Table of Contents

Advertisement

Quick Links

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact@mouvex.com - www.mouvex.com

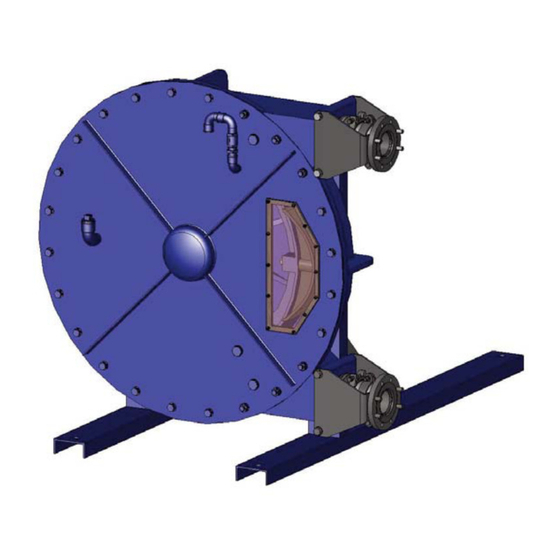

PUMP AS125

INSTRUCTIONS 1101-P00 e

Section

Effective

Replaces

Original instructions

INSTALLATION

OPERATION

MAINTENANCE

Your distributor :

3, Poruchik Nedelcho Bonchev Str., . 5

1528 So a, Bulgaria

tel: +359 2 973 27 67

e-mail: o ce@daisglobal.eu

1101

August 2010

July 2010

Advertisement

Table of Contents

Summary of Contents for Dover MOUVEX AS125

- Page 1 INSTRUCTIONS 1101-P00 e Section 1101 Effective August 2010 Replaces July 2010 Original instructions PUMP AS125 INSTALLATION OPERATION MAINTENANCE Your distributor : 3, Poruchik Nedelcho Bonchev Str., . 5 1528 So a, Bulgaria tel: +359 2 973 27 67 Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE e-mail: o ce@daisglobal.eu Tel.

-

Page 2: Table Of Contents

MOUVEX PERISTALTIC HOSE PUMP SAFETY INSTRUCTIONS, STORAGE, INSTALLATION AND MAINTENANCE MODEL : AS125 TABLE OF CONTENTS Page TECHNICAL CHARACTERISTICS • Maximum pump speed acceptable* : 1. OVERALL DIMENSIONS ......3 •... -

Page 3: Overall Dimensions

1. OVERALL DIMENSIONS NT 1101-P00 08.10 AS125 e 3/18... -

Page 4: Installation

2. INSTALLATION 2.1 Operator principle 2.4 Pipe diameters The pump operates by alternating contraction and The location of the pump in the transfer or recycling circuit relaxation of a specially designed elastomeric hose. should always be determined so as to reduce the suction height and length of the piping as much as possible. -

Page 5: Direction Of Rotation

2. INSTALLATION (continued) 2.8 Working with vaccum on the suction side If the liquid may freeze or solidify, prepare for draining the piping by installing drain taps at the low points and Because of the operating principle of the pump, using it air vents at the high points. -

Page 6: Anchoring The Pump Units

2. INSTALLATION (continued) 2.11 Anchoring the pump units It is important to control the alignment at every step of installation in order to ensure that none of these steps The correct seating of the pump is vital for its efficient generates stress on the pump unit or the pump itself : operation and its longevity. -

Page 7: Use

3. USE 3.1 Pump storage 3.5 Starting-up the pump If the pump is inactive for more than 3 months, remove WARNING the hose or the shoes. If you do not wish to remove the hose or the shoes, operate the pump for 5 minutes once FAILURE TO RELIEVE THE SYSTEM a week. -

Page 8: Maintenance Operations

4. MAINTENANCE OPERATIONS WARNING WARNING IF PUMPING HAZARDOUS OR TOXIC DISCONNECT THE ELECTRICITY SUP- FLUIDS, THE SYSTEM MUST BE FLUSHED PLY BEFORE ANY MAINTENANCE OPE- PRIOR TO PERFORMING ANY SERVICE RATION. OPERATION. Hazardous or toxic Dangerous voltage. fluids can cause Can cause injury and death serious injury. - Page 9 4. MAINTENANCE OPERATIONS (continued) TOP PORT NOTES Repeat the steps described above from 2 to 10. If the pump is not re-assembled immediately, dry unpainted surfaces and coat them with the pump WARNING lubricant in order to protect them against corrosion. Dispose of the drained products in accordance with the rules and regulations in force.

