Advertisement

Quick Links

OWNER'S /

OPERATOR'S

MANUAL

MODEL NO.'s

MPF-900

MPF-2000

MPF-2000B/G

SSPF-242

FLPF-2000

JDPF-2000

PF-448

SSPF-3748

SSPF-442

SSPF-448

SSPF-5548

GLPF-442

GLPF-448

GLPF-5548

JDPF-5442

JDPF-5448

JDPF-6748

JDPF-H48048

JDPF-H48060

CAUTION

For Safe Operation

Read Rules And

Instructions Carefully

SI NO LEEINGLES, PIDA AYUDA

A AIGUIEN QUE SI LO LEA

PARA QUE LE TRADUZCA LAS

MEDIDAS DE SEGURIDAD.

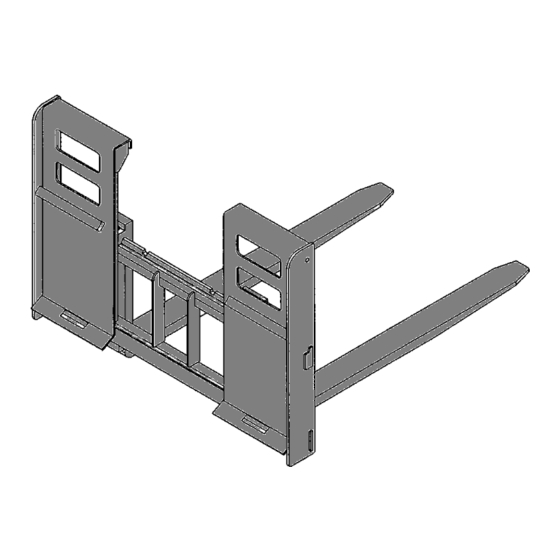

PALLET FORK

FOR SKID STEER

TRACTOR FRONT LOADERS

Safety Instructions

Tractor Preparation

Operating Instructions

PF-448

GLPF-5548

MPF-2000

Assembly & Mounting

Maintenance

Repair Parts

SSPF-442/448/5548

SSPF-242

JDPF-5442/5448

JDPF-48048/48060

Advertisement

Summary of Contents for Worksaver MPF-900

- Page 1 PALLET FORK OWNER’S / OPERATOR’S FOR SKID STEER MANUAL TRACTOR FRONT LOADERS MODEL NO.’s MPF-900 Safety Instructions Assembly & Mounting MPF-2000 Tractor Preparation Maintenance MPF-2000B/G Operating Instructions Repair Parts SSPF-242 SSPF-442/448/5548 FLPF-2000 JDPF-2000 PF-448 PF-448 SSPF-3748 SSPF-442 SSPF-448 SSPF-5548 SSPF-242...

- Page 2 Like all mechanical products, it will require cleaning and upkeep. Use only genuine Worksaver, Inc. service parts. Substitute parts will void the warranty and may not meet stan- dards required for safe and satisfactory operation. Record the model and serial number of your Pallet Fork here: Model:________________________________________ Serial Number:_______________________________ RETAIL CUSTOMER’S RESPONSIBILITY...

- Page 3 2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident. 3. If parts not made or supplied by Worksaver have been used in connection with the unit, if, in sole judgement of Worksaver such use affects its performance, stability, or reliability.

- Page 4 To the Owner/Operator/Dealer All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded opera- tor who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance of accidents. BEFORE YOU START!! Read the safety messages on the implement and shown in your manual.

- Page 5 SAFETY INSTRUCTIONS (continued) EQUIPMENT SAFETY GUIDELINES Safety of the operator is one of the main concerns in designing and developing a new piece of equipment. Designers and manufacturers build in as many safety features as possible. However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment.

- Page 6 SAFETY INSTRUCTIONS (continued) OPERATIONAL SAFETY Start prime mover only when properly seated in the operator’s seat. Starting a prime mover in gear can result in injury or death. Do not mount or dismount while the prime mover is moving. Mount or dismount only when the prime mover and all moving parts are completely stopped.

- Page 7 SAFETY INSTRUCTIONS (continued) OPERATIONAL SAFETY (continued) Do not allow children or others to ride on the power unit with an operator. Riders are subject to injury such as being struck by foreign objects or being thrown off. Riders obstruct the operator’s view resulting in unsafe oper- ation.

- Page 8 SAFETY INSTRUCTIONS (continued) OPERATIONAL SAFETY (continued) Be certain the power unit is in neutral or park position before starting engine. Always shut off power unit and shift to “Park” or set brakes when leaving unit. Always lower bucket or attachment to ground, relieve all hydraulic pressure. Remove key when leaving equipment unattended. Park in level area.

- Page 9 SAFETY INSTRUCTIONS (continued) TRANSPORT SAFETY Comply with state and local laws governing highway safety and movement of farm machinery on public roads. The use of flashing amber lights is acceptable in most localities. However, some localities prohibit their use. Local laws should be checked for all highway lighting and marking requirements. When driving the tractor and equipment on the road or highway under 20 mph (32 kph) at night or during the day, use flashing amber warning lights and a slow moving vehicle (SMV) identification emblem.

- Page 10 SAFETY INSTRUCTIONS (continued) MAINTENANCE SAFETY Good maintenance is your responsibility. Poor maintenance is an invitation to trouble. Before working on this machine, drive to a level area, disengage the PTO, lower implement or loader (or if working underneath, raise and block securely), shut off the engine, relieve all hydraulic pressure, set the brakes, and remove the ignition keys.

