Table of Contents

Advertisement

Quick Links

VESTIL MANUFACTURING CORPORATION

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

sales@vestil.com • www.vestil.com

Contents

Installation Instructions ..................................2-3

Routine Maintenance & Safety Chocks ............ 4

Belt Tensioning Procedure ............................... 5

Operation Instructions ...................................... 6

Exploded Mast Parts Drawing & BOM ...........8-9

WARNINGS & SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the following.

• Read and understand the owner's manual before using or

servicing the stretch-wrap machine.

• Ensure that all safety and warning labels stay in place and

that they are legible.

• Do not use the machine if any damage or unusual noise

is observed.

• Watch the pallet or container carefully when the turntable

is in motion, particularly in the case of any overhanging load.

• Rotating the palletized loads can become unstable. Be

prepared to stop the turntable in the even the load shifts.

• Make certain that the load is centered and stable before

operating the turntable.

• Warning: Keep all personnel clear of the machine when it

is in operation. Be certain no part of any person, fork truck,

or other object is in the path of the rotating load before

rotating the turntable.

• Warning: Do not stand or sit on the turntable or its load at

any time.

• Warning: Keep all body parts and clothing away from the

machine's drive system(s).

• Do not perform any modifications to the stretch-wrap

machine or its mast without the manufacturer's approval.

Failure to receive authorization for changes to the equipment

could void the warranty.

• Maintenance and repairs are to be done only by personnel

qualified to perform the required work. Consideration will

not be given for warranty repair labor charges without prior

written authorization by the manufacturer.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to shipment.

However, it is possible that the unit may incur damage during transit.

Inspect the unit closely when it arrives. If you see evidence of

Revised 0507

A company dedicated to solving ergonomic and material

handling problems since 1955 .

OWNER'S

MANUAL

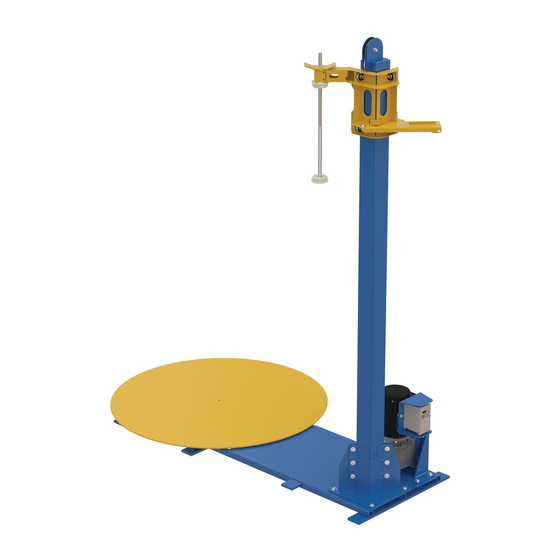

SEMI-AUTOMATIC STRETCH WRAP MACHINE

MODEL SWA-48, POW-CAR

SWA-48, POW-CAR Electrical Diagram ........ 10

Powered Mast Electrical Diagram .................. 11

Motor Speed Controller Parameters ............... 13

Troubleshooting ............................................. 13

Safety Label Identification .............................. 14

Warranty ......................................................... 15

damage or rough handling to either the packaging or to the product

when it is being unloaded, immediately make a note of it on the Bill

of Lading!

It is important that you remove the product's packing upon its arrival

to ensure that there is no concealed damage or to enable a timely

claim with the carrier for freight damage.

Also, verify that the product and its specifications are as ordered.

WHEN ORDERING REPLACEMENT PARTS

We take pride in using quality parts on the equipment we

manufacture. We are not responsible for equipment problems

resulting from the use of unapproved replacement parts. To

order replacement or spare parts for this equipment, contact

the manufacturer.

In any communication with the manufacturer, please be

prepared to provide the machine's serial number, which is

indication of the machine dataplate.

SEMI-AUTOMATIC STRETCH WRAP MACHINE

MODEL SWA-48, POW-CAR

20-126-103

1

Advertisement

Table of Contents

Summary of Contents for Vestil SWA-48

-

Page 1: Table Of Contents

SEMI-AUTOMATIC STRETCH WRAP MACHINE MODEL SWA-48, POW-CAR Contents Installation Instructions ........2-3 SWA-48, POW-CAR Electrical Diagram ..10 Powered Mast Electrical Diagram ....11 Routine Maintenance & Safety Chocks .... 4 Belt Tensioning Procedure ....... 5 Motor Speed Controller Parameters ....13 Operation Instructions ........ -

Page 2: Installation Instructions

Consult the manufacturer in the event there are any questions or problems at the time of installation, or for information regarding optional features not covered by the owner’s manual. The model SWA-48 stretch-wrap machine must be removed from the shipping wood and securely anchored to the floor before use! •... - Page 3 ATERIAL OLDER SSEMBLY 14. Unscrew and remove the plastic tension grip handle from the top of the stretch-wrap material holder rod. 15. Remove the top plastic stretch-wrap material tube retainer (it should have a bearing pressed into it) from the material holder rod. 16.

