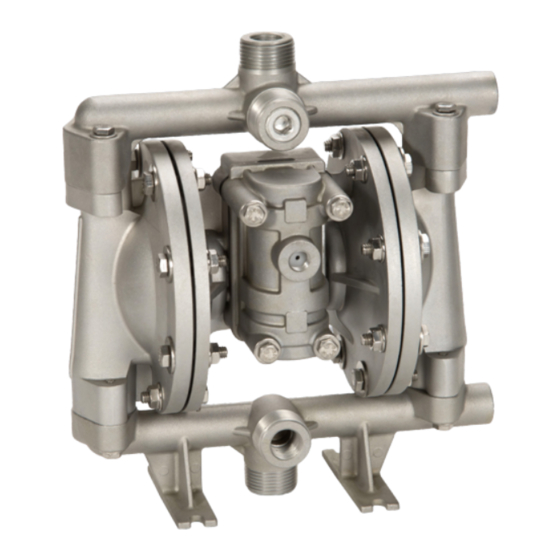

Dover PSG ALL-FLO A075 Installation, Operation & Maintenance Manual

Metal 3/4 inch air-operated double-diaphragm pump

Hide thumbs

Also See for PSG ALL-FLO A075:

Summary of Contents for Dover PSG ALL-FLO A075

- Page 1 INSTALLATION OPERATION & MAINTENANCE A075 METAL 3/4 INCH AIR-OPERATED DOUBLE-DIAPHRAGM PUMP...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SECTION 1 WARNINGS, DANGERS AND CAUTIONS SECTION 2 MODEL DESIGNATION MATRIX & REPAIR KITS SECTION 3 PRINCIPLES OF OPERATION SECTION 4 DIMENSIONAL DRAWINGS SECTION 5 PERFORMANCE CURVES RUBBER DIAPHRAGMS ..............9 TPE DIAPHRAGMS ................9 PTFE DIAPHRAGMS ..............9 SECTION 6 INSTALLATION INSTALLATION ................... -

Page 3: Warnings, Dangers And Cautions

SECTION CAUTIONS — READ FIRST! READ THESE WARNINGS AND SAFETY PRECAUTIONS PRIOR TO WARNING = Hazards or unsafe practices which INSTALLATION OR OPERATION. FAILURE TO COMPLY WITH THESE could result in severe personal injury, INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND OR death or substantial property damage PROPERTY DAMAGE. -

Page 4: Model Designation Matrix & Repair Kits

SECTION MODEL DESIGNATION MATRIX & REPAIR KITS- ALUMINUM FLUID CONNECTION TYPE VALVE SEAT SPECIAL OPTION (HARDWARE, MUFFLER, LUG) N = NPT P = Polypropylene 3 = Standard (Zinc Plated Steel Hardware, Plastic Muffler) 3 = Stainless Steel 4 = Zinc Plated Steel Hardware, Metal Muffler B = BSPT 7= Stainless Steel Hardware, Plastic Muffler A = Aluminum... - Page 5 MODEL DESIGNATION MATRIX & REPAIR KITS - STAINLESS STEEL VALVE SEAT SPECIAL OPTION (HARDWARE, MUFFLER, LUG) FLUID CONNECTION TYPE 3 = Stainless Steel 7 = Standard (Stainless Steel Hardware, Plastic Muffler) N = NPT P = Polypropylene 8 = Stainless Steel Hardware, Metal Muffler B = BSPT A = Aluminum B = PTFE Coated Stainless Steel Hardware,...

-

Page 6: Principles Of Operation

SECTION PRINCIPLES OF OPERATION HOW AN AIR OPERATED DOUBLE DIAPHRAGM PUMP WORKS The air-valve directs pressurized air behind the diaphragm on the right, causing the diaphragm on the right to move outward (to the right). Since both the right diaphragm and the left diaphragm are connected via a diaphragm rod, when the right diaphragm moves to the right, the left diaphragm (through the action of the diaphragm rod) moves to the right also. -

Page 7: Dimensional Drawings

SECTION 3/4” PUMP DIMENSIONS ALUMINUM CENTER SECTION 3/4” FNPT OR FBSPT ONLY 1/4”-18 FNPT (Air Inlet) 11.2” (284mm) 9.5” (241mm) 6.7” (170mm) 1.8” (46mm) 10.3” (262mm) 6.4” (163mm) Aluminum 0.31” (8mm) Stainless Steel 0.28 (7mm) 3.2” (81mm) 3.6” (91mm) 4.0” (102mm) 1.1”... - Page 8 SECTION 3/4” PUMP DIMENSIONS POLYPROPYLENE CENTER SECTION 3/4” FNPT OR FBSPT ONLY 1/4”-18 FNPT (Air Inlet) 11.2” (284mm) 9.5” (241mm) 6.3” 6.3” (160mm) (160mm) 1.8” (46mm) 10.3” (261.62mm) Aluminum 0.31” (8mm) 7.3” (185mm) Stainless Steel 0.28 (7mm) 4.1” (104mm) 3.6”(91mm) 4.0”...

