Summary of Contents for Resodyn LabRAM II

- Page 1 LabRAM II Installation and Users’ Manual Resodyn Acoustic Mixers 130 N. Main Street Butte, MT 59701 406-497-5333 www.resodynmixers.com...

-

Page 2: Table Of Contents

Processing Accessories ....................11 System Specifications ....................12 Voltage Level ......................12 Power Consumption ....................12 Installation and Support ....................13 Unpacking, Lifting, and Placing LabRAM II ..............13 Mounting ........................13 Door Operation ......................14 Remove the Shipping Lock Bar ...................15 Vessel Holder Assembly .....................16 Electrical Connections ....................18 Quick Start ........................19... - Page 3 Screen Operations – Edit a Configuration .............55 13.7.2 Screen Operations – Create a Configuration ..........56 13.7.3 Configuration Usage ..................57 13.8 Data Tab ........................58 Care and Maintenance ....................59 14.1 Preventive Maintenance .....................59 14.2 Cleaning Procedures ....................59 14.3 Accelerometer Calibration ...................59 Resodyn Acoustic Mixers Revision 063020...

- Page 4 Major Repairs ....................59 14.4.2 Recommended Maintenance Schedule ............60 14.5 Replacement of Serviceable Parts ................60 14.5.1 Fuse Replacement ..................60 14.5.2 Bellows Replacement ...................61 14.5.3 Accelerometer Replacement .................61 14.5.4 Technical Support for Mixer Operation: ............61 Troubleshooting and Service ..................62 Resodyn Acoustic Mixers Revision 063020...

-

Page 5: Introduction

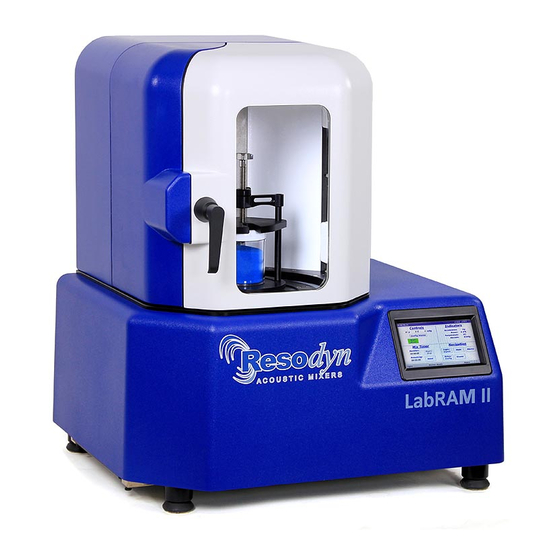

LabRAM II Operations Manual Introduction Introduction The LabRAM II is an advanced, low-frequency, acoustic mixer. It is the second generation of ResonantAcoustic Mixers LabRAM, an innovative approach to multiple mixing applications. ® These applications include powder-powder systems, liquids, creams, highly viscous gels and pastes, as well as sieving and grinding (with the proper vessels and attachments). -

Page 6: Definitions

LabRAM II Operations Manual Definitions Definitions Acceleration: A change in velocity with respect to time that is expressed in “g.” Different mix media mixes at different accelerations, based on the material and the expected results. (See “g” below.) Damping: A term to quantify the instantaneous amount of energy absorbed by the mix media while mixing. -

Page 7: Safety

LabRAM II Operations Manual Safety Safety Every effort has been made to assure that the LabRAM II is easy to use, reliable, and safe. This section outlines the general safety considerations and defines caution and warning symbols used throughout this manual. -

Page 8: Important Safety Notes

40°C (32°F – 104°F). Component Replacement The system is designed with components that are specifically rated for use with the LabRAM II machine. Only replace worn or damaged components with direct factory replacement parts or parts approved by Resodyn Acoustic Mixers. Incorrect component replacement can impair the safety of the equipment and risk injury to personnel. - Page 9 LabRAM II Operations Manual Safety Allow only Resodyn Acoustic Mixers Service Engineers to repair a LabRAM II or • return to Resodyn after receiving a Return Authorization. Resodyn Acoustic Mixers Revision 063020...

