Table of Contents

Advertisement

Quick Links

LEHNER

AgroDos

AgroDos-001

®

Operating instructions with parts list

Controller LAS PSM

Software from Version 1.1 onwards

Status: September 2012

Serial number: ...................................................................

Software version: ...............................................................

Translation of original operating instructions

Advertisement

Table of Contents

Summary of Contents for LEHNER AgroDos

- Page 1 LEHNER AgroDos AgroDos-001 ® Operating instructions with parts list Controller LAS PSM Software from Version 1.1 onwards Status: September 2012 Serial number: ..............Software version: ............... Translation of original operating instructions...

- Page 2 Operating instructions LEHNER Maschinenbau GmbH Haeuslesaecker 14 D-89198 Westerstetten, Germany Tel.: +49 7348 9596-22 Fax: +49 7348 9596-40 www.lehner.eu info@lehner.eu This document is not allowed to be distributed, duplicated or utilised, nor is its content allowed to be communicated, without express permission.

-

Page 3: Table Of Contents

2.5 Electrical connection ..............15 2.6 Operating additional spreaders (electrical connection) ....15 2.6.1 Electrical connection of the AgroDos® 12 litre variant ..... 16 2.6.2 Electrical connection of the AgroDos® 22 litre variant ..... 17 2.6.3 Electrical connection of the AgroDos® 70 litre variant ..... 17 2.7 Operating additional spreaders (mechanical connection) ... - Page 4 5. Maintenance and cleaning ..........35 5.1 Maintenance ................35 6. Appendix ................37 6.1 Identification ................37 6.2 Spreader spare parts list ............. 38 6.2.1 AgroDos® 70 litre variant ............38 6.2.2 AgroDos® 22 litre variant ............40 6.2.3 AgroDos® 12 litre variant (container) ........41...

- Page 5 Operating instructions 6.2.4 AgroDos® 12 litre and 22 litre variant (electric motor) ..... 42 6.3 Spare parts list rotary feeder ............43 6.4 AgroDos® spreading table for GOLDOR BAIT ......44 6.5 AgroDos® spreading table for Nemathorin ......... 45 6.6 AgroDos® spreading table for Physiostart ........46...

-

Page 6: What You Should Know

Maintaining and servicing in accordance with the operating instructions en- sures the safety of the device and maintains the value of your AgroDos®. 1.2 About these operating instructions This operating manual forms part of the AgroDos® and must always be read- ily available. -

Page 7: Intended Use

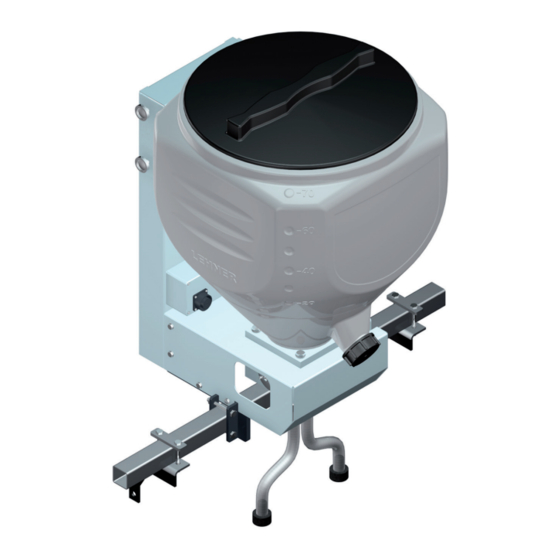

The output rate is between 4 and 40 kg/ha. Special rotary feeders are available if different output rates are required. In this regard, please contact the product specialists at Lehner. 1.4 Designated use The spreader consists of a frame, hopper (capacity 12, 22 or 70 litres, de- pending on variant), dosing device with two rotary feeder valves (standard 5.9... -

Page 8: Warranty

Installation instructions What you should know 1.5 Warranty We offer a 24 month warranty on the AgroDos ® Caution! Danger of short circuit Faulty or incorrectly sized plugs and cables can lead to malfunctions. Only use original plugs and cables, or ones approved by the manufacturer. -

Page 9: About Your Safety

• During all working procedures, make sure that no pesticide is spilled onto the ground. • After completing work, always perform a complete residual discharge of the spreader. • Lehner Agrar GmbH declines any liability for storage and application of the spreading material. -

