Summary of Contents for Mindray Z6 Pro

- Page 1 Z6/Z6T/Z6S/Z6W Z6 Pro/Z6 Expert/Z6Vet Z8/Z8S/Z8 Pro/Z8 Expert Diagnostic Ultrasound System Service Manual Revision 5.0...

-

Page 3: Table Of Contents

Table of Content Table of Content........................i Revision History ........................I Intellectual Property Statement ..................I Applicable for........................I Statement ..........................II Responsibility on the Manufacturer Party ................ II Customer Service Department ................... II Preface........................1-1 Meaning of Signal Words ....................1-1 Meaning of Symbols ...................... - Page 4 3.4.4 Installing External DVD-R/W ..................3-9 System Configuration ....................3-10 3.5.1 Power ON / OFF ....................3-10 3.5.2 Enter Doppler ......................3-10 3.5.3 System Preset ......................3-11 3.5.4 Print Preset ......................3-13 3.5.5 Network Preset ...................... 3-15 3.5.6 System Information ....................3-18 Hardware Principle ....................

- Page 5 Structure of the Complete System ................... 7-1 Field Replaceable Unit ....................7-2 Preparations ........................7-13 7.3.1 Tools Required ....................... 7-13 7.3.2 Engineers Required ....................7-13 7.3.3 Assembly/Disassembly Required ................7-13 Assembly/Disassembly ....................7-13 7.4.1 Battery Connecting Board ..................7-14 7.4.2 Power Supply Module ....................

- Page 6 10.1.1 Module or Board Related ..................10-1 10.1.2 Key Points Supporting Troubleshooting ..............10-1 10.1.3 Troubleshooting ..................... 10-1 10.2 System Cannot Start up Normally .................. 10-2 10.2.1 Module or Board Related ..................10-2 10.2.2 Key Points Supporting Troubleshooting ..............10-2 10.2.3 Troubleshooting .....................

-

Page 7: Revision History

Intellectual Property Statement SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray) owns the intellectual property rights to this Mindray product and this manual. This manual may referring to information protected by copyright or patents and does not convey any license under the patent rights or copyright of Mindray, or of others. -

Page 8: Statement

Mindray or repairs by people other than Mindray authorized personnel. -

Page 9: Preface

Preface This chapter describes important issues related to safety precautions, as well as the labels and icons on the ultrasound machine. Meaning of Signal Words In this operator’s manual, the signal words DANGER, WARNING, CAUTION and NOTE are used regarding safety and other important instructions. The signal words and their meanings are defined as follows. -

Page 10: Warning Labels

rear Caution panel 1.2.2 Warning Labels Warning Labels Meaning Please carefully read this manual before use device. The following labels are a. Do not place the device on a sloped surface. Otherwise the available when the system device may slide, resulting in personal injury or the device works with the mobile malfunction. - Page 11 VGA signal output VGA port AC indicator Lower left corner on the control panel Battery indicator Standby indicator Lower right corner on the control panel Hard disk indicator Probe connector A Rear panel Probe connector B This product is provided with a CE marking in accordance with the regulations stated in Council Directive 93 / 42 / EEC concerning...

-

Page 12: Safety Precautions

Do not use any cables other than the cables provided with the device by Mindray. 3. Use the cable provided with this system to connect the printer. Other cables may result in electric shock. -

Page 13: Mechanical Safety

The user is not allowed to open the covers and panel of the system, neither NOTE: device disassemble is allowed. To ensure the system performance and safety, only Mindray engineers or engineers authorized by Mindray can perform maintenance. Only technical professionals from Mindray or engineers authorized by Mindray after training can perform maintenance. -

Page 15: Product Specifications

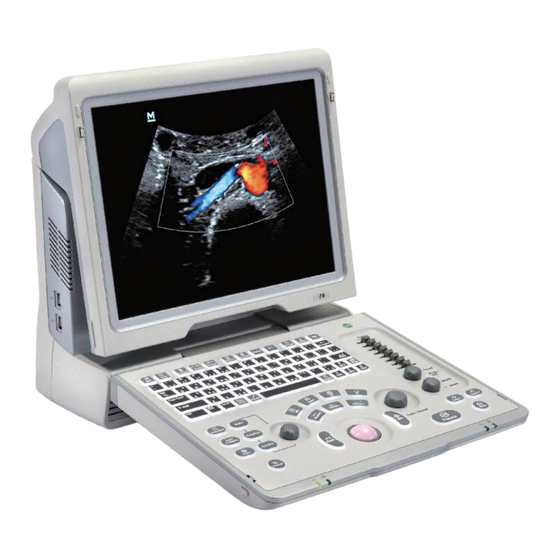

Product Specifications Overview 2.1.1 Intended Use Z6 series and Z8 series are diagnostic ultrasound system, which are intended for use in clinical ultrasonic diagnosis. 2.1.2 Introduction of Each Unit Rear view: Product Specifications 2-1... - Page 16 Left side: 2-2 Product Specifications...

- Page 17 Name Function Probe holder Sets the probe Display Displays the image and parameters Man-machine interface for operation control, for details, Control Panel please refer to “2.1.2.1 Control Panel”. Handle For lifting the machine Signal input / output panel, for details, please refer to “2.1.2.2 IO Panel IO Panel”.

- Page 18 Name Description Function Off: when system is turned off; Power button Green: when system is turned on by pressing this button. Exit Press to exit the current status to the previous status. Press to display or hide the help information on Help screen.

- Page 19 Name Description Function 3D/4D Press to enter or exit the 3D/4D status. Cursor Press to show the cursor. Trackball Roll the trackball to change the cursor position. Press to confirm an operation, same as the left-button of a mouse. Press to enter PW mode Color Press to enter Color mode Press to enter M mode...

- Page 20 Name Description Function Indicator 3 Standby indicator Standby: blinking in orange Other status: light off HDD status indicator Read/ write: blinking in green Other status: light off Indicator 4 NOTE: DO NOT move the machine when the indicator blinking in green. Otherwise the HDD may be damaged by sudden shake.

