IV Produkt Envistar Top Series Operation And Maintenance Manual

Hide thumbs

Also See for Envistar Top Series:

- Operation and maintenance (60 pages) ,

- Operation and maintenance (64 pages)

Summary of Contents for IV Produkt Envistar Top Series

- Page 1 Operation and Maintenance Envistar Top Order number: Project: Translation of the original instructions...

- Page 2 Unit specifications Unit type Size 04 06 09 12 16 Control equipment TEC-R TEC-M Home Concept model Unit parts and accessories Filter supply air Rotary heat exchanger TXRR ePM10-60% / M5 Counter-flow exchanger TXMM ePM1-50% / F7 ePM1-60% / F7 Air heater water ETAB-VV Output var Excl.

-

Page 3: Table Of Contents

Table of Contents Safety precautions 1.1 Personal protective equipment ......................1.2 Prevent injury to personal and damage to air handling units ........1.3 Product signs, information and warning stickers ............... 1.4 Safety message ............................1.5 General safety messages ........................General 2.1 Intended use .............................. - Page 4 Table of Contents, cnt’d Operation 5.1 Hygiene inspection ..........................5.2 Actions in case of standstill ......................5.3 Commissioning ............................5.4 Cooling Status – Cooling unit (code TEC-R, TEC-M), size 04 ....... 5.5 Status Cooling - cooling unit (code TEC-R) size 06-12, (code TEC-M) size 6, 10) ........................

-

Page 5: Safety Precautions

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 1 1 Safety precautions Follow all safety precautions in this document and pay attention to all warning signs on the air handling unit. Failure to comply with the safety precautions may result in injury to persons or damage to air handling units. -

Page 6: Product Signs, Information And Warning Stickers

Page 2 1.3 Product signs, information and warning stickers Keep signs and stickers free from soiling and replace them if they are lost, damaged or illegible. Contact IV Produkt for replacement stickers; specify the item number. 1.4 Safety message The following warning symbols and signal words are used in this document to inform of risks. -

Page 7: General Safety Messages

The unit must not be energised until all ducts have been connected. BE CAREFUL! Wiring of connections and other electrical work may only be carried out by a qualified electrician or by service personnel recommended by IV Produkt. Continuous product development may give rise to specification changes without notice. - Page 8 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 4 Inspection hatches WARNING! Risk of personal injury. Overpressure in unit. Allow the pressure to drop before you open the inspection doors. WARNING! Risk of personal injury. The doors in front of moving parts shall normally be locked; there are no contact guards.

- Page 9 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 5 WARNING! Risk of personal injury. Rotating fan impellers can cause crushing injuries or lacerations. Working on/servicing the unit – Shut down the unit via the service switch in the control equipment, then turn the safety switch to the 0 position and lock it.

-

Page 10: General

Page 6 2 General 2.1 Intended use The air handling units in the Envistar Top series are intended for comfort ventila- tion in buildings. When installed indoors, the unit must be installed in an area that maintains a temperature between +7 and +30°C, and with a moisture content of <3.5 g/kg in dry air in the winter. -

Page 11: Ce Marking And Eu Declaration Of Conformity

Refrigerant charge Circuit 1 Refrigerant charge Circuit 2 Refrigerant charge Circuit 3 Contains fluorinated greenhouse gases covered by the Kyotot protocol. IV Produkt AB 0409 VÄXJÖ, SWEDEN 00018 Typical CE label for cooling units For units without integrated control equipment... -

Page 12: Handling Of Refrigerant

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 8 2.6 Handling of refrigerant The following information summarises the requirements and guidelines for hand- ling the refrigerant used in cooling units. For further information, see the F-gas Regulation (EU/517/2014 on fluorinated greenhouse gases) and the Swedish Refrigerant Regulation (SFS 2016:1128). -

Page 13: Extended Warranty

Produkt Service and Warranty Manual must be presented. 2.8 Spare parts Spare parts and accessories for this unit can be ordered from IV Produkt's nearest dealership. When ordering, the order number and designation must be given. These are stated on a model identification label, affixed to each functional section. -