-

Page 10: Handling/Lifting

Safety Handling/Lifting The LabRAM II mixer weighs 260 lbs. with no additional options. The mixer should be lifted by at least 4 people, one on each side. The two primary lifting positions are on either side of the LabRAM II machine where retractable, integral lifting handles are located (Figure 1 below). -

Page 11: Guards And Safety Devices

Using Retractable Handles When the LabRAM II has been located in the area of final installation, make sure the area is prepared and ready for installation. Carefully follow the unpacking instructions in Section 6 on Page 15 of the User’s Manual. -

Page 12: System Overview

Air vents ResonantAcoustic ® Mixing Platform The LabRAM II delivers energy to the material being mixed by moving the mixing vessel up and down 60 times per second at up to 100 g of acceleration. Resodyn Acoustic Mixers Revision 063020... -

Page 13: Acoustic Enclosure

Touch Screen Human Machine Interface (HMI) The HMI is the primary user interface on the LabRAM II. The LabRAM II is digitally controlled through the HMI. All data entry and operations are provided through software keypads and buttons on the screen. -

Page 14: Standard Vessel Fixture And Vessels

System Overview Standard Vessel Fixture and Vessels The standard and supplied Vessel Holder, or hold-down fixture, for the LabRAM II is 5” in diameter and accommodates vessels between the heights of 2.5” and 5.125.” Components and function of the Vessel Holder are described in detail below. -

Page 15: Processing Accessories

LabRAM II accessories are available to expand its processing capabilities. Those accessories include Manual and Automatic Vacuum Systems, Jacketed Vessel Heating/Cooling Systems, and Spray Coating Systems. For details on operation of these systems with the LabRAM II, refer to the detailed Installation and Operation Manual provided with each system. -

Page 16: System Specifications

2) Mini USB 3) Fuses (X2) 4) Communication Connector for Automatic Vacuum System All external connections are found in the back panel of the LabRAM II machine. See Page 21 for a detailed illustration. Table 5-1. LabRAM II System Specification. -

Page 17: Installation And Support

LabRAM II to its final position. Mounting The LabRAM II should be installed on a stable, rigid surface that is rated to support the mixer’s weight. If other equipment or materials are to be placed or used on the same surface, a higher weight rating should be used as appropriate. -

Page 18: Door Operation

180°, releasing the right-hand door. Pull the handle outward to open. NOTE: When power is supplied to the LabRAM II, the mixing chamber is lit internally whenever the doors are closed and secured. The light automatically turns off when the door is opened. -

Page 19: Remove The Shipping Lock Bar

Installation and Support Remove the Shipping Lock Bar The LabRAM II is shipped with a Lock Bar to secure the resonator during transportation. The Lock Bar MUST be removed before proceeding with installation or attempting to operate the LabRAM II. -

Page 20: Vessel Holder Assembly

LabRAM II Operations Manual Installation and Support Vessel Holder Assembly Remove the Vessel Holder Assembly from Hood Rear Hold Down the accessory box accompanying the Knob Plate shipment. Jam Nut Mixing Cross Bar NOTE: The Vessel Holder is shipped with... - Page 21 5” vessel holder is ¼-20 threads measuring 5.75” center-to-center. The mounting plate that comes standard with the LabRAM II also has mounting holes to accept fixtures and vessels from the original LabRAM. The fastener holes are four ¼-20 threads measuring 4.375”...

-

Page 22: Electrical Connections

LabRAM II Operations Manual Installation and Support Electrical Connections Electrical power is provided to the LabRAM II through the cord labeled Rear View of LabRAM II “Power” which connects to the Power Cord Socket on the back panel of the LabRAM II. -

Page 23: Quick Start

Section 6 must be completed before attempting a Quick Start or operation of the LabRAM II. Setup To first set up the LabRAM II mixer, the mixing vessel must be installed. The fixture must have a vessel installed before operating the mixing vessel. 7.1.1 Open the Hood Door(s) Door operation is described in detail and illustrated in Section 6.3 - Door Operation. -

Page 24: Login

RAM Logo: Power Applied Login Before running the LabRAM II, a user login is required. For quick-start, the lowest level login will be used. Both the username and password are “operator.” 1. Touch the <Login/Logout> button. 2. Touch the <Username:> text box. This will launch the “Enter Username” alpha-numeric keypad. -