-

Page 21: Peripherals Supported

2.1.2.3 Power Supply Panel <1> <2> 100-240~ 50/60Hz 1.5-0.8A Name Function Power inlet AC power inlet Used for equipotential connection, that balances the protective Equipotential earth potentials between the system and other electrical terminal equipment. 2.1.3 Peripherals Supported Item Model HP Color LaserJet CM1015 MFP HP LaserJet p1007 HP LaserJet 1020 plus... -

Page 22: Specifications

If the ultrasound system cannot recognize the SONY UP-X898MD and SONY UP-D898MD printers automatically, you may need to change the settings on the printer: NOTE: push <PUSH ENTER> to enter the main menu and select [DIGITAL]->[DRIVER], and select [897]. Specifications 2.2.1 Dimensions and Weight Dimensions:... -

Page 23: System Installation

System Installation Preparations for Installation Do not install the machine in the following locations: NOTE: Locations near heat generators; Locations of high humidity; Locations with flammable gases. 3.1.1 Electrical Requirements 3.1.1.1 Requirement of Regulated Power Supply Requirement of power supply is referring to 2.2.2.Due to the difference of the power supply stability of different districts, please advise the user to adopt a regulator of good quality and performance such as an on-line UPS. -

Page 24: Installation Condition

3.1.2 Installation Condition 3.1.2.1 Space Requirements Place the system with the necessary accessories at a proper position for convenient use. 1. Place the system in a room with good ventilation or having an air conditioning unit. 2. Leave at least 20cm clearance around the system to ensure effective cooling. 3. -

Page 25: Unpacking

3.2.1 Unpacking Use the scissor to clip the 2 rubber belts as follows: Use a knife to open the tapes: Take out the operation manual: Take out the probe box 1: System Installation 3-3... - Page 26 Take out the accessory box: Take out the probe box2, as follows (the box is below the accessory box): Hold the handle tightly and pull the machine with the surrounding foam: Remove the surrounding protective foam to take out the main system. 3-4 System Installation...

-

Page 27: Checking

3.2.2 Checking 1. After unpacking, check the objects in the container with the package list to see if anything is in short supply or is wrong. 2. Inspect and make sure there is no damage to the machine, no indentation, no cracks. Installation of Main Unit 3.3.1 Installing Battery... -

Page 28: Display Adjusting

Maximum folding The clip on the right position side keyboard Figure 3-2 Control Panel Adjustment 3.3.3 Display Adjusting 1. Open the display as described in 3.3.2 2. Put the finger into the bottom of the display and pull the display to tilt the display (30 degrees max.) 3. -

Page 29: Installing Probe Holder

Restore the factory default settings Open the page via “Setup <F10>→General” and restore the brightness/contrast to factory default setting. NOTE: On the monitor, the brightness adjustment comes before contrast. After readjusting the monitor’s contrast and brightness, adjust all preset and peripheral settings. 3.3.4 Installing Probe Holder Fix the probe holder hanger into the groove in the right side and the rear-right side of the main... -

Page 30: Installing Peripherals

NOTE: Before inserting the connector into the probe port, inspect the connector pin. If the pin is bent, do not use the probe until it has been inspected / repaired / replaced. Installing Peripherals For the models of the supported peripherals, please refer to “2.1.3 Supported Peripherals”. 3.4.1.1 Footswitch Installation Connecting: Take 971-SWNOM as an example: insert the USB connector to the system... -

Page 31: Installing A Graph / Text Printer

Insert the power cord to a power supply receptacle that is well grounded. Video cable Remote port Figure 3-6 Installing Analog Video Printer Digital Video Printer Connect one terminal of the data cable of the video printer to the USB port of the ultrasound system and the other terminal to the video input port of the video printer;... -

Page 32: System Configuration

ultrasound system; Connect the power supply adapter plug of the DVD recorder to an appropriate receptacle that is well grounded. cable Figure 3-7 Installing External DVD System Configuration 3.5.1 Power ON / OFF Connect the system power cord to the AC power, and make sure the ultrasound system and other optional devices are correctly connected. -

Page 33: System Preset

3.5.3 System Preset Press the <Setup> key to enter the [Setup] menu. Click <System Preset> to enter the screen as follows: Region System Installation 3-11... - Page 34 In the Region page, set the system language, date format, date, time and hospital related information, etc. General Click <System Preset> to enter: In this page, set the time of standby, brightness/contrast and color temperature of display,etc. Key Config 3-12 System Installation...

-

Page 35: Print Preset

Function of keyboard keys F1 and the footswitch keys (left, mid, right) are user-defined. Key brightness, key volume, trackball backlight and trackball sensitivity can be adjusted. Image Preset Click [Image Preset] to enter: General image parameters can be set in this page. 3.5.4 Print Preset Press <Setup>... - Page 36 After connecting the local printer, Click “Printer Driver”, the system will display the printer name and status (Ready) automatically which already installed printer driver successfully. Return “Printer Service” page, Select the corresponding service from the printer list and increase the service. The system integrates drivers of HP printers, after HP printers are connected, drivers will be installed automatically (about 10s).If auto installation fails, icon will display on the right lower corner of the screen to warn you that manual installation is necessary.

-

Page 37: Network Preset

Download the ppd file from HP official website (contact R&D engineer if necessary), and copy the ppd file to the storage device (USB disk as an example). Connect the U disk to the USB port nearside the control panel of ultrasound system, click the icon to pop up the screen, select the U disk to run the ppd file and finish the installation. - Page 38 Name Description Current Network Adapter To select the network connection mode If “DHCP” is selected, IP address will be automatically obtained DHCP from DNS server; if “Static” is selected (using static IP address), / Static you need to enter the IP address. IP address of the system should be at the same network segment IP Address with the server IP.

- Page 39 If connection is successful, click [Add] to add the service to the Service list. If the currently entered name has already existed, the system will pop up: “The server NOTE: name exists!” Click [OK] to enter another name. Click [DICOM Service] to open the DICOM Service screen. Only when the system is configured with DICOM basic function module, and installed DICOM Work list, MPPS, DICOM Structured Reporting and Query/ Retrieve modules, can the corresponding preset settings be found in DICOM Service screen.

-

Page 40: System Information

3.5.6 System Information In System Information screen, it displays the product configuration, software version, hardware & boards, and driver related information. You can check the product information here. 1. Press the <Setup> and click [System Info]. 2. Click [About Detail] to check the detailed board information. 3. -

Page 41: Hardware Principle

Hardware Principle General Structure of Hardware System Monitor Probe IO board board 4D drive board Main module Control panel board Battery DC-DC connecting Battery Charge/ board discharge board Ultrasound signal AC-DC Power supply board Comm&control AC IN Figure 4-1 Schematic Diagram of System As a portable black-and-white ultrasonic product,the system supports two probe slots. -

Page 42: Main Unit

Main Unit The main unit mainly involves 3 boards: Probe board Main board IO board 4D drive board 4.2.1 Probe Board 4.2.1.1 Probe Board of Z6 Series and Z8 series A+5V LC filter A+95V +95V 3.3V/5V/+95V/-95V PRB_A_VDD_EN, BOARD ID A-95V... -

Page 43: Main Board

The probe board supplies power to corresponding Flash of saving probe ID when reading probe ID, and Flash power shuts off after getting probe ID. Support two 156-array probes (A and B), and only one probe could be chosen by relay switching on the probe board. - Page 44 32/64-channel transmission wave forms according to scanning time sequence and control parameters. 32/64-channel transmission wave forms to 32/64-channel high-voltage transmission wave by driver. Echo receiving LNA is to enlarge fixed gain. By the control of TGC, echo receiving carries out variable gain amplification by depth. ...