-

Page 9: Performance Curves

SECTION PERFORMANCE CURVES PERFORMANCE CURVE (3/4” RUBBER)* Performance Specifications PERFORMANCE CURVE (1/2", RUBBER) Max. Flow: 14 gpm (53.0 lpm) DISCHARGE FLOW-Liters/Min. 15.1 22.7 30.3 37.9 45.4 60.6 Max. Air Pressure: 120 psi (8.3 bar) (8,2) (83,9) AIR CONSUMPTION (SCFM) Max. Solids: ”... -

Page 10: Installation

SECTION INSTALLATION, TROUBLESHOOTING AND MAINTENANCE INSTALLATION Ensure that the air supply is sufficient for the PIPING volume of air required by the pump. Refer to product specifications for further details. For reliable Whenever possible ensure the pump is installed using operation, install a 5 micron air filter, air-valve and the shortest possible pipe lengths with the minimum pressure regulator. - Page 11 SUGGESTED INSTALLATION This illustration is a generic representation of an air operated double-diaphragm pump. ALF-12040-E-01 All-Flo...

-

Page 12: Troubleshooting

TROUBLESHOOTING PROBLEM EFFECT/SOLUTION Pump Will Not Cycle Discharge line closed or plugged Discharge filter blocked Check valve stuck Air filter blocked Air supply valve closed Air supply hooked up to muffler side of pump Compressor not producing air or turned off Muffler iced or blinded Diaphragm ruptured Plant air supply line ruptured... -

Page 13: Operation

OPERATION MAINTENANCE The Air-Operated Double Diaphragm Pump requires Due to the unique nature of each application, periodic a minimum of 20 psig of air to operate, with some inspection of the pump is the best method to determine variation according to diaphragm material. Increasing a proper maintenance schedule. -

Page 14: Repair And Assembly

SECTION REPAIR AND ASSEMBLY PUMP WET END REMOVAL WARNING Prior to servicing the pump, ensure that the air TOOLS NEEDED and fluid lines are closed and disconnected. While wearing personal 1) One Wrench, Inch protective equipment, flush, drain and process liquid from the pump in a safe manner. - Page 15 STEP 7 STEP 8 STEP 9 In order to remove “Outer Cham- Remove both “Outer Chambers” Using two ¾ Inch wrenches, bers”, using two ½ inch wrenches, from the “Intermediate”. remove “Outer Diaphragm Plate”, remove eight “Hex Head Cap Screws “Diaphragm”, “Inner Diaphragm (5/16”–18 x 1-3/4”)”, eight “Flat and Plate”...

-

Page 16: Air Valve Removal

REPAIR AND ASSEMBLY AIR VALVE REMOVAL WARNING TOOLS NEEDED Prior to servicing the pump, ensure that the air and fluid lines are closed and disconnected. While wearing personal 1) One Wrench, Inch protective equipment, flush, drain and process liquid from the 2) One Pick, General Purpose pump in a safe manner. - Page 17 STEP 7 STEP 8 STEP 9 Remove the “Air Valve Spool” from Using the pick, remove the “Lip Using the pick, remove the the main “Air-Valve Assembly”. Seal (Air Valve)” from the main second “Lip Seal (Air Valve)” from “Air-Valve Assembly”. the main “Air-Valve Assembly”.

-

Page 18: Pilot Valve Removal

REPAIR AND ASSEMBLY PILOT VALVE REMOVAL WARNING TOOLS NEEDED Prior to servicing the pump, ensure that the air and fluid lines are closed and disconnected. While wearing personal 1) One Screwdriver, #2 Phillips protective equipment, flush, drain and process liquid from the 2) Two Wrenches, Inch pump in a safe manner. -

Page 19: Torque Specifications

PILOT VALVE ASSEMBLY To assemble the pilot valve, reverse the order of disassembly. Should process fluid have contact with the pilot valve O-rings, they should be replaced as swelling may occur and cause irregular operation. During assembly, ensure that the open side of the lip-seals are facing outward. Lubrication of the pilot sleeve assembly, with a non-synthetic lubricant, is recommended in order to facilitate re-assembly into the intermediate. -

Page 20: Exploded Views And Parts Lists

SECTION EXPLODED VIEW & PARTS LIST ALUMINUM AND STAINLESS STEEL PUMPS WITH ALUMINUM CENTER SECTION (A075-*A*-****-***) ALF-12040-E-01 All-Flo... - Page 21 PARTS LIST - ALUMINUM AND STAINLESS STEEL PUMPS WITH ALUMINUM CENTER SECTION (A075-*A*-****-***) ITEM DESCRIPTION PUMP MODEL PART NO. MATERIAL DISCHARGE MANIFOLD A075-N*A-****-*** 11329-A075-20-N Aluminum A075-B*A-****-*** 11329-A075-20-B Aluminum A075-N*3-****-*** 11329-A075-26-N Stainless Steel A075-B*3-****-*** 11329-A075-26-T Stainless Steel BALL A075-***-*V**-*** 11000-13 A075-***-*G**-*** 11000-19 Geolast ®...

