Table of Contents

Advertisement

Quick Links

SERVICE MANUAL

GENERAL INFORMATION .......................................................................................................................... 4

INTRODUCTION AND THEORY OF OPERATION .............................................................................................................4

ASSEMBLY NUMBER EXPLANATION ...............................................................................................................................4

WINCH BREAK-IN ..............................................................................................................................................................4

MODEL CODES ........................................................................................................................................... 5

MAINTENANCE............................................................................................................................................ 6

OIL LEVELS........................................................................................................................................................................7

BRAKE ADJUSTMENT .......................................................................................................................................................8

DISASSEMBLY ............................................................................................................................................ 9

RUFNEK 30 BRAKE DISASSEMBLY..................................................................................................................................9

MODEL 34 BRAKE DISASSEMBLY....................................................................................................................................10

CLUTCH AND DRUM DISASSEMBLY................................................................................................................................11

GEARBOX DISASSEMBLY.................................................................................................................................................12

GEAR INSPECTION INSTRUCTIONS ................................................................................................................................13

ASSEMBLY ................................................................................................................................................ 14

GEARBOX ASSEMBLY ......................................................................................................................................................14

MODEL 34 BRAKE ASSEMBLY..........................................................................................................................................15

RUFNEK 30 BRAKE ASSEMBLY........................................................................................................................................15

CLUTCH AND DRUM ASSEMBLY......................................................................................................................................16

TROUBLESHOOTING................................................................................................................................ 17

BILL OF MATERIAL................................................................................................................................... 18

TORQUE SPECIFICATIONS CHART ........................................................................................................ 19

CLUTCH INSPECTION .............................................................................................................................. 19

ISOMETRIC VIEW ...................................................................................................................................... 19

RUFNEK BRAKE, HYDRAULIC MOTOR, & CLUTCH POSITION INDICATOR...................................... 19

SEL-0046-001.DOC

REV- July 2020

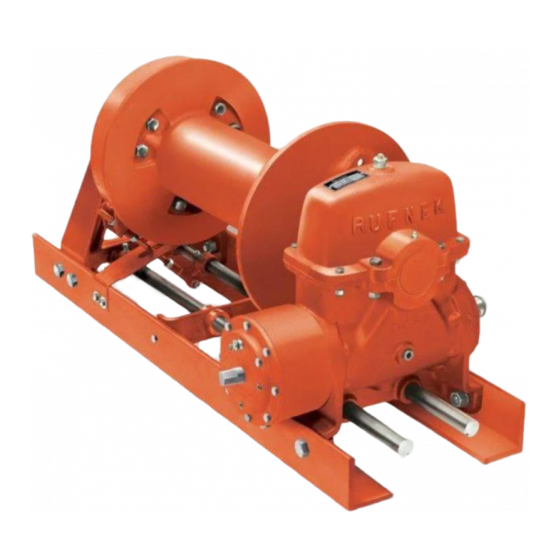

RUFNEK 30

AND

MODEL 34

DESIGN SERIES 001

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tulsa RUFNEK 30

-

Page 1: Table Of Contents

WINCH BREAK-IN ................................4 MODEL CODES ............................5 MAINTENANCE............................6 OIL LEVELS..................................7 BRAKE ADJUSTMENT ...............................8 DISASSEMBLY ............................9 RUFNEK 30 BRAKE DISASSEMBLY..........................9 MODEL 34 BRAKE DISASSEMBLY............................10 CLUTCH AND DRUM DISASSEMBLY..........................11 GEARBOX DISASSEMBLY..............................12 GEAR INSPECTION INSTRUCTIONS ..........................13 ASSEMBLY ..............................14 GEARBOX ASSEMBLY ..............................14 MODEL 34 BRAKE ASSEMBLY............................15... - Page 2 FAILURE TO HEED THE FOLLOWING WARNINGS MAY RESULT IN SERIOUS INJURY OR DEATH. The safety of the winch operator and ground personnel should always be of great concern, and all necessary precautions to insure their safety must be taken. The primary mover and the winch must be operated with care and concern for the equipment and the environment and with a thorough knowledge of the equipment and its performance capabilities must be understood.

- Page 3 Operator: Must read and understand the operating and service manual. Both the SERVICE MANUAL and OPERATING AND MAINTENANCE MANUAL are available online at http://www.team-twg.com/TulsaWinch/ Must never lift or move people with this winch. This winch is not designed or intended for any use that involves moving people. Must stay clear of the load at all times.

