Summary of Contents for Bosch Rexroth IH04

- Page 1 General operating instructions Press modules for hydraulic presses Type IH04 RE 63124-B, Edition: 08.2021, Replaces: -, EN...

- Page 2 It must be remembered that our products are subject to a natural process of wear and aging. © All rights are reserved to Bosch Rexroth AG, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

-

Page 3: Table Of Contents

Assembling the press module .............. 25 7.3.1 Installing the press module ............... 25 7.3.2 Hydraulically connecting the press module .......... 26 7.3.3 Electrically connecting the press module .......... 29 Commissioning .................. 31 Bleeding the hydraulic system .............. 32 Operation .................... 33 RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... - Page 4 Technical data .................. 48 Glossary .................... 49 17.1 General terms for press components ............ 49 17.2 General terms for press control functions .......... 51 17.3 General terms for press operating modes .......... 52 Alphabetical index ................. 53 Bosch Rexroth AG, Edition 08.2021, RE 63124-B...

-

Page 5: About This Documentation

Installation, commissioning and maintenance of servo valves and 07700 Data sheet high-response valves Installation, commissioning and maintenance of proportional valves 07800 Data sheet Reliability characteristics MTTFd regarding the functional safety 08012 Data sheet according to EN ISO 13849 This document is presently in preparation. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 6: Representation Of Information

Indicates a dangerous situation which may cause death or WARNING severe injury if not avoided. Indicates a dangerous situation which may cause minor or CAUTION medium (personal) injury if not avoided. Damage to property: The product or the environment NOTICE could be damaged. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 7: Symbols

The following abbreviations are used in this documentation: Table 4: Abbreviations Abbreviation Meaning Active opto-electronic safeguard Bottom dead centre Contactless safeguard Rexroth document in the English language REXXXXX-MON Rexroth assembly instructions in the English language Top dead centre RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 8: Safety Instructions

• use in the original condition and/or without damage. All operating modes such as automatic mode, single stroke and set-up/jog mode with slow closing speed (<10 mm/s) are allowed. They work according to a fixed working cycle specified in the type-specific data sheet. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 9: Improper Use

• Use of the press module for operation in explosive environments • Use of the press module under aggressive oder corrosive environmental conditions Bosch Rexroth AG does not assume any liability for damage caused by improper use. The user assumes responsibility for all risks surrounding improper use. -

Page 10: Qualification Of Personnel

• in particular, completely understanding the relationships regarding the safety equipment and • having knowledge of the function and set-up of hydraulic components. Bosch Rexroth offers training in specific fields. An overview over the training contents can be found online at: www.boschrexroth.com/de/de/academy/. -

Page 11: General Safety Instructions For Press Modules

EN ISO 16092, 5.3.6 and/or EN 289, 5.4.1.1.3. For hydraulic presses according to EN289 with a depth of the clamping plate greater than 800 mm and stroke greater than 500 mm, a mechanical restraint device according to EN 289, 5.4.1.1.3. is required. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 12: Product- And Technology-Dependent Safety Instructions

Danger to life! Risk of injury! Damage to property! ▶ Only use the press module within the approved hydraulic fluid temperature range. ▶ In case of leakage, immediately replace damaged seal rings and/or the affected valve. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... - Page 13 ▶ Use an oil binding agent in order to bind the leaked hydraulic fluid. ▶ Remove and dispose of the contaminated oil binding agent, see chapter 13 "Disposal". ▶ Wear the protective equipment, e.g. safety shoes, prescribed for your activity. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG...

- Page 14 Risk of injury! ▶ Comply with the cleanliness classes required in the relevant data sheet. ▶ If necessary, flush the hydraulic system for commissioning. Bosch Rexroth AG, Edition 08.2021, RE 63124-B...

