Summary of Contents for Resodyn LabRAM II

- Page 1 LabRAM II* Spray System Installation and Users’ Manual * Including LabRAM II, and PharmaRAM II Models Resodyn Acoustic Mixers, Inc. 130 N. Main Street, Suite 630 Butte, MT 59701 (406) 497-5333 www.resodynmixers.com...

- Page 2 LabRAM II Spray System Instruction Manual Rev. 042618 Purchase and Installation Information Resodyn Acoustic Mixers, Inc. www.resodynmixers.com...

-

Page 3: Table Of Contents

Connect Peristaltic Pump Options to Ultrasonic Nozzle ........19 Connecting Syringe Pump to Ultrasonic Nozzle ............ 20 Operating Instructions ........................21 Power-up Equipment .................... 21 LabRAM II Spray System Operation ..............22 Power-Down ......................28 Maintenance and Cleaning ................... 29 General Cleaning Instructions ................32 Warranty and Service ........................ -

Page 4: Introduction

Obtain additional accessories or replacement parts The LabRAM II Spray System is supplied with a fixture to hold either a 16 fl oz (0.47 liters) or a 32 fl oz (0.95 liters) mixing vessel that is 3.5” (8.9 cm) in diameter and 4” or 8” in height (10.2 cm). -

Page 5: Definitions

European Union (EU) directives describing what equipment and work environment is allowed in an area with an explosive atmosphere. LabRAM II Spray System is designed for non-hazardous environments. Damping: A term to quantify the instantaneous amount of energy absorbed by the mix media while mixing. -

Page 6: Safety Information

SAFETY Safety Information Every effort has been made to assure that the LabRAM II Spray System is easy to use, reliable, and safe. This section outlines the general safety considerations and highlights important information with caution and warning symbols used throughout this document. -

Page 7: Warnings And Cautions

LabRAM II Spray System Instruction Manual SAFETY Warnings and Cautions Throughout the manual, the following symbols are used to identify warnings and cautions: The caution symbol indicates a potential hazardous situation which could result in minor injury or damage to the product. -

Page 8: Important Safety Notes

LabRAM II Spray System. Note: Changes in noise level or frequency are common during mixing operations. If rattling, metal-on-metal, or obnoxious noises occur, turn off the LabRAM II Spray System and call or email the Resodyn Acoustic Mixers Technical Support line at 406-497-5333. - Page 9 LabRAM II Spray System Instruction Manual SAFETY DANGER: Disconnect all power from the pump before any cleaning operation is started. WARNING: Disconnect all power from the pump before attempting any maintenance. CAUTION: To avoid electrical shock, the pump power cord protective grounding conductor must be connected to ground.

- Page 10 Masterflex L/S Precision Variable Speed Console Drive 3.3.4.1 Observe safety precautions at all times, especially when pumping volatile, explosive, caustic, acidic, or reactive liquids. The LabRAM II Spray System is designed for use in non-hazardous environments. 3.3.4.2 If the pump makes unusual noises or if bunching of the tubing in the pump can be observed, make sure the tubing is clamped down tightly and/or replace it with a new piece of tubing.

-

Page 11: General Notes

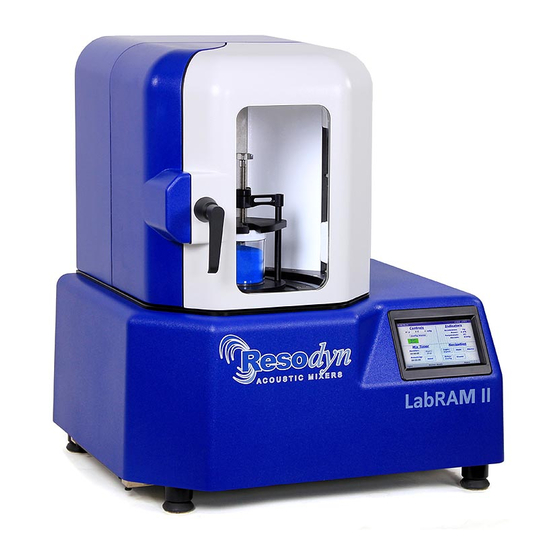

OPTIONS: peristaltic and/or syringe pump The LabRAM II Spray System’s components are shown in Figures 4-1 through 4-4. (A LabRAM II mixer is required for this accessory. If you do not have a LabRAM II Mixer, please contact Resodyn at 406-497-5333) - Page 12 The components consist of one or more of the following items: a. A 130 kHz, Wide Spray Atomizer Nozzle (Resodyn Part Number: 002041 ) b. An Ultra Sonic Atomizer Controller (Resodyn Part Number: 002891) c.

