AFRISO WMS-WP6 Operating Instructions Manual

Hide thumbs

Also See for WMS-WP6:

- Operating instructions manual (146 pages) ,

- Operating instructions manual (151 pages)

Table of Contents

Advertisement

Quick Links

Operating instruc-

tions

Boiler water low level alarm

Version: 07.2017.0

ID: 900.000.0384

WMS-WP6 - mechanical

Copyright 2017 AFRISO-EURO-INDEX GmbH.All rights reserved.

0036

Lindenstraße 20

74363 Güglingen

Telefon+49 7135 102-0

Service+49 7135-102-211

Telefax +49 7135-102-147

info@afriso.com

www.afriso.com

Advertisement

Table of Contents

Summary of Contents for AFRISO WMS-WP6

- Page 1 Operating instruc- tions Boiler water low level alarm WMS-WP6 - mechanical Copyright 2017 AFRISO-EURO-INDEX GmbH.All rights reserved. Lindenstraße 20 74363 Güglingen Telefon+49 7135 102-0 0036 Service+49 7135-102-211 Telefax +49 7135-102-147 info@afriso.com Version: 07.2017.0 www.afriso.com ID: 900.000.0384...

- Page 2 The manufacturer shall not be liable in any form whatsoever for direct or con- sequential damage resulting from failure to observe these operating instruc- tions or from failure to comply with directives, regulations and standards and any other statutory requirements applicable at the installation site of the prod- uct. WMS-WP6...

-

Page 3: Information On Safety

Comply with all safety instruc- tions in conjunction with this symbol to help avoid possible death, injury or equipment damage. This symbol alerts to hazardous electrical voltage. If this symbol is used in a safety message, there is a hazard of electric shock. WMS-WP6... - Page 4 When using the product, perform all work and all other activities in conjunc- tion with the product in compliance with the conditions specified in the oper- ating instructions and on the nameplate, as well as with all directives, stand- ards and safety regulations applicable at the installation site of the product. WMS-WP6...

- Page 5 Modifications to the product Only perform work on and with the product which is explicitly described in these operating instructions. Do not make any modifications to the product which are not described in these operating instructions. WMS-WP6...

-

Page 6: Transport And Storage

Use the original packaging when transporting the product. • Store the product in a clean and dry environment. • Verify that the product is protected against shocks and impact during trans- port and storage. Failure to follow these instructions can result in equipment damage. WMS-WP6... -

Page 7: Product Description

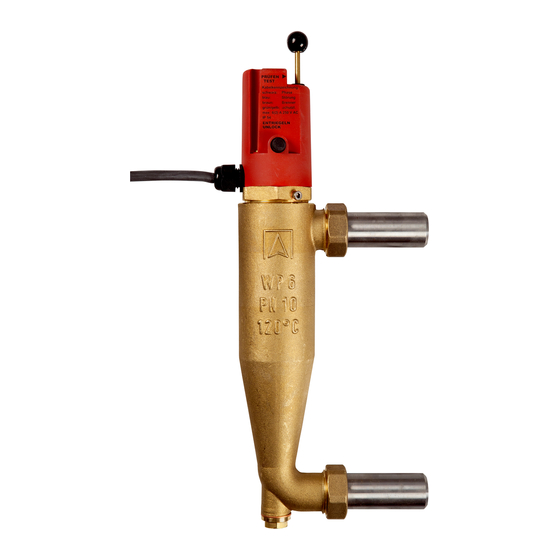

Product description Overview A. Test button B. Cover C. Nameplate D. Unlock pushbutton E. Vent screw F. Welding socket G. Switch off level (88 mm) H. Float I. Housing J. Welding socket K. Sludge removal opening Fig. 1: WMS-WP6 WMS-WP6... - Page 8 Product description A. Cover B. Test button C. Switch D. Unlock pushbutton E. Screw connection with venting F. Protective pipe G. Float H. Connection cable Fig. 2: WMS-WP6 with short protective pipe WMS-WP6...

- Page 9 Product description Dimensions and connections 43 mm 112 mm 23 mm 54 mm Fig. 3: WMS-WP6 WMS-WP6...

- Page 10 Product description Approx. Ø 56 mm Fig. 4: WMS-WP6 with short protective pipe WMS-WP6...

- Page 11 Product description Application example(s) A. Flow B. Return Fig. 5: WMS-WP6 Fig. 6: WMS-WP6 with short protective pipe WMS-WP6...

- Page 12 The product is suitable for continuous operation. Approvals, conformities, certifications The product complies with: • EMC Directive (2014/30/EU) • Low Voltage Directive (2014/35/EU) • Pressure Equipment Directive (2014/68/EU) • RoHS Directive (2011/65/EU) Approvals WMS-WP6 and WMS-WP6 with short protective pipe: • Type approval mark TÜV.WBH.15-232 WMS-WP6...

- Page 13 Product description Technical specifications Parameter Value Value WMS-WP6 WMS-WP6 with short protective pipe General specifications Height 358 mm 271 mm Housing material Brass Brass Protective pipe material - Brass Float material Plastic Plastic Connections Welding socket DN 20 Operating pressure Max.

- Page 14 Verify that the pump does not influence the position of the float in the prod- uct (for example, strong flow or suction effects). Verify that no shut-off fitting is mounted to the product. Verify that the probe body is removed before welding work is performed. WMS-WP6...

-

Page 15: Electric Shock

Disconnect the mains voltage supply before performing the work and ensure that it cannot be switched on. • Verify that no hazards can be caused by electrically conductive objects or media. Failure to follow these instructions will result in death or serious injury. WMS-WP6... - Page 16 A. AC 230 V, horn F. Burner B. Blue G. Junction box C. Product with locking H. Green yellow, protective earth conductor D. Changeover contact I. Black E. Unlocking J. Brown WMS-WP6...

- Page 17 1. Connect the locking unit provided on site according to the figure. A. Product without locking G. Locking to be provided by cus- tomer B. On/off H. Brown C. Problem I. Black D. Burner J. Blue E. Burner contactor K. Green yellow, protective earth F. Unlocking conductor WMS-WP6...

- Page 18 - The system is on. Function test The water level does not need to be lowered to test the device. 1. Press the test button. - The burner switches off. 2. Switch on the product by pressing the unlock pushbutton. WMS-WP6...

-

Page 19: Maintenance

Maintenance Maintenance Maintenance intervals When Activity At regular intervals Perform the function test at least once per year. WMS-WP6... -

Page 20: Troubleshooting

Problem Possible reason Repair Mains connection cable Mains cable must be defective replaced by the manu- facturer with a specific mains cable (tempera- ture resistance 150 °C). Other malfunctions Contact the AFRISO service hotline WMS-WP6... -

Page 21: Decommissioning / Disposal

2. Dismount the product (see chapter "Mounting", reverse sequence of steps). 3. Dispose of the product. Returning the device Get in touch with us before returning your product. Warranty See our terms and conditions at www.afriso.com or your purchase contract for information on warranty. WMS-WP6... -

Page 22: Spare Parts And Accessories

Boiler water low level alarm 42305 (AFRISO) "WMS-WP6" without lock- 42326 ing, with welding socket DN Boiler water low level alarm 42319 "WMS-WP6 R2 with protec- tive pipe" with locking Spare parts and accessories Product designation Part no. Figure Upper part "WMS-WP6"... - Page 23 Appendix Appendix 13.1 Approval documents WMS-WP6...

- Page 24 Appendix WMS-WP6...

- Page 25 Appendix 13.2 EU Declaration of Conformity WMS-WP6...

Need help?

Do you have a question about the WMS-WP6 and is the answer not in the manual?

Questions and answers