-

Page 45: Io Broad

implements display interface, user's operation interface, power module controlling interface and all kinds of Peripherals Supported interface. Also provides system monitoring, running status of the monitor system, indicator of system status and running status of the indicating system via LED. Function describes as following: ... -

Page 46: Drive Board

IO board supports Video and S-Video, and the two channels of signal get by Video Encoder driven by Multifunction FPGA. IO board supports REMOTE signal, which is obtained by Multifunction FPGA on the main board. IO board supports ECG signal, which is obtained by Multifunction FPGA on the main board. ... -

Page 47: Ultrasound System Monitor

4.2.5 Ultrasound System Monitor Multifunction module FPGA D12V D-12V D-5V SMBUS D2.5V D1.8V D1.5V D1.2V Voltage of clock battery Main unit front- end FPGA temperature System monitor CPU module curcuit temperature Main unit fan Temperature sensor Power supply module fan Power supply Back-end of main board module... -

Page 48: Ultrasound System Indicator

4.2.6 Ultrasound System Indicator 5VSTB_CPU Power supply module Control panel AC supply status driver indicator Power Power-on status management driver indicator FPGA Standby status driver indicator Battery status driver indicator HDD indicator driver +12V Module Power status 3.3V indicator Main board IO Board Figure 4-8 Principle Diagram of Ultrasound System Indicator Function describes as following:... -

Page 49: Display

4.2.7 Display Parameter High-voltage Inverter board board screen Display Brightness 3.3V 3.3V LVDS ON/OFF control IO board Brightness 3.3V control triode triode LVDS Control signal Brightness of switch Multifunction FPGA Main board Figure 4-9 Principle Diagram of Display Monitor mainly consists of the inverter board, LCD and the parameter board. Function describes as following: ... -

Page 50: Control Panel

4.2.8 Control Panel Trackball TGC board Control panel PCBA ADC curcuit FPGA 5 status backlight Trackball indicators scan scan backlight Main driver curcuit board Main Interface Functional control Single- chip button encoder scan board +12V PWM generating Double- curcuit encoder board Buzzer driver curcuit Buzzer... -

Page 51: Power System

Power System Power supply module DC-DC Main board boar POWER 14.8V,6600mAh drive board Display Battery in place ARM control signal MUL FPGA Control signal AC in place Restart automatically Power on/off signal control Battery connecting board CPU module Power 12V、5V Temperature signal management Battery in... -

Page 52: System Power-On Control

Power Support circuit module or function Remarks description 3 +5V HDD, Control panel, Front-end of main board, Probe board Front-end of main board 4 -5V 5 5Vst CPU module Front-end of main board, Back-end of main board, Display 6 VDD Back-end of main board (FPGA core voltage) 7 1V2 8 1V8A... - Page 53 Controlling signal Description Remarks SUS_S3_N CPU module output effectively represents that CPU system has been in the standby status, when 5VSTB which is controlled by power management FPGA is in the charging status. SUS_S4_N CPU module output effectively represents that CPU system has been in the dormancy status.

- Page 54 Pressing power button (Control panel) Receiving PWR_BTN_N effective (Power management FPGA) Is AC in place? (Ppower management FPGA) CPU_PWR_BTN_N is valid PWR_5VSTB_EN_N is valid (Power management FPGA) (Power management FPGA) SUS_S3_N and SUS_S4_N 5VSTB start-up is invalid(CPU module) (Power supply module) Indicating PWR_5VSTB_OK_N is valid 5VSTB_CPU...

-

Page 55: Function And Performance Checking Method

The chapter supplies the method to verify main function and performance of product. This is only used for reference, not preventive execution. Function checking and testing of this part shall be carried out by Mindray service engineers and the user together. -

Page 56: General Exam

General exam 5.3.1 Check Flow Check the control panel Check the monitor Check DVD Check peripherals Check ECG module Check I/O ports 5.3.2 Checking Content 5.3.2.1 Check Control Panel Procedure Standard Check the functions of all keys and knobs All keys and knobs are effective. Follow the direction: left to right, and up to down. - Page 57 5.3.2.2 Check the Display Procedure Standard Press “<Fn>+< >”, the brightness increases; and press Adjust LCD brightness “<Fn>+< >”, the brightness decreases. Adjust LCD contrast Press “<Fn>+< >”, the contrast increases; and press Display color temperature “<Fn>+<...

-

Page 58: Function Checks

bar Code scanner: The bar code is correctly displayed on the screen. Perform code bar scanning when the ultrasound system is running normally. 5.3.2.5 Check ECG Module Procedure Standard Confirm if the ECG module is ECG trace is displayed; the heart icon is displayed configured, then: at the upper right corner of the screen. -

Page 59: Check Flow

5.4.1 Check Flow Check each imaging mode Check the measurements Check in cine mode Check the probe application Image & video manage Record and save the exam 5.4.2 Checking Content 5.4.2.1 B Mode In B Mode scanning, the image parameter area in the right corner of the screen will display the real-time parameter values as follows: Display Image Parameters... - Page 60 Press <B> Enter B mode, and B image displays Gain adjustment. Rotate clockwise to increase Rotate <Gain/iTouch> Rotate anticlockwise to decrease The adjusting range is 0-100.The real-time value will be displayed in the image parameter area in the upper right corner of the screen. Depth Adjustment Rotate clockwise to increase Press <Depth/zoom>...

- Page 61 AP value is displayed in real time in the upper part of the screen. mode menu [A.power] You should perform exams according to actual situation and follow the ALARA Principle. Focus Click [Focus Number] and rotate the multifunctional knob to adjust (B mode image has max.

- Page 62 line. Then press [M] Press [M] on the control panel again to enter M Mode, then you can observe the again. tissue motion along with anatomical images of B Mode. Press <Update> To switch between the active B image and frozen B image. Tips: Adjustment of the depth, focus position or TGC to the B Mode image will lead to corresponding changes in M Mode image.

- Page 63 Menu Procedure Standard Speed Click [Speed], and rotate the multifunction knob to adjust the parameter. B mode menu-> [Speed] The lower the value the faster the refreshing. Display Format There are 4 formats available for image display: L/R, V1:1, V1:2, Full. M mode menu->...

- Page 64 5.4.2.4 PW Mode In PW Mode scanning, the image parameter area in the right corner of the screen will display the real-time parameter values as follows: Display Angle Pulse Sample Sample Image PW/CW Wall Frequency Angle Repetition Volume Volume Parameters Gain Filter...