-

Page 13: Voltage Level And Power Consumption

Voltage Level and Power Consumption The mixer is designed to be very efficient by operating at a resonant condition. The LabRAM II is designed to utilize single phase 110-120 VAC @ 50Hz/60Hz supply voltages. Maximum power consumption is less than 1 kW. -

Page 14: Installation

Installation Spray System Overall Assembly Pictures If purchased with a LabRAM II ResonantAcoustic® Mixing (RAM) system, The LabRAM II Spray System will arrive packed in a separate box with the components packed in foam for protection against damage during shipping. The images of the key components in the following section are shown unpackaged and will be referred to throughout this manual. - Page 15 LabRAM II Spray System Instruction Manual SPRAY SYSTEM REMOVAL AND INSTALLATION Figure 5-4 illustrates the Atomizer Nozzle and Atomizer Holder. Atomizer Front View Rear View Clamp Atomizer Atomizer Nozzle Clamp Nozzle Holder Figure 5-4: Ultrasonic Atomizer Nozzle and Atomizer Holder 6-32”...

-

Page 16: Spray System Installation

Locate and identify the Atomizer Base Vessel Holder baseplate as shown in Figure 5.2 (Resodyn Part Number: 104225), which will include the two vertical support standoffs attached, and position over the appropriate mounting holes in the resonator plate surface. Secure to the resonator plate... - Page 17 LabRAM II Spray System Instruction Manual SPRAY SYSTEM REMOVAL AND INSTALLATION Nozzle Vessel Top Holder (Resodyn Part No. 101825) can be lifted. Lifting the Nozzle Vessel Top Holder attached to the Spray System Nozzle Arm and Atomizer Assembly, slide the glass mixing vessel into position. Tighten the thumb screw knobs by hand only.

- Page 18 Fitting Figure 5-6: Nozzle Connections Connect power supplies to the LabRAM II mixer, ultrasonic nozzle controller, and fluid pumps, if so equipped, after completing the following instructions as appropriate for your installation. The reinstallation of the system is performed in reverse order. Please call 406-497-5401 is help is needed.

-

Page 19: Installing The Ultrasonic Atomizer Nozzle Generator

LabRAM II Spray System Instruction Manual SPRAY SYSTEM COMPONENT INSTALLATION Installing the Ultrasonic Atomizer Nozzle Generator The Ultrasonic Atomizer Nozzle Generator connection procedure is as follows: Place the ultrasonic generator in reasonably close proximity to the LabRAM Attach one end of the BNC cable assembly (supplied with the generator unit) to the back of the generator. -

Page 20: Connecting Syringe Pump To Ultrasonic Nozzle

Connecting Syringe Pump to Ultrasonic Nozzle If you are using a KD Scientific Legato 100 Infuse Only Syringe Pump, connect the pump to the ultrasonic nozzle in the following manner: (Resodyn Part Number 900658) Figure 5-15: Syringe Pump Installation Resodyn Acoustic Mixers, Inc. -

Page 21: Operating Instructions

Power-up Equipment LabRAM II Power-up Ensure that power is applied to the LabRAM II. Turn on power switch on the rear panel of the LabRAM II. It will take a few seconds for the RAM operating system and HMI to boot. Once the full screen is displayed, the LabRAM II is ready for operation. -

Page 22: Labram Ii Spray System Operation

SPRAY SYSTEM OPERATING INSTRUCTIONS LabRAM II Spray System Operation All operation of the LabRAM II is controlled through HMI screen located on the front of the machine. Refer to the LabRAM II Instruction Manual for details pertaining to the functions of the LabRAM II and its operating system. - Page 23 These adjustments help you to identify your optimized spray characteristics. 1. Open the LabRAM II doors to install a 16 fl oz (0.47 liters), 3.5 inch diameter glass (or 32 fl oz) vessel into the LabRAM II as previously described in 5.3.2.

- Page 24 Note that instead of using a different vessel, if desired, the previous vessel may be cleaned, dried, and reused for this step. 6.2.2.7 Turn on the LabRAM II system. 6.2.2.8 Important: the acceleration level should not exceed 30 g when mixing powder materials that incorporate atomized liquids.

- Page 25 These adjustments help you to identify your optimized spray characteristics. 14. Open the LabRAM II doors to install a 16 fl oz (0.47 liters), 3.5 inch diameter glass (or 32 fl oz) vessel into the LabRAM II as previously described in 5.3.2.

- Page 26 LabRAM II Spray System Instruction Manual SPRAY SYSTEM OPERATING INSTRUCTIONS ultrasonic nozzle in a dry state for an extended time will damage the nozzle. 19. Once liquid is observed to be dripping from the nozzle, turn on the ultrasonic power to the nozzle at 50%.