-

Page 15: Personal Protective Equipment

• Effects of an emergency stop, how to free a person who has become entrapped in the die area, in particular as a result of bypassing or misuse of the safety equipment or after an emergency stop has been triggered, see EN 289, par. 7.2.3 RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 16: General Information On Damage To Property And Damage To Product

▶ Check the compatibility of the various hydraulic fluids and their compatibility with the components and seals. Mixing of hydraulic fluids may occur for example due to hydraulic fluid residues in a component. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... - Page 17 ▶ Before installation works, separate the device from the mains or from the voltage source or de-energize it. ▶ Do not plug in or pull off the electric plug-in connector as long as the voltage supply is activated. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG...

-

Page 18: Scope Of Delivery

For further information on the supplied documentation, refer to chapter 1.2 “Required and additional documentation”. The warranty only applies to the delivered configuration. The claim to warranty expires if the product is assembled, commissioned and operated incorrectly, not used as intended and/or handled improperly. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 19: Product Information

Fig. 1: Exemplary representation of a name plate Fig. 2: Schematic illustration of a name plate 1 Manufacturer's logo 5 Area / works number 2 Material number 6 Date of production 3 Type designation 7 Designation of origin 4 Serial number 8 Customer material number RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 20: Transport And Storage

▶ Before transport, close all openings using the supplied protective caps/covers in order to prevent dirt or humidity from penetrating the press module, and leaking of any oil residues due to oil-wetted surfaces within the press module. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

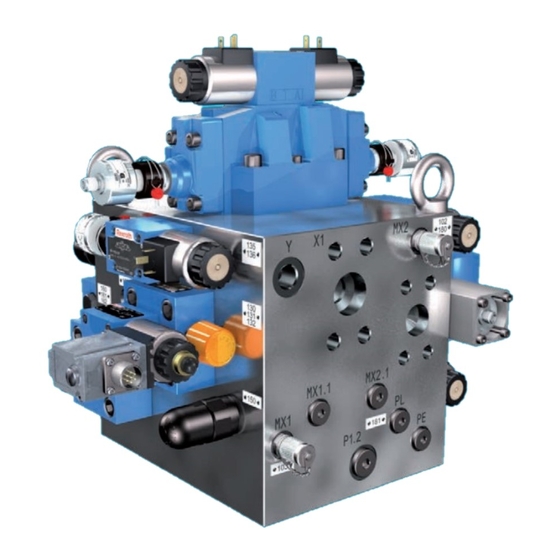

Page 21: Use Of Attachment Points

▶ Observe the maximum length and load-bearing capacity of the attachment devices. Two ring bolts already attached to the press module at the factory serve as attachment points. Fig. 3: Example of type IH04C module with ring bolts 1 Ring bolt RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 22: Transport Using Forklifts And Similar Floor Conveyors

▶ Do not lift the press module by the attached components, e.g. by the attached extension module. ▶ Observe the maximum load-bearing capacity of the lifting gear used. ▶ Attach suitable securing and/or safety gear if necessary. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 23: Storing The Press Module

▶ Do not remove covers from the hydraulic connections on the press module until just before assembly. Storage longer ▶ For storage periods longer than 6 months, consult with Bosch Rexroth. than 6 months After expiry of the maximum storage time, Bosch Rexroth recommend having the press module checked by your competent Rexroth service. -

Page 24: Assembly

▶ It is imperative to provide for absolute cleanliness. Contamination of the hydraulic fluid may considerably impair the operating life of the hydraulic component. ▶ Select the installation position according to your technical requirements. Overhead installation is excluded. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 25: Assembling The Press Module

▶ Assemble the press module using a manual torque wrench. ▶ If necessary, pay attention to the tank penetration shown in the installation drawing. To install the press module, proceed as follows: RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 26: Hydraulically Connecting The Press Module

• Pipelines shall be uninterrupted from one component to the next wherever possible. • Precautions must be taken to prevent damage due to thermal expansion. Rigid pipelines shall be securely fastened at short intervals to prevent vibration and movement. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... - Page 27 ▶ When assembling pipelines, proceed according to the instructions of the suppliers of flanges and fittings (e.g. Voss): – Determination of the tightening torque – Pipe preparation – Oiling the steel pipes – Pipe deformation – Check and final assembly RE 63124-B, Edition: 08.2021, Bosch Rexroth AG...

