Table of Contents

Advertisement

Quick Links

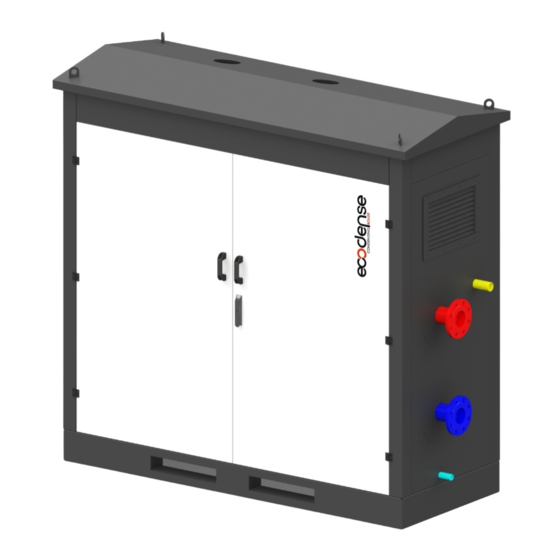

ROOF TOP SERIES CONDENSING BOILER

INSTALLATION, OPERATING AND MAINTENANCE

MANUAL

ECODENSE RT-65 One

ECODENSE RT-80 One

ECODENSE RT-90 One

ECODENSE RT-100 One

ECODENSE RT-110 One

ECODENSE RT-115 One

ECODENSE RT-125 One

ECODENSE RT-150 One

14.12.2021 Rev. 03

ECODENSE RT-65 Twin

ECODENSE RT-80 Twin

ECODENSE RT-90 Twin

ECODENSE RT-100 Twin

ECODENSE RT-110 Twin

ECODENSE RT-115 Twin

ECODENSE RT-125 Twin

ECODENSE RT-150 Twin

www.ecodense.com

Advertisement

Table of Contents

Summary of Contents for Ecodense ROOF TOP Series

- Page 1 ROOF TOP SERIES CONDENSING BOILER INSTALLATION, OPERATING AND MAINTENANCE MANUAL ECODENSE RT-65 One ECODENSE RT-65 Twin ECODENSE RT-80 One ECODENSE RT-80 Twin ECODENSE RT-90 One ECODENSE RT-90 Twin ECODENSE RT-100 One ECODENSE RT-100 Twin ECODENSE RT-110 One ECODENSE RT-110 Twin...

- Page 2 DEAR USER, The Roof Top Series Condensing Boilers ECODENSE RT-65 One, ECODENSE RT-80 One, ECODENSE RT-90 One, ECODENSE RT-100 One, ECODENSE RT-110 One, ECODENSE RT-115 One, ECODENSE RT-125 One, ECODENSE RT-150 One, ECODENSE RT-65 Twin, ECODENSE RT-80 Twin, ECODENSE RT-90 Twin,...

-

Page 3: Table Of Contents

TERMS OF WARRANTY ........................6 2.1. Out of Warranty Conditions ......................6 GENERAL CHARACTERISTICS OF CONDENSING BOILER ............7 3.1. ECODENSE Roof Top Series Condensing Boilers for Outdoor Installation ........ 8 3.2. Technical Specifications......................... 8 3.3. Boiler Safety ........................... 8 3.4. -

Page 4: Warnings

1. WARNINGS 1.1. Warning Symbols and Descriptions Symbols Symbol Descriptions Important information and useful hints. Warning of danger to life or property. Warning of electrical voltage. Product handling information. GAZ HATTINI TEMİZLEYİNİZ. CLEAN GAS LINE. "Clean the gas line" warning on gas line. ЧИСТАЯ... -

Page 5: General Safety Rules

1.2. General Safety Rules • All personnel engaged in installation, disassembly, commissioning, operation, control, maintenance and repair should have received the necessary training and fully read and understood this manual. • No changes that might damage the safety of the device must be made by persons and/or organizations on the device. - Page 6 Before commissioning and If there is pressure loss in the system due to seasonal maintenance; After water addition process, it is necessary to carry out that air removal process and must be observed that there is absolutely no air in the system. If there is air in the system repeat the deaeration process.