- Page 65 Press <ESC> or <Cine> cine review. The images are still frozen but the system exits cine review. Auto Review Region Total frames Start mark Current frame Playback mark End mark 5.4.2.6 Measurement Procedure Standard Enter the application measurement mode. In B mode ...

-

Page 66: Performance Test

Performance Test 5.5.1 Test Process Resolution Detection depth Geometric Position Accuracy Blackout area test Record the exam images 5.5.2 Test Content The image used here is only for reference, stick to the image effect in the real NOTE: situation. Requirements: Display: set the contrast and brightness at the clinical application value (or the default status) Operation environment: dark room, simulating the clinical application environment. - Page 67 In condition that the transverse resolution testing targets are horizontally displayed, record the minimal distance of two targets that can be clearly recognized. Repeat the operation above for the transverse resolution testing targets at other depths. As shown in figure below. ...

- Page 68 When using the convex probe, keep the transverse resolution testing targets to NOTE: be displayed near the midline. When using a linear probe with steer function, do not turn on the steer function when perform the transverse resolution test. Zoom in the region where the targets located if necessary. The diameter of the target point at a certain depth is equal to the transverse resolution at the depth.

- Page 69 5.5.2.3 Geometric positioning accuracy Longitudinal geometric positioning accuracy Test Step: Do adjustments as the way in testing the maximum depth. Record the distance by 20mm each segment on the longitudinal targets line using the measurement caliper; Select the value with the greatest error (to 20mm), calculate the accuracy using the formula below The measurement caliper should be positioned at the upper edge of the target, NOTE:...

- Page 70 Transverse geometric positioning accuracy Test Step: Cover the scan surface of the phantom with water or couple gel, gently contact the probe with the scan surface Adjust the depth, making the transverse targets to be displayed in the image. Adjust the focus point to be posited beside the transverse targets (the standard is not clear) Adjust parameters like gain, TGC, making each transverse targets to be clearly displayed.

- Page 71 5.5.2.4 Blackout Area Test Step: Cover the scan surface of the phantom with water or couple gel, gently contact the probe with the scan surface Adjust the depth at a lower value, and set the focus at the nearest place to the scan surface. Decrease the value of parameters like AP, Gain until the background noise just can be seen.

-

Page 73: Software Upgrade And Maintenance

Software Upgrade and Maintenance WARNING: DO NOT directly remove a USB memory device; otherwise, the USB memory device and / or the system may be damaged. Enter the Maintenance Window NOTE: Log on the system with the identity of Service before perform system maintenance. To log on the system: When access control function has not been activated: press “Ctrl+/”... -

Page 74: System Software Installation/ Restoration

System Software Installation/ Restoration Refer to recovery guide. Installation of Optional Devices Copy the optional devices to the U disk, then insert it to the USB port of the ultrasound system; Enter [Preset], click [Maintenance] to enter [Option] menu to select the option module to be installed. - Page 75 3. Click [Install]. Select key file from the dialog box, and then click [OK]. 4. The options become Installed after the key files are installed. The corresponding function is activated after returning from preset. Note: After all modules are installed, please go to the previous interface to confirm. ...

- Page 76 Note: the promotion function is only applied to the uninstalled key. If the optional key is installed, the promotion function is disabled. 2. Select the key to be promoted. 3. Click [OK] to complete the promotion. Note: it is unavailable to use promotion for multiple optional keys. For the optional key which is promoted, it can also be installed.

-

Page 77: Data Backup And Storage

Return to the system preset interface. The option status changes into Uninstalled. The uninstalling function is exclusive to internal users. The service engineers must Note: log in the system with the account of Service, and then conduct the uninstallation. Data Backup and Storage 6.4.1 Manage Settings Press <Setup>... -

Page 78: Patient Data Backup And Restore

6.4.1.1 Back up the Preset Data 1. On Manage Settings page, Click [Export] to open the [Export Data] dialogue box. 2. Select the path to save data. 3. Click [OK], a progress bar will appear and the preset data of the selected items will be exported to the specified path. -

Page 79: Software Maintenance

Software Maintenance 6.5.1 Product Configuration [Config] is available on the Maintenance menu only if the operator logged on the NOTE: system as Service. Make the product configuration file—PCF file (generated by the production line or already archived PCF file) according to specific requirements and copy to the USB disk. Connect the USB disk to the machine, click [Config] and load the file in the popped up dialogue box. - Page 80 Select the path in the Browse page to save the log, and click [OK]. When the log is exported, the system prompts “Export succeed!” click [OK] to return to the Maintenance menu. The log can be exported to the external USB storage device only, make sure the NOTE: connection between U disk and ultrasound is normal before the exporting.

-

Page 81: Display Parameter Setting

Before uploading the log, make sure the ultrasound system has been connected NOTE: to network, otherwise, the system may warn “could not connect to server” The server (smtp.163.com) is already specified by the system, the user doesn’t have to select it. Display Parameter Setting NOTE: In normal condition, when changing display assembly or main board assembly, the... -

Page 82: Hdd Partition

Figure 6-1 Main Monitor Maintenance Screen 4. After update is successful, restart the machine after power off to make the data effective. HDD Partition The storage capacity of the system HDD is 500G or more, and the partition information is as follows: Blocks(G) system... - Page 83 obd.bin OBD data file version.txt Version file Comment Comment file AnatomyImage Anatomical images Measurement Measurement library Doppler program and related boot configuration main file and plug-ins, remote desktop server Multilanguage string file \exe videoplay Video play exe file Sound Cine saving and hint sound file version.txt Version file Picture...

- Page 84 \Preset \Current User preset data \temporary Temporary file \PatientBack Patient back up data E drive Catalog Data Illustration Demo Ivision default DEMO path E:z6 Patient Backup Patient data back up demofile.txt Ivision default DEMO path 6-12 Software Upgrade and Maintenance...

-

Page 85: Structure And Assembly/Disassembly

Structure and Assembly/Disassembly Structure of the Complete System Figure 7-1 Overall Exploded View Name Name Holder Null turning axis of keyboard Rear cover assembly of main unit Silicon cap of keyboard Assembly of main unit rack Top cover assembly of keyboard Display assembly Bottom cover assembly of keyboard Structure and Assembly/Disassembly 7-1... -

Page 86: Field Replaceable Unit

Field Replaceable Unit Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl Mainboard Assembly(Z8/FRU) Used for Z6/Z8 and Z6&Z8 Z6Vet of any Doppler 115-031629-03 Series software version. Used for Z6/Z8 and Z6Vet with Doppler software version Refer Main unit V02.01.00 or above. related to7.4.5 After replacement,... - Page 87 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl 115-031629-03. BayTrail PC Module; CPU Module with 115-043600-00 has been discontinued. If it is out of stock, please use BayTrail PC Module Z6&Z8 Refer 115-043600-00 115-043600-01 to (1112/1114 FRU) Series to7.4.5 order and restore the latest Doppler software and...