- Page 22 PARTS LIST - ALUMINUM AND STAINLESS STEEL PUMPS WITH ALUMINUM CENTER SECTION (A075-*A*-****-***) ITEM DESCRIPTION PUMP MODEL PART NO. MATERIAL AIR VALVE END PLUG A075-*A*-****-*** 11706-20 ‡ Aluminum MUFFLER ALL MODELS 13008-00 Standard MUFFLER (METAL) Optional 13002-00 Metal PAN-HEAD MACH SCREW (#6-32 x 7/16) A075-**A-****-*** 12585-26 Stainless Steel...

- Page 23 EXPLODED VIEW & PARTS LIST ALUMINUM AND STAINLESS STEEL PUMPS WITH PLASTIC CENTER SECTION (A075-*P*-****-***) ALF-12040-E-01 All-Flo...

- Page 24 PARTS LIST - ALUMINUM AND STAINLESS STEEL PUMPS WITH PLASTIC CENTER SECTION (A075-*P*-****-***) ITEM DESCRIPTION PUMP MODEL PART NO. MATERIAL DISCHARGE MANIFOLD A075-N*A-****-*** 11329-A075-20-N Aluminum A075-B*A-****-*** 11329-A075-20-B Aluminum A075-N*3-****-*** 11329-A075-26-N Stainless Steel A075-B*3-****-*** 11329-A075-26-T Stainless Steel BALL A075-***-*V**-*** 11000-13 A075-***-*G**-*** 11000-19 Geolast ®...

- Page 25 PARTS LIST - ALUMINUM AND STAINLESS STEEL PUMPS WITH PLASTIC CENTER SECTION (A075-*P*-****-***) ITEM DESCRIPTION PUMP MODEL PART NO. MATERIAL AIR VALVE END PLUG -*P*-****-*** 11703-60 Polypropylene A075 ‡ MUFFLER ALL MODELS 13008-00 Standard MUFFLER (METAL) Optional 13002-00 Metal MUFFLER PLATE A075-*P*-****-*** 13111-60 Polypropylene...

-

Page 26: Elastomers

SECTION ELASTOMERS WETTED ELASTOMERS BUNA-N (NITRILE) GEOLAST® is a general purpose elastomer used with water and is an injection molded thermoplastic material with many oils. Temperature range 10°F to 180°F (-12°C characteristics similar to Nitrile. Has excellent to 82°C). abrasion resistance. Temperature range 10°F to 180°F (-12°C to 82°C). - Page 27 SECTION ATEX PROTECTION SUMMARY POTENTIAL IGNITION CAUSE DESCRIPTION OF PROTECTION MEASURES APPLIED SOURCE The maximum surface temperature of the equipment does not depend on the equipment itself, but mainly the process. Friction between stationary Hot Surface The relevant information has been given in the instructions and moving parts for use and the equipment has been marked T6-T3 in order to inform the user about this special situation.

- Page 28 All-Flo Pumps comply with the following European Union directives: The Machinery Directive 2006/42/EC: Annex I, and complies with the relevant requirements of the following standards: BS EN ISO 12100:2010, BS EN 809:2009, and BS EN 12162:2009 The ATEX Directive 2014/34/EU: Annex II, and complies with the relevant requirements of the following standards: EN ISO 80079-36:2016, and EN ISO 80079-37:2016.

- Page 29 SECTION WARRANTY AND REGISTRATION WARRANTY. All All-Flo products shall be covered by the standard All-Flo Limited Warranty in effect at the time of shipment. This warranty (which may be modified by All-Flo at any time) provides: MATERIALS SOLD ARE WARRANTED TO THE ORIGINAL USER AGAINST DEFECTS IN WORKMANSHIP OR MATERIALS UNDER NORMAL USE (RENTAL USE EXCLUDED) FOR FIVE YEARS AFTER PURCHASE DATE.

- Page 30 22069 Van Buren Street Grand Terrace, CA 92313-5651 USA P: +1 (440) 354-1700 F: +1 (440) 354-9466 all-flo.com All-Flo is committed to the pursuit of designing and manufacturing the highest quality product available to industry. Since the beginning in 1986, All-Flo engineers have used their extensive knowledge of today’s engineered materials, advanced air system logic and manufacturing techniques to develop the superior group of lube-free, air-operated diaphragm pumps found in this catalog.

Need help?

Do you have a question about the PSG ALL-FLO A075 and is the answer not in the manual?

Questions and answers