- Page 28 5. Make sure that all pipe and hose lines and every combination of connection pieces, couplings or connection points with hoses or pipes are checked for their operational safety by a person with appropriate knowledge and experience. Bosch Rexroth AG, Edition 08.2021, RE 63124-B...

-

Page 29: Electrically Connecting The Press Module

▶ Provide for proper grounding. NOTICE Short-circuit or damage to the integrated electronic card due to incorrect connection of electric components! Damage to property! ▶ Connect the electric components according to the electric circuit diagram and the pin assignment. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... - Page 30 (+/-10 V, 0…10 V) connection ▶ For pin assignment, please refer to the data sheet of the respective valve. The electrical signals (e.g. actual value) transmitted via valve electronics must not be used for switching off safety-related machine functions. Bosch Rexroth AG, Edition 08.2021, RE 63124-B...

-

Page 31: Commissioning

▶ Make sure that the hydraulic system is only filled with a filtered hydraulic fluid. ▶ Ensure that no contaminations are able to penetrate when sealing the ports. For commissioning of the press module, always observe the operating instructions of the overall machine/system. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 32: Bleeding The Hydraulic System

Mechanical damage due to inadmissibly high acceleration of the hydraulic fluid and the valve spools is thus avoided and the press module's life cycle is increased. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 33: Operation

• for slow closing speed with hold-to-run device below 10 mm/s (optional and only for press modules type C and E) • for a temporary muting of the safety functions according to EN ISO 16092-1, par. 5.4.2 (optional and only for press modules type-C and D) RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 34: Maintenance And Repair

▶ Remove external coarse dirt and keep sensitive and important parts such as solenoid coils, valve electronics, pressure/temperature displays and warning signs clean. ▶ Use residue-free industrial wipes for cleaning. ▶ Before loosening fittings and components, clean the external area using residue-free industrial wipes. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 35: Inspection

The seals of attached and mounted valves are subject to a natural process of wear and aging. Bosch Rexroth recommends replacement at appropriate time intervals. The intervals are mainly determined by the operating conditions such as temperature and the cleanliness of the hydraulic fluid. -

Page 36: Maintenance

The seals of attached and mounted valves are subject to a natural process of wear and aging. Bosch Rexroth recommends replacement at appropriate time intervals. The intervals are mainly determined by the operating conditions such as temperature and the cleanliness of the hydraulic fluid. -

Page 37: Repair

The press module may only be repaired by specialist personnel according to chapter 2.4 "Qualification of personnel". Bosch Rexroth has an extensive service offer regarding the repair of valves. Part tested and pre-assembled original Rexroth assemblies allow for successful repair works requiring only little time. -

Page 38: Replacement Of Valves

The safety-relevant components may only be replaced by components of the same type. Spare parts from stock that have not been filled or treated with corrosion protection fluid may resinate. Clean them with grease solvent and build up a new oil film. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... - Page 39 ▶ Check whether the affected valve has cooled down sufficiently for you to dismantle it. ▶ Dispose of the defective valve, see chapter 13 "Disposal". ▶ Install the new valve. ▶ Check the reaction time of all safety-related valves after the replacement of a safety-relevant valve. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG...

-

Page 40: Decommissioning

▶ Connect the pressure gauge to the measuring points Mxx and drain the hydraulic fluid into a suitable oil tray until the pressure has completely dissipated. ▶ Keep the disassembly tools and suitable lifting devices ready. You can now start the disassembly. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 41: Disassembly And Replacement

▶ Decommission the overall machine/system as described in chapter 11. ▶ Keep the disassembly tools and suitable lifting devices ready. ▶ Have sufficiently dimensioned containers, residue-free industrial wipes and oil binding agent ready in order to collect or bind leaking hydraulic fluid. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 42: Disassembly Process

– The weight is shown on the installation drawing. ▶ Loosen the mounting screws diagonally, crosswise, and remove them. ▶ Now slowly remove the press module from the contact surface. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 43: Disposal