Page 10: Technical Data Of Agrodos

Installation instructions What you should know 1.7 Technical data of AgroDOS ® AgroDos® AgroDos® AgroDos® 12 litre variant 22 litre variant 70 litre variant Length [mm] 462 mm 425 mm 554 mm Width [mm] 300 mm 489 mm Height [mm]... -

Page 11: Taking Agrodos® Into Operation

As a result, the implement holder is not supplied. Implement holder for AgroDos® AgroDos-004 For the AgroDos® 12 litre and 22 litre variants, we recommend using a square-profile tube (1) with dimensions 30 x 30 x 3 mm as the implement holder. For the AgroDos® 70 litre, we recommend using a square-profile tube (1) with... -

Page 12: Mounting Agrodos

Installation instructions Taking AgroDos® into operation 2.2 Mounting AgroDos® On the AgroDos® 12 litre and 22 litre variants, the holders for attaching to the square-profile tube are pre-installed on the supplied unit. The holder for the AgroDos® 70 litre variant is installed as described below. AgroDos® 70 litre variant 1. Positioning the holder AgroDos-005 Attach the holder (2) on AgroDos®... - Page 13 Taking AgroDos® into operation Installation instructions 2. Tightening the holder AgroDos-006 Screw self-locking nuts (2) with washers (1) onto the screws and tighten 3. Installing the spreader AgroDos-003...

-

Page 14: Installing Fishtails

(M8x65 8.8) and two backing plates (3). Check that AgroDos® is securely attached and that the container is sitting correctly in the container mounting. The AgroDos® 12 litre and 22 litre variants are mounted in accordance with the 70 litre variant. 2.3 Installing fishtails Install fishtails so that a mounting height A of 4 - 7 cm above the ground is guaranteed during operation. -

Page 15: Installing Hoses

Differently sized rotary feeders have different output rates. It is possible to connect up to 5 AgroDos® units together electrically and op- erate them with one control panel. The electrical connection is the same on all three AgroDos® variants... -

Page 16: Electrical Connection Of The Agrodos® 12 Litre Variant

Installation instructions Taking AgroDos® into operation 2.6.1 Electrical connection of the AgroDos® 12 litre variant For the electrical connection, connect the cable of each added spreader to the multi-pin socket of the spreader that has already been mounted. AgroDos-018... -

Page 17: Electrical Connection Of The Agrodos® 22 Litre Variant

Taking AgroDos® into operation Installation instructions 2.6.2 Electrical connection of the AgroDos® 22 litre variant See the description of the electrical connection in 2.6.1 2.6.3 Electrical connection of the AgroDos® 70 litre variant AgroDos-019 See the description of the electrical connection in 2.6.1... -

Page 18: Operating Additional Spreaders (Mechanical Connection)

2.7.1 Mechanical connection of the AgroDos® 22 litre variant For connecting the spreaders, it is first necessary to position them on the square-profile tube and then secure them. Position the driving spreader on the outside with the electric motor pointing outwards. Insert the coupling rod into the flanges between two spreaders by pulling apart. Secure the connecting element with screws in the flanges to prevent them from falling out. It is possible to connect up to 4 AgroDos® units mechanically. (1) Universal joint shaft (2) Satellite drive AgroDos-017... -

Page 19: Mechanical Connection Of The Agrodos® 70 Litre Variant

Taking AgroDos® into operation Installation instructions 2.7.2 Mechanical connection of the AgroDos® 70 litre variant See the description of the mechanical connection in 2.7.1 AgroDos-016 (1) Universal joint shaft (2) Satellite drive... -

Page 20: Operating Agrodos

Operating instructions Operating AgroDos® Operating AgroDos® 3.1 Controls on the control panel Switching on / off Display Start/stop spreader Green LED lights up: Rotary feeder valve drive motor running Yellow LED lights up: Rotary feeder valve drive motor off Switch automatic dosing on and off... -

Page 21: The Display

Operating AgroDos® Operating instructions 3.2 The display When EHR connected (operating mode: Automatic dosing) GOLDOR BAIT 0.75 m 10 kg/ha 1. Selected spreading table 2. Distance between plant or seed rows 3. Output rate in kg/ha When EHR not connected (operating mode: Manual mode) -