Page 25: Select The Recipe

Quick Start Select the Recipe The LabRAM II is provided with a demonstration recipe to use as a reference and guideline. The following demonstrates how to select a recipe for mixing using that demonstration recipe. 1. Touch the <Select Recipe> button. The “Select Recipe” screen is displayed. -

Page 26: Completion

Repeat the Demo Mix recipe for familiarization if necessary or required. Completion When the middle section of the Recipe Status Bar reads “Status: Ready”, the LabRAM II’s doors can be opened and the Mixing Vessel can be removed. 1. Open the doors. -

Page 27: Hmi (Human Machine Interface) - Overview

HMI (Human Machine Interface) – Overview HMI (Human Machine Interface) – Overview The HMI is the primary user interface on the LabRAM II. The LabRAM II is completely digitally controlled and control is provided by the HMI. All data entry and operations are provided through software keypads and buttons on the screen. -

Page 28: Login

HMI (Human Machine Interface) – Overview Login As illustrated in the Quick Start section, in order to operate the LabRAM II, user authentication (login) is required. Four different login privilege levels are provided to control access to machine features. The LabRAM II is delivered with pre-configured users at each level of login for demonstration purposes. -

Page 29: Viewer

LabRAM II Operations Manual HMI (Human Machine Interface) – Overview The Level 0 (operator) login level does not have any access to the Setup and Configurations screen set, while other levels have varying access to features. The breakdown of feature access is defined in Section 9.1 Login Levels and Privileges. -

Page 30: Hmi Operation - Security And Login

HMI Operation – Modes of Operation HMI Operation – Security and Login To protect the LabRAM II from unauthorized use and to maintain a record of which users operated the mixer, the system uses a user authentication system. Users are required to enter a username and password before operating the mixer. -

Page 31: Screen Operations - Logging In/Out

LabRAM II Operations Manual HMI Operation – Modes of Operation Screen Operations - Logging In/Out The following table outlines the steps for logging in using the pre-configured supervisor login. Touch the <Login/Logout> button The “Login” screen will appear. Touch the textbox beneath “Username:.”... -

Page 32: Log Files

(image 2 above). Log Files Every login attempt, successful or not, is logged to data files in the LabRAM II’s memory. These files can be uploaded to a PC via USB for data archiving. See Section 13.8 Data Tab. -

Page 33: 10 Hmi Operation - Modes Of Operation

10.1 Screen Operations - Recipe Mode The following table details the steps for operating the LabRAM II in Recipe Mode. Note that this sequence assumes the user has already logged in to the system. Touch “Demo Recipe Group” (item 1) to expand Touch the <Select Recipe>... - Page 34 0C and 0torr, respectively. When the timer of the final segment expires, the The LabRAM II can be stopped by touching the mixer will stop. The <Stop Mixer> button changes <Stop Mixer> button during a recipe mix. Normally, to and the <Start Mixer>...

-

Page 35: Screen Operations - Auto Mode

10.2 Screen Operations - Auto Mode The following details the steps for operating the LabRAM II in Auto Mode. Note that this sequence assumes the user has already logged in to the system with authorized login credentials to operate in Auto Mode. - Page 36 LabRAM II Operations Manual HMI Operation – Modes of Operation Touch the <Mode> button. The “Mode Select” dialog is displayed. Touch the <Auto> button to change from Recipe to Auto Mode. The Main Screen will appear but will have some Touch the <OK>...

- Page 37 Control” dialog. a Configuration, touch the <Config/Alarms> button. NOTE: If the LabRAM II is mixing or in acceleration, the setpoint would be used as soon as a valid setpoint was entered. The LabRAM II does not wait for you to touch <Done>.

- Page 38 LabRAM II Operations Manual HMI Operation – Modes of Operation The “Auto Mode Configuration and Alarms” screen 10. The “Select Configuration” dialog will appear, and is displayed. This screen allows a user to enter the Configuration can be selected from the list (only limitations that will shut the machine down (and one configuration is defined in the image).

- Page 39 LabRAM II will begin accelerating/mixing. The text entered in this screen is stored in a log file in <Start Mixer> button changes to the <Stop Mixer> the LabRAM II’s memory. Touch <OK> when button. Depending on Auto Mode Timer mode finished.