-

Page 7: Terms Of Warranty

2. TERMS OF WARRANTY Main and auxiliary equipment and all components used in ECODENSE RT-65 One, ECODENSE RT-80 One, ECODENSE RT-90 One, ECODENSE RT-100 One, ECODENSE RT-110 One, ECODENSE RT-115 One, ECODENSE RT-125 One, ECODENSE RT-150 One, ECODENSE RT-65 Twin, ECODENSE RT-80 Twin, ECODENSE RT-90 Twin, ECODENSE RT-100 Twin, ECODENSE RT-110 Twin, ECODENSE RT-115 Twin, ECODENSE RT-125 Twin, ECODENSE RT-150 Twin Roof Top Series Condensing Boilers are guaranteed for 1 year by TERMO ISI SİSTEMLERİ... -

Page 8: General Characteristics Of Condensing Boiler

RT-100 Twin, ECODENSE RT-110 Twin, ECODENSE RT-115 Twin, ECODENSE RT-125 Twin, ECODENSE RT-150 Twin are heating devices operating with natural gas or LPG with a very low suction power, and equipped with high-duty, premix condensing control system with micro-processor. The boiler is composed of a heat exchanger with aluminum cooling fins and a steel premix burner equipped with ignition and ionization flame control, modulating fan and gas valve. -

Page 9: Ecodense Roof Top Series Condensing Boilers For Outdoor Installation

3.1. ECODENSE Roof Top Series Condensing Boilers for Outdoor Installation ECODENSE Roof Top series condensing boilers offer solution in hot water production for rooftop outdoor installation in many applications such as shopping centers, office buildings, hospitals and hotels. ECODENSE condensing boilers, when used as CASCADE, meet high-capacity energy requirements with line-up operation and also expand the life-cycle by ensuring equal aging in boilers. -

Page 10: Ecodense Roof Top Series Boiler Components

3.5. ECODENSE Roof Top Series Boiler Components ECODENSE WT 65 – ECODENSE WT 80– ECODENSE WT 90– ECODENSE WT 100 Assembly No Part Name Assembly No Part Name Venturi Gas Inlet Heater circuit return Gas valve Water flow sensor Control panel... - Page 11 ECODENSE WT 110 – ECODENSE WT 115 - ECODENSE WT 125- ECODENSE WT 150 Assembly No Part Name Assembly No Part Name Venturi Gas Inlet Heater circuit return Gas valve Water flow sensor Control panel Heater circuit supply Control card...

-

Page 12: Condensing Boiler Gas, Flue Gas And Heating Water Schema

4. CONDENSING BOILER GAS, FLUE GAS AND HEATING WATER SCHEMA 14.12.2021 Rev. 03... - Page 13 WT-S 45/55/65 14.12.2021 Rev. 03...

- Page 14 WT-S 100/120/145 14.12.2021 Rev. 03...

-

Page 15: Closed Circuit Components

5. CLOSED CIRCUIT COMPONENTS 5.1. Balance Tank Balance Tank (Separator) must be vertical. Advantages: Ø No hydraulic response occurs between the boiler circuit and the heating circuit. Ø Boilers and heating zones operate under suitable water flow. Sizing of Balance Tank: Ø... -

Page 16: Sizing Table For Expansion Tank

5.2. Sizing Table For Expansion Tank EXPANSION INLET & SYSTEM TANK OUTLET CAPACITY DIAMETER(D) DIAMETER(Ø) 1035 1150 1265 1380 1495 1610 1725 14.12.2021 Rev. 03... -

Page 17: Expansion Tank

5.3. Expansion Tank Expansion tank fore pressures must be adjusted according to system. Expansion tank should be placed parallel to circuit return line. 5.4. Manometer A manometer with capacity of at least 0 to 6 bar must be connected to system. Manometer should be placed to easily visible spot from filling point, preferably same point as expansion tank. -

