Table of Contents

Advertisement

Quick Links

Operation/Repair/Parts

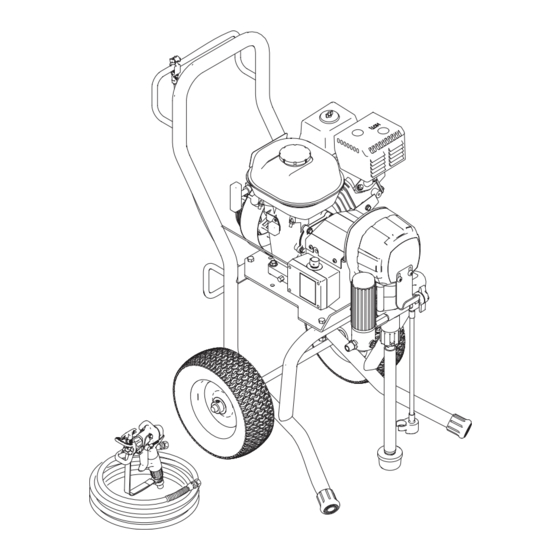

Airless Paint Sprayer

For application of architectural paints and coatings. For professional use only.

Airlessco - GS800 24F574, 16M531

3000 psi (20.7 MPa, 207 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Related Manuals

Gun Manual

289316:

312363 - English

312364 - Spanish

312365 - French

24H289:

3A0479 - English

3A0480 - French

3A0481 - Spanish

3A1186F

EN

ti16161a

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for AIRLESSCO 3A1186F

- Page 1 Operation/Repair/Parts 3A1186F Airless Paint Sprayer For application of architectural paints and coatings. For professional use only. Airlessco - GS800 24F574, 16M531 3000 psi (20.7 MPa, 207 bar) Maximum Working Pressure Important Safety Instructions Read all warnings and instructions in this manual.

- Page 2 Pressure Relief Procedure for turning off the unit. • Check hoses and parts for signs of damage. Replace any damaged hoses or parts. • This system is capable of producing 3000 psi. Use Airlessco replacement parts or accessories that are rated a minimum of 3000 psi.

- Page 3 • Do not kink or over-bend the hose. • Do not expose the hose to temperatures or to pressures in excess of those specified by Airlessco. • Do not use the hose as a strength member to pull or lift the equipment.

- Page 4 • Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer. CALIFORNIA PROPOSITION 65 The engine exhaust from this product contains a chemical known to the State of California to cause cancer, birth defects or other reproductive harm. 3A1186F...

-

Page 5: Component Identification

It is in the Open position when there is a wider gap between valve handle and cam body. Prime/Pressure (PR) Relief Valve Pressurizes system when closed. It is in the Closed position Closed Position when there is only a slight gap between handle and body. 3A1186F... -

Page 6: Operation

NOTE: The valve handle can move both clockwise and NOTE: The 6’ whip hose should always be 3/8”. counter clockwise and can face different directions. 3A1186F... -

Page 7: Prime And Flush Storage Fluid

3. Place the suction tube into the pail or place the pail Before beginning a new spraying project you need to under the pump. prime the sprayer and flush the storage fluid out of the sprayer. 3A1186F... - Page 8 1. Prepare the material according to the material man- to the left. . ufacturer’s recommendations. Closed (Pressure) 2. Place the suction tube into the material container. 3. Start the sprayer. Prime/PR Valve must be “OPEN” in the prim- ing position. ti14790a 3A1186F...

-

Page 9: Adjusting The Pressure

1. Flush sprayer with compatible solvent before stor- ing, then fill the pump and hoses with an oil based Adjusting the Pressure solvent such as mineral spirits or Graco or Airlessco Pump Armor. • For oil base paint: flush with mineral spirits •... -

Page 10: Daily Maintenance

Maintenance Daily Maintenance Keep displacement pump packing nut/wet cup lubri- cated with Airlessco Throat Seal Oil at all times. The TSO helps protect the packings and rod. Inspect the packing nut daily. If seepage of paint into the packing nut and/or movement of the piston upward is found (while not spraying), the packing nut should be tight- ened just enough to stop leakage. -

Page 11: Servicing The Outlet Valve

7. Tighten packing nut clockwise until resistance is felt against the Belleville Springs, go 3/4 of a turn more. Put five drops of Airlessco Throat Seal Oil in the packing nut. 8. Run the machine at full pressure for several min- utes. -

Page 12: Servicing The Inlet Valve

O-ring, suction ball and suction tion retainer. ball guide in the suction nut and screw onto fluid pump body. 3. Clean all parts and inspect them for wear or dam- age, replacing parts as needed. ti16055a 3A1186F... -

Page 13: Packing Replacement Procedures

(14). 17. Tighten the packing nut (21) into the top of the fluid pump body (4) and tighten until you feel slight resis- tance against the Belleville Springs (16). Using the 3A1186F... -

Page 14: Replacement Of Electrical Control Board

350-400 psi, the clutch will engage and build pressure to 3000 psi and disengage. Trigger gun several times to ensure proper pressure setting. 6. Turn Pressure Control Knob to minimum position. The clutch should disengage and pump stop mov- ing. 3A1186F... - Page 15 BLACK PRESSURE CALIBRATION ADJUSTMENT BLUE BLUE CONTROL BOARD SENSOR BLACK BLACK ti15392b TO CONTROL BOX TO ENGINE Engine - Double Wire Models TO CLUTCH BLUE BLACK PRESSURE CALIBRATION ADJUSTMENT BLUE BLUE CONTROL BOARD SENSOR BLACK BLACK ti14817b TO ENGINE 3A1186F...