Page 14: Technical Description

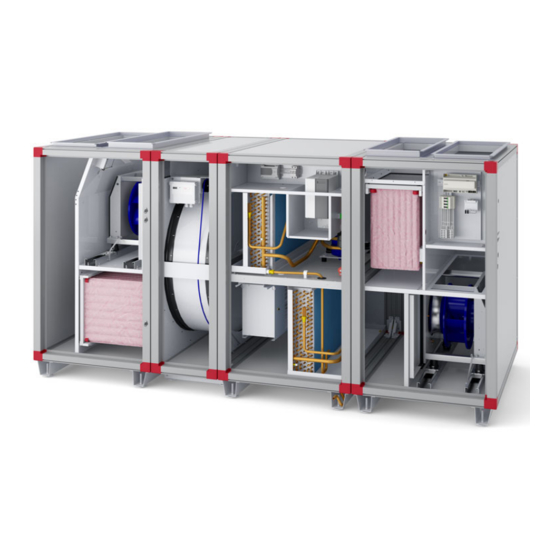

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 10 3 Technical description 3.1 Envistar Top air handling unit Envistar Top with counter-flow exchanger (code TEM) Envistar Top with rotary heat exchanger (code TER) Envistar Top is manufactured as a compact unit or modularly, depending on the size and version selected. -

Page 15: Cooling Unit (Tec-R, Tec-M)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 11 3.3 Cooling unit (TEC-R, TEC-M) Envistar Top with EcoCooler (TEC-R and TEC-M) size 10 The integrated cooling unit with EcoCooler (code TEC-R, TEC-M) cooling recovery is available as an optional extra to an Envistar Top unit with a rotary heat exchanger or counter-flow heat exchanger. - Page 16 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 12 Cooling function For integrated control equipment (MX), the cooling unit is interlocked across the ventilation unit. If any of the fans stop, the cooling unit will also stop. The interlock and demand signal is sent via Modbus. For external control equipment (US, UC, MK), the interlock signal must be sent via a potential-free relay.

- Page 17 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 13 Cooling circuit function A cooling system has four basic components: evaporator, condenser, expansion valve and compressor. The compressor carries out the work required to run the cooling process. The evaporator is located in the supply air for the unit. The heat from the outdoor air is taken up in this coil, thereby cooling the supply air.

- Page 18 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 14 00023 Flow chart for refrigerant system size 16-21 Compressor Condenser Extract air fan High-pressure switch Measurement outlet – high pressure Drying filter Expansion valve Evaporator Supply air fan 10 Measurement outlets – low pressure 11 Low pressure control 12 Control unit 13 Suction gas sensor (temp after evaporator)

-

Page 19: Reversible Heat Pump Thermocooler Hp (Code Ttc)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 15 3.4 Reversible heat pump ThermoCooler HP (code TTC) Envistar Top with ThermoCooler HP (code TTC) size 10 Envistar Top with ThermoCooler HP (code TTC) Size 12 The integrated reversible heat pump ThermoCooler HP (code TTC) is available as an optional extra to an Envistar Top unit with a rotary heat exchanger. - Page 20 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 16 Cooling circuit function The reversible heat pump has four basic components: evaporator, condenser, expansion valve and compressor. A 4-way valve is used to shift between cooling and heating. For cooling, the 4-way valve is in cooling mode. For heating, the 4-way valve is in heating mode.

- Page 21 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 17 Cooling mode The compressor carries out the work required to run the cooling process. The evaporator is located in the supply air for the unit. The heat from the outdoor air is taken up in this coil, thereby cooling the supply air.

- Page 22 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 18 Heating mode is blocked if the return air temperature does not reach the permit- ted minimum temperature. The interlock and demand signal is sent via Modbus. Circuit board The circuit board for the unit contains: •...