Page 18: Water Quality

6. WATER QUALITY 1. Before connection of condensing boilers any dirt and residue in circuit must be cleaned. 2. Water Hardness and pH measurements should be made by the authorized or central service in the field where the boiler will be commissioned before the commissioning, and it should be decided whether the water can be used in the boiler water installation. -

Page 19: Technical Data

BOILER TYPE CAPACITY GAS INLET OPERATING NUMBER PRESSURE PRESSURE mbar ECODENSE RT-65 One ECODENSE RT-80 One ECODENSE RT-90 One ECODENSE RT-100 One ECODENSE RT-110 One ECODENSE RT-115 One ECODENSE RT-125 One ECODENSE RT-150 One ECODENSE RT-65 Twin ECODENSE RT-80 Twin... - Page 20 ECODENSE WT NG SERIES WALL TYPE CONDENSING BOILER TECHNICAL SPECIFICATIONS Unit WT 65 WT 80 WT 90 WT 100 WT-110 WT 115 WT 125 WT 150 Thermal Capacity Maximum Heating Capacity Minimum Heating Capacity 14,1 14,1 14,2 Maximum Heat Output (80°C / 60°C)

- Page 21 ECODENSE WT-S SERIES WALL TYPE CONDENSING BOILER WT-S WT-S WT-S WT-S WT-S WT-S TECHNICAL SPECIFICATIONS Unit Thermal Capacity Maximum Heating Capacity Minimum Heating Capacity 14,5 Maximum Heat Output (80°C / 60°C) 43,7 53,4 63,1 116,4 140,7 Minimum Heat Output (80°C / 60°C)

-

Page 22: Condensing Boiler Dimensions

7.2. Condensing Boiler Dimensions Device must be shipped in original packaging! Clean the inside of fuel line thoroughly before installing the burner to the fuel line. Any damage that may occur due to solid objects and metal particles from the fuel line shall not be covered by our company. -

Page 23: Noise Level

7.3. Noise Level When the condensing boiler is in operation, the maximum noise level released is <70 dBA. The noise level value corresponds to the value measured with semi-anekoik (semi-unreflecting acoustic) room testing according to the product standards at the time of expansion of the smoke release system, when the condensing boiler operates at the maximum heating power. -

Page 24: External Outdoor Sensor (Optional)

8.2. External Outdoor Sensor (Optional): Connect the sensor to the relevant terminal. The length of electric cable for external sensor connection is max. 25 m. A 2x1.5 cable should be used. The sensor must not be exposed to the morning sun and if possible, to direct sunlight. -

Page 25: Assembly

10. ASSEMBLY 10.1. ECODENSE Assembly Instructions ECODENSE condensing boilers are designed to work as CASCADE; they provide suitable space utilization for every stokehold design at required capacities. 10.2. ECODENSE Single/CASCADE Assembly Instructions Ensure that required gas pressure supplied. Check the hydraulic circuit according the PID. -

Page 26: Ecodense Control Instructions Before Start-Up

11. ECODENSE CONTROL INSTRUCTIONS BEFORE START-UP 1. Ensure that boilers are mounted on fixed, firm and robust wall. Use metal hangers on improper walls. 2. Ensure that every boiler has connected to their own 6A fuse. 3. Maximum operation pressure is 6 bars in the closed circuit. Ensure that in CASCADE SYSTEMS, Balance tank is used below 6 bars and plate heat exchanger is used above 3 bars. - Page 27 On first start-up if there is deficiency in the system detected by ECODENSE authorized service technicians, technicians are not allowed to activate the system. Do not connect the circulation pump as the engine will be above and the engine will be below.