- Page 88 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl latest Doppler software and compatible OS as well after replacement. Z8 Platform, this board should be used Main unit Z6&Z8 Refer 4D Module Kit 115-044346-00 with software of related Series to7.4.5 version V04.00.00and later.

- Page 89 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl HDD Assembly (Z6 Pro/CE/FRU) 115-044358-00 HDD Assembly (Z6 Expert/CE/FRU) 115-044359-00 HDD Assembly (Z6S/CE/FRU) 115-044360-00 HDD Assembly (Z6T/CE/FRU) 115-044361-00 HDD Assembly (Z6W/CE/FRU) 115-044362-00 HDD Assembly (Z6Vet/CE/FRU/for 115-018455-03 V4.0 to V5.0) HDD Assembly...

- Page 90 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl HDD Assembly 115-018453-04 (Z6Vet/FDA/FRU/for V5.0 or above) Main unit Battery connecting 801-1150-00004-0 Z6&Z8 Refer related board Series to7.4.1 Z8 Platform, this board should be used Main unit Z6&Z8 Refer IO Board (Z8/FRU) 115-044349-00 with software of related...

- Page 91 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl Main unit Probe Board Z6&Z8 Refer 115-044347-00 Z8 Platform related Assembly(Z8/FRU) Series to7.4.4 power supply 801-1150-00009-0 Z6&Z8 Refer to module Series 7.4.2 Power related Z6&Z8 Refer to AC-DC board( FRU) 115-051844-00 Series 7.4.2 Structure and Assembly/Disassembly 7-7...

- Page 92 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl Z6&Z8 Refer to DC-DC board( FRU) 115-051845-00 Series 7.4.2 Z6&Z8 Refer Battery (CE) 115-011471-00 Series For CE to7.4.1 (CE) Z6&Z8 Refer Battery(FDA) 115-011472-00 Series For FDA to7.4.1 (FDA) 7-8 Structure and Assembly/Disassembly...

- Page 93 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl Z8 Platform, this Top Cover of board should be used Z6&Z8 Refer Keyboard 115-044348-00 with software of Series to7.4.6.5 Assembly(Z8/FRU) version V04.00.00and later. Control Panel Z6&Z8 Refer 115-044386-00 Z8 Platform Cover(Z8/FRU) Series to7.4.6.5 Silicon...

- Page 94 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl Refer to “Focus/Freq 801-1150-00013-0 Z6&Z8 Refer Double encoder and Depth/Zoom” Series to7.4.6.1 Refer to “Gain” or 801-1150-00014-0 Z6&Z8 Refer Single encoder Series "Nav.Rot" to7.4.6.1 801-1150-00015-0 Z6&Z8 Refer Trackball Series to7.4.6.2 801-1150-00016-0 Z6&Z8 Refer TGC board...

- Page 95 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl Monitor 1150 Display Z6&Z8 Refer 115-045050-00 related assembly Series to7.4.7 Z6&Z8 Refer Backboard fan 024-000147-00 Series to7.4.5 Z6&Z8 Refer Power fan 024-000146-00 Series to7.4.2.1 Others Z6&Z8 Refer Speaker 115-045172-00 Series to7.4.9 Structure and Assembly/Disassembly 7-11...

- Page 96 Assembly/ Classification Description Photo Order Number Model Compatibility Disassembl ECG Module (AHA 115-050430-00 Only for maintenance lead/CE/Z6Vet) ECG Module (IEC 115-050431-00 Only for maintenance lead/CE/Z6Vet) ECG Module (AHA 115-050517-00 Only for maintenance lead/FDA/Z6Vet) ECG Module (AHA 115-044646-00 Only for maintenance lead/CE) ECG Module (IEC 115-044647-00...

-

Page 97: Preparations

Cross-headed screwdriver: 1pcs, Spec: 105 X100 Anti-static gloves: 1 pair 7.3.2 Engineers Required Only technical professionals from Mindray or engineers authorized by Mindray after training can perform maintenance and check. 7.3.3 Assembly/Disassembly Required You should perform the following preparations before the disassembling of ultrasound equipment. -

Page 98: Battery Connecting Board

Main unit rear cover Battery connecting Probe board Display Power board assembly assembly module assembly Probe Backligh Power boar DC-DC AC-DC board tailboard scree power power inverter assembl board board board Main board assembly Top cover Main unit assembly front cover of keyboard Main board... - Page 99 Figure 7-3 Disassembly of Battery (2) Remove panhead screws with washers (5 M3X8 and 2 M3X12) which are installed on the rack of the main unit rear cover. Figure 7-4 Disassembly of Rear Cover Assembly of Main Unit (1) Hold the battery bay and then remove the rear cover of the main unit simultaneously, pull out the plugs from the battery connecting board.

-

Page 100: Power Supply Module

Figure 7-5 Disassembly of Rear Cover Assembly of Main Unit (2) Remove panhead screws with washers (2 M3X6) fixed on the main unit box, and then take off the battery connecting board. Figure 7-6 Removing the Battery Connecting Board 7.4.2 Power Supply Module 1. - Page 101 Figure 7-8 Disassemble the Power Module Assembly (1) Figure 7-9 Disassemble the Power Module Assembly (2) 7.4.2.1 Power module Fan Removing panhead screws with washers (5 M3X6) fixed on the power module assembly and pulling out the plug of the fan connecting cables and power input outlet connecting cables, you can take off the rear panel of power supply assembly.

- Page 102 Figure 7-12 Disassemble the Power Module Fan During the assembly, fan label must be pasted towards the surface of the machine, NOTE: and don’t confuse with fans of other products. 7.4.2.2 DC-DC Power Board Remove panhead screws with washers M3X6 (4) used to fix the DC-DC power board. Figure 7-13 Disassemble the DC-DC Power Board (1) Remove the plug of fan cable.

-

Page 103: Io Broad

Figure 7-15 Disassemble the DC-DC Power Board (3) 7.4.2.3 AC-DC Power Board Remove panhead screws with washers M3X6 (5) used to fix the AC-DC power board. Figure 7-16 Disassemble the AC-DC Power Board (1) After removing the connecting plug between DC-DC power board and AC-DC power board, you could take out the AC-DC power board. -

Page 104: Probe Board

Figure 7-18 Disassemble the IO Board Assembly NOTE: Make sure that you could pull out and push into the IO board sockets vertically when pulling out and assembling the IO board assembly on the position of the handle. Remove panhead screws with washers M3X6 (4) used to secure the IO board, and then you could take out the IO board. -

Page 105: Main Board And Cpu Module

could take out the probe board. Figure 7-21 Disassemble the Probe Board 7.4.5 Main Board and CPU Module Remove rear cover assembly of the main unit (referring to 7.4.1 the 1~4 step) Remove panhead screws with washers (4 M3X6) which are fixed on the main unit, take out the power shielding board and then pull out two cables connecting the main board to the power module assembly. - Page 106 Figure 7-23 Disassemble the Main Board Assembly (2) When removing panhead screws with washers (4 M3X6) used to fix the CPU module, you can take out the CPU module. Figure 7-24 Disassemble the CPU module You can’t draw out the CPU module abruptly, but you would pull it out after NOTE: loosening the board from the left/right side to avoid damaging the main board FPGA.