-

Page 23: Wiring Instructions And Fuse Protection

For recommended fuses, refer to Order Unique Documentation at docs.ivprodukt.com (Technical Data and Control Diagram), or the product program IV Produkt Designer. • The unit has a shared power supply for all unit functions as standard, but can be ordered with separate power supplies on special order. -

Page 24: Mk - Fans And Heat Exchangers Electrically Connected To Terminal

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 20 4.2 MK – Fans and heat exchangers electrically connected to terminal Code MK - units supplied without control equipment but with fans and heat ex- changers connected electrically to terminals. Connections to terminal blocks are located on each unit section. For wiring instructions and recommended fuses, refer to Order Unique Docu- mentation at docs.ivprodukt.com... - Page 25 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 21 Ziehl EC Air Heater electric (Code ETAB-EV*, ETKB-EV**) 1×230 V 1.35 kW For power supply, output variant and recommen- fan impeller 031/035 ded fuse, refer to Order Unique Documentation at docs.ivprodukt.com (Technical Data).

-

Page 26: Operation

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 22 5 Operation 5.1 Hygiene inspection Envistar Top conforms to guidelines in VDI 6022 Part 1: Hygiene and Hygiene Inspections of HVAC Systems. For this to apply, a hygiene inspection of the system must be carried out and the system must be cleaned thoroughly as needed before start-up. -

Page 27: Commissioning

The validity of the product warranty is conditional on the system having been correctly commissioned. Working on the unit during the warranty period without the approval of IV Produkt shall render the warranty void. Prior to commissioning, the contractor must:... -

Page 28: Cooling Status - Cooling Unit (Code Tec-R, Tec-M), Size 04

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 24 5.4 Cooling Status – Cooling unit (code TEC-R, TEC-M), size 04 With control equipment (code MX) Status information is read on the Climatix display. Information Value/example Explanation Cooling unit status Unit ON Normal status for cooling mode if the compressor is running depends on the cooling load. - Page 29 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 25 Without control equipment (code UC, MK or US) Status information is read on the Carel display (Main menu/Status - I/O). Information Value/example Explanation Status U6 = Cool.demand: Cooling load from ventilation control Remove start delay: No / Yes Opportunity to quick start the compressor if Yes is set.

- Page 30 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 26 Status Value/example Explanation Cooling load, Output signal, Speed High pressure Condensation temperature Status Hot gas temperature Suction gas temperature Low pressure Evaporating temperature Status Status Off/Run/Alarm/Heat Current 4.3 Arms Compressor’s power consumption Voltage 124 Vrms Power to compressor...

-

Page 31: Status Cooling - Cooling Unit (Code Tec-R) Size 06-12, (Code Tec-M) Size 6, 10)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 27 5.5 Status Cooling - cooling unit (code TEC-R) size 06-12, (code TEC-M) size 6, 10) With control equipment (code MX) Status information is read on the Climatix display. Information Value/example Explanation Danfoss-VSD Danfoss Variable Speed Drive High pressure... - Page 32 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 28 Without control equipment (code UC, MK, US) Status information is read on the Carel display (Main menu/Status - I/O). Information Value/example Explanation Status Compressor: Off 60.0 Hz Compressor frequency. Drive status: Compressor Off Status of compressor.

-

Page 33: Cooling Status - Cooling Unit, Size (Code Tec) Size 16-21

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 29 5.6 Cooling Status – Cooling unit, size (code TEC) size 16-21 With control equipment (code MX) Status information is read on the Climatix display. Information Value/example Explanation Cooling unit status Unit ON Normal status for cooling mode if the compressor is running depends on the cooling load. - Page 34 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 30 Without control equipment (code UC, MK, US) Status information is read on the Carel display (Main menu/Status - I/O). Information Value/example Explanation Status B1 = Cool.demand: Cooling load from ventilation control B2 = Heat demand Heating requirement Remove start delay:...