The materials for disposable packaging are mostly cardboard, wood, and expanded polystyrene. They can be recycled without any problems. Due to ecological reasons, disposable packaging should not be used for returning products to Bosch Rexroth. 13.4 Materials used Hydraulic components from Bosch Rexroth do not contain any hazardous materials that could be released during intended use. -

Page 44: Recycling

Due to the high metal content, hydraulic products can mostly be recycled. In order to achieve an ideal metal recovery, disassembly into individual assemblies is required. The metals contained in electric and electronic assemblies can be recovered by means of special separation procedures as well. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 45: Extension And Modification

Certifications and If you undertake any extensions to or modifications of the product marketed declarations shall by Bosch Rexroth, you are changing the condition as supplied. Any certifications and become invalid statements made by Bosch Rexroth regarding this product will then become invalid. -

Page 46: Troubleshooting

▶ If you could not remedy the occurred error, please contact one of the contact addresses you can find at www.boschrexroth.com Bosch Rexroth AG Service Bgm.-Dr.-Nebel-Str. 8 97816 Lohr am Main Phone: +49 (0) 9352 - 40 - 50 60 service@boschrexroth.de Bosch Rexroth AG, Edition 08.2021, RE 63124-B... - Page 47 Cable break ▶ Replace the connection cable. Replace the connection cable ▶ Replace the solenoid connection plug. In case of faults in individual components, please consult the documentation of the respective component. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG...

-

Page 48: Technical Data

The permitted technical data of the respective press module, can be found in the respective data sheet, see chapter 1.2 "Required and additional documentation". The data sheet can be found on the Internet at www.boschrexroth.com/mediadirectory For further information, refer to the online product catalog www.boschrexroth.com Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 49: Glossary

Contactless guard (BWS) Arrangement of devices and/or components that work together to provide access protection or presence detection, including: • a sensor element • control/monitoring elements • output devices • all connection cables RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... - Page 50 Fixed part of the die on the clamping plate. Press slide (see Fig. 4, pos. 4) Main part of the press that performs the stroke movement and to which the upper die/punch is attached. Upper die/punch Movable part of the die. Bosch Rexroth AG, Edition 08.2021, RE 63124-B...

-

Page 51: General Terms For Press Control Functions

Stop by interrupting the energy supply to the machine drives to prevent dangerous machine movements due to control system faults. Secure operational stop Stop with additional control system measures to prevent dangerous machine movements due to control system faults. RE 63124-B, Edition: 08.2021, Bosch Rexroth AG... -

Page 52: General Terms For Press Operating Modes

(e.g. die cushion, workpiece ejector) including the supply and removal of material or the workpiece; in the case of hydraulic presses along a programmed movement sequence from a start position until the same position is reached again. Bosch Rexroth AG, Edition 08.2021, RE 63124-B... -

Page 53: Alphabetical Index

- Packaging ......... 43 Automatic mode ...... 52 - Recycling ........ 44 - Automatic mode with AOS, double - Return to Bosch Rexroth AG .. 43 interruption ........ 52 - Automatic mode with AOS, single interruption ........ 52 Electrically connecting the press - OFF ... - Page 54 – Signal word ....... 6 Scope of delivery ...... 18 Secure operational stop ..... 51 Spare parts ........ 37 Working cycle ...... 52 Storage ........ 20 Storing the press module ... 23 Symbols ........ 7 Bosch Rexroth AG, Edition 08.2021, RE 63124-B...

- Page 55 Alphabetical index | Press modules Type IH04 55/56 RE 63124-B, Edition: 08.2021, Bosch Rexroth AG...

- Page 56 Bosch Rexroth AG Industrial Hydraulics Zum Eisengießer 1 97816 Lohr a. Main Germany Tel. +49 (0) 9352/40 30 20 my.support@boschrexroth.com www.boschrexroth.com Subject to change without notice Printed in Germany RE 63124-B/08.2021...

Need help?

Do you have a question about the Rexroth IH04 and is the answer not in the manual?

Questions and answers