-

Page 107: Top Cover Assembly Of Keyboard

1. The button cell model of the main board PCBA is Lithium 3V220mAh D20*3.2. NOTE: 2. During assembly, please assemble the main board and fasten with the screws, and then install the CPU module. Turn the main board, remove the panhead screws with washers M3X6 (4 pcs), and then the 4D board can be removed. - Page 108 After removing one countersunk head self-tapping screw PT3X10 fixed on the top cover of keyboard and take out the plug of the keyboard and the main unit connecting cables, you could remove the top cover of keyboard assembly. Figure 7-28 Disassembly of the Top Cover Assembly of Keyboard (3) 7.4.6.1 Encoder Board Draw out the 4 knobs upwards fixed on the encoder board on the control panel assembly.

- Page 109 Figure 7-31 Disassembly of the Trackball 7.4.6.3 TGC Board Draw out the 8 knobs upwards fixed on the TGC board on the control panel assembly. Figure 7-32 Disassembly of the TGC Board (1) After removing the connecting cable plug of TGC board and removing screws PT3X10 (4) fixed on the TGC board, you could remove the TGC board.

- Page 110 Figure 7-34 Disassembly of the Buzzer 7.4.6.5 Top cover assembly of keyboard(basic) Pull out the 8 TGC knobs and 4 encoder knobs upward from the control panel. Figure 7-35 Disassemble the Control Panel (1) Remove the encoder board, TGC board and trackball. The remained part is top cover assembly of keyboard (basic).

-

Page 111: Display Assembly

Figure 7-37 Disassemble the Control Panel (3) 7.4.7 Display Assembly Remove rear cover assembly of the main unit (referring to 7.4.1 the 1~4 step) Remove combination screws (6 M3X8) used to be secured the monitor on the front cover of the main unit by a screwdriver. - Page 112 pull out the corresponding cable plugs. Figure 7-40 Disassemble the Display assembly Pull the display assembly upwards to make it separated from the main unit. Figure 7-41 View of Display Assembly 7.4.7.1 Backlight Inverter Board Remove combination screws (4 M3X8) used to be secured the display on the front cover of the main unit by a screwdriver.

- Page 113 Figure 7-43 View of the Front Cover of the Display (2) After pulling out inverter board a few from the bulges of the rear cover, and removing connecting cables of the inverter board and backlight extension cables from the inverter board, you could take out the inverter board.

- Page 114 Figure 7-46 Disassemble the Monitor Assembly (2) Split slowly copper paper used to paste LCD signal cable at the back of the LCD screen, and pull out LCD signal cable. After removing combination screws M3X4 (each for 2) used to fix the supporting assembly of display on the left and right, you can pull out the LCD screen.

-

Page 115: Hard Disk

7.4.8 Hard Disk NOTE Please pay attention to the following matters during disassembling/assembling, otherwise the hard disk will be damaged: Hold the side of the hard disk, and please do not touch the board of the hard disk. Fasten the screws with the handy screw driver, and do not with the electric screw driver. -

Page 116: Speaker

the HDD assembly upwards. Figure 7-51 Disassembly of HDD (3) NOTE: After replacing the HDD, you need to: Restore the system; Install the optional functions: Key file must be written according to MAC address of the machine, Or else, the optional function of the product will be lost. Load configuration file, set the regulation type, system language and time zone. - Page 117 Cables of the display Cables of the speaker Cables of the Cables of the ECG keyboard assembly Figure 7-53 Disassembly of Speaker (2) Fasten one M3x12 screw removed (7.2.4.2) into the damping axis adjusting hole of display about 2-3 rings to confirm that the screw is fixed, then pull out the monitor simultaneously rotate the display assembly to adjust the monitor to the horizon position.

- Page 118 Figure 7-56 Disassembly of Speaker (5) 8. Remove 4 ST2.6X10 screws used to fix the speaker, and then take out the speaker. 9. As shown in the figure, remove 8 PT2.6X6 cross countersunk head self-tapping screws used to fix the speaker and then take out the speaker assembly. 图...

- Page 119 图 7-59 Disassembly of Speaker (8) Structure and Assembly/Disassembly 7-35...

-

Page 121: System Diagnosis And Support

System Diagnosis and Support General Status Indicator 8.1.1 Status Indicators of the Control Panel Status Icon Status definition and indicators Position indicators Power-on The indicator is not on when the system is turned off; The Control status Panel Press the key, the indicator blinks green at power on. indicator on the upper After power on, the indicator is green. -

Page 122: Status Indicator Of The Power Supply On The Io Board

Screen-saver default is and the backlight of the “mindray” showing on the freezing status automatically. control panel both monitor. restore to the previous 8-2 System Diagnosis and Support... -

Page 123: Starting Process Of The Whole System

The system is frozen. status. Ultrasound imaging hardware system is in the dormancy mode The system is on the Press the power switch for a power-off status: when connected the AC power short time, and then the system Starting the system by Power-off supply the AC indicator is is turned off by choosing from... -

Page 124: Start Process Of Complete System

8.2.1 Start Process of Complete System 8.2.1.1 Powered on by AC Basic Procedures Phenomenon The original status: no indication Finishing loading The AC status indicator on the control panel lights on, but the 3.3VSTB,Finishing loading indicators of HDD and standby are off. 5VSTB Press the power button, The Power-on status indicator flashes continuously on the control... -

Page 125: Start-Up Process Of Bios

8.2.2 Start-up Process of BIOS The start-up process of BIOS is a black-box operation, and the primary description is as following: Basic Procedures Basic phenomenon Self-test after the system power-on The LCD is blank screen in a short time. Initialization& The settings of record system & BIOS start-up display Providing the resident programmer library &... -

Page 126: Start-Up Of Doppler

8.2.4 Start-up of Doppler 8.2.4.1 Procedure of Startup Linux app initialization Initialize Related PC HDD peripherals along with PC initialization PC software initialization Initialize ultrasonic Ultrasonic HDD initialization Finish related Ultrasonic startup ,operation and software application of ultrasonic initialization software Finish initialization 8.2.4.2... - Page 127 Initializing gui… Platform initialization Ultrasonic software Initializing ultrasound peripheral… Peripheral The total initialization initialization increment is 1 Initializing ultrasound image… Imaging The total initialization increments are 2 Initializing ultrasound application… Application The total initialization increment is 1 Initialization completed… Finishing The total initialization increment is 1...

