Table of Contents

Advertisement

Quick Links

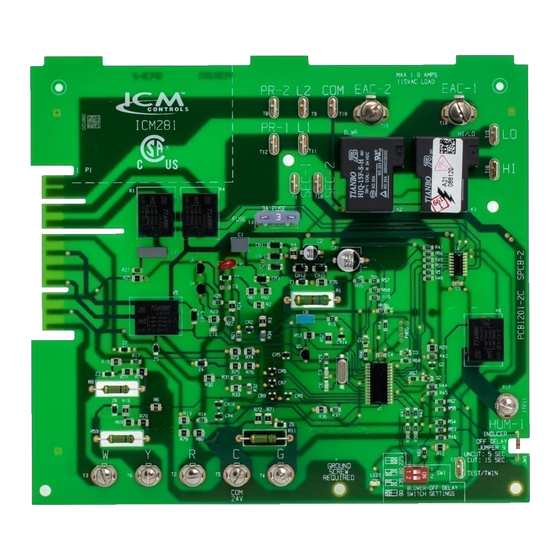

Fixed Speed Furnace Control Replacement Module

Replaces: Carrier CESO1 10057-00, CESO1 10057-01, CESO1 10057-02

Features

• Controls gas valve, ignitor, blower motor, inducer, humidifier and air cleaner

• Microprocessor-based

• Designed for 100% gas shutoff in case of ignition failure

• Twinning compatible with other ICM281 boards

• Reverse polarity protection

• Secondary brownout voltage protection

• Compatible with 24 VAC standard thermostat

• Provides diagnosti c LED to aid in troubleshooting

Safety Considerations

Only trained personnel should install or service heating equipment.

When working with heating equipment, be sure to read and

understand all precautions in the documentation, on labels, and

on tags that accompany the equipment. Failure to follow all safety

guidelines may result in damage to equipment, severe personal

injury or death.

Introduction

The ICM281 fixed speed furnace control replaces the following

Carrier/BDP modules: CESO110057, CESO110057-1,

CESO110057-2, CESO110048, CESO110020, and HH84AA016

The ICM281 has incorporated LED diagnostics to assist in

troubleshooting.

It is recommended that a sight glass (not included) be installed

in a convenient location on the furnace to take advantage of this

feature. If a sight glass is not installed, the self-test feature of the

board can still be used for routine troubleshooting. A fault code label

is included in this package and must be installed on the furnace.

Electrostatic Discharge (ESD) Precautions

CAUTION!

Use caution when installing and servicing the furnace to avoid

and control electrostatic discharge; ESD can impact electronic

components. These precautions must be followed to prevent

electrostatic discharge from hand tools and personnel. Following

the precautions will protect the control from ESD by discharging

static electricity buildup to ground.

1. Disconnect all power to the furnace. Do not touch the control

or the wiring prior to discharging your body's electrostatic

charge to ground.

2. To ground yourself, touch your hand and tools to a clean,

metal (unpainted) furnace surface near the control board.

3. Service the furnace after touching the chassis. Your body

will recharge with static electricity as you shuffle your feet or

move around, and you must reground yourself.

4. Reground yourself if you touch ungrounded items.

5. Before handling a new control, reground yourself; this will

protect the control. Store used and new controls in separate

containers before touching ungrounded objects.

6. ESD damage can also be prevented by using an ESD service

kit.

I C M 2 81

Electrical

• Voltage Range: Line (98 to 132 VAC) @ 60Hz

• Ignitor: 5A @ 120 VAC

• Cool Blower: 30A, 2HP, 240 VAC

• Heat: 5A, 1/2 HP, 240 VAC

• Inducer Motor: 4A, FLA-8.0 LRA @ 120 VAC

• Gas Valve: 1.5A @ 30 VAC

Step 1: Remove Existing Control

Failure to do so may result in wiring errors can cause dangerous

Step 2: Install the New Control

Specifications

CAUTION!

To service control, and prior to disconnection, label all wires.

operation.

1. Turn thermostat to OFF position or set it to the lowest

possible setting.

2. Turn OFF electrical supply to furnace.

3. Turn OFF gas supply to furnace.

4. Remove furnace blower and control access doors.

5. Remove control box cover.

CAUTION!

Failure to turn off gas and electric supplies can result in

explosion, fire, death, or personal injury.

6. Disconnect thermostat wires and humidifier wires (if equipped

with a humidifier).

7. Disconnect line voltage, blower, electronic air cleaner wires (if

equipped), and transformer wires.

8. Remove wiring harness edge connector and gasket from

circuit board.

9. Remove screws or any other fasteners and old circuit board.

10. Examine control and control box to check for water stains.

11. Make repairs if any sources of water leakage are found.

Be sure to check humidifiers, evaporator coils, and vent

systems in the area of the control.

1. Ground yourself. When handling circuit board, hold it by the

edges.

2. For 90 percent efficient furnaces, clip JW9 jumper wire. The

JW9 jumper is found close to the right hand corner of the

circuit board, beneath the HUM-1 terminal (see Figure 1).

This will result in a 15-second inducer OFF delay.

3. Insert board's edge between control box tabs.

4. Fasten circuit board with retaining screws.

IMPORTANT:

For 58EJA or 349MAV horizontal furnaces, the bottom control

board bracket may need to be notched and trimmed to pre-

vent the LED and circuit trace from interfering with the mount-

ing bracket. This may cause a short and result in damage to

the control.

To prevent:

a. Remove the mounting bracket from the control box.

b. Mark, notch and trim the bracket between where the

bottom center and bottom right mounting holes/pins align.

Be sure to trim enough of the bracket so the circuitry on

the underside of the control board lies clear of the bracket.

Advertisement

Table of Contents

Summary of Contents for ICM Controls ICM281

- Page 1 Introduction 2. Turn OFF electrical supply to furnace. 3. Turn OFF gas supply to furnace. The ICM281 fixed speed furnace control replaces the following 4. Remove furnace blower and control access doors. Carrier/BDP modules: CESO110057, CESO110057-1, 5. Remove control box cover.

- Page 2 Twinning Instructions 5. Connect thermostat wires. 6. Install blower door and access door. A 3/16” quick connect terminal is provided on the ICM281 control 7. Turn power ON. board for communication between another ICM281 control board 8. Turn gas ON.

Need help?

Do you have a question about the ICM281 and is the answer not in the manual?

Questions and answers