- Page 27 LabRAM II Spray System Instruction Manual SPRAY SYSTEM OPERATING INSTRUCTIONS 6.2.3.4 Remove the16 fl oz (0.47 liters) or 32 fl oz glass vessel from LabRAM II. 6.2.3.5 The spray system is now ready to be operated at the determined conditions with your materials.

-

Page 28: Power-Down

These connections are used for the vacuum and vacuum sense lines. Vacuum Vacuum Sensor Figure 6-1: Vacuum Connections Power-Down Turn the LabRAM II power off the rear of the machine. Similarly, AC power to the pump and ultrasonic generator should just be switched off. Resodyn Acoustic Mixers, Inc. Pub 042618... -

Page 29: Maintenance And Cleaning

LabRAM II Spray System Instruction Manual MAINTENANCE AND CLEANING Maintenance and Cleaning The LabRAM II Spray System is designed with few serviceable or replaceable parts. Masterflex L/S Precision Variable Speed Console Drive: 6.4.1.1 Completely disconnect power from the pump before any maintenance operation is started. - Page 30 LabRAM II Spray System Instruction Manual MAINTENANCE AND CLEANING 6.4.4.1 84Remove snap ring on top of Nozzle Gasket / Vessel Holder with the snap ring pliers provided with your unit. Place tines of snap ring pliers in each hole of ring. Compress snap ring and pull up with the pliers. Note: the beveled edge of the snap ring is always installed facing up.

- Page 31 LabRAM II Spray System Instruction Manual MAINTENANCE AND CLEANING Atomizer Nozzle External Cleaning Procedure: The Atomizer Nozzle (Resodyn Part Number 002041) can be taken out of the nozzle holder for cleaning and replacement of the sealing O-rings holding the nozzle in place. LabRAM II...

-

Page 32: General Cleaning Instructions

Nozzle and Nozzle Gasket: 6.5.4.1 Place additional cleaning liquid in 16 fl oz glass vessel if needed. 6.5.4.2 Run LabRAM II at 30 g until gasket and nozzle surfaces are clean. 6.5.4.3 Remove vessel. 6.5.4.4 Wipe gasket and nozzle gently to dry. -

Page 33: Warranty And Service

The warranties provided herein will apply only to those Products and integral components thereof that are identified by a unique LabRAM II Spray System part number and for any Service provided by Aero Spec, Inc. employees or their authorized agents. Seller does not warrant any third party Products or Service even if included with other LabRAM II Spray System Branded Products or Service. -

Page 34: Supplemental Information

LabRAM II Spray System Instruction Manual COMPONENT OPERATING MANUALS Supplemental Information Other Operating Manuals Supplemental information is provided in the following PDF links. Operating Manual for Masterflex L/S PTFE Tubing Pump, Model 77390-00 http://www.coleparmer.com/Assets/manual_pdfs/77390-00.pdf Operating Manual for Masterflex L/S Precision Variable Speed Console Drives, Models 07528-10, 07528-20 and 07528-30 http://www.coleparmer.com/Assets/manual_pdfs/07528-10,%20-20,%20-... -

Page 35: Replacement Parts

Innovative Mixing Technologies Replacement Parts 130 North Main St., Suite 630, Butte, MT 59701 406-497-5333 www.resodynmixers.com info@resodynmixers.com... - Page 36 Innovative Mixing Technologies Figure 8-1: LabRAM II Spray System Components Item Quantity Part No. Description 000310 Elbow 1/8" Tube, 1/8" NPT 000539 16oz Glass Vessel w/ Lid 002127 Ferrule Set, PTFE 002543 Dowel Pin, 3/32" x 0.5" 002544 Retaining Ring, Internal...

- Page 37 Innovative Mixing Technologies Figure 8-2: LabRAM II Supplied Parts and Tools Item Quantity Part No. Description 000539 16oz Glass Vessel w/ Lid 001446 5/32" Allen Wrench 002545 O-ring, -234, EPDM 002560 Tubing, PTFE, 1/16" (25 ft) 002561 Retaining Ring Pliers...

- Page 38 Innovative Mixing Technologies Notes and Record Dates 130 North Main St., Suite 630, Butte, MT 59701 406-497-5333 www.resodynmixers.com info@resodynmixers.com...

- Page 39 Innovative Mixing Technologies 130 North Main St., Suite 630, Butte, MT 59701 406-497-5333 www.resodynmixers.com info@resodynmixers.com...

- Page 40 Innovative Mixing Technologies OmniRAM RAM 5 RAM 55 LabRAM II™ II LabRAM II™ II H LabRAM II I™ 130 North Main St., Suite 630, Butte, MT 59701 406-497-5333 www.resodynmixers.com info@resodynmixers.com...

Need help?

Do you have a question about the LabRAM II and is the answer not in the manual?

Questions and answers