- Page 40 LabRAM II Operations Manual HMI Operation – Modes of Operation 20. When timer expires, the LabRAM II will stop 19. When the timer is actually running the <Reset> accelerating/mixing. If the Auto Mode timer is set to button will be disabled. Also, the timer duration the manual option, the middle portion of the Status cannot be changed when the timer is running.

-

Page 41: 11 Hmi Operation - Alarming

HMI Operation – Alarming 11 HMI Operation – Alarming The LabRAM II protects itself and the user by monitoring parameters that could cause damage or injury. When any of these parameters are violated, the mixer will stop accelerating/mixing and the user is notified at the Main Screen by a change in the color of the Alarm section of the Status Bar to red or yellow. - Page 42 LabRAM II Operations Manual HMI Operation – Alarming The alarm font turns blue and a time is inserted The alarm message disappears when an into the “Ack.” Column. The blue color indicates an acknowledged alarm recovers. alarm that is still active but has been acknowledged.

-

Page 43: 12 Hmi Operation - Viewer

HMI Operation – Viewer 12 HMI Operation – Viewer The LabRAM II measures several parameters important to mixing efficiency. These measure parameters can be viewed in real-time as time-history plots. To view real-time plots, touch the <Viewer> button in the Navigation Pane of the Main Screen. - Page 44 LabRAM II Operations Manual HMI Operation – Viewer The “Select Trend Plot” dialog will appear. This This image shows only the four mixer parameters dialog allows selecting the display of specific in the plot as indicated by the contents of the Plot parameters.

-

Page 45: 13 Hmi Operation - Setup And Configuration

Configuration screen provides user control of optional features, and manages the configuration of the LabRAM II. The Setup and Configuration screen is accessed by touching the <Setup/Config> button from the Main Screen. If logged in at Level 0 (operator), this button is disabled, while the button is enabled for all other login levels (refer to image), but the content of the Setup and Configuration screen is adjusted based on the user’s login level. - Page 46 LabRAM II Operations Manual HMI Operation – Setup and Configuration Level 1 (Technician) NOTE: The following descriptions and instructions of the Setup and Level 2 (Calibration) Configuration screen in Section 13 assume a Level 3 (Supervisor) login. Level 3 (Supervisor)

-

Page 47: Status Tab

13.3 Recipe Tab The Recipe Tab is used to create and edit recipes and recipe groups. The LabRAM II has the capability to store 10 recipe groups with 10 recipes per group, for a total of 100 recipes. Recipe groups can be thought of “folders,” and recipes are analogous to “files” on a computer. Recipe Groups can be created, renamed, and deleted in the recipe tab. - Page 48 After touching the recipe name, an arrow will appear The recipe contents will be read from the LabRAM II’s indicating that the recipe has been selected. To view/edit memory and displayed in the screen shown above. The the contents of this recipe touch the <Edit Recipe>...

- Page 49 The “Acceleration Recipe Entry” dialog will appear. Use LabRAM II is equipped with these options. this dialog entry the same as the Auto Mode acceleration Touch the <Add> button on the left-side of the screen to entry.

- Page 50 LabRAM II Operations Manual HMI Operation – Setup and Configuration A new segment, segment 4, is now added to the end of 10. To add another segment betweeen existing segments in the this recipe. Using the methods previously described, the recipe, the <Insert> button will be used this time.

-

Page 51: Screen Operations - Create New, Rename, And Delete

LabRAM II Operations Manual HMI Operation – Setup and Configuration This concludes the “edit Recipe portion of Section 13.3.1. The following section continues to assume Log In as a Supervisor 15. A confirmation dialog will appear. Touch <Yes> to save. - Page 52 LabRAM II. Touch the <Recipe Alarms> button. The “Recipe Alarms” screen will appear. This screen 10. LabRAM II will automatically check for input errors. To performs the identical function as the “Auto Mode demonstrate the error checking functionality, touch the Configuration and Alarms”...

- Page 53 LabRAM II Operations Manual HMI Operation – Setup and Configuration 11. The “Bad Recipe Segment” dialog will appear and it 12. Correcting the contents of the recipe by entering specifies that something is wrong with the definition of qualifying data allows saving. Touch <Save File>.

- Page 54 LabRAM II Operations Manual HMI Operation – Setup and Configuration 17. Touch <Yes> on the “Recipe Delete Confirmation” dialog 18. Selecting “new group” again will confirm that the recipe is to delete the recipe. deleted. Recipe Groups are also renamed and deleted from this screen.