-

Page 28: Electrical Diagram

12. ELECTRICAL DIAGRAM 14.12.2021 Rev. 03... -

Page 29: Commissioning

13. COMMISSIONING 13.1. Before Commissioning Ø Open all open/closed valves between the device and systems. Ø Check gas connections by using foam and water solution for determining leakages on connections carefully. Ø Check the initial pressure of expansion tank. Ø Fill the water system. Ø... -

Page 30: Checks During Commissioning

Ø Make sure that parameters are programmed correctly. 14. ADJUSTING COMBUSTIN PARAMATERS Instructions below are specially prepared for ECODENSE service technicians. Before shipment parameters of all the boilers are adjusted at suitable capacity and pressure at factory’s test stand. Settings mentioned below are for combustion optimization at field conditions. -

Page 31: Control Panel Button Specifications

15. CONTROL PANEL BUTTON SPECIFICATIONS 15.1. Adjusting Minimum Capacity 1. Connect probe of flue gas analyzer to measurement point. 2. Connect a manometer to the gas feed pressure measurement point and control if the pressure is at suitable value. 3. In order to operate the boiler at minimum capacity activate cooling mode via A button. “Controller stop function on “) Press selecting heating button for 3 seconds ( will be seen on the... -

Page 32: Adjusting Maximum Capacity

15.3. Adjusting Maximum Capacity Via Adjusting of room Comfort setpoint button set boiler capacity to 100%. Later when you press OK button, boiler will start working at medium capacity According to flue gas measurement values at maximum capacity, use A and C points for gas flow rate. -

Page 33: Maintenance

16. MAINTENANCE 16.1. Monthly Maintenance Monthly maintenance is a comprehensive process where general checks of condensing boiler and peripheral components are performed to prevent possible faults. After completion of maintenance and adjustment processes, make sure to perform an emission analysis. Ø... -

Page 34: List Of Error Code

17. LIST OF ERROR CODE Error Error Description Code Code Exterior temperature, sensor error Boiler temperature 1, sensor error Solid fuel boiler temperature, sensor error General flow water temperature, sensor error Flue gas temperature, sensor error Flow water temperature 1, sensor error Flow water temperature 1, cooling, sensor error Flow water temperature 2, sensor error Flow water temperature, main control device, sensor error... - Page 35 Error Error Description Code Code Temperature limit safety closing Water pressure is very high Water pressure is very low Water pressure switch disengaged Heating circuit 1 flow water temperature not reached Heating circuit 2 flow water temperature not reached Maximum boiler temperature exceeded DHW supply temperature not reached DHW legionella temperature not reached Flame loss in operation...

- Page 36 Error Error Description Code Code Maximum time per charging exceeded Maximum time for charging per week exceeded Heating circuit error Motor monitoring Diverter valve fan air error Boiler error Sensor error Pressure control Flow sensor error for efficiency measurement Return sensor error for efficiency measurement Pool sensor error Flow water temperature 3 sensor error...

- Page 37 Error Error Description Code Code Accumulation tank address error Main control device/system pump, address error Unpressurized cap, address error B10 sensor is lost Heating circuit 3 flow water temperature Heating circuit 3 temperature limiter Additional module 3 Sitherm Pro calculation BV step motor Drift test limit value Drift test is prevented...

-

Page 38: Solution Recommendations For Some Of The Problems

18. SOLUTION RECOMMENDATIONS FOR SOME OF THE PROBLEMS Problem Cause Explanation-Recommendation Gas line/Gas Control of leak proofing of connections is required. Gas smell connections Be sure that measurement points are closed. Be sure that flue connections are leak proof and Unburned gas smell Flue tightness measurement points are closed. -

Page 39: After Sales Services

Tel: +90 282 685 44 80-81 Fax: +90 282 685 42 09 You can also reach us through www.ecodense.com website and servis@ecodense.com e-mail address. Please observe the following recommendations. • Use the product in accordance with the principles of this manual. -

Page 40: Notes

20. NOTES Please record and forward your measurements and observations to us. www.ecodense.com 14.12.2021 Rev. 03...

Need help?

Do you have a question about the ROOF TOP Series and is the answer not in the manual?

Questions and answers