spool and Coil Kit for TFC 172557 Spool for TFC 172585 Coil for TFC 172583 Spool and Coil Kit for Agitator... -

Page 30: Electrical Components

Electrical Components Item Part # Description Item Part # Description 130815 Controller Switch 152119 Fuse Holder 130482 Switch Cover 130505 Fuse 18A 130788 Auto/Manual Switch 130222 Relay 130814 Switch Cover 130113 Relay 130481 Fwd/Rev Switch 153870 Relay Socket 130814 Switch Cover 130782 Low Flow Switch Transfer Oil Temperature 200596... -

Page 31: Isuzu Diesel Engine And Pump Parts List (See Supplement For Compressor Models)

Engine Components Item Part # Description Item Part # Description 111726 Engine (Non-Compressor) 152047 Rubber Isolator 111727 Engine (Compressor) 422167 Engine Mount (RH) 111479 Fan Belt (Non-Compressor) 425244 Engine Mount (LH) 111372 Fan Belt (Compressor) 406139 Generator with Pulley 153619 Exhaust 110036 Belt A-31 (Non-Compressor Engine) 111111 Air Filter Element... -

Page 32: Plumbing System Parts List

Material Plumbing Components Item Part # Description Item Part # Description 120803 M aterial Pump 170602 M otor 120498 Gate Valve 172395 Cylinder 405065 Outlet Adapter 407870 Ear Weld 422053 Pump Plate 130581 Clevis 120396 Pipe Nipple 110500 Bearing 155330 Tee Weld 152127 3"... - Page 33 Material Plumbing Components...

-

Page 34: Material Pump Parts List

Material Pump Parts List (For Reference Only—We do not stock rebuild parts) 120803 (20 GPM) & 154151 (30 GPM) - Page 35 Material Pump Parts List (For Reference Only—We do not stock rebuild parts)

-

Page 36: Sealing Hose And Wand

Sealing Hose & Wand Item Part # DESCRIPTION Item Part # DESCRIPTION 407863 Wand Sub weld 407872 Support Handle 170635 Live Swivel 426987 Spacer 407862 Handle Weld 155297 Spring 120412 Pipe Nipple 427116 Spring Guard 120560 Ball Valve 155272 Met al Sleeve 130323 Swit ch (qt y 2) 111725 Brass Washer... -

Page 37: Sealing Tips

Sealing Wand Attachments * 2.5" wide band PIVOTING SHOE / 403137 * 3/4" NPT inlet * Open shoe design for clear visibility of material * Pivoting inlet tube maintains contact with the road. * 2" or 3" wide band SEALING DISC 3.5” / 403162 * 3/4"... -

Page 38: Agitation System Parts List

Agitation System Parts List Item Description Item Description 110294 Key 3/8 x 2 110488 Chain 170467 Motor, Agitation - 150 111087 Sprocket - 50BS30 x 1.50 170602 Motor, Agitation - 230 170602 Motor, Agitation - 410 153772 Viton Seal Kit for 170602 & 170467 171081 Seal Kit For 170602 153135 Agitator Mount Gasket 404327 Agitator Motor Mount - 410... -

Page 39: Oil Burner Parts List

Oil Burner Parts List Item Part # Description 152197 150 Oil Burner, Complete 404428 230 Oil Burner, Complete 404388 410 Oil Burner, Complete 152305 Nozzle, 1.75 GPH x 90B Model 150 152204 Nozzle, 2.0 GPH x 90B Model 230 153445 Nozzle, 2.25 GPH x 90B Model 410 153505 Square Plate , Gasket... -

Page 40: Combustion Chamber Parts List And Tank Insulation

Combustion Chamber Parts List and Tank Insulation Item Part # Description 402893 Combustion Chamber Skin 403400 Chamber Lining Kit (board) 402898 Burner Mount 417041 Inspection Cover 402923 Lining Retainer 424534 Burner Cover 406252 Burner Hinge 155401 Bottom Insulation Kit 150 & 230 (Blanket) 153417 Bottom Insulation Kit 410 (Blanket) 152487 Blanket... -

Page 41: Fuel And Hydraulic Tank Components

Hydraulic Reservoir and Diesel Tank Components Item Part # Description 172372 Hydraulic Tank 172373 Diesel Tank 172127 Return Filter Assy (Non-Compressor) 172185 Return Filter Assy (Compressor) 170407 Element - Return Filter (Non-Compressor) 172333 Element - Return Filter (Compressor) 152044 Filler Cap Assy 171631 Sight Gauge 172186 Suction Strainer 155396 Fuel Gauge/Cap... -

Page 42: Miscellaneous Parts

Miscellaneous Parts Item Part # Description 172289 Battery Box 140333 Pintle Hitch, 2 1/2" 403135 Pintle Hitch, 3" 403271 Ball Hitch, 2" (150 only) 402954 Ball Hitch, 2 5/16" 150212 Battery, 12 V-M 140330 Jack - 5000 lb. 140546 Radial Tire Assy. (150 only) 140381 Radial Tire R15 (410 only) 140282 Tire / Wheel Assy. - Page 43 Miscellaneous Parts...

-

Page 44: Spare Parts Kit

Spare Parts Kit Option Item Part # Description 152105 Electric Eye 200352 Primary Control 130113 Relay (Heated Hose & Burner) 152399 Coupling 200482 Controller 153537 Fuse 10 Amp (Qty 5) 130097 Thermocouple (Oil) 153621 Thermocouple (Pump) 153644 Fuse ABC 15 404695 Complete Spare Parts Kit 2,6,9... -

Page 45: Compressor Option

Compressor Option Item Part # Description 155086 Compressor 155161 Oil Filter 155162 Air Filter 155163 Spin on Coalescer... - Page 46 NOTES...

- Page 47 NOTES...

- Page 48 2601 Niagara Lane · Plymouth, MN 55447 · (763) 557-1982 · (800) 328-3874 · Fax (763) 557-1971...

Need help?

Do you have a question about the Magma 150 and is the answer not in the manual?

Questions and answers