- Page 10 4. MAINTENANCE OPERATIONS (continued) BOTTOM PORT 4.1.5 FILLING WITH LUBRICANT 1. Check the state of the nipple 6 and change it if necessary. CAUTION 2. Coat the nipple 6 with pump lubricant. 3. Slide the nipple 6 on the body port 1. 4.

-

Page 11: Re-Assembling And Disassembling The Wheel

4. MAINTENANCE OPERATIONS (continued) 4.2 Re-assembling and disassembling the 4.3 Replacing the shoes wheel To replace the shoes 5, the pump hose must be disas- sembled (see § REPLACING THE HOSE). Disassembly and reassembly of the wheel 3 are required when : •... -

Page 12: Setting Of Pump At Service Pressure Needed

4. MAINTENANCE OPERATIONS (continued) 4.4 Setting of pump at service pressure needed Shims may have to be added under the shoes (see § SHIMMING THE SHOES). The cover 2 need not be removed. 4.4.1 ADDING OR TAKING OFF SHIMS First shoe : 1. - Page 13 4. MAINTENANCE OPERATIONS (continued) CAUTION 4.4.2 FILLING WITH LUBRICANT 1. Unscrew the plug 124. 2. Fill the pump body with lubricant, as indicated in THE PUMP LUBRICANT IS VERY SLIPPERY § LUBRICATION. AND MAY CAUSE SERIOUS INJURY. ANY SPILLS MUST BE CLEANED UP. 3.

-

Page 14: Technical Specifications

5. TECHNICAL SPECIFICATIONS Flowrate (m3/h) 11,0 16,5 22,0 27,5 33,0 38,5 44,0 49,5 55,0 60,5 66,0 71,5 77,0 80000 15 bar 10 bar 7,5 bar 5 bar 70000 60000 50000 Max service @50°C Max service @60°C 40000 Max service @70°C Max service @80°C 30000 20000... -

Page 15: Characteristics

5. TECHNICAL SPECIFICATIONS (continued) 5.1 Characteristics 5.2 Shimming the shoes Light grey area : Continuous service (24h/24). Suitable shimming of the shoes lengthens the service life of the hose. Dark grey area : Intermittent service (continually for 2 hours then stopped for 1 hour). 5.2.1 SERVICE PRESSURE SPECIFIED AT ORDER The flow rates shown have been obtained by pumping If the service pressure has been specified at order, the... -

Page 16: Maintenance

6. MAINTENANCE 6.1 Lubrication 6.3 Seals The hose is lubricated with a special mixture. MOUVEX 6.3.1 SHAFT SEAL 26 lubricant is recommended to lengthen the service life of The shaft seals 26 must be replaced if lubricant leakage the hose. is observed near the drip strip, located on the rear side It is recommended to change the lubricant when : of the pump body 1. -

Page 17: Troubleshooting

7. TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION THE PUMP Check the connections : WILL NOT There must be 3 phases START Electric power supply failure. The connections are suitable for the voltage (delta-star) If possible, check the parameters for the different motor frequencies (starting torque, power input…) When the pump has not been used for a long Operate the pump intermittently to try to free the wheel... -

Page 18: Certificate Of Conformity

8. CERTIFICATE OF CONFORMITY CERTIFICATE OF CONFORMITY Mouvex, ZI La Plaine des Isles – Rue des Caillottes – 89 000 Auxerre France, declares the following equipment: Set-up : Pump / Compessor « bare-shaft » Pumping Unit / Compressor Unit Type : Eccentric Disc Pump Vanes Pump Lobes Pump...

Need help?

Do you have a question about the MOUVEX AS125 and is the answer not in the manual?

Questions and answers