-

Page 55: Setup1 Tab

This group box controls the behavior of the optional strobe light feature for the LabRAM II. The controls in this group box will only be active if the LabRAM II is equipped with the strobe option. The top three selections (<Slow Strobe>, <Med. Strobe>, <Fast Strobe>) adjust the strobe speed. -

Page 56: Operational Options Group Box

Clear Mix Comment: By default, the previous Mix Log Comment is retained • between a LabRAM II shutdown and re-start. This can be useful if a specific comment protocol is required. Checking this option will clear the Mix Log Comment between starts and force the user to re-type the mix comment. -

Page 57: Screen Operations - User Management

LabRAM II Operations Manual HMI Operation – Setup and Configuration 13.5.1 Screen Operations – User Management This details how to create a new Level 2 (Calibration) user login. Touch the <Edit User/Password> button. The “User Management” dialog appears. Touch the <Add User>... -

Page 58: Config Tab

LabRAM II Operations Manual HMI Operation – Setup and Configuration The password has been changed when the “User Confirm user delete by touching the <Yes> button in the Management” dialog reappears. Otherwise, a failure “User Delete Confirmation” dialog. dialog will notify the user of failed password change. To delete a user, select it, and touch the <Remove User>. -

Page 59: Screen Operations - Edit A Configuration

HMI Operation – Setup and Configuration 13.7.1 Screen Operations – Edit a Configuration The following walk-through modifies the configuration provided with the LabRAM II called “default.” This sequence assumes that temperature measurement option is equipped, and that temperature #1 was not used initially. -

Page 60: Screen Operations - Create A Configuration

LabRAM II Operations Manual HMI Operation – Setup and Configuration The “Fixture Definition/View” screen will appear. The parameters for the selected fixture are displayed. When new fixtures are ordered, fixture files will need to be installed on the mixer using the procedure accompanying the fixture. -

Page 61: Configuration Usage

LabRAM II Operations Manual HMI Operation – Setup and Configuration 13.7.3 Configuration Usage This section will provide a refresher of how Configurations are used. Configurations are used for both Recipe and Auto Mode. In Recipe Mode, the Configuration is selected as soon as a new recipe is created or by touching the textbox next to “Config:.”... -

Page 62: Data Tab

13.8 Data Tab The LabRAM II stores log files for a variety of purposes. The list below summarizes the files that are captured on the LabRAM II. Data Logs: Measured parameters are captured and written to data log files when the •... -

Page 63: 14 Care And Maintenance

14.3 Accelerometer Calibration The LabRAM II acceleration should be calibrated once a year or per the end users specified preventative maintenance schedule or when the accelerometer is replaced. The calibration kit can be purchased or rented from Resodyn Acoustic Mixers. -

Page 64: Recommended Maintenance Schedule

If this occurs, please call your Resodyn Acoustic Mixers representative for further instructions. Fuse access is located on the lower left area of the back of the LabRAM II, shown in Section 6.6 Electrical Connections. Turn the fuse cap counterclockwise to remove fuse. -

Page 65: Bellows Replacement

14.5.3 Accelerometer Replacement The LabRAM II is equipped with an accelerometer that is mounted to the underside of the Payload Plate. The accelerometer is designed for an operational life greater than 2,000 hours. Should replacement be required, instructions for the accelerometer are provided with the replacement part. -

Page 66: 15 Troubleshooting And Service

Troubleshooting and Service 15 Troubleshooting and Service The LabRAM II system should only be operated when it is in good working condition. If the system shows any signs of visible damage or fails to operate as outlined in this manual, the system should not be operated. - Page 67 Remove mix material until it is within the maximum specified load limits. Incorrect fixture file Ensure that the correct fixture file is being used for the fixture on the LabRAM II. Over Acceleration (g) Mixer exceeded maximum Contact Resodyn Acoustic Mixers.

- Page 68 LabRAM II Operations Manual 063020 Resodyn Acoustic Mixers 130 N. Main Street, Butte, MT 59701 USA 406-497-5333 info@ResodynMixers.com...

Need help?

Do you have a question about the LabRAM II and is the answer not in the manual?

Questions and answers