-

Page 35: Cooling Status - Reversible Heat Pump (Code Ttc)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 31 5.7 Cooling Status - reversible heat pump (code TTC) With control equipment (code MX) Status information is read on the Climatix display. Information Value/example Explanation Cooling unit status UnitOn Normal status for cooling mode if the compressor is running depends on the cooling load. - Page 36 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 32 Information Value/example Explanation Freq. inv. output x.x% Shows how much of the full capacity is used by the compressor. Compr. no Comp1 No. of compressors Compr. Sum alarm Normal Display of sum alarm. Danfoss invert.

-

Page 37: Maintenance Instructions

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 33 6 Maintenance instructions 6.1 Service schedule The service schedule comprises actions and service intervals for functional sections that can be part of the air handling unit. For current parts, refer to docs.ivprodukt.com (Technical data). - Page 38 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 34 Cooling unit (code TEC-R, TEC-M) Service year 20 Order no. Project ................Comments Service performed * (date and signature) ................Recommended action Page Functional section Code 12 mths 24 mths 36 mths 48 mths (insp.)

-

Page 39: Filters (Code Elef)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 35 6.2 Filters (code ELEF) 00032 1. Filter The air filters in an air handling unit are designed to prevent dust and other impurities from entering the building. They should also protect sensitive com- ponents inside the unit, e.g. - Page 40 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 36 FLC calculates the volume of air passing through the carbon filters and triggers the alarm for filter replacement when the preset value has been reached. The value for air passing through is specified in mega cubic metres (Mm³). The function does not take into account the odour content of the air, which means that the indica- tion should be regarded as a recommendation for checking the filter function.

- Page 41 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 37 Filter data For filter data, refer to Filter Overview under Documentation at ivprodukt.docfactory.com. Actual filters are shown in Technical data (see the page Material specification) and Spare part list under order unique documentation at docs.ivprodukt.com.

-

Page 42: Rotary Heat Exchanger (Code Txrr)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 38 6.3 Rotary heat exchanger (code TXRR) 00013 1. Rotary heat exchanger The purpose of the recovery unit is to recover heat from the extract air and transfer this heat to the supply air in order to minimise energy use. Faults in recovery unit functionality result in reduced heat recovery efficiency and increased energy use and means that the design supply air temperature cannot be obtained when the outdoor temperature is low... - Page 43 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 39 2. Wait until the fans have stopped, then open the inspection door. 3. Check that the rotor rotates easily. If it is sluggish, you might have to adjust the bristled sealing strip. 4.

- Page 44 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 40 For units (code TER/TXR), the pressure balance must be ensured by check- ing that the under pressure P3 is greater than the pressure P2 (min. diff 25 Pa). Otherwise an ETSP-TR trim damper can be used on the extract air side in order to throttle in the correct pressure balance.

- Page 45 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 41 9. Check the differential pressure across the rotor. The purging sector is factory-installed, set to the maximum open position. Depending on the unit’s pressure difference across the rotor, the purging sector may need adjustment.

-

Page 46: Cleaning

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 42 00031 Schematic diagram - sizes and model may vary. 1. Exhaust air 2. Outdoor air 3. Extract air 4. Direction of rotation 5. Supply air 6.4 Cleaning WARNING! Risk of serious personal injury and/or damage to air handling unit. -

Page 47: Counter-Flow Exchanger (Code Txmm)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 43 6.5 Counter-flow exchanger (code TXMM) The purpose of the counter-flow exchanger is to recover heat from the extract air and transfer this heat to the supply air in order to minimise energy use. Faults in counter-flow exchanger functionality reduce recovery efficiency and increase energy consumption. - Page 48 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 44 Cleaning WARNING! Risk of serious personal injury and/or damage to air handling unit. Read and understand the entire chapter "1.5 General safety messages" before working on, servicing, or inspecting the air handling unit.

- Page 49 During full heat recovery and when the unit is switched off, the dampers should be fully open (bypass damper closed). The frosting and bypass functions are preset at the factory and any adjustments may only be performed by IV Produkt. Continuous product development may give rise to specification changes without notice.