- Page 11 SAFETY INSTRUCTIONS (continued) STORAGE SAFETY Following operation or when unhooking, stop the tractor, set the brakes, shut off the engine, relieve all hydraulic pressure and remove the ignition keys. Store the unit in an area away from human activity. Do not permit children to play on or around the stored unit. Do not park equipment where it will be exposed to livestock for long periods of time.

- Page 12 SAFETY SIGNS BE CAREFUL! Use a clean, damp cloth to clean safety decals. Avoid spraying too close to decals when using a pres- sure washer; high-pressure water can enter through very small scratches or under edges of decals causing them to peel or come off. REMEMBER: If Safety Signs have been dam- aged, removed, become illegible or...

- Page 13 A heavy load can cause instability in driving a to the frame. power unit. Make sure the rear of the tractor is Above instructions not for Model MPF-900. Install properly counter-balanced with weights. Always the MPF-900 tines by removing the ”...

- Page 14 INSTRUCTIONS (continued) COMPACT TRACTOR LOADER BRACKETS FOR MODEL FLPF-2000 PALLET FORK ASSEMBLY – QUICK ATTACH ASSEMBLY – TRACTOR LOADERS If your tractor loader has a bucket Quick Attach feature, – PIN ON ATTACHMENT check with your dealer on the availability of adapter brackets for your brand and model loader.

- Page 15 INSTRUCTIONS (continued) MODEL PF-448 NOTE: For loaders that require brackets that provide —————————————————— additional roll back, order #830335 (1” pins). The Universal model PF-448 Pallet Fork attachment is Connect the above assembly to the loader arms using designed to fit most double-cylinder front end loaders the bottom hole in the channel and attach the upper con- with a load-arm center distance of 52 inches or less.

- Page 16 "Universal" type attachment on the loader. fork attachment will make the front end heavy. The Model MPF-900 can handle loads up to 900 Ib. When going up or down hill, the machine could The Model MPF-2000 can handle loads up to 2,000 Ib.

- Page 17 INSTRUCTIONS (continued) MODELS SSPF-242/ 442 / 448/3748 ATTACHMENT TO PRIME MOVER —————————————————— WARNING Improper attachment of the Pallet Fork could result in injury or death. Do not operate this product until you have positive indication that the attachment is securely mounted. 1.

- Page 18 INSTRUCTIONS (continued) MODELS JDPF-2000 / 5442 / 5448 ATTACHMENT TO PRIME MOVER —————————————————— The pallet fork model JDPF-2000 is specifically designed for John Deere 200 and 300 series loaders. It is rated for loads up to 2,000 lbs. The pallet fork models JDPF-5442 and JDPF-5448 are specifically designed for John Deere 400 and 500 series loaders.

- Page 19 INSTRUCTIONS (continued) MODEL JDPF-6748 ATTACHMENT TO PRIME MOVER —————————————————— The Model JDPF-6748 pallet fork is specifically designed for John Deere 600 and 700 series loaders with quik-change latches. It has a load rating of up to 5,500 lbs. NOTE: Procedure is the same for all attachments. Bucket attachment shown.

- Page 20 INSTRUCTIONS (continued) 4. Raise loader and retract tilt cylinders until latch MODELS GLPF-442 / 448 / 5548 closes. ATTACHMENT TO PRIME MOVER —————————————————— 5. Lower attachment and shut off engine. Installation is The Models GLPF-442, GLPF-448, and GLPF-5548 are now complete. specifically designed for tractor front loaders with the Euro or Global bucket quick-change system.

- Page 21 OPERATING INSTRUCTIONS OPERATION WARNING —————————————————— ■ ■ Rear ballast is required to ensure 25% of gross vehicle weight is transferred to the rear axle. Safety is a primary concern in the design and manufacture of our products. Unfortunately, our Attachment and load must be included as weight. efforts to provide safe equipment can be wiped out Adequate rear weights are required to counterbal- by an operator’s single careless act.

- Page 22 OPERATING INSTRUCTIONS (continued) OPERATION TRANSPORTING (continued) —————————————————— —————————————————— CAUTION CAUTION When traveling on public roads, whether at night or during the day, use accessory light and devices for A heavy load can cause your prime mover to tip adequate warnings to operators of other vehicles. over.

- Page 23 MODEL MPF-900 PARTS LIST...

- Page 24 MODELS MPF-2000 & MPF-2000B/G PARTS LIST...

- Page 25 MODEL FLPF-2000 PARTS LIST...

- Page 26 MODEL PF-448 PARTS LIST...

- Page 27 MODEL SSPF-242 PARTS LIST...

- Page 28 MODELS SSPF-442, SSPF-448 & SSPF-5548 PARTS LIST...

- Page 29 MODEL JDPF-2000 PARTS LIST...

- Page 30 MODELS JDPF-5442 & JDPF-5448 PARTS LIST...

- Page 31 MODEL JDPF-6748 PARTS LIST...

- Page 32 MODELS GLPF-442, GLPF-448 & GLPF-5448 PARTS LIST...

- Page 33 MODELS JDPF-H48048 & JDPF-H48060 PARTS LIST...

- Page 34 Please work, drive, play, and live each day with care JDPF-5442 and concern for your safety and that of your family and JDPF-5448 fellow citizens. JDPF-6748 JDPF-H48048 JDPF-H48060 MARCH 2014 WORKSAVER, INC. P.O. BOX 100 LITCHFIELD, IL 62056-0100 (217) 324-5973 WEB: http:// www.worksaver.com E-MAIL: sales@worksaver.com WS-PF001-OG...

Need help?

Do you have a question about the MPF-900 and is the answer not in the manual?

Questions and answers