Page 22: Automatic Dosing

Operating instructions Operating AgroDos® 3.4 Automatic dosing In Automatic dosing, the speed of the rotary feeder is calculated according to the following values: • Speed • Output rate • Distance between plant or seed rows • Calibration value of the spreading material The calibration value can be stored in a spreading table, see chapter 4.8... -

Page 23: Changing The Setting

Operating AgroDos® Operating instructions The start key has no function until a travel speed of at least 2 km/h has been reached and the hydraulics have been lowered sufficiently. An audible signal indicates when dosing has started correctly. Three audible signals indicate there is a fault and dosing has not been started. -

Page 24: Manual Mode

Operating instructions Operating AgroDos® 3.6 Manual mode In manual mode, the speed of the rotary feeder is set manually. Setting Press the Automatic dosing key This changes between automatic dosing and manual mode. Display in manual mode: The following appears on the display: • Manual: Manual operating mode... -

Page 25: Residual Discharge

Operating AgroDos® Operating instructions Press the key. Manual RFV 42 U Green LED lights up. Rotary feeder valve drive motor running. Dosing ON The following appears on the display: • Manual: Manual operating mode • Speed of the rotary feeder in rpm • Dosing ON: Rotary feeder valve... -

Page 26: Error Message

Operating instructions Operating AgroDos® 3.8 Error message Message on the display: Explanation: xE = The 7-pin plug is not connected to the GOLDOR BAIT control panel. 0.75m 10.0kg/ha ↓E = The 7-pin plug is connected to the GOLDOR BAIT ↓E control panel, but there is no speed ↑... -

Page 27: Troubleshooting

Operating AgroDos® Operating instructions 3.9 Troubleshooting No signal from the - Check the distance between the sensor and wheel wheel sensor nuts and set if necessary. Distance should be less than or equal to 4 mm. - Check the wheel sensor/control panel plug connec- tion. -

Page 28: Basic Settings And Displays

Operating instructions Basic settings and displays Basic settings and displays The control element can be used to make the following settings: • Language • Quantity adaptation • Calibrating the wheel sensor • Setting the EHR signal • Entering the calibration values • Creating products 4.1 Making settings Switch off the machine. -

Page 29: Displaying Product Lists And Deleting Products

Basic settings and displays Operating instructions 4.3 Displaying product lists and deleting products Switch off the spreader: Press the +, - and On/Off keys at the Language same time. German Press the toggle switch to call up the View list product list. -

Page 30: Quantity Adaptation

Operating instructions Basic settings and displays 4.4 Quantity adaptation The spreading value stored in the spreading table can be changed temporar- ily. This change is not stored when the spreader is switched off. Press the Automatic dosing key for Quantity adapta- approx. -

Page 31: Setting Signal For Electronic Lifting Gear Control (Ehr)

Basic settings and displays Operating instructions Press the + key to store the value. Store 0.12 /m + = YES - = NO Press the Automatic dosing key to Speed pulses wheel return to the operating mode or 0.12 /m press the toggle switch to set the EHR signal now. -

Page 32: Ehr Function

Operating instructions Basic settings and displays Press the key to set the EHR signal. EHR signal EHR signal for lifting: High active High active is displayed EHR signal for lowering: Low active is displayed Press the Automatic dosing key to return to the operating mode or Press the toggle switch to display the Speed pulse EHR... -

Page 33: Spreading Tables And Calibration Procedure

Basic settings and displays Operating instructions Sensor signal 1. Mount the sensor in the joint area of the lower link. 2. Mount the magnetic encoder to the lower link. 3. Set the position of the sensor and the magnetic encoder. Maximum distance 10 mm. - Page 34 Operating instructions Basic settings and displays Press the + key. Calibrating..The spreader starts the calibration procedure. The calibration procedure has finished as soon as the spreader stops, and a weight value is shown on the display. 4. Weigh the spreading material dispensed from one hose and input this weight: Press the +/- keys to enter the Input result:...

-

Page 35: Maintenance And Cleaning

This extends the service life of your spreader. Carry out this mainte- nance work, otherwise the warranty may be invalidated. 1. Removing the pressure piece AgroDos-007 • Unscrew the hexagon socket screws (1) (M4x16) and pull out the pres- sure piece (2). - Page 36 Maintenance and cleaning 2. Removing the rotary feeder shaft • Pull out the rotary feeder shaft (2) with the supplied tool (1). AgroDos-008 • Strip down and clean the rotary feeder shaft (2). 3. Dismantling and assembling the rotary feeder shaft • Pull the rotary feeders (wearing parts) (1) off the shaft and clean them.