-

Page 50: Air Heater Water (Code Etab-Vv) And Thermoguard (Etab-Tv)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 46 6.6 Air heater water (code ETAB-VV) and Thermoguard (ETAB-TV) 00025 The heating coil consists of a number of copper tubes with aluminium fins pressed on them. The coil will have impaired capacity if dust forms a coating on the coil surfaces. - Page 51 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 47 Venting WARNING! Risk of serious personal injury and/or damage to air handling unit. Read and understand the entire chapter "1.5 General safety messages" before working on, servicing, or inspecting the air handling unit.

-

Page 52: Air Heater Electric (Code Etab-Ev, Etkb-Ev, Etab-Sv)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 48 6.7 Air Heater electric (Code ETAB-EV, ETKB-EV, ETAB-SV) • ETAB-EV for unit assembly • ETAB-SV for unit assembly reversible heat pump • ETKB-EV for duct mounting 00027 Air heater electric (ETAB-EV, ETAB-SV) 00026 Air heater electric size 04-12 (ETKB-EV) The electric heater consists of encapsulated stainless steel smooth pipe ele-... - Page 53 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 49 Inspection WARNING! Risk of serious personal injury and/or damage to air handling unit. Read and understand the entire chapter "1.5 General safety messages" before working on, servicing, or inspecting the air handling unit.

-

Page 54: Air Cooler Water (Code Etkb-Vk)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 50 6.8 Air cooler water (code ETKB-VK) 00028 The cooling coil consists of a number of copper tubes with aluminium fins press- sed onto them. The coil will have impaired capacity if dust forms a coating on the coil surfaces. - Page 55 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 51 Cleaning WARNING! Risk of serious personal injury and/or damage to air handling unit. Read and understand the entire chapter "1.5 General safety messages" before working on, servicing, or inspecting the air handling unit.

-

Page 56: Fan Unit (Code Elff)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 52 6.9 Fan unit (code ELFF) The purpose of the fans is to transport air through the system, i.e. the fan must overcome the flow resistance in air terminals, air ducts and the unit. The fan speed is regulated to provide correct air flow. - Page 57 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 53 Inspection 00021 Example fan unit size 04-06 1. Screws suspension 2. Connection plate 3. Inlet cone 4. Vibration damper 5. Anti-vibration support 6. Fan impeller with motor 7. Edge cover 8. Earth braid 9.

- Page 58 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 54 00022 Example fan unit size 09-21 1. Screws side cover 2. Pins 3. Anti-vibration mounting 4. Earth braid 5. Motor 6. Fan impeller 7. Side cover WARNING! Risk of serious personal injury and/or damage to air handling unit.

- Page 59 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 55 5. For size 09-21: Fan impeller (5) and motor (4) are mounted on a frame equip- ped with rubber vibration dampers. Check that the vibration dampers (3) are intact and firmly fitted. 6.

- Page 60 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 56 Cleaning WARNING! Risk of serious personal injury and/or damage to air handling unit. Read and understand the entire chapter "1.5 General safety messages" before working on, servicing, or inspecting the air handling unit.

-

Page 61: Damper (Code Etsp-Um, Etsp-Tr, Etrl)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 57 6.10 Damper (code ETSP-UM, ETSP-TR, ETRL) • ETSP-UM Shut-off damper, rotary heat exchanger and counter-flow exchanger • ETSP-TR Commissioning damper, rotary heat exchanger • ETRL Return air damper, rotary heat exchanger 00034 Damper ETSP-UM, ETSP-TR and ETSP-UM, ETSP-TR, ETRL The purpose of the dampers is to regulate the air flow. - Page 62 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 58 Cleaning WARNING! Risk of serious personal injury and/or damage to air handling unit. Read and understand the entire chapter "1.5 General safety messages" before working on, servicing, or inspecting the air handling unit.

