National Instruments SCXI-1125 Calibration Procedure

Signal conditioning module

Hide thumbs

Also See for SCXI-1125:

- User manual (101 pages) ,

- Calibration procedure (18 pages) ,

- Getting started (158 pages)

Advertisement

Quick Links

CALIBRATION PROCEDURE

SCXI -1125

™

Introduction

What Is Calibration?

Why Should You Calibrate?

How Often Should You Calibrate?

™

™

CVI

, LabVIEW

, National Instruments

names mentioned herein are trademarks or trade names of their respective companies.

370271A-01

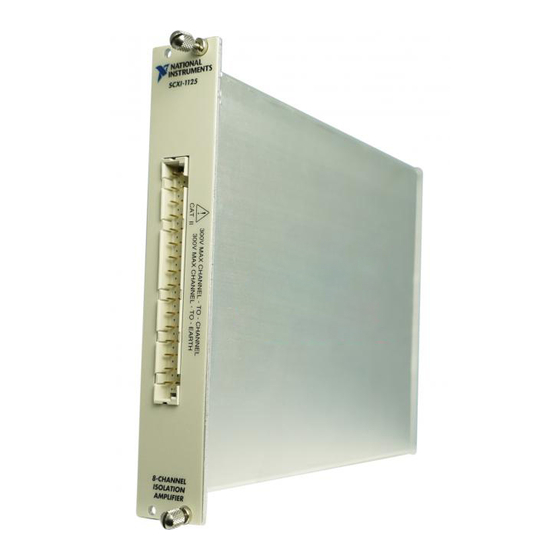

This document contains information and step-by-step instructions for

verifying and calibrating the National Instruments SCXI-1125 signal

conditioning module.

Calibration

is a procedure of reading offset and gain errors from a device

and updating special analog calibration circuitry that corrects these errors.

National Instruments calibrates every SCXI-1125 module at the factory.

During the factory calibration process, the calibration constants are stored

in the non-volatile memory of the device. These values are loaded from

memory and used as needed by the device.

Offset and gain errors drift with time and temperature changes, which could

invalidate the factory-set calibration of a device and increase measurement

uncertainty. Calibration restores the device to its specified accuracy.

The measurement accuracy requirements of your application

determine how often you should calibrate your SCXI-1125 module.

National Instruments recommends you perform a complete calibration

at least once every year. You can shorten this interval to six months or

90 days, based on the demands of your application.

™

™

™

, ni.com

, NI-DAQ

, and SCXI

© Copyright 2000 National Instruments Corp. All rights reserved.

™

are trademarks of National Instruments Corporation. Product and company

December 2000

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for National Instruments SCXI-1125

- Page 1 National Instruments calibrates every SCXI-1125 module at the factory. During the factory calibration process, the calibration constants are stored in the non-volatile memory of the device.

-

Page 2: Software And Documentation

If you do not have custom connection hardware, you will need a connector block Note such as the National Instruments SCXI-1320, a shielded 68-pin connector cable, a 50-pin ribbon cable, a 50-pin breakout box, and an SCXI adapter. These components give easy access to the individual pins on the SCXI-1125 front and rear connectors. -

Page 3: Test Conditions

Start»Programs»National Instruments DAQ»NI-DAQ Help. The user manual provides instructions on installing and configuring National Instruments DAQ devices. This manual also includes detailed information on creating applications that use the NI-DAQ driver. These are your primary references for writing your calibration utility. For further information on the products you are calibrating, refer to your device user manuals. - Page 4 Setting Up Your Module Complete the following steps to set up your module for testing: Install the SCXI-1125 in slot 1 of the SCXI chassis. Connect a 68-to-68-pin cable between the SCXI module and the E Series DAQ device installed in the host computer.

- Page 5 (CH0+) is pin A32. The negative input for channel 0 (CH0–) is pin C32. If you are using an SCXI-1320 terminal block connected to the SCXI-1125, connect the calibrator to the CH0+ and CH0– inputs. Call to configure the module for SCXI_Single_Chan_Setup single-channel measurements.

- Page 6 Adjusting for Gain and Offset Errors The following two sections explain how to determine the gain and offset errors of your SCXI-1125 and how to adjust the calibration constants to correct for these errors. Determining Gain and Offset Errors...

- Page 7 SCXI_Set_Gain • SCXIchassisID—The ID of the SCXI chassis obtained when you configure the chassis with MAX • moduleSlot—1, because the SCXI-1125 should be installed in slot 1 • channel—The same channel number from step 6 • gain—The gain value you want to adjust. Refer to Table 1 for...

- Page 8 CH0+. The negative input for channel 0 is pin C32, which is labeled CH0–. If you are using an SCXI-1320 terminal block connected to the SCXI-1125, connect the calibrator to the CH0+ and CH0– inputs. 10. Connect the DMM to the positive output on pin 3 (MCH0+) and negative output on pin 4 (MCH0–) on the rear panel connector.

- Page 9 SCXI-1125 • binary1 and binary2—The first and second binary readings for the gain values that you are about to save on the SCXI-1125 • calConst1 and calConst2—These are return values Repeat step 1, changing calibrationArea to 1.

- Page 10 Verifying Adjusted Values After completing the adjustments to your SCXI-1125 module, it is important that you verify the analog input operation by repeating the steps listed in the Verifying Gain and Offset Errors section of this document. Reverifying after adjustments ensures that your SCXI-1125 module is now operating within its specifications.

- Page 11 CH4+ CH4– CH5+ CH5– CH6+ CH6– CH7+ CH7– RSVD RSVD RSVD RSVD +5 V CJTEMP CHSGND RSVD This symbol indicates that no physical pin is present Figure 1. Front Signal Connector Pin Assignments © National Instruments Corporation SCXI-1125 Calibration Procedure...

- Page 12 27 28 SLOT0SEL* 29 30 31 32 DIGGND 33 34 35 36 SCANCLK SERCLK 37 38 39 40 41 42 43 44 45 46 SYNC 47 48 49 50 Figure 2. Rear Signal Connector Pin Assignments SCXI-1125 Calibration Procedure ni.com...

-

Page 13: Specifications

Specifications The following table contains the specifications you should use when verifying and calibrating your SCXI-1125 module. If your device has been calibrated within the last year, the test point value should fall between the Upper Limit and Lower Limit values. - Page 14 Table 1. SCXI-1125 Specifications at 25 °C ±10 °C (Continued) Gain Range Test Point Upper Limit (V) Lower Limit (V) –0.025 –0.024750 –0.02468642 –0.02481358 0.02 0.019800 0.01985126 0.01974874 0.000000 0.000022 –0.000022 –0.02 –0.019800 –0.01974874 –0.01985126 0.01 0.009900 0.00992663 0.00987337 0.000000 0.000012...

Need help?

Do you have a question about the SCXI-1125 and is the answer not in the manual?

Questions and answers