-

Page 128: Alarming And Abnormal Information

Initializing Set related information of the zoom, languages, font In increments of 1. locale… library and input Construct widget factory Configure the GUI layer Set menu items Initialize function library Construct UICenter Initializing Configure the application layer In increments of 1. gui…... -

Page 129: Turning On The System Configuration File Is Abnormal

8.3.1 Turning on the System Configuration File is Abnormal Alarming tips LOG record Suggestion Fail to open the file none Reinstall the system software. "SystemConfiguration.ini", and please check HDD data. 8.3.2 The voltage of system power is abnormal Alarming tips LOG record Suggestion ×××: System Monitor: Power supply alert! [VBAT], Current... -

Page 130: Fan Alarming

[VVV] represents the current value, and [LLL] represents the first limit of CPU temperature. Temperature The log records are the same The second alarming, XX temperature of CPU [VVV] represents the current value, and [LLL] Shut down represents the second limit of CPU temperature. Suggestion as above (XX means inversion timing,... -

Page 131: Phv Related Alarming

replace with new battery please change the battery Replace battery and confirm Battery I2C error, the malfunction module. Shutdown State Stop the illegal operation. Battery Hot Plug, Shutdown State 8.3.6 PHV Related Alarming Alarming tips LOG record Potential reason Alarm! Something is wrong with the programmed High-voltage voltage of power module, which make... -

Page 133: Care And Maintenance

Care and Maintenance Overview These procedures in this chapter are recommended. 9.1.1 Tools, Measurement Devices and Consumables Table 9-1 Tools and Measurement Devices Tool/Measurement Devices Qty. Remarks Resin or plastic container 1 pcs Can accommodate two probes Soft brush 1 pcs About a toothbrush size Small plastic basin 1 pcs... -

Page 134: Care And Maintenance Items

9.1.2 Care and Maintenance Items Table 9-3 Maintenance Items and Frequency Maintain content Frequency Method Clean display Monthly Referring to 9.2.1 Clean trackball Monthly Same as the above Clean control panel Monthly Same as the above Clean probes (the head) Every time after using Same as the above Clean probe cable and the surface of... -

Page 135: Cleaning

Cleaning 9.2.1 Clean the System 9.2.1.1 Flow of Cleaning Power off and pull out the power cables Clean display Clean trackball Clean control panel Clean probe Clean holders Clean cover Figure 9-1 View of Cleaning Maintenance Before cleaning the system, be sure to turn off the power and WARNING: disconnect the power cord from the outlet. - Page 136 Trackball is one of important interface parts, which are embedded into the main unit keyboard, and part of which is exploded to be operated by users in order to implement variety of module’s control functions. Trackball is one of the most using frequency of input assemblies on the whole operation panel, and the trackball similar to a multi-directory caster can rotate in every direction drived manually, due to the feature, gas or dust can enter into module internal easily, as a result, contamination of lens would lead to the failure of the trackball.

- Page 137 Clean control panel Tools: dry soft cloth, mild soapy water Method: Use dry soft cloth to clean the surface of the system. If the system is dirty, moisten the soft cloth with mild soapy water and wipe off any stains. Use dry soft cloth to remove any moisture and allow all hard surfaces to completely air-dry.

-

Page 138: Clean The Peripherals

9.2.3 Clean the Peripherals Do the cleaning maintenance according to your actual peripheral configuration; items which are not configured can be skipped. Table 9-4 Peripherals Cleaning List Content Description First wipe off dust or stain attached to the cover of printer with Color and B/W video soft dry cloth, then clean the inside of printer. -

Page 139: System Function Check

Content Method Check the battery periodically : a) Check if battery can be charged normally when power-on: That the current capacity is 100% or capacity increases after a short time indicates that the battery can be charged normally. It takes less than 2 minutes to increase 1% capacity when the total Battery capacity is less than 90% and it takes more time when the... -

Page 140: Peripherals And Options Check

9.3.3 Peripherals and Options Check If the system is not configured with any module or peripheral, the corresponding items checking can be skipped. Table 9-7 Options, Peripherals and Accessories Check list Content Method Color and B/W video Check if the output of video printer is normal. printer Graph / text printer Check if the output of graph / text printer is normal. -

Page 141: Electrical Safety Inspection

9.3.5 Electrical Safety Inspection Only technical professionals from Mindray or engineers authorized by Mindray after training can perform electric safety inspection. Please refer to appendix A: Electrical Safety Inspection for details. Care and Maintenance 9-9... -

Page 143: Troubleshooting Of Regular Malfunctions

Troubleshooting of Regular Malfunctions 10.1 System cannot be powered on 10.1.1 Module or Board Related Descriptions Remarks Battery Li-ion 14.8V 6600mAh LI34I002A Power supply module CPU module 10.1.2 Key Points Supporting Troubleshooting Key Points Supporting Troubleshooting Remarks AC power indicator Located on control panel Power-on status indicator Backlight of the power button... -

Page 144: System Cannot Start Up Normally

The AC input is normal ,AC power indicator Power supply module fails Replace power remains off; supply module Power indicators: off AC power indicator: ON; Power supply module fails Replace power supply module Power-on status indicator: off after power button pressed Power indicators: off AC power indicator: ON;... -

Page 145: Image Fault

interface CPU module failure Replace CPU module BIOS start-up graphics is normally displayed, but it cannot be kept on Enters BIOS start-up graphics. Cannot find operating system, Find the failure cause the HDD or OS in HDD may by entering BIOS No LINUX start-up graphics be damaged. -

Page 146: Key Points Supporting Troubleshooting

IO board 10.3.2 Key Points Supporting Troubleshooting Key Points Supporting Troubleshooting Remarks Image feature, including dark strips and noise Images appearance when contact occurs between different types of probe in different interface of probe socket. 10.3.3 Troubleshooting Fault Cause Analysis Measure Description NO echo signal... -

Page 147: Probe Socket System Malfunction

The image abnormality may be caused by Replace the probe, or the swivel of the 4D probe or the 4D drive replace the 4D drive board board. It is suggested to replace the probe first, and then replace the 4D drive board. Failed to recognize ECG. -

Page 148: Io Interface System

10.5 IO Interface System 10.5.1 Module or Board Related Descriptions Remarks Main board CPU module IO board Speaker 10.5.2 Key Points Supporting Troubleshooting Key Points Supporting Troubleshooting Remarks Working condition of the control panel Confirm if the USB main device is functional since the control panel is connected by internal USB cable Working condition of each USB port... -

Page 149: Control Panel

10.6 Control Panel 10.6.1 Module or Board Related Descriptions Remarks Silicon key Control panel Dual encoder module Single encoder module Trackball module TGC module 10.6.2 Key Points Supporting Troubleshooting Points Supporting Remarks Troubleshooting Backlight of control panel To confirm if the control panel is powered on normally; Key sound of the control panel. -

Page 150: Lcd Display

speed in system preset; Replace the trackball module Degenerated trackball performance All key of control panel are Single encoder malfunction Replace the encoder board normal, Single encoder failed. All key of control panel are TGC board malfunction Replace TGC board normal, Single key of TGC failed. - Page 151 The color of some mode key turns on orange. monitor board or monitor malfunction assembly No display (blank screen) on the LCD, with backlight only; or, disordered screen. Control panel powered on normally and no key CPU module Replace CPU module indicator turns on orange.

