Advertisement

Quick Links

Installation Manual

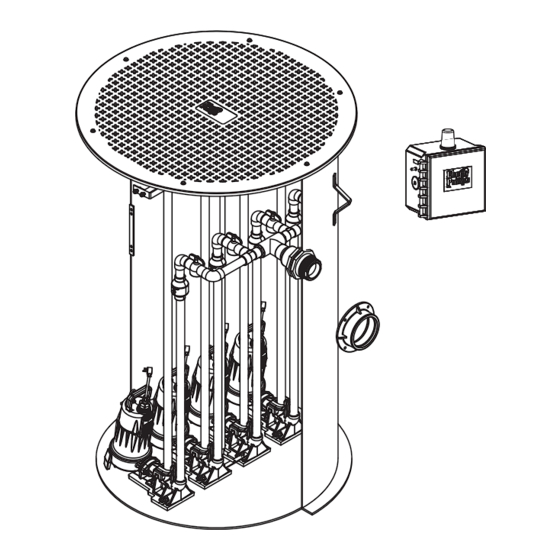

Engineered Pump Systems (EPS)

for Ordinary and Hazardous Locations

Common Components:

• Fiberglass Basin

• Sump, Effluent, Sewage or Grinder Pump(s)

• Inlet Hub

• Control Panel

• Alarm System

• NEMA 4X Junction Box

• Pre-Mounted Float System

• Factory Installed Guide Rail System

For pressure sewer applications, verify a Redundant Check Valve Assembly (curb stop and check valve) is installed between the pump

discharge and the street main, as close to the public right-of-way as possible, on all installations to protect from system pressures.

IMPORTANT: All Liberty Pumps products are supplied with their own

separate Installation/Operation/Maintenance manuals. Ensure receipt of

these manuals, and that they are read and understood prior to installation.

For questions, call Liberty Pumps customer service at 1-800-543-2550.

7000 Apple Tree Avenue

Bergen, NY 14416

ph: 1-800-543-2550

fax: 1-585-494-1839

www.LibertyPumps.com

Keep this manual handy for future reference.

For replacement manual, visit LibertyPumps.com,

or contact Liberty Pumps at 1-800-543-2550.

Retain dated sales receipt for warranty.

Copyright © Liberty Pumps, Inc. 2021 All rights reserved.

Installer: Manual must remain with owner or

system operator/maintainer.

Record information from pump nameplate:

System:

Model(s):

Serial(s):

Control Panel:

Mfg Date:

Install Date:

7298000E

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Liberty Pumps EPS

- Page 1 Installer: Manual must remain with owner or IMPORTANT: All Liberty Pumps products are supplied with their own system operator/maintainer.

- Page 2 Some products may have internal capacitors that could cause shock. Avoid contact with plug ends after removing from energy source. 2 | EN Copyright © Liberty Pumps, Inc. 2021 All rights reserved. 7298000E...

- Page 3 All electrical and motor repairs and service must be Sewage and effluent systems produce and may contain performed by a repair facility approved by Liberty Pumps and flammable and explosive gases. Prevent introduction of certified to work on explosion-proof motor enclosures.

- Page 4 Before any attempt is made to move a basin, verify that all equipment and Information about the EPS can be found on a metal tag located on accessories have sufficient capacity and reach to lift and lower the the basin cover.

- Page 5 Pumps or its agent. Any repairs must be first authorized in writing Careful selection, placement, and compaction of approved backfill by Liberty Pumps and then be done in accordance with Liberty material is critical to a successful basin installation. Among the Pumps instructions.

- Page 6 SAFE INSTALLATION PROCEDURES ARE ENTIRELY THE RESPONSIBILITY OF THE INSTALLER Figure 1. Basin Installation Reference 6 | EN Copyright © Liberty Pumps, Inc. 2021 All rights reserved. 7298000E...

- Page 7 EPS typically include a 3 float control panel in a simplex or 4 float 13” [33 cm] control panel in a duplex configuration. Correct height settings for each float are critical for optimal pump cycling and operation of the system.

- Page 8 Installation See Liberty Pumps line of CSV-Series Curb Stop/Swing Check Valve Assemblies and CK-Series Connection Kit. Pump Station Grade RISK OF ELECTRIC SHOCK All installation and maintenance of pumps, controls, Curb Box protection devices, and general wiring shall be done by qualified personnel.

- Page 9 Connect the inlet line to the inlet hub per engineer’s specifications. GR-Series Guide Rail System The optional GR20, GR22 or GR30 quick-disconnect assembly guide rail system provided with the EPS system is designed to Rubber sealing allow easy installation and removal of the pump. When installed...

- Page 10 (anything higher than a 3% drop would Because an EPS can contain a large array of components, it would be insufficiently sized). be ineffective to include a complete troubleshooting list for each To detect a voltage drop, measure the voltage at the and every combination of components.

- Page 11 By raising the floats by hand or with water, it is easy to tell if a float is not functioning depending on whether or not it turns on its corresponding LED. 7298000E Copyright © Liberty Pumps, Inc. 2021 All rights reserved. 11 | EN...

- Page 12 Liberty Pumps, Inc. shall not be liable for any loss, damage, or expenses resulting from installation or use of its products, or for indirect, incidental, and consequential damages, including costs of removal, reinstallation or transportation.

Need help?

Do you have a question about the EPS and is the answer not in the manual?

Questions and answers