-

Page 37: Appendix

The serial number of the spreader is applied to the rear of the frame. Note the serial number in this operating manual so that it is readily available for inquiries. The hardware and software versions are briefly displayed when the control panel is LEHNER GmbH switched on. LAS-PSM V1.1... -

Page 38: Spreader Spare Parts List

Operating instructions Appendix 6.2 Spreader spare parts list 6.2.1 AgroDos® 70 litre variant... - Page 39 Appendix Operating instructions Object Number Parts number Name 80107 81075 70 litre container 80393 Residual discharge lid 80264 Container mounting 81277 Satellite drive 81258 Drive with bevel gearbox 81293 Motor flange 81277 Driver 81276 Sliding disc 81098-1 Adapter right 81084 Sheet metal housing 81085 Hose connection 81229...

-

Page 40: Agrodos® 22 Litre Variant

Operating instructions Appendix 6.2.2 AgroDos® 22 litre variant Object Number Parts number Name 81300 22 litre container Hexagon screws M10x20 Control housing cover Control housing 81296 Frame 81277 Satellite drive Cable gland Cable gland 81374 O-ring... -

Page 41: Agrodos® 12 Litre Variant (Container)

Appendix Operating instructions 6.2.3 AgroDos® 12 litre variant (container) AgroDos-012 Object Number Parts number Name 81299 12 litre container Hexagon screws M10x20 81374 O-ring... -

Page 42: Agrodos® 12 Litre And 22 Litre Variant (Electric Motor)

Operating instructions Appendix 6.2.4 AgroDos® 12 litre and 22 litre variant (electric motor) AgroDos-011 Object Number Parts number Name 81235 Straight drive 81258 Drive with bevel gearbox... -

Page 43: Spare Parts List Rotary Feeder

Appendix Operating instructions 6.3 Spare parts list rotary feeder AgroDos-015 AgroDos-015 Object Number Parts number Name Designation Nut M12 81278 Rotary feeder spacer disc 81234 Felt ring 81379 Rotary feeder M 5.9 ccm Standard 81378 Rotary feeder S 3.9 ccm... -

Page 44: Agrodos® Spreading Table For Goldor Bait

Operating instructions Appendix 6.4 AgroDos® spreading table for GOLDOR BAIT Rotary feeder shaft rpm 37.5 cm 50 cm 70 cm 75 cm 77.5 cm 80 cm 100 cm spacing 2 km/h 3 km/h 4 km/h 5 km/h 6 km/h 7 km/h... -

Page 45: Agrodos® Spreading Table For Nemathorin

Appendix Operating instructions 6.5 AgroDos® spreading table for Nemathorin Rotary feeder shaft rpm 37.5 cm 50 cm 70 cm 75 cm 77.5 cm 80 cm 90 cm spacing 2 km/h 3 km/h 4 km/h 5 km/h 6 km/h 7 km/h... -

Page 46: Agrodos® Spreading Table For Physiostart

Operating instructions Appendix 6.6 AgroDos® spreading table for Physiostart Rotary feeder shaft rpm 37.5 cm 50 cm 70 cm 75 cm 77.5 cm 80 cm 90 cm spacing 2 km/h 3 km/h 4 km/h 5 km/h 6 km/h 7 km/h... -

Page 47: Ec Declaration Of Conformity

6.7 EC Declaration of conformity EC Declaration of conformity in accordance with the EC Machinery Directive 2006/42/EC, app. II, 1.A Manufacturer: LEHNER Agrar GmbH Häuslesäcker 5-9 D-89198 Westerstetten Person resident in the Community who is entitled to assemble the relevant technical documents: Jürgen Beck-Graf... - Page 48 Operating instructions...

- Page 49 Operating instructions LEHNER Maschinenbau GmbH Haeuslesaecker 14 D-89198 Westerstetten, Germany Tel.: +49 7348 9596-22 Fax: +49 7348 9596-40 www.lehner.eu info@lehner.eu...

Need help?

Do you have a question about the AgroDos and is the answer not in the manual?

Questions and answers