- Page 153 Appendix A ELECTRICAL SAFETY INSPECTION The following electrical safety tests are recommended as part of a comprehensive preventive maintenance program. They are a proven means of detecting abnormalities that, if undetected, could prove dangerous to either the patient or the operator. Additional tests may be required according to local regulations.

-

Page 154: Electrical Safety Inspection

ELECTRICAL SAFETY INSPECTION 1- Power Cord Plug TEST PROCEDURE The Power Plug The Power Plug Pins No broken or bent pin. No discolored pins. The Plug Body No physical damage to the plug body. No physical damage to the strain relief. No plug The Strain Relief warmth for device in use. - Page 155 ELECTRICAL SAFETY INSPECTION Device Enclosure And Accessories TEST PROCEDURE Visual Inspection No physical damage to the enclosure and accessories. No physical damage to meters, switches, connectors, etc. No residue of fluid spillage (e.g., water, coffee, The Enclosure and Accessories chemicals, etc.).

- Page 156 ELECTRICAL SAFETY INSPECTION Device Labeling TEST PROCEDURE Check the labels provided by the manufacturer or the healthcare facility is present and legible. Main Unit Label Integrated Warning Labels Slope and High Voltage Caution Label Don’t Stress Label A-4 Electrical Safety Inspection...

- Page 157 ELECTRICAL SAFETY INSPECTION 4- Protective Earth Resistance VOERVIEW Protective Earth Resistance is measured using the RED test lead attached to the DUT Protective Earth terminal or Protective Earth Metal enclosure or equipotential terminal. Select the test current by pressing SOFT KEY 3 to toggle between 1AMP, 10AMP, and 25AMP. The front panel outlet power is turned off for this test.

- Page 158 ELECTRICAL SAFETY INSPECTION 4- Protective Earth Resistance metal area. Press shortcut key 3. The Protective Earth Resistance test is displayed. Press SOFT KEY 3 to select a test current (1AMP, 10AMP, or 25AMP). The selected test current is displayed in the upper right corner of the display. Press START TEST to start the test.

- Page 159 ELECTRICAL SAFETY INSPECTION Earth Leakage Test OVERVIEW Run an Earth Leakage test on the device being tested before performing any other leakage tests. Leakage current is measured the following ways: ♦ Earth Leakage Current, leakage current measured through DUT outlet Earth ♦...

- Page 160 ELECTRICAL SAFETY INSPECTION Earth Leakage Test Figure 1 Earth leakage test Failure Check any short-circuits of the Y capacitor on power unit. Replace a new one if any portion defective. Check any broken of the Power Unit. Replace a new one if any portion defective. Inspect mains wiring for bad crimps, poor connections, or damage.

- Page 161 ELECTRICAL SAFETY INSPECTION Patient Leakage Current OVERVIEW Patient leakage currents are measured between a selected applied part and mains earth. All measurements may have either a true RMS or a DC-only response. TEST PROCEDURE Prepare Perform a calibration from the Mains on Applied Part menu. The following outlet conditions apply when performing this test: Normal Polarity, Earth Open, Outlet ON Normal Polarity, Outlet ON...

- Page 162 ELECTRICAL SAFETY INSPECTION Patient Leakage Current the 601PRO. Press the print data key at any time to generate a printout of the latest measurement. Figure 2 patient leakage Current Note 1, In addition to Probes ,Patient leakage current test should be perform if ECG or PCG parts used;...

- Page 163 ELECTRICAL SAFETY INSPECTION Patient Leakage Current LIMITS All countries For BF ECG input and transducer 100μA Normal Condition 500μA Single Fault Condition Electrical Safety Inspection A-11...

- Page 164 ELECTRICAL SAFETY INSPECTION Mains on Applied Part Leakage OVERVIEW The Mains on Applied Part test applies a test voltage, which is 110% of the mains voltage, through a limiting resistance, to selected applied part terminals. Current measurements are then taken between the selected applied part and earth. Measurements are taken with the test voltage (110% of mains) to applied parts in the normal and reverse polarity conditions as indicated on the display.

- Page 165 ELECTRICAL SAFETY INSPECTION Mains on Applied Part Leakage Attach the applied parts to the 601PRO applied part terminals. Attach the red terminal lead to a conductive part on the DUT enclosure. Press shortcut key 7. The Mains on Applied Part test is displayed. Select the desired outlet configuration and applied part to test using the appropriate SOFT KEYS: Press START TEST (SOFT KEY 1) to begin the test.

- Page 166 ELECTRICAL SAFETY INSPECTION Mains on Applied Part Leakage could be used instead. Change another probe to confirm if the fail is caused by console. Inspect wiring for bad crimps, poor connections, or damage. If the leakage current measurement tests fail on a new unit and if situation cannot be corrected, submit a Safety Failure Report to document the system problem.

- Page 167 ELECTRICAL SAFETY INSPECTION FORM (Class I equipment) Overall assessment: □ Scheduled inspection Test item: 1, 2, 3, 9 □ Unopened repair type Test item: 1, 2, 3, 9 □ Opened repair type, not modify the power part Test item: 1, 2, 3, 4, 5, 9 including transformer or patient circuit board □...

-

Page 169: Appendix B Phantom Usage Illustration

Appendix B Phantom Usage Illustration Note: The use of Phantom is not required during Preventive Maintenance. Customer may use it as part of their Quality Assurance Program tests。 Best storage and operating temperature of phantom is 10℃~35℃, do not use phantom Note: beyond the specified temperature range, otherwise tested performance indicators may be affected. - Page 170 Targets disposal of Phantom KS107BD A1——A4 Axial resolution target group B1——B4 Lateral resolution target group Longitudinal target group Horizontal target group E1——E3 Mimic sacs with diameters of 2, 4, 6mm 4. Line Target System There are 8 groups of line targets disposed in TM material as shown in the figure. 1.A1——A4:...

- Page 171 Phantom Usage Illustration B-3...

- Page 173 P/N: 046-010452-00 (5.0)

Need help?

Do you have a question about the Z6 Pro and is the answer not in the manual?

Questions and answers