-

Page 4: General Information

INTRODUCTION AND THEORY OF OPERATION INTRODUCTION AND THEORY OF OPERATION The Tulsa worm gear winch is operated by turning the input of the worm using a hydraulic motor or PTO driven sprocket and chain. The winch utilizes the adjustable, spring applied, multiple disc oil brake that activates only during pay-out to provide maximum efficiency during pay-in. -

Page 5: Model Codes

MODEL CODES MODEL CODES MODEL CODES MODEL CODES RN30 W M R F O M X THE RUFNEK 30 SERIES WINCHES ARE ONLY AVAILABLE WITH LEFT HAND GEARS. Motor Type Gear Type 1. Single Speed Gear Motor W=Worm 2. Two Speed Gear Motor P=Planetary 3. -

Page 6: Maintenance

The oil in the gear and brake section should be changed every 1000 hrs or 6 months of normal usage. • Tulsa Winch recommends that the oil level in the gearbox be checked and adjusted as part of the pre-use inspection. If the oil level drops frequently or oil leakage is detected during an inspection, maintenance should be performed to correct any problems. -

Page 7: Oil Levels

OIL LEVELS OIL LEVELS OIL LEVELS OIL LEVELS GEARBOX FILL/VENT GEARBOX OIL LEVEL GEARBOX OIL DRAIN BRAKE FILL/VENT BRAKE OIL DRAIN BRAKE OIL LEVEL... -

Page 8: Brake Adjustment

BRAKE ADJUSTMENT BRAKE ADJUSTMENT In general, worm brakes on Tulsa winches should be set to hold the load you are currently working with. Excessive brake torque will result in excessive heat generation and brake wear. The best way to insure proper brake adjustment is to pull the cable tight against the load and stop to ensure the brake holds. -

Page 9: Disassembly

DISASSEMBLY DISASSEMBLY DISASSEMBLY DISASSEMBLY RUFNEK RUFNEK RUFNEK RUFNEK 30 30 BRAKE DISASSEMBLY BRAKE DISASSEMBLY BRAKE DISASSEMBLY BRAKE DISASSEMBLY 1. Remove the bottom drain plug 5. Inspect parts as follows, replace if (100) to drain oil from brake. necessary: 2. Loosen the spring tension inside A. -

Page 10: Model 34 Brake Disassembly

MODEL MODEL 34 MODEL MODEL 34 BRAKE DISASSEMBLY BRAKE DISASSEMBLY BRAKE DISASSEMBLY BRAKE DISASSEMBLY 1. Loosen the capscrews (26). 7. Inspect parts as follows, replace if necessary: 2. Remove the capscrews (30) from the cover (87). A. Inspect the brake shoes (86) for wear. -

Page 11: Clutch And Drum Disassembly

CLUTCH AND DRUM DISASSEMBLY CLUTCH AND DRUM DISASSEMBLY CLUTCH AND DRUM DISASSEMBLY CLUTCH AND DRUM DISASSEMBLY 1. Remove the rod (44) by removing and nuts (24) attaching the brake the cotter keys (43). band to the frame. 2. Remove the arms (34) by removing 9. -

Page 12: Gearbox Disassembly

GEAR GEAR GEAR GEARBOX BOX DISASSEMBLY DISASSEMBLY DISASSEMBLY DISASSEMBLY 1. Supporting the end of the shaft (68), 5. From the brake end, push the worm remove the cover (76) by removing (57) out of the housing (61). If the capscrews (46 and 78), nuts (20 and brake has not been removed, see 24), and washers (19 and 23). -

Page 13: Gear Inspection Instructions

GEAR INSPECTION INSTRUCTIONS GEAR INSPECTION INSTRUCTIONS GEAR INSPECTION INSTRUCTIONS GEAR INSPECTION INSTRUCTIONS LAND Check gear wear by removing the cover and visually inspecting the bronze gear. If the gear is worn such that there is no visible land on the throat of the gear between the gear flanks as shown in picture above the gear should be replaced. -

Page 14: Assembly

ASSEMBLY ASSEMBLY ASSEMBLY ASSEMBLY GEARBOX GEAR BOX ASSEMBLY ASSEMBLY GEAR GEAR ASSEMBLY ASSEMBLY 1. Press the bearings (54) onto the 4. Slide the carrier (72) over the keys worm (57) then install the worm and (70). Install the spacer (73) using bearings into the housing (61). -