-

Page 16: Troubleshooting

Clean or replace prime valve. bypassing Packings and/or piston worn Tighten packing nut, repack unit. Unit does not maintain good Blown spray tip Replace spray tip. spraying pressure Packings and/or pistons worn Repack unit. Upper seat worn Replace upper seat. 3A1186F... - Page 17 Check the spacing between the clutch field and plate. The gap should be about .015”. If the gap is greater than .015, replace the clutch assem- bly. Electrical Control Board If the magneto and sensor are functioning, replace the electrical control board. 3A1186F...

-

Page 18: Airless Spray Gun

Incompatible drop placed on top of paint mixes or flattens out on the paint mixture and thinners on the surface. If not, try different thinner in fresh batch of paint. Test the Pattern Spotty Pattern, Good, Full Increase Pressure ti15991a 3A1186F... -

Page 19: Manifold Filter

867647 SUPPORT 867077 BASE 867420 PLUG 867309 NIPPLE 3/8”M x 1/4”M 557391 PLUG 1/4” ti16052a Inlet Valve Ref. Part Description 331011 FLUID PUMP BODY 331029 SUCTION BALL GUIDE 331030 SUCTION BALL 108526 O-RING 331292 SUCTION SEAT 331034 SUCTION NUT ti16055a 3A1186F... -

Page 20: Packing Replacement

331018 SPACER 331025 WASHER, SPRING 331022 MALE GLAND 331023 PACKING POLYETHYLENE 331021 FEMALE GLAND 331019 PACKING HOLDER 331037 PACKING NUT 331307 PACKING LEATHER 331306 PACKING LEATHER 107313 WHITE O-RING 108771 O-RING 867783 CAP 331210 PACKING KIT 331093 PISTON ASSEMBLY ti16056c 3A1186F... - Page 21 Notes Notes 3A1186F...

-

Page 22: Motor And Drive

Notes Motor and Drive ti16162a 3A1186F... - Page 23 342506 LABEL NEVER/ALWAYS LP&SL 29+* 867474 RING,RETAINING,EXTER- 342524 LABEL- PRIME VALVE NAL,15MM 342461 LABEL, ENGINE SPEED 867238 SWIVEL,FTG- SWIVEL, 1/4 X 1/4 16F584 LABEL,AIRLESSCO, GS800, 867290 KEY,5MM X 25MM FRONT 162453 FITTING,(1/4 NPSM X 1/4 NPT) 342522 LABEL, PRIME VALVE 866338 SCREW,SHOUL-...

-

Page 24: Frame Assembly

110838 NUT,LOCK HSE3850 HOSE 3/8” x 50’ (24F574) 331048 BOOT,RUBBER BOOT 865675 HOSE 3/8” X 50’ (16M531) 143029 COLLAR,SCREW,SET (SPECIAL 289316 GUN,500,2 FINGER,ASM,PACK- AGED (24F574) 867736 WHEEL-10’ OD X3.5’W 150LB 24H289 GUN, 009 (16M531) 866356 SPACER .75 LG PVC 3A1186F... -

Page 25: Suction Assemblies

331292 SUCTION SEAT ASSY 331400 INLET TUBE 187190 INLET STRAINER ti16062a Ref. Part Description 331290 SUCTION HOSE ASSY 187651 INLET STRAINER 120777 PTFE O-RING DRAIN HOSE 241920 THREADED DEFLECTOR 867759 MALE CONNECTOR 865721 INCLUDES (4, 5, 6, 8) 276888 DRAIN LINE CLIP 3A1186F... -

Page 26: Electrical System

TO ENGINE Engine - Double Wire Models TO CLUTCH BLACK BLUE PRESSURE CALIBRATION ADJUSTMENT BLUE BLUE SENSOR BLACK BLACK ti14817b TO ENGINE Ref. Part Description Ref. Part Description 331184 SPACER 865676 CONTROL BOARD 867291 KNOB 866334 SENSOR 867352 O-RING 3A1186F... -

Page 27: Technical Data

Sound Pressure** 96 dBa Wetted parts zinc and nickel-plated carbon steel, nylon, stainless steel, PTFE, acetal, leather, UHMWPE, aluminum, tung- sten carbide Notes ** Sound pressure measured at 3.1 feet (1m) from equipment. † Sound power measured per ISO- 3744. 3A1186F... -

Page 28: Airlessco Standard Warranty

With the exception of any special, extended, or limited warranty published by Airlessco, Airlessco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Airlessco to be defective.

Need help?

Do you have a question about the 3A1186F and is the answer not in the manual?

Questions and answers