-

Page 63: Sound Attenuator (Code Etld)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 59 6.11 Sound attenuator (code ETLD) 00029 Circular sound attenuator TER-04 and rectangular size 04-21 The function of the sound attenuator is to reduce the sound level in the system. Inspection WARNING! Risk of serious personal injury and/or damage to air handling unit. -

Page 64: Cooling Unit (Code Tec-R, Tec-M) And Reversible Heat Pump (Code Ttc)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 60 6.12 Cooling unit (code TEC-R, TEC-M) and reversible heat pump (code TTC) General The operation parameters for the unit must not be changed unless a check is first made to ascertain that the changes will be within the unit’s operating range. Leakage inspection and registration For information on the operator’s responsibility with regards to leakage inspec- tion and registration, see "2.6 Handling of refrigerant"... -

Page 65: Alarm Management And Troubleshooting

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 61 7 Alarm management and troubleshooting For units with control equipment (code MX), alarm information can be read on the Climatix display. For units without control equipment (code UC, MK, US), alarm information can be read on the Carel display. - Page 66 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 62 Troubleshooting via symptoms Symptom Possible cause Corrective action Low cooling power – too The power supply has been interrupted Check the control/safety switches and high temperature in the fuses cooled object/medium No or too low air flow across evaporator.

-

Page 67: Cooling Unit (Code Tec-R) Size 06-12, (Code Tec-M) Size 06, 10

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 63 7.2 Cooling unit (code TEC-R) size 06-12, (code TEC-M) size 06, 10 Troubleshooting via symptoms Symptom Possible cause Corrective action The high pressure switch No or too low air flow across the Check the air flow across the condenser. - Page 68 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 64 Alarm information for inverter and compressor Alarm Climatix (code Alarm Carel (code UC, MK, Explanation and corrective action Peripherals AL P02 Compressor Drive: Communication error with the electronic expansion valve. PERIPHERALS_ERROR Compressor runs at limited speed.

- Page 69 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 65 MOC safety AL D06 Compressor Drive: Motor Orientated Control has detected an error. The inverter is stopped. MOC_SAFETY Errors must be remedied and alarms reset. The alarm may be the result of a tripped high pressure switch (the inverter loses all power).

- Page 70 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 66 High pressure switch alarm If the high pressure switch has tripped, “Cooling unit alarm: Alarm” is displayed. Since the inverter loses all power when the high pressure switch is tripped, a communication error alarm is also displayed, “Com.Modbus alarm Danfoss: Alarm”.

-

Page 71: Reversible Heat Pump (Code Ttc)

Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 67 7.3 Reversible heat pump (code TTC) Alarm troubleshooting Inspection Possible cause Corrective action YES ⇒ No or too low air flow across the Has the high pressure Check the air flow across the switch tripped? condenser condenser. - Page 72 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 68 Alarm information for inverter and compressor Alarm Climatix Explanation and corrective action Sum alarm Sum alarm, check alarm in Carel, see table below. Alarm C1 R. pressure switch High pressure switch tripped or alarm for frequency inverter. Alarm C1 EEV motor fault Fault on electrical connection to expansion valve.

- Page 73 Operation and Maintenance Envistar Top 04-21 DSET.220501.07.en Page 69 Troubleshooting via symptoms Symptom Possible cause Corrective action Low cooling power - too The power supply has been interrupted Check the control/safety switches and high temperature in the fuses. cooled object Separate supply not connected Connect supply None or too low air flow across evapora-...

- Page 74 You are welcome to contact us Switchboard: +46 (0)47 075 88 00 Control support: +46 (0)47 075 89 00 styr@ivprodukt.se Service: +46 (0)47 075 89 99 service@ivprodukt.se Spare parts: +46 (0)47 075 88 00 spareparts@ivprodukt.com Visit us at: www.ivprodukt.com Documentation for your unit: docs.ivprodukt.com Technical documentation: DU@ivprodukt.se...

Need help?

Do you have a question about the Envistar Top Series and is the answer not in the manual?

Questions and answers