Page 15: Model 34 Brake Assembly

6. Adjust the brake using the procedure and washers (29). on page 8 of this manual. RUFNEK RUFNEK RUFNEK RUFNEK 30 30 BRAKE ASSEMBLY BRAKE ASSEMBLY BRAKE ASSEMBLY BRAKE ASSEMBLY 1. Press the oil seal (90) into the brake 4. Install the spring (105). -

Page 16: Clutch And Drum Assembly

CLUTCH AND DRUM ASSEMBLY CLUTCH AND DRUM ASSEMBLY CLUTCH AND DRUM ASSEMBLY CLUTCH AND DRUM ASSEMBLY 1. Install bushings (60) into drum (14). 3. Install the sliding clutch (11) and end Install the drum (14) onto the output bracket assembly onto the shaft (68), shaft (68). -

Page 17: Troubleshooting

TROUBLESHOOTING TROUBLESHOOTING TROUBLESHOOTING TROUBLESHOOTING FAILURE PROBABLE CAUSE Clutch handle won’t latch a) Clutch jaws aren’t aligned. Align the jaws by rotating drum. b) Damaged yoke or linkage. Replace the yoke or clutch Oil leaks from housing a) Seal damaged or worn. Replace the seal(s). -

Page 18: Bill Of Material

BILL OF MATERIAL BILL OF MATERIAL BILL OF MATERIAL BILL OF MATERIAL BOM DATED SEPTEMBER 2005 DESCRIPTION 20517 32842 BUSHING 20266 CAPSCREW 21128 GREASE ZERK 20053 END CAP 20256 BRACKET 20129 BRACKET 1741 BRAKE BAND ASSEMBLY 20515 SET SCREW 20096 WASHER 20262 SLIDING CLUTCH... -

Page 19: Torque Specifications Chart

20286 PIPE PLUG 939269 LEFT FRAME 20293 RIGHT FRAME 20098 22443 SHAFT 32839 BUSHING 20574 21157 CAPSCREW 22438 CARRIER 20569 SPACER 164056 21643 RIGHT HAND GEAR 21642 LEFT HAND GEAR 20127 MODEL 34 COVER 44030 RUFNEK 30 COVER 26799 BREATHER... - Page 20 BILL OF MATERIAL BILL OF MATERIAL BILL OF MATERIAL BILL OF MATERIAL CONTINUED CONTINUED CONTINUED CONTINUED DESCRIPTION 20268 CAPSCREW 20326 GASKET 20519 LOCKWASHER 20273 20279 29503 BRAKE DRUM 20115 LOCKWASHER 20114 LOCK NUT 1733 BRAKE SHOE 3568 CAM PLATE 43962 BRAKE HOUSING 40546 CAPSCREW...

- Page 21 TORQUE SPECIFICATION TORQUE SPECIFICATIONS CHART S CHART TORQUE SPECIFICATION TORQUE SPECIFICATION S CHART S CHART Plated Lubricated Plated Lubricated Grade 5 Grade 5 Grade 5 Grade 8 Grade 8 Grade 8 Torque Torque Torque Torque Torque Torque Nominal Size *(Ft- *(Ft- *(Ft- *(Ft-Lbs)

-

Page 22: Clutch Inspection

CLUTCH INSPECTION CLUTCH INSPECTION CLUTCH INSPECTION CLUTCH INSPECTION... - Page 23 ISOMETRIC ISOMETRIC ISOMETRIC ISOMETRIC VIEW VIEW VIEW VIEW FOR RUFNEK BRAKE AND HYDRAULIC MOTOR, SEE PAGE 24...

- Page 24 RUFNEK BRAKE, HYDRAULIC MOTOR, & CLUTCH POSITION INDICATOR RUFNEK BRAKE, HYDRAULIC MOTOR, & CLUTCH POSITION INDICATOR RUFNEK BRAKE, HYDRAULIC MOTOR, & CLUTCH POSITION INDICATOR RUFNEK BRAKE, HYDRAULIC MOTOR, & CLUTCH POSITION INDICATOR RUFNEK OIL BRAKE CLUTCH POSITION INDICATOR KIT HYDRAULIC MOTOR VIEW PO Box 1130 Jenks OK 74037-1130 USA Phone: 918-298-8300...

Need help?

Do you have a question about the RUFNEK 30 and is the answer not in the manual?

Questions and answers