-

Page 4: Routine Maintenance & Safety Chocks

& S – SWA-48, POW-CAR OUTINE AINTENANCE AFETY HECKS o Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures before beginning work. o Only qualified individuals trained to understand mechanical devices and their associated electrical circuits should attempt troubleshooting and repair of this equipment. -

Page 5: Belt Tensioning Procedure

-- SWA-48, POW-CAR ENSIONING ROCEDURE... -

Page 6: Operation Instructions

(RPM) in a clockwise rotation around palletized, stable, non-hazardous loads. The maximum diameter (or diagonal, measured corner-to-corner) load size for the SWA-48 is 76”, the maximum load height is 78”. Always ensure that the load is centered on the turntable. -

Page 7: Exploded Turntable Parts Drawing & Bom

— SWA-48, POW-CAR XPLODED PARTS VIEW AND ATERIALS Item# Part Number Description Quantity 20-110-003 Bearing, cam follower, 1" dia. 20-540-001 Assembly, lever / tension arm 20-117-001 Retaining ring, internal 20-110-001 Bearing, ball 20-542-006 Weldment, pulley / pin, driven, 9" OD 20-117-003 Retaining ring, external, 1"... -

Page 8: Exploded Mast Parts Drawing & Bom

Exploded Parts View — Stretch-Wrap Masts... - Page 9 Bill of Materials — Stretch-wrap Masts (On All Models) Item# Part Number Description Used on Quantity 20-025-001 Grip, handle, threaded Both 13-025-003 Grip, handle, 1-1/8"ID Both (two used on the manual mast) 20-117-002 Retaining ring Both 20-110-002 Bearing, ball Both 20-014-006 Tube retainer, top Both...

-

Page 10: Swa-48, Pow-Car Electrical Diagram

Electrical Diagrams -- SWA-48, POW-CAR *** Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures before beginning work. Ensure that power have been removed before attempting to work on the electrical system. *** Only qualified individuals trained to understand mechanical devices and their associated electrical and hydraulic circuits should... -

Page 11: Powered Mast Electrical Diagram

Powered Mast... - Page 12 HANGING ELTA OTOR PEED ONTROLLER ARAMETERS Prog Press to switch to the program mode. Data a) The following screen will appear: Indicating the specified parameter group. b) Use the following keys to change all parameter settings in Step 2. Press "PROG/DATA" key to select parameter group and to store entered data. Prog "END"...

-

Page 13: Motor Speed Controller Parameters

— SWA-48, POW-CAR ROUBLESHOOTING UIDE Warning: Before performing any task, always disconnect the power supply. Consult the manufacturer for problems at time of installation, or for any problems not addressed below. Problem Possible Cause(s) Action • The turntable does not rotate. -

Page 14: Safety Label Identification

AFETY ABEL DENTIFICATION * Product safety signs or labels should be periodically inspected and cleaned by the ONE YEAR LIMITED WA product users as necessary to maintain good legibility for safe viewing distance — ANSI 535.4 (10.21). Contact the manufacturer for replacement labels. -

Page 15: Warranty

’ W OWERED PRODUCTS ARRANTY ONE YEAR LIMITED WARRANTY The manufacturer warrants for the original purchaser against defects in materials and workmanship under normal use one year after date of shipment (not to exceed 15 months after date of manufacture). Any part that is determined by the manu- facturer to be defective in material or workmanship and returned to the manufacturer, shipping costs prepaid, will be, as the exclusive remedy, repaired or replaced at our option. - Page 16 Time is money. Increased productivity equals greater profitability, cost minimization and worker compatibility. Ergonomic products will assist you with your production and safety goals. Mobile Lift & Tilt 45° Container Tilter Work Stand Ground Lift Tilter Copyright 2007 Vestil Manufacturing Company...

Need help?

Do you have a question about the SWA-48 and is